|

By simplyconnected - 17 Years Ago

|

|

In 1959, roller timing chains were all but unheard of. Every 292 was fitted with a new link-type timing set, and they served their purpose well past the warranty period. Over many miles, your engine wears, and starts hesitating. It no longer gives that instant response that it did when it was new; something every car owner makes gas pedal adjustments for at every green light. Many of today's 292's are still running on original parts, but a 'major' overhaul is inevitable. Today, link-type chain sets are still readily available everywhere. In the racing world, roller chains reign supreme. Roller sets are preferred over gear sets, too. Link chains are still available at a third the price of a roller set, but are seldom used because roller sets last so much longer. Here is discussion from the "Accelerator Pump Problem" link: Ted (4/3/2009)

simplyconnected (4/1/2009)

Roller timing chains don't stretch nearly as bad as original chains, which makes them last three times longer. You can tell a roller chain; it looks like two rows of bicycle chain side-by-side. Original chains look like 'fingers' that grow and shrink as they flex around their sprockets.Dave. My experience has been that the link chains actually stretch at a slower rate than the roller type of chains. I examined this in detail back in the Seventies and found that the stretch occurs specifically through the links themselves but this only applies to those applications where the link chains are actually wider than the alternative roller chain setups for the same application such as on the Y-Block or FE Fords. A link chain in most applications simply has more connecting links between each pin thereby making the link belt type of chain more robust and less prone to stretching as compared to a roller type of chain that uses fewer connecting links between pins. On those engine applications where the link chains and roller chains have the same number of connecting links, then the wear factor at the gears themselves becomes critical thus making a link chain the less desirable setup. Friction or drag related to the two types of chains is a completely different topic however as the roller type of chains wins this contest easily. And the different types of roller types of chains haven't even been touched upon here although chain elasticity has been brought up to a small degree. Ted, I agree that link chains stretch at a slower rate, but they also stretch MUCH farther than a roller set. I have a well-worn set from my 292. Here's a picture of the original cam sprocket:

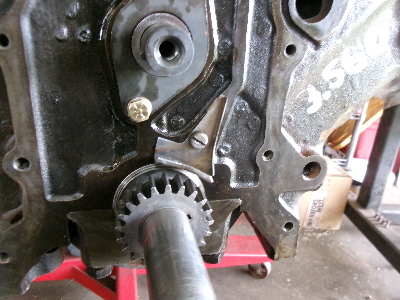

The chain was VERY sloppy, but what does the sprocket 'witness marks' tell?

* First, the finger-grooves are on the leading AND lagging sides of each tooth. If cam drag (valve train, oil pup and distributor gear train), were in one direction only, the wear pattern would be heavy on one side and light on the other. These are about equal.

* Crud at the bottom shows, the chain fingers stopped about half way down. Here's a crank sprocket:

Again, same story. This is the DRIVING GEAR, but it has wear on both sides, but only half way down each tooth. I can tell the direction of rotation. I can also see the wear from when the cam was actually driving the crank (when the driver got off the gas from high revs). Double roller chain sets don't wear like this. They don't have fingers that fold up. Instead, they use hardened steel pins with bearing-sleeves that reduce friction by turning freely. A roller chain incorporates much more precision but costs three times more than a link chain. In this case, you get what you pay for. Our 292's aren't a hot item any more, so fewer manufacturers make aftermarket parts for the Y. The double roller chain is out there, but much harder to find than link chains.

This one is going in my Y-Block next week. Dave

|

|

By simplyconnected - 17 Years Ago

|

|

If anyone tells you that timing chain slop has nothing to do with your ignition timing, don't believe it. You can see leading-edge sprocket wear on both sprockets, from the pictures. Coupled with chain stretch, your cam will lag its original timing at least six degrees before jumping a tooth or coming off. Timing slop shows when you use your timing light. The damper pulley mark tends to jump around, which is exactly what happens when you're driving down the road. When starting from a light, you always get that gas pedal lag because the cam is so far retarded. That 'tight engine' feel always comes back as soon as you change your timing chain.

|

|

By HoLun - 17 Years Ago

|

|

where do you get that roller set? I have 2 roll master sets, they both have slop worse then my origional links type, i need to get it replace, timing at 500 rpm is all over the place.

|

|

By marvh - 17 Years Ago

|

The Rollmaster were available from Romac USA.

The last set I bought was about six months ago from the USA company

the part number is CS4065.

The Australia site list them as made to order

There are different grades of Rollmaster chains.

http://www.romac.com.au/pdf/2005%20C&B%20Product%20List.pdf

The link to the USA site is

http://romacusa.com/

http://romacusa.com/Rollmaster_Applications.pdf

marv

|

|

By HT32BSX115 - 17 Years Ago

|

Howdy, that (fairly worn) timing gear looks like that engine not only didn't get the oil changed frequently, but may have even used an older type oil SA/SB/SC etc. (LOT of sludge)

I'm not trying to make this an oil thread at all but it's at least worth mentioning that todays timing sets (both types) might last a little longer due to better oils and maybe the fact that people change it often enough to prevent a sludge build up like that timing gear has on it.

