|

Author

|

Message

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.8K,

Visits: 306.3K

|

So what way is the best?

Camshaft thrust plate modification?

OR

Through mod?[/quote]

Both.

____________________________

|

|

|

|

|

jimcar-9

|

|

|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 89,

Visits: 894

|

So what way is the best? Camshaft thrust plate modification? OR Through mod? Best regards Jimmy

Best regards Jimmy Carlsson, Fagersta (Sweden) Ford F100 1956, 272 , 3 manual with OD

Follow my restoration on http://dinnerhillspeedshop.blogspot.se/

|

|

|

|

|

jimcar-9

|

|

|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 89,

Visits: 894

|

Thanks Ted :-) Ted (10/29/2019)

jimcar-9 (10/29/2019)

Just to be clear, the slot in the trust plate will be pointing about 90 degree to the right (seen from the front of the engine)? Right ?Any direction technically works but 90° to the right (looking from the front) is likely best.How deep is the slot, in the trust plate, at the edge of the plate ? 0.030”-0.040” deep

Best regards Jimmy Carlsson, Fagersta (Sweden) Ford F100 1956, 272 , 3 manual with OD

Follow my restoration on http://dinnerhillspeedshop.blogspot.se/

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.8K,

Visits: 306.3K

|

THANX! for taking your time to show that ...

____________________________

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

KULTULZ (11/1/2019)

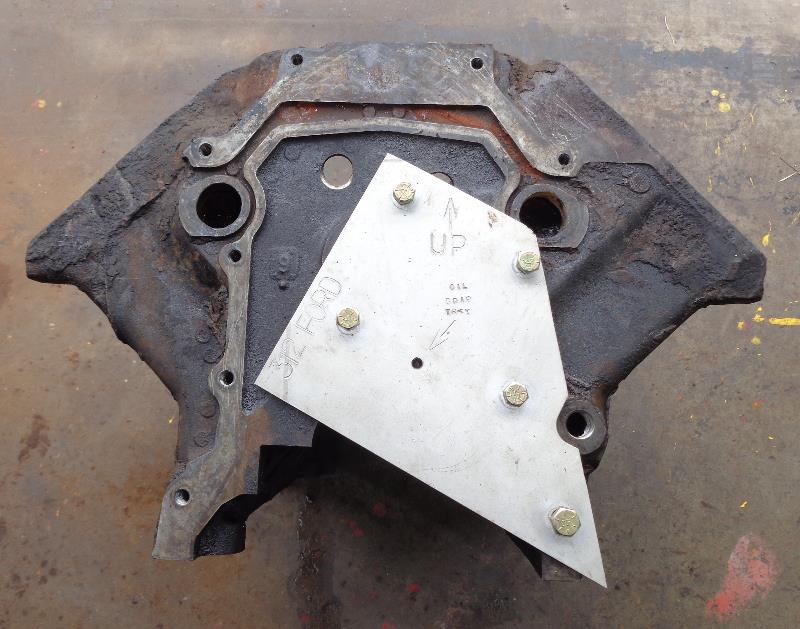

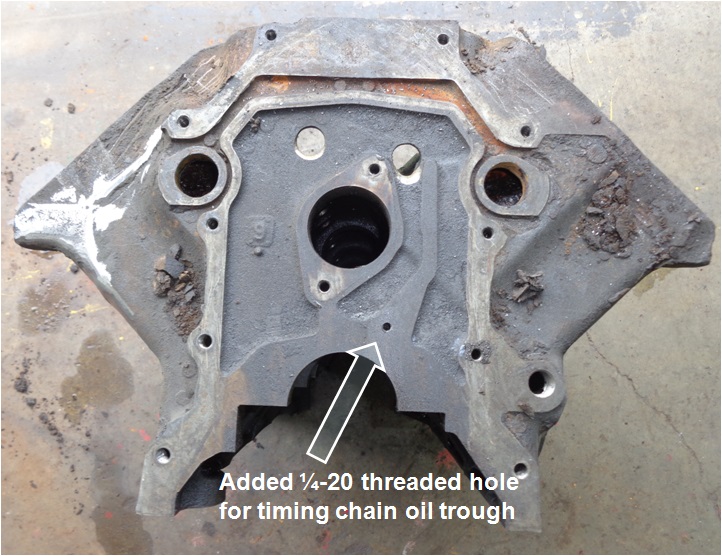

... my understanding is that the oil trough was only originally installed on production y-blocks in model years 1955 and 1956. I've sourced several of these in the past from discarded engines. The trough was originally secured to the engine block by a pan head machine screw. As I write this, I forget the thread size. Drilling and tapping the single hole in the correct block location is easily accomplished. Personally, I use medium strength blue Loctite when installing the single screw. Most would likely agree that isn't needed, but . . . The delete was part of the valve-train redesign(s) in 1956. It seems to me it would still be needed to direct oil to the chain rather than allowing it to just drop to the crank gear, especially with the modification TED EATON describes. Same as the upper oil deflectors being needed, especially if the rocker arm shafts are pressurized. I swear TED had either an article or offered the trough retro-fit. THANX! for the reply. Due to server changes, some of the older and relevant pictures posted earlier in this thread are not being correctly linked which makes them currently unavailable. Here’s are pictures showing the fixture I made to properly locate the required threaded hole in the block so that the 1954-1956 lower timing gear oil trough can be used.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 798,

