|

Author

|

Message

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

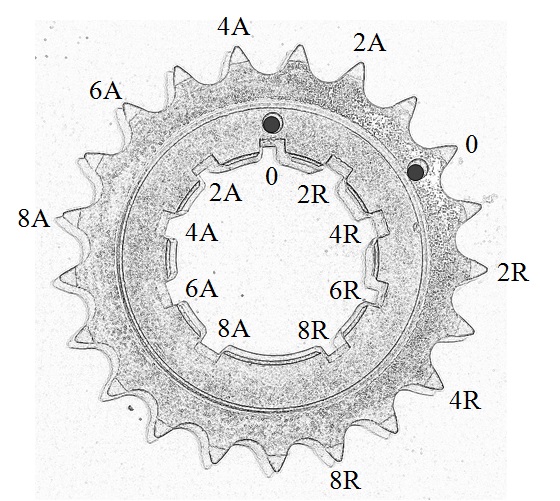

wanted I saw this on Ted's page, I think I got the camshaft setting wrong. I have the twelve pins between the only two marks they bring, do I have to count the twelve from the tooth marked in the drawing as A6?

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 927,

Visits: 190.0K

|

my opinion oaths post is it has got far to long,also it promotes exotic over kill on rebuilding a Y block.the real world if iwe want to compet in a hp race it would not make cents to start with a 292 or a 312. Ted has proven he can make a old dog make huge hp numbers, i have great respect for his achievements. the 292 post showes how to piss away big bucks to accomplish nor much.

i would venture to say starting with a sound core a 292 /or 312 could be built for under 4000 canadian that would be very dependable and fun to drive., that would detail come cents in reusability, new parts are reasonable and my idea is ys ran 100000 miles with cast pistons and rings,reground cams and lifters, stock timing chain etce

i ame sure my post will ster up some rebuttal,i look forward to that

|

|

|

|

|

Dave C

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 101,

Visits: 31.2K

|

capelo (4/3/2020)

Dave C (4/3/2020)

capelo (4/2/2020)

I have disassembled the new oil pump and the gasket has come out of a piece, I still have a new one, I am going to wash and oil and reassemble, does the gasket have some kind of sealant?  Depending on how long it would be before installing and the first start, I would recommend using some sort of assembly lube on the internal surfaces of the oil pump as regular oil could "drain" off and cause issues with the pump losing it prime and not want to pick up the oil on initial start. This is no real issue if you prime the oil system prior to starting the engine. Just some thoughts as I have had issues a couple of times with engines/new oil pumps refusing to pick up oil even using a priming tool.. Dave Thanks for the comment, my intention is to rotate the pump before starting until I see pressure on the oil gauge and see that the oil reaches the rocker arms. On the gasket of the pump, does it have a sealant or, like the gasket that connects it to the block, does it carry nothing? You should not need any sealant on that gasket. Both sides are a machined surface. Dave

|

|

|

|

|

ian57tbird

|

|

|

Group: Forum Members

Last Active: 4 hours ago

Posts: 502,

Visits: 21.7K

|

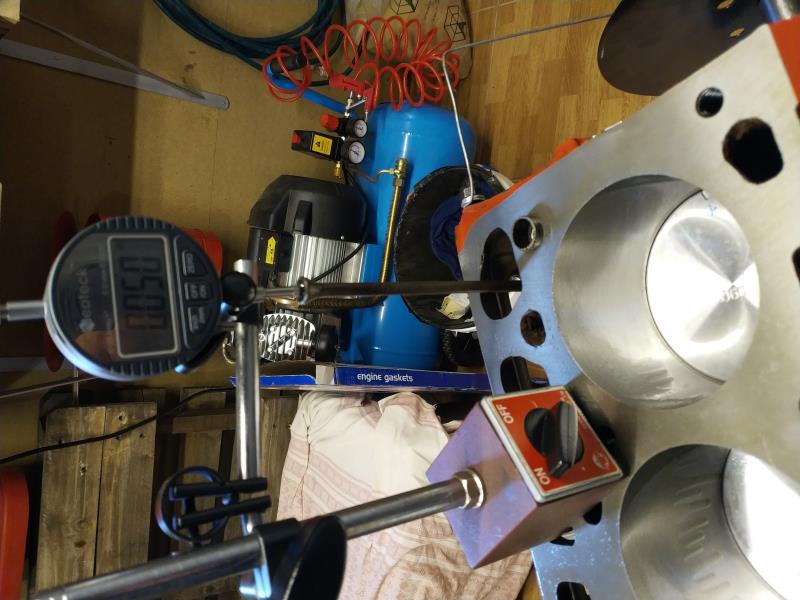

Just referring to your post where you are measuring deck clearance with a dial gauge. I have not found that it easy to get a consistent reading when releasing and reattaching a magnetic base. For that I would trust a good straight edge and feeler gauges more. Others might have a different opinion.