Cheers,

Rick

|

|

By simplyconnected - 17 Years Ago

|

|

I'm not a salesman, but I occasionally buy & sell items on eBay (never timing chains, eBay name: simplyconnected). I'm a Ford restorer, relentlessly searching for better products and methods for our common 'labor of love,' restoring Fords. Some restorers are nearly militant about keeping everything 'bone stock.' That's not me, I like electric WS wipers, disk brakes, and I'd never dream of loading up my family in the '59 and running the freeway with bias-ply tires and no seatbelts. I am grateful for this forum, where restorers freely help other restorers in their passion. You guys have a treasure-trove of experience, resources, and talent, and I am very pleased to be welcomed here. HoLun (4/4/2009)

where do you get that roller set? I have 2 roll master sets, they both have slop worse then my origional links type, i need to get it replace, timing at 500 rpm is all over the place.HoLun, I simply called Tee-Bird Products in Pennsylvania (800) 423-3723, and spoke with Salesman, Ellis. He hooked me up with this American-made timing chain set, out of Elgin Illinois:

I probably paid too much, I don't know, but I think Tee-Bird is in the ballpark.

My engine machine shop owner had a Millings catalog listing for this timing chain number, but NOT the sprockets (very strange). Millings calls it "heavy duty." We'll see. Hoosier, this is America! We're all free to exercise our personal preferences. If you like link chains, everyone carries them at a very reasonable price. Enjoy. Ted, you have a wealth of background and knowledge regarding timing chains. Thank You for sharing your experiences, testing and using both chain types. I believe the more info we all get, the better we can make educated choices. I too, remember the days when cam sprockets were 'nylon.' After years of heat and stress, the polymers would bake out, they broke apart, and pistons tried closing valves. GM was the first, Ford followed. It wasn't pretty. If that wasn't ugly enough, Ford used rubber timing belts, starting with Pinto in '71, and Escort in '81. I owned both. Rick, I agree. This was an 'unknown' engine I bought from a man parting out his '59 Galaxie in the Boston area. He drove the car into his shop, put it up on a hoist, and after noticing extensive frame rot, decided to part the car out. I bought the engine, Cruise-o-Matic, steering column, brake pedal support, and driveshaft. He threw in a T&C radio and all the linkage. After engine teardown, the lower end looked beautiful, but I bored the cylinders .060" My stock 1959 292 was oil-starved in two areas, rocker arm shafts (and all the rocker arms), and timing chain. Those little tubes did a good job of diverting oil away from the rocker arms and down the holes. Consequently, dirt and varnish plugged all the rocker arm holes because oil pressure was at atomspheric (zero). This was a stock 292 Cleveland Engine. McTim's video convinced me to plug those tube holes with NO relief holes, which forces oil through all the rocker arms. The old timing chain sprocket pictures shown above, speak for themselves. But this is a new day. Romeo and Windsor modular engines have always used roller chains; 4-valve engines use four, two long and two short. For sixteen years I beat the crap out of my 351W, fitted with a roller chain (on Edelbrock Performer RPM heads, driving daily to Ford Rouge, Dearborn). Wear: negligible. Certainly not nearly as bad as every link chain I ever owned, regardless of brand. Certainly, today's time proven technology with better materials are far superior to the resources they had back in the '50's. Ford's accomplishments were amazing, considering what they had to work with. Dave Dare

Ford Motor Co., Dearborn

|

|

By HoLun - 17 Years Ago

|

the thing is, my block is not align bored, I dont know why it has that much slack in the chain, I am gonna email rollmaster and see if i can get the shorter chain only before i try a new stock HP set.

also, how do i determent slack vs length to purchase?

when I swap out to the lighter springs i made sure the weight pivot freely, and i have verified with a timing light that at 500 rpm the weights are not moving, so the only thing i can think of now its the slack of the chain. or there might be too much backlash on the disturbitor gear

|

|

By simplyconnected - 17 Years Ago

|

|

HoLun (4/4/2009)

the thing is, my block is not align bored, I dont know why it has that much slack in the chain, I am gonna email rollmaster and see if i can get the shorter chain only before i try a new stock HP set.

also, how do i determent slack vs length to purchase?

when I swap out to the lighter springs i made sure the weights pivot freely, and i have verified with a timing light that at 500 rpm the weights are not moving, so the only thing i can think of now its the slack of the chain. or there might be too much backlash on the disturbitor gearIf your main bearing caps and saddles have not been altered by align-boring, a stock chain set should work just fine. I don't know why your new chain should be sloppy. New chains I installed were 'a fight' to get the cam sprocket on the camshaft (then you have that confounded cam key or bushing to contend with).

Perhaps you got ahold of a non-stock, or wrong chain set. Again, new timing sets are tight. For an align-bored block, it wouldn't take much for the factory to oversize the sprockets to correct for a sloppy chain.

|

|

By 2DRHRDTP57 - 17 Years Ago

|

Hey guys, interesting thread, one thing I know is I never stop learning reading these threads, there is a wealth of espertise here. I purchased a double roller from Mummert a rollmaster product, and like other comments in this thread it was tight to get on the shaft and very little slack once installed.

I would check that they have supplied a correct part, as i commented mine was not slack at all.

Hope this helps,

|

|

By pcmenten - 17 Years Ago

|

Thank you Ted. Always very informative.

