|

Author

|

Message

|

|

CK and his 55Tbird

|

|

|

Group: Forum Members

Last Active: 12 Years Ago

Posts: 104,

Visits: 273

|

But that's what Hot Rodding is all about. Finding something close to what you want and tinkering with it until its right.

I guess wooden pegs were great for making peg guns. we used to pinch them from the clothes line

pull one apart for the spring and attach it to an elastic band, and another one was attached to a piece of wood or stick etc.

the spiral of the spring would then be placed in the peg attached to stick and then the elastic would be stretched to the end of the stick. when you pushed on the peg it would release the spiral of spring and the band would send the two flying. It was alway a joy to find the big thick bands as they went further.

Mum used to alway wonder were her rubber gloves went too, though thats another story.

|

|

|

|

|

aussiebill

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 1.8K,

Visits: 11.4K

|

CK and his 55Tbird (3/4/2014)

Having a larger base circle and higher rocker ratio creates a stronger structured lobe, being the lobe effectively becomes a smaller raise with increased material. Yet the larger ratio rocker actuates the lift even at the base circle which requires greater precision of manufacture. probably why they started with 1.43:1? So gaining strength at the lobe increases weight at the rocker???

Yet rolling is by far better than rubbing!

And fitting rockers is a darn sit easier than cam shafts in Y blocks!

On that has any of you guys made a clamp/s for lifters on these Y blocks. Like you may have seen brake line clamps, yet more defined and shaped ( peg )to the round lifter which protrudes from the block at lift. I think it would be nice to clamp them raised, once push rods are removed and then the cam could be removed in Car and not having to remove and turn upside down. Alternatively if the tip which protrudes had a hole drilled before fitment they could be used to retain a raised lifter by applying a pin etc.

??????

NO sense reinventing the wheel again ! Wooden clothes pegs WORK! even without being highly modified! i,ve proven this eover 45 yrs.

AussieBill YYYY Forever Y Block YYYY AussieBill YYYY Forever Y Block YYYY Down Under, Australia

|

|

|

|

|

lyonroad

|

|

|

Group: Forum Members

Last Active: 11 Years Ago

Posts: 703,

Visits: 3.1K

|

John, my wife could supply the Canadian market if your wife wants to go International. On this subject, not that I plan to remove a cam this way, I have wondered if you couldn't fabricate a tool with rare earth magnets to hold the lifter up during the cam change. I can visualize the cloths pins slipping off at the worst possible time. However, the problem with magnets, although I see that Ford advocates the use of magnets in the shop manual, is that they attract metal debris. Since the magnet will induce some magnetism into the lifter any metal debris will be difficult to extract and will undoubtedly find its way into the lifter bore. I suppose one could lay a sheet of saran wrap over the lifters before getting the magnet anywhere near them.

Mark

1956 Mercury M100

1955 Ford Fairlane Club Sedan

Delta, British Columbia

|

|

|

|

|

Hoosier Hurricane

|

|

|

Group: Moderators

Last Active: Yesterday

Posts: 3.7K,

Visits: 323.3K

|

Alan: You're right. My wife still uses the solar clothes dryer in the summer and has a lot of wooden spring loaded clothes pins. She also has a few made of plastic. We may be sitting on a gold mine!

John - "The Hoosier Hurricane"

|

|

|

|

|

bird55

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 1.1K,

Visits: 58.8K

|

wooden clothes pins aren't exactly that common anymore either!

Wait! I can see it now-

RARE, early wooden yblock lifter retention tools (Full set) on EBAY buy it now! only $75.

A L A N F R A K E S ~ Tulsa, OK

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

And here’s the link to the thread showing a picture of the lifter tool used to install the tappets by way of the cam tunnel. Clothes pins still have to be used as the lifters are placed in their respective holes. http://forums.y-blocksforever.com/FindPost29355.aspx

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

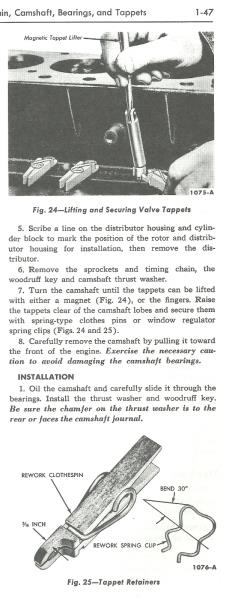

The service manual shows the wooden clothes pins that John is talking about being used to hold the lifters in place while the camshaft is being serviced in the vehicle. Here’s the excerpt from the 1957 Service Manual.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Hoosier Hurricane

|

|

|

Group: Moderators

Last Active: Yesterday

Posts: 3.7K,

Visits: 323.3K

|

Spring type clothespins do a good job of holding the lifters up for a cam change. But, as we all know, changing the cam should include changing the lifters, and that's where it gets tedious. Special tools were made for that purpose, and I once borrowed one from a Ford dealer. After changing the lifters I decided it was less work and less tedious to just pull the engine and turn it over on the engine stand.

John - "The Hoosier Hurricane"

|

|

|

|

|

CK and his 55Tbird

|

|

|

Group: Forum Members

Last Active: 12 Years Ago

Posts: 104,

Visits: 273

|

Having a larger base circle and higher rocker ratio creates a stronger structured lobe, being the lobe effectively becomes a smaller raise with increased material. Yet the larger ratio rocker actuates the lift even at the base circle which requires greater precision of manufacture. probably why they started with 1.43:1? So gaining strength at the lobe increases weight at the rocker???

Yet rolling is by far better than rubbing!

And fitting rockers is a darn sit easier than cam shafts in Y blocks!

On that has any of you guys made a clamp/s for lifters on these Y blocks. Like you may have seen brake line clamps, yet more defined and shaped ( peg )to the round lifter which protrudes from the block at lift. I think it would be nice to clamp them raised, once push rods are removed and then the cam could be removed in Car and not having to remove and turn upside down. Alternatively if the tip which protrudes had a hole drilled before fitment they could be used to retain a raised lifter by applying a pin etc.

??????

|

|

|

|

|

pegleg

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 3.0K,

Visits: 8.7K

|

Charlie, and THAT'S why when I visit John, I sit and listen. He learned enough about castings and pattern making from watching and asking to build cylinder head patterns that work. I have seen large automotive companies fail at this. GM for example, tried to develope an aluminum head at Central foundry in Ohio. They wound up sending it to us in Indiana because they could not make it work. We made castings. The people who started "Trick Flow" were unable (or unwilling) to build an aluminum Y block head. John accomplished this in a couple years.

Frank/RebopBristol, In ( by Elkhart)

|

|

|

|