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

Ted (4/4/2020)

capelo (4/4/2020)

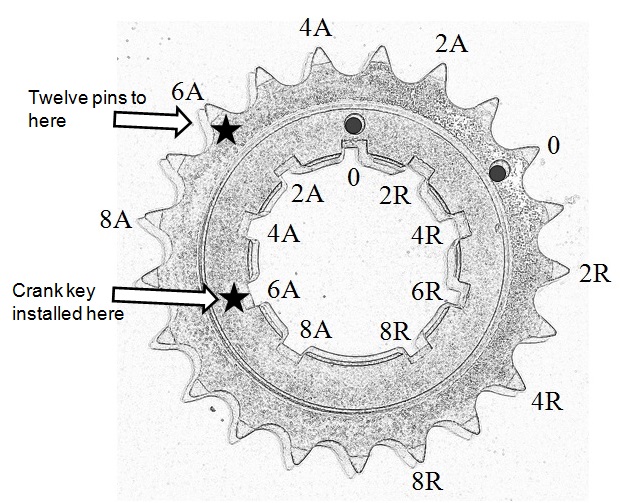

Not sure where you are going with the picture of the front of your engine. I’m assuming you degreed in the camshaft and need to advance it 6° to put it where you need it? If you have not started the degree in process yet, then you will need to start the process with the lower gear in the zero position. Assume nothing at this point. Because of manufacturing variances, the camshaft will likely have to be advanced or retarded to some degree to get it exactly where you require it. Because I have come across different camshafts being as much as 18° advanced or retarded when the timing sets were simply installed with the marks properly aligned, it’s imperative that the camshaft be degreed in during its installation. Taking it to the next level will have you checking the cam timing on at least one cylinder on each bank to insure that the camshaft was ground on the correct lifter bank angle. Unfortunately most engines will crank and run regardless if they are off as much as a full tooth on the timing set but the key here is you want it to run optimally; hence the reasoning for at least checking the camshaft timing. The Rollmaster crank gear is only marked on the outer row with the zero position for the twelve pins. If moving the gear to either a advanced or retarded keyway position, you’ll need to put some kind of mark at the outer row of teeth so you can get a true twelve tooth count to the new mark. Here’s the picture with new marks added for the 6° advance position to help clarify how to count the twelve pins when moving the crank gear position.

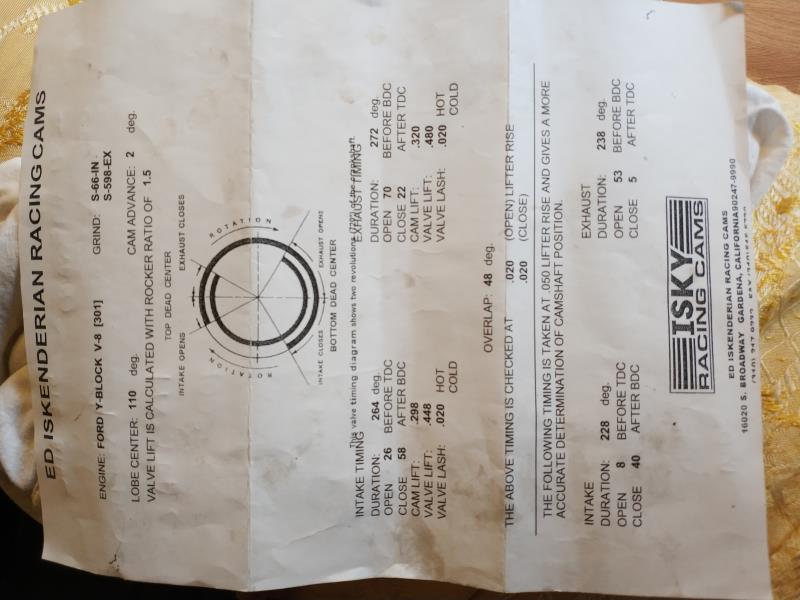

Following his camshaft graduation tutorial and using the central lobe mode, he throws me this data: 53 ° ATDC. ATDC 147 ° that together give us 200 ° and divided into two fa 100 °, which treated at 110 ° announced in the cam are 10 °.  Now, how should I finally graduate distribution?

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

And here is the total advance before deadlock greater than 0.050 "

|

|

|

|

|

capelo

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 279,

Visits: 4.5K

|

Also verified in the exhaust with these values: 162 ° DTDC and 74 ° DTDC that added and divided by two are 118 ° less than the announced 110 ° are 8 °. As before they came out 10 °, adding the 100 ° of before and these 118 ° added and divided by two are 109 °. Checking the exhaust opening at 0.050 ".

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

Assuming that the crankshaft gear is in the zero position and if targeting for 4-6° of camshaft advance, then you will need to remove and reinstall the crankshaft timing gear so it is in the 4° retard keyway. Be extremely cautious when removing both timing gears in that you do not pry on the pins and instead push the gears forward by prying only on the flats on the chain. Prying on the pins will force the pins forward and cause the chain links to come loose later. Once you have the gears and chain reinstalled in the new position, then recheck both the intake and exhaust lobe centerline numbers and verify that the camshaft is sitting in the 5° advanced position. If it is, you are good to go once you have insured that both the cam thrust and cam gear retaining bolts are properly tightened. Before removing the degree wheel from the engine, put the crankshaft in the TDC position so that the timing cover, timing pointer, and damper can be installed to verify that the TDC on the damper aligns correctly with the pointer. If it doesn’t, then tweak the pointer so it aligns with the TDC mark on the damper.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|