Three items;

Spark scatter - seems like a crank trigger would help in that area. But I would be more concerned with 'cam scatter', or the inaccuracy of the valve events due to the chain jumping around.

Chain tension - I worked on a Toyota 18R that had a very long timing chain. It has a tensioner that pushes a shoe against the long stretch of chain. Smokey Yunick talks about watching the timing chain on a Scrub jumping around like a snake at 7000 RPMs. (Wow, talk about spark scatter). I still don't understand why there aren't aftermarket chain tensioners for V8's. Seems like a simple idea.

Oiling - only the passenger side has an overflow tube that dumps out to the timing chain. Perhaps the driver's side could be pressurized and the passenger side left to flow.

Also oiling, my 56 Fairlane with a Thunderbird 292 V8 came stock with a little tray that bolted underneath the chain to help direct oil onto the chain. Any issue with that? Seems like a roller chain would especially benefit from good lubrication.

And finally, the passenger side overflow tube just directs oil down a hole in the head. Perhaps an extension of that tube that continues through the valley and out the front, over the chain would be helpful.

Speaking of over the chain, perhaps it would be helpful to modify the front of the block to ensure that oil lands on the chain, not just flow down past the chain.

Oh, and an afterthought - beehive springs run at lower pressures. Seems like that would play into the whole chain-stretch equation. Also, lightened valve train components reduce spring pressure requirements; titanium retainers, aluminum rockers, titanium pushrods, hollow lifters.

|

|

By LON - 17 Years Ago

|

|

Rollmaster timing chains are (were ? ) made here in Qld .I heard a rumor that they were not making any more for Y-Blocks . I used one in the Vicky and the Rod .I'll try and find out if production has stopped . Why hasn't someone made a timing belt for Y-blocks .You can get them for SBF and that other brand ,so why not for Y-Blocks ??????????? I don't see a big difference . Lon

|

|

By HT32BSX115 - 17 Years Ago

|

|

LON (4/5/2009)

Rollmaster timing chains are (were ? ) made here in Qld .I heard a rumor that they were not making any more for Y-Blocks . I used one in the Vicky and the Rod .I'll try and find out if production has stopped .

Why hasn't someone made a timing belt for Y-blocks .You can get them for SBF and that other brand ,so why not for Y-Blocks ??????????? I don't see a big difference .

Lon

A timing BELT to replace the gears and chain/rollers?

That would be some tiny little belt! do you have a link to a picture?

I guess the "other" choice (since no one has mentioned it) would be a gearset.

Most people don't like them because they're noisy and adds to the "moving parts" count.....

Hmm,

Found one on EBAY $500 or so. Found a few more on the net via a search.....$1000 or more for the kit.

Sort of makes it pretty expensive. I wonder if it would be worth it. Someone of course, would have to make them for the Y. With the limited number it would be like aluminum heads.....the production run would be small and prohibitively expensive...... People probably wouldn't buy them...

Cheers,

Rick

|

|

By oldcarmark - 17 Years Ago

|

|

I noticed on the Elgin timing gear seat the Ford part#s the prefix B6T indicates a truck application.Were the larger trucks with a Y-block manufactured with the double wide timing gear set originally hence the "heavy duty" designation?

|

|

By aussiebill - 17 Years Ago

|

|

Hi, here in Australia , the 1st 292,s were in 59 f600 trucks, there was the fabled HD 292 in some and resulted in the steel crank, rods, and double row timing chain mentioned earlier,the hunt was allways on for one of these, and could mostly be identified by spider wheels and 2 speed diff. I,M not sure taking the theory of these chain differences to the finest point achieves much, ford surely wouldnt have designed the double row setup at the time if it was,nt suitable. but i,ve ran em all for 40 yrs and nowadays we just dont do the everyday miles we did as teenagers etc. just a note on Rollmaster chains, be aware the Nitrided version crank gear requires a light polishing to fit to crank as size has shrunk due to the treatment. Regards aussiebill.

|

|

By LON - 17 Years Ago

|

|

Bill , Thanks for reminding me about the Nitrided gears .Had a slight fitment problem with the Vicky .From memory it was .003 .I tried to phone my mate Scott Sterling today to see if they are still being made ,will try again tomorrow . Lon

|

|

By speedpro56 - 17 Years Ago

|

My rollmaster chains are oiled this way. Place the cam sprocket in place, there's an oil galley between the crank and cam. On the oil galley mark the spot with a magic marker put a dot where the cam sprocket teeth are. That's where you drill an approx .030 hole for oil to spray onto the sprocket teeth to oil the chain . I did away with the overflow tubes too pressurized the rockers and have no more galled shafts. I also use a restricter in place to restrict the oil to the rockers. . I did away with the overflow tubes too pressurized the rockers and have no more galled shafts. I also use a restricter in place to restrict the oil to the rockers.

|

|

By mctim64 - 17 Years Ago

|

speedpro56 (4/6/2009)

