|

Author

|

Message

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

MplsMike (4/22/2020)

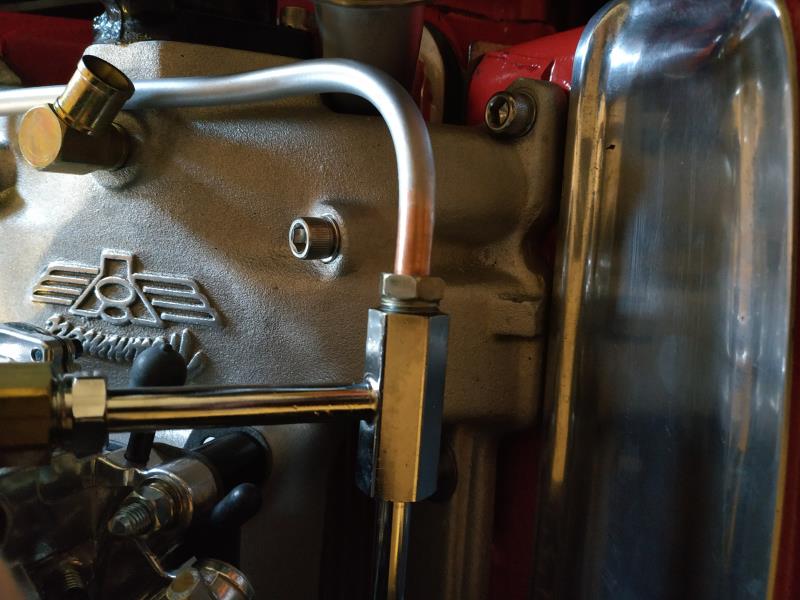

Capelo, it’s been a week since your last post. We are worried about you! I hope you are still making good progress. Thanks for the interest, everything is fine here. I have no news, I have everything ready waiting for the heating hoses to arrive so that I can fill the cooling circuit and then start the engine. I am also a little worried about the connection of the fuel line from the pump to the carb, when I filled the carb I lost some fuel, because of the carb joint I dried it, I squeezed but I don't know when there is pressure if it will lose again what it would be a serious problem 😏

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

with this connection is the one with which I am not very convinced.  The one on the left is the original flare that is double and I could only make it simple that you see on the left.  I am also looking at another option.  I am also looking at another option.

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

A single flare is ok for fuel line.

Lawrenceville, GA

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

I’ll have to disagree with Charlie regarding the use of a single flare end on the fuel line. And I also have an issue with using copper instead of steel for fuel lines. I’ve been both ways early on (teenager) and the single flare ends to have a tendency to split at the flare opening while copper is seamed tubing which also has a tendency to crack along the seams when vibration is present. A fire as a result of a broken or cracked line would not make for a happy day. My recommendation is a steel line with the appropriate double flare. The quality of the flaring tool also makes a difference. If you need some kind of pictorial showing how to do double flares, just let me know and I’ll see what I can work up.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

Ted (4/25/2020)

I’ll have to disagree with Charlie regarding the use of a single flare end on the fuel line. And I also have an issue with using copper instead of steel for fuel lines. I’ve been both ways early on (teenager) and the single flare ends to have a tendency to split at the flare opening while copper is seamed tubing which also has a tendency to crack along the seams when vibration is present. A fire as a result of a broken or cracked line would not make for a happy day. My recommendation is a steel line with the appropriate double flare. The quality of the flaring tool also makes a difference. If you need some kind of pictorial showing how to do double flares, just let me know and I’ll see what I can work up. thanks for the comments, an illustration never hurts. A question, how big is the thread of the image connection?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

capelo (4/25/2020)

thanks for the comments, an illustration never hurts. A question, how big is the thread of the image connection? The size designation for the fitting that goes into the Summit fuel line is ‘3/8” Inverted Flare’. A normal straight threaded fitting will not work as it does need a bevel on the fitting to match the bevel within the fuel line so insure a positive seal.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

|

|

|

|

|

kevink1955

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 236,

Visits: 237.6K

|

Now put the OH CRAP flare nut on the tube.

Please remember the flare nut MUST be on the tube BEFORE you do the flare if there are any bends or the other end has already been flared.

Ask me how I know this Lol

Great Tutorial TED as always

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

|

|

|

|

|

57RancheroJim

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 729,

Visits: 112.0K

|

Is that copper or nicopp?

|

|

|

|