Visits: 113.5K

|

Greetings to all: About 5-6 yeas ago when I refreshed my 64 292 with new cam, lifters, link timing chain assembly, I added the trough. Pressurizing the oil system with a modified distributor shaft and drill motor showed how the oil flowed from cylinder drain holes to lower sprocket. I would describe the quantity of oil from the trough like this: Opening a faucet just beyond a drip. Like, a small but healthy steady stream. It showed the trough provides a beneficial role in directing a sufficient flow where needed to lube the timing chain assembly. The rockers were semi pressurized by pinching off the overflow tubes about 50% or so. I actually shot a video of all this and if I was good enough with this computer I would provide it here for all to see. I don't believe the video can be "placed" in this site like a picture. Maybe after a few suggestions I'll try it. The 7mb video is not super quality but does show the true functionality of the trough.

64F100 57FAIRLANE500

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.8K,

Visits: 306.3K

|

... my understanding is that the oil trough was only originally installed on production y-blocks in model years 1955 and 1956. I've sourced several of these in the past from discarded engines. The trough was originally secured to the engine block by a pan head machine screw. As I write this, I forget the thread size. Drilling and tapping the single hole in the correct block location is easily accomplished. Personally, I use medium strength blue Loctite when installing the single screw. Most would likely agree that isn't needed, but . . .

The delete was part of the valve-train redesign(s) in 1956. It seems to me it would still be needed to direct oil to the chain rather than allowing it to just drop to the crank gear, especially with the modification TED EATON describes. Same as the upper oil deflectors being needed, especially if the rocker arm shafts are pressurized.

I swear TED had either an article or offered the trough retro-fit.

THANX! for the reply.

____________________________

|

|

|

|

|

NoShortcuts

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 1.4K,

Visits: 179.6K

|

KULTULZ. Yes, I see advantage to using the oil trough for directing the oil onto the gear which in turn distributes the oil onto the chain assembly. Unfortunately, my understanding is that the oil trough was only originally installed on production y-blocks in model years 1955 and 1956. I've sourced several of these in the past from discarded engines. The trough was originally secured to the engine block by a pan head machine screw. As I write this, I forget the thread size. Drilling and tapping the single hole in the correct block location is easily accomplished. Personally, I use medium strength blue Loctite when installing the single screw. Most would likely agree that isn't needed, but . . . Remember, the bean counters grilled the engineers and determined that the camshaft counterweight, the sheet metal oil deflection trays under the rocker arm shafts, and the timing chain oil trough were not necessary for the y-block engine beginning with 1957 year production. Happily, the engineers had data from the field by 1959 to determine that there were enough blocks with cracks in the crankshaft main bearing webbing that it was important to increase the length of the bolts used to secure the main bearing caps to avoid having to replace the engine blocks when rebuilding. Rest assured that the change in y-block engine production cost FoMoCo some change . . .  NoShortcuts

NoShortcuts

a.k.a. Charlie Brown

near Syracuse, New York

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.8K,

Visits: 306.3K

|

See if these two pictures help. The first picture shows the additional hole drilled into the block that intersects the oil gallery. That hole is larger at the surface and then much smaller where it breaks into the vertical oil galley. The second picture shows the thrust plate with the groove that redirects the oil flow so it’s sideways and thrown towards the chainTED EATON

Would it be advisable to have the oil directed to the to the trough (if so equipped) and then have it splashed on the chain? I see you offer that retro-fit for the later engines.

____________________________

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 927,

Visits: 190.0K

|

RE TIMEING CHAIN lube,i had valve covers off,running warm engine to check clearance(i have enlarged groove on the cam and drain tubes removed and blocked,lots of oil to the top,between the oil going down the pushrods, plus oil down the lower drain (talking about the pasenger side front) there is plenty of lude going to the chain. i would say the excess oil to the top end will reduce the load on the cam substanchely.the friction on the valve train due to uneven lubrication to rockers, valves push rods etc must be pretty high. i tried drilling into the oil gallery(front main supply on a partial assembled)292 pre lubeing the system with a drill and felt to much loss of pressure, so pluged the hole and went with what i did to my present lube mod on 292 in my 1949 merc pickup. i have a large oil presure guage on the dash never see a drop of presure on severe stops(disk brakes) on the truck, no drop on exceleration)292 with 4v intake ,600 cfm holley dura spark ignition 3.73 rear axel 4speed t0p loader . my opinion tho never excepted on this site, is lots of oil to the valve train re blocking drain tubes is the common cents way. now those running high output race cars with ys is another world. i want a good running Y for every day running.also i run 5/40 oil quaker state. i am not a rebuilder but do 2or3 ys pr year no failures ,no race cars all good to ferry good performers

|

|

|

|