My rollmaster chains are oiled this way. Place the cam sprocket in place, there's an oil galley between the crank and cam. On the oil galley mark the spot with a magic marker put a dot where the cam sprocket teeth are. That's where you drill an approx .030 hole for oil to spray onto the sprocket teeth to oil the chain  . I did away with the overflow tubes too pressurized the rockers and have no more galled shafts. I also use a restricter in place to restrict the oil to the rockers. You are not alone, this is what I've been doing to get oil to the timing set after pressurizing the rockershafts. I drill the hole behind the cam thrust plate and cut a small trench downward so the oil runs down to the spade and onto the crank gear though, instead of spraying it on.

|

|

By aussiebill - 17 Years Ago

|

|

Lon, rollmaster were taken over a few years back and moved to another state, i,ve spoken to them re the nitrided clearance problem. you,re trunk lock wedge is in the mail. aussiebill.

|

|

By simplyconnected - 17 Years Ago

|

mctim64 (4/6/2009)

You are not alone,... I drill the hole behind the cam thrust plate and cut a small trench downward so the oil runs down to the spade and onto the crank gear though, instead of spraying it on.  Amazing ways, all of them. Tim McMaster, do you have a picture?

Ted showed a sheet metal detail I don't have on my '59 292. After studying the oiling system, it would be a miracle if that little trough worked without your pressurized oil supply hole.

I look at my block's drain holes for witness marks, clean paths where oil flowed. I don't really see much hope with the stock system:

This engine is sitting on a pallet (that's how it came off the truck). It is filthy, but shows how bad the oil system had been over its life. If the block tips down in the back, NO oil will ever get to the chain, which is what happened. I understand in the old days, extermal oiling kits were sold for Y-Blocks with plumbing running all over this engine from the oil pump. They drilled holes in the rocker covers for oil tubes. Hey, whatever it takes...

|

|

By HoLun - 17 Years Ago

|

I got an email back from rollmaster, they say they dont even make a shorter chain, guess i have some nice machined paperweights, gonna order a stock HD roller set when I am going to work on my Y again....

or is there another maker that makes roller sets?

|

|

By PF Arcand - 17 Years Ago

|

|

Dave; Looking at that extremely cruddy block indicates to me that oiling wasn't it's only problem. The crankcase ventilation system was likely plugged for a long time. Unfortunately in the hands of Joe public, the crankcase venting system which required reasonable maintenance, was often overlooked...

|

|

By simplyconnected - 17 Years Ago

|

|

PF Arcand (4/8/2009)

Dave; Looking at that extremely cruddy block indicates to me that oiling wasn't it's only problem. The crankcase ventilation system was likely plugged for a long time. Unfortunately in the hands of Joe public, the crankcase venting system which required reasonable maintenance, was often overlooked...I don't know the history of this engine, in fact I only bought it because it was attached to a Cruise-o-Matic. (My wife asked me to turn our '59 Galaxie into an automatic for her.) Bought the whole setup from a guy in Mass., and this is what I got. Without question, it's the dirtiest engine I ever worked. You are right, PF. The crud wasn't tar-like, it was baked-on dirt. Even the crankshaft balance holes were HEAVILLY packed with dirt. Took me a long time to clean everything properly. I am amazed with the transformation of this engine. The block is bored and honed to 3.800" (which is +.060"), but the machine shop 'head' man was ill today. The block is better than new, because it's machined and seasoned. When it goes back together, I will install positive crankcase ventilation. Right now, I have questions for Ted Eaton regarding my Fel Pro neoprene rear main seal. Loved your balance articles, Ted. I was looking for the part about shaving the rod-tops to compensate for new larger pistons. I love McTim's method of oiling the timing chain by drilling a hole in an oil galley (I'd love to see a pic of that). Tim's video convinced me, so I pressurized the rocker shafts. I would also like to use the 'oversized' 180* thermostat. This engine will be oiled using Rotella-T 15W-40.

|

|

By mctim64 - 17 Years Ago

|

simplyconnected (4/7/2009)

[ Amazing ways, all of them. Tim McMaster, do you have a picture?

... I'll post a picture later today.

|

|

By simplyconnected - 17 Years Ago

|

|

John, I'm a dues-paying member of AACA with the same name, 'simplyconnected'.

I had the pistons (and rings) in my hand yesterday. They are marked "+.060" on the Sealed Power pistons (and +.060" on the Hastings moly rings). I may have misread, "3.800" on the pistons box. You're right, that doesn't add up. The machinist that bored the block said the only place he could find piston-to-bore spec's was in an old Edsel book he had from the '60's. He maintained .002" clearance, and said the piston set sizes were all the same (thank God). Thanks, John (for bringing that to my attention). I will go back today and re-check, along with my heads which should be done today. - Dave

|

|

By simplyconnected - 17 Years Ago

|

|

Thanks, John. He did mess me up in one area: I asked him to order a GOOD full gasket set with a neoprene rear seal. He got Fel Pro (which is good quality), but it came with a rope AND two little half-moon neoprene seals. I called Fel Pro. The guy said both seals are included because Ford switched from rope to neoprene. If my rear bearing was machined for a rope, I had to stay with it. If it was machined for neoprene, that's included in the gasket set too. Ted Eaton gave me the straight answer, saying Best makes a neoprene seal for my stock 292 (with a rope). I ordered the Best seal. I should have ordered the Best full gasket set. Cost me an extra $18 to learn that Best offers a much cheaper price. Fel Pro was a lot more. Thanks again John, for noticing the difference in piston sizes.

