|

Author

|

Message

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

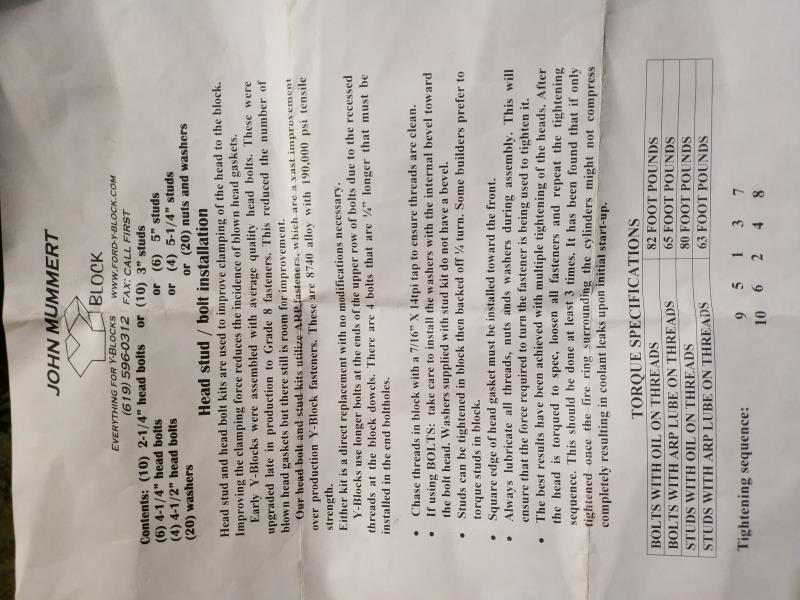

Tomorrow I will start mounting the heads. I have bought a new set of ARP bolts from Mummert, it comes with an assembly sheet, but this one, both in the form of tightening and in force and order does not correspond to the previous one read by me here. What is the correct way to act?

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

sorry the tightening order if it is the same

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

For grade eight bolts on the Ford Y, I typically torque them 70# for the short bolts and 75# for the long bolts using oil on the threads. I’ll bring them up in three steps being 35, 50, & 70/75. Bringing the top row to 70 on the third step and then finishing them off at 75# works for me. I’ll use a circular pattern starting at the middle and working outwards on each step. Clockwise (CW) or counter-clockwise (CCW) will not make a difference. 9 5 1 4 8 10 6 2 3 7 Deviations in this work as long as the head bolts are tightened in steps and not to full torque from zero in one step. If someone else has variations in doing this, feel free to chime in.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

Ted (4/7/2020)

For grade eight bolts on the Ford Y, I typically torque them 70# for the short bolts and 75# for the long bolts using oil on the threads. I’ll bring them up in three steps being 35, 50, & 70/75. Bringing the top row to 70 on the third step and then finishing them off at 75# works for me. I’ll use a circular pattern starting at the middle and working outwards on each step. Clockwise (CW) or counter-clockwise (CCW) will not make a difference. 9 5 1 4 8 10 6 2 3 7 Deviations in this work as long as the head bolts are tightened in steps and not to full torque from zero in one step. If someone else has variations in doing this, feel free to chime in. Thanks for the advice. The bolts are ARP I guess grade 8 and I have greased the threads like the washers the ARP assembly lubricant. Following that order and that pair is it necessary to repeat it three times as the paper says to seat the joints? I am using "The BEST Gasket"

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

Ted (4/6/2020)

capelo (4/6/2020)

Do you use any sealant here?  No sealant is required for the gasket. Are you using a spin on oil filter? If so, then the nut you show in the picture is not correct for the spin on oil filter plate. about this commented?  this is correct?

|

|

|

|

|

Dave C

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 101,

Visits: 31.2K

|

Only thing I would add. If the engine isn't going back in the car the same day, I would come back after it sits over night pull the last number again. What I mean is torque according to what Ted said. Then next day pull that 70/75 one more time. You might be surprised. I have had mine be several pounds loose even using different head gaskets, Felpro, Cometic and even copper..

Do this prior to setting valve lash.

Anyway that is the way I do mine.

Dave

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

Dave C (4/7/2020)

Only thing I would add. If the engine isn't going back in the car the same day, I would come back after it sits over night pull the last number again. What I mean is torque according to what Ted said. Then next day pull that 70/75 one more time. You might be surprised. I have had mine be several pounds loose even using different head gaskets, Felpro, Cometic and even copper.. Do this prior to setting valve lash. Anyway that is the way I do mine. Dave Ok thaks 👍

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

Today I end it, it already looks like an engine. Intake and cylinder heads, tight.

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

Tomorrow I get with them

|

|

|

|

|

MplsMike

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 204,

Visits: 92.3K

|

The pictures of the engine are beautiful! How about some pictures of that awesome looking truck in the background?

MplsMike

'56 Parklane

Minneapolis, MN

|

|

|

|