|

|

By mctim64 - 17 Years Ago

|

|

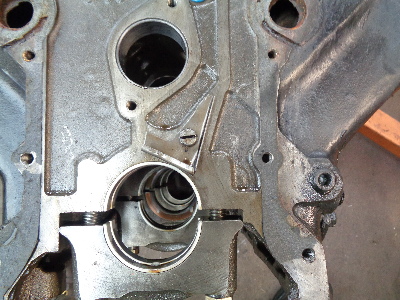

I have used Fel Pro and Victor seals with no machining other than to polish the seal area and, unless someone is keeping a secret from me, the seal area is the same dia. on all Y cranks. Both early and late except the 312. Also, here are the pics of the oil hole I drill in the front to lube the chain. I would have had it sooner but all the engines I have out in the garage are closed up and I hadn't taken any picture of this mod before.

|

|

By GREENBIRD56 - 17 Years Ago

|

|

Tim and Ted - We have got to find a way to get all of this good stuff in an accessible file. I was just looking for the tip about drilling and tapping the back of the block for the "direct insert" PCV and couldn't for the life of me remember enough to find the right thread. But it is the best way to do that particular operation I've seen .......really need a good way to clue in the new guys without a constant re-hash.

|

|

By mctim64 - 17 Years Ago

|

AZ28 (4/10/2009)

Tim and Ted - We have got to find a way to get all of this good stuff in an accessible file. I was just looking for the tip about drilling and tapping the back of the block for the "direct insert" PCV and couldn't for the life of me remember enough to find the right thread. But it is the best way to do that particular operation I've seen .......really need a good way to clue in the new guys without a constant re-hash. Steve, that one was Dutchys idea, and a good one, I've now done that to my own block.

|

|

By simplyconnected - 17 Years Ago

|

mctim64 (4/10/2009)

Steve, that one was Dutchys idea, and a good one, I've now done that to my own block.  Steve, Thank You sooo much for the distributor upgrade doc's. I'm chasing parts and definately going with the Duraspark system. Hey guys, does the PM thing work? I PM'ed Dutchy, asking for his PVC mod a couple days ago, but I don't see where it went through!? Tim I love the positive oiling for your chain with the sheetmetal deflector. I will definately do that with mine. Do you think it might work as well, grinding the 'trench' in the cam keeper plate instead of the block? So, what is the rear block PVC mod? Can you show or describe it? Thanks again, guys. Happy Easter. Dave

|

|

By GREENBIRD56 - 17 Years Ago

|

|

Dave - There is a tapped hole at the drivers side rear of the valley cover, facing up - the one closest to the centerline of the block I believe (the others outboard mount two throttle linkage pivots). This hole either joins - or can be drilled to join - the valley cavity of the engine. When drilled and tapped for the proper fitting, it provides a PCV port - and allows use of a valley cover that has no vent hole at the rear. Makes a neat installation and seals another potential leak point.

|

|

By Butch Lawson - 17 Years Ago

|

|

AZ28 (4/12/2009)

Dave - There is a tapped hole at the drivers side rear of the valley cover, facing up - the one closest to the centerline of the block I believe (the others outboard mount two throttle linkage pivots). This hole either joins - or can be drilled to join - the valley cavity of the engine. When drilled and tapped for the proper fitting, it provides a PCV port - and allows use of a valley cover that has no vent hole at the rear. Makes a neat installation and seals another potential leak point.Steve, What threaded pcv valve do you use?

|

|

By mctim64 - 17 Years Ago

|

simplyconnected (4/12/2009)

[ Tim I love the positive oiling for your chain with the sheetmetal deflector. I will definately do that with mine. Do you think it might work as well, grinding the 'trench' in the cam keeper plate instead of the block? Dave Yes, I do think that would work just as well.

|

|

By GREENBIRD56 - 17 Years Ago

|

|

Dave - I don't have this style of PCV set-up installed on my engine - mine has an adapter to the road draft tube port at the left rear of the T-bird valley cover. What it takes is a PCV that has 1/4 pipe threads on the "unchecked" (engine) side of the valve (poor choice of words.......). The Ford part (I believe) has the pipe threads on the suction side and usually screws into the spacer under the carb(?).

|

|

By yblock - 12 Years Ago

|

simplyconnected (4/9/2009)

John, I'm a dues-paying member of AACA with the same name, 'simplyconnected'.

I had the pistons (and rings) in my hand yesterday. They are marked "+.060" on the Sealed Power pistons (and +.060" on the Hastings moly rings). I may have misread, "3.800" on the pistons box. You're right, that doesn't add up. The machinist that bored the block said the only place he could find piston-to-bore spec's was in an old Edsel book he had from the '60's. He maintained .002" clearance, and said the piston set sizes were all the same (thank God). Thanks, John (for bringing that to my attention). I will go back today and re-check, along with my heads which should be done today. - Dave

like your post. i just got my 292 back from machinist. he recomended .oo2 cl on.040 pistons with moly rings. I decided to stay with the stock style chain, mainly because when I was 18 my first car 55meteor (can.ford with 272) never changed gears till valve float, at 80000 miles did a 2nd valve st, the engine was spotles in side, chain was not bad and it burned little oil. tho as i was mechanics helper had axcess to shop at nights and changed oil and filter every 1000 miles (as it was free) the oil in the camp was 10/30 series 1 oil used in all gas and deisel engines. you should reconsider the rotela t oil as it is designed strictly for diesel engines and low sulphur fuel. the sludged up engines in pictures are signs of extremley poor servicing. these conditions would not exist with 10/30 prem. motor oil serviced at proper intervals re use, and of course the engine breather as well. i sent the rod reverend some 30 pages of research on engine oils . there have been other posts on oils here. rotela t has far less ability to high loads than most standerd gas engine oils, and like i mentioned on prev. post it was marked at 1 time diesel engines only, and do not use on flat tappet cams.

|

|

By jimcar-9 - 7 Years Ago

|

I would really like to see the pictures Tim has shared on this thread. However they seems to have gone missing? Anyone that have saved them?

Thanks in advance

Jimmy

|

|

By 2721955meteor - 7 Years Ago

|

|

rotela t is a big mistake. not to be used on flat tapes engines

|

|

By jimcar-9 - 7 Years Ago

|

Thanks alot Ted, that really helped out alot :-)

Just to be clear, the slot in the trust plate will be pointing about 90 degree to the right (seen from the front of the engine)? Right ?

How deep is the slot, in the trust plate, at the edge of the plate ?

|

|

By 2721955meteor - 7 Years Ago

|

|

RE TIMEING CHAIN lube,i had valve covers off,running warm engine to check clearance(i have enlarged groove on the cam and drain tubes removed and blocked,lots of oil to the top,between the oil going down the pushrods, plus oil down the lower drain (talking about the pasenger side front) there is plenty of lude going to the chain. i would say the excess oil to the top end will reduce the load on the cam substanchely.the friction on the valve train due to uneven lubrication to rockers, valves push rods etc must be pretty high. i tried drilling into the oil gallery(front main supply on a partial assembled)292 pre lubeing the system with a drill and felt to much loss of pressure, so pluged the hole and went with what i did to my present lube mod on 292 in my 1949 merc pickup. i have a large oil presure guage on the dash never see a drop of presure on severe stops(disk brakes) on the truck, no drop on exceleration)292 with 4v intake ,600 cfm holley dura spark ignition 3.73 rear axel 4speed t0p loader . my opinion tho never excepted on this site, is lots of oil to the valve train re blocking drain tubes is the common cents way. now those running high output race cars with ys is another world. i want a good running Y for every day running.also i run 5/40 oil quaker state. i am not a rebuilder but do 2or3 ys pr year no failures ,no race cars all good to ferry good performers

|

|

By KULTULZ - 7 Years Ago

|

See if these two pictures help. The first picture shows the additional hole drilled into the block that intersects the oil gallery. That hole is larger at the surface and then much smaller where it breaks into the vertical oil galley. The second picture shows the thrust plate with the groove that redirects the oil flow so it’s sideways and thrown towards the chainTED EATON

Would it be advisable to have the oil directed to the to the trough (if so equipped) and then have it splashed on the chain? I see you offer that retro-fit for the later engines.

|

|

By NoShortcuts - 7 Years Ago

|

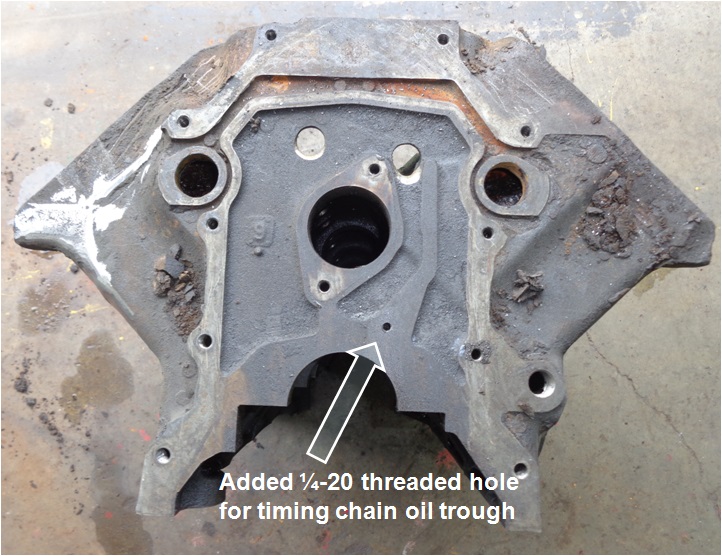

KULTULZ. Yes, I see advantage to using the oil trough for directing the oil onto the gear which in turn distributes the oil onto the chain assembly.

Unfortunately, my understanding is that the oil trough was only originally installed on production y-blocks in model years 1955 and 1956. I've sourced several of these in the past from discarded engines. The trough was originally secured to the engine block by a pan head machine screw. As I write this, I forget the thread size. Drilling and tapping the single hole in the correct block location is easily accomplished. Personally, I use medium strength blue Loctite when installing the single screw. Most would likely agree that isn't needed, but . . .

Remember, the bean counters grilled the engineers and determined that the camshaft counterweight, the sheet metal oil deflection trays under the rocker arm shafts, and the timing chain oil trough were not necessary for the y-block engine beginning with 1957 year production. Happily, the engineers had data from the field by 1959 to determine that there were enough blocks with cracks in the crankshaft main bearing webbing that it was important to increase the length of the bolts used to secure the main bearing caps to avoid having to replace the engine blocks when rebuilding. Rest assured that the change in y-block engine production cost FoMoCo some change . . .

|

|

By KULTULZ - 7 Years Ago

|

|

... my understanding is that the oil trough was only originally installed on production y-blocks in model years 1955 and 1956. I've sourced several of these in the past from discarded engines. The trough was originally secured to the engine block by a pan head machine screw. As I write this, I forget the thread size. Drilling and tapping the single hole in the correct block location is easily accomplished. Personally, I use medium strength blue Loctite when installing the single screw. Most would likely agree that isn't needed, but . . .

The delete was part of the valve-train redesign(s) in 1956. It seems to me it would still be needed to direct oil to the chain rather than allowing it to just drop to the crank gear, especially with the modification TED EATON describes. Same as the upper oil deflectors being needed, especially if the rocker arm shafts are pressurized.

I swear TED had either an article or offered the trough retro-fit.

THANX! for the reply.

|

|

By FORD DEARBORN - 7 Years Ago

|

Greetings to all: About 5-6 yeas ago when I refreshed my 64 292 with new cam, lifters, link timing chain assembly, I added the trough. Pressurizing the oil system with a modified distributor shaft and drill motor showed how the oil flowed from cylinder drain holes to lower sprocket. I would describe the quantity of oil from the trough like this: Opening a faucet just beyond a drip. Like, a small but healthy steady stream. It showed the trough provides a beneficial role in directing a sufficient flow where needed to lube the timing chain assembly. The rockers were semi pressurized by pinching off the overflow tubes about 50% or so. I actually shot a video of all this and if I was good enough with this computer I would provide it here for all to see. I don't believe the video can be "placed" in this site like a picture. Maybe after a few suggestions I'll try it. The 7mb video is not super quality but does show the true functionality of the trough.

|

|

By KULTULZ - 7 Years Ago

|

THANX! for taking your time to show that ...

|

|

By jimcar-9 - 7 Years Ago

|

Thanks Ted :-)

Ted (10/29/2019)

jimcar-9 (10/29/2019)

Just to be clear, the slot in the trust plate will be pointing about 90 degree to the right (seen from the front of the engine)? Right ?Any direction technically works but 90° to the right (looking from the front) is likely best.How deep is the slot, in the trust plate, at the edge of the plate ? 0.030”-0.040” deep

|

|

By jimcar-9 - 7 Years Ago

|

So what way is the best?

Camshaft thrust plate modification?

OR

Through mod?

Best regards Jimmy

|

|

By KULTULZ - 7 Years Ago

|

So what way is the best?

Camshaft thrust plate modification?

OR

Through mod?[/quote]

Both.

|

|

By Hoosier Hurricane - 17 Years Ago

|

|

Dave: Thanks for starting the new thread. We were way off topic on the carb thread. You told pegleg that you answered my question. Where is the answer to my kinetic energy question? Re: your pictures of the sprockets with wear on leading and trailing faces of the teeth. Wouldn't stretched chain links cause the pitch of the chain to be different from the pitch of the gears and make them wear both faces of the teeth? I feel no need to continue this discussion, we both have our opinions. I will use the link chains in my engines, you use the rollers in yours, and we can both be happy.

|

|

By Hoosier Hurricane - 17 Years Ago

|

|

Dave: Incidentally, 3.800 is .050 over, not .060. There is a Dave Dare that posts on the model T site. Is that you?

|

|

By Hoosier Hurricane - 17 Years Ago

|

|

Dave:s If he matched the pistons to the bores, we don't really care what the numbers are. 3.800 is standard 312 bore size, and the pistons are completely compatatable with the 292 block, crank, and rods. It's not an uncommon practice. Even today quite a few people bore their 292 blocks to 3.830 (.030 oversize 312), me included. Works fine.

|

|

By charliemccraney - 17 Years Ago

|

|

What's the deal with "machined for neoprene"? The seal area wasn't machined in any particular way for both builds of my engine. In fact, I didn't even need to turn the crank for the first go round. The neoprene seals did fine. One is still doing fine. A rope seal was removed from the engine during tear down after I got it from the salvage yard.

|

|

By Ted - 17 Years Ago

|

|

HoLun (4/4/2009)

where do you get that roller set? I have 2 roll master sets, they both have slop worse then my original links type, i need to get it replace, timing at 500 rpm is all over the place.The Rollmaster true roller timing sets for a Y were available in shorter sets to compensate for block differences either from the factory or when align honing or boring the mains. On the Y engines, it’s not uncommon to use a timing set that’s 0.008” shorter than standard to tighten up the ‘slop’ in the chain. And I'm not aware of any fresh stocks of Rollmaster timing sets out there right now. You could potentially have the same problem with the truck timing set in regards to slop depending upon exactly where the cam and crankshaft reside in relation to each other. At 500 rpms, the distributor is only running 250 rpms which may not have your weights in a stable or uniform area of operation. You might check that the distributor springs are both snug to insure that no low rpm ‘slop’ within the distributor is coming into play. Also check that the weights work smoothly on their roll pins as they are prone to wear and can end up binding or have a ‘kink’ in their movement in the off idle position.

|

|

By Ted - 17 Years Ago

|

|

Dave. Thanks for making a new topic out of this. This will definitely makes searches on the topic much easier down the road. I’m not out to prove one type of chain is better than the other but simply give another point of view regarding the link versus roller timing chain comparison. Everyone bear with me on this one as I feel the early morning mental juices starting to flow but could very well end up being random thoughts. But first a little background on timing chain oiling for the Y as there are a couple of key points here to consider. Early in ’56, Ford simply did away with the oil trough on the front of the block above the lower timing gear which then promoted an increase in timing gear wear as a result of the reduction in lubrication supplied at this point. Not enough wear that it will be a warranty problem but enough that it will be evident over the long haul when comparing the two oiling approaches side by side in controlled conditions. The rocker shaft overflow tube on the right hand or passenger side of the engine is where a majority of the timing area oiling was originally designed to be derived from and the lifter valley within block is also cast with a channel or trough in which to promote this. Pressurizing the rocker shafts also takes away oil from the timing chain area and insteads diverts a majority of the oil that would have normally gone to the front of the engine to the rear instead. The 3° slant of the engine simply compounds the issue of oil getting to the timing chain area when the rocker arm overflow tubes are either blocked or eliminated. Getting back to the main topic, on a racing or hot street engine a roller timing chain is much more desirable for a number of reasons. Reduced drag is at the top of the list and especially when a ‘true’ roller timing chain is used. But the real advantage to a roller chain is the increase in elasticity that’s available with the roller chain design. Elasticity is where the chain stretches a given amount at the higher rpms but that elongation comes back when the rpms are also brought back. Picture the chain acting like a rubber band. This elasticity can be seen with a timing light where after total timing is achieved, the ignition timing actually starts to back up (retard) as the rpms continue to climb. Where the ignition timing is driven off of a crank trigger, this essentially becomes apparent from idle to whatever rpm the engine is taken up to. On a distributor with a full curve, this is seen only after full igntion advance is achieved. The higher the valve spring pressure, the more predominant chain elasticity becomes. And of course there are two major types of roller chains with one being a true roller and the other being a pseudo roller or ‘wanna be’ for lack of a better description. The truck roller set for a Y is in the pseudo roller chain category and these are known to wear the sprockets at an alarming rate when not being oiled correctly. I’ve seen the lower gears when used with these chains with extremely pointed teeth due to the wear after an extended number of miles so these are not impervious to wear either. It’s just more difficult to see this wear without looking for it as when looking for teeth marks in a gear that’s used a link belt type of chain. The other problem with the pseudo chains is that the sheaves on the pins can get peeled off if hitting a crank or cam gear tooth just right after a nominal amount of wear has already taken place. If you’ll look at the sheaves on each pin on a pseudo roller chain, there is a groove where the sheaves clamp around the pins themselves. It’s these grooves that will get caught on the teeth and allow the sheave to be peeled off of the chain. But this is something I commonly see with high valve spring pressures and not on the run of the mill daily drivers. A true roller timing set has machined rollers around each pin which are much larger in diameter than the rollers on a pseudo roller chain and besides being more robust in design, also exhibit less turning friction than that of a pseudo chain. Now let’s switch gears and go back to a link chain. This is where testing and having some real data comparisons come into play. In this instance, I’ll use a 428 Ford Super Stocker with a roller camshaft that was used as the basis for testing. The link chain while used in conjunction with the older nylon toothed style of cam gear actually made more horsepower than with a true roller timing chain setup used in this test. Extreme care was taken to insure that the camshaft was installed or degreed in exactly the same in both instances. In this particular test, the improved ignition timing stability obtained with the link chain used along with the nylon toothed gear was determined to be a major factor for the improvement in that spark scatter in the ignition was reduced. This more than compensated for any perceived benefit of the camshaft retarding at the higher rpms due to the increased elasticity of the roller chain versus that of the link belt chain. Simplified, there was less ignition timing retard at the upper rpm levels with the link chain than with the roller chain which was the measure at the time for the chain elasticity. The number of degrees could be translated mathmatically back into a valid stretch value. As I said before, this is just another point of view but much of it is based on prior testing and numerous engine teardowns in controlled or known environments. But if it’s any consolation, I’ll use ‘true’ roller chains when given the option over a link type simply due to the reduction in friction or overall drag of the timing set. There is a proven benefit to the elasticity aspect of the roller chains in an engine that runs in a wide range of rpms such as an engine being used in a performance street or road race application. On an engine operating in a vary narrow rpm operating range, then a gear drive proves to be more beneficial over a chain.

|

|

By Ted - 17 Years Ago

|

|

pcmenten (4/5/2009)

.....the passenger side overflow tube just directs oil down a hole in the head. Perhaps an extension of that tube that continues through the valley and out the front, over the chain would be helpful.The passenger side rocker overflow tube does direct the oil to an engineered path in the block to the timing chain area. When examining the front area of the lifter valley in a Y block, you’ll see a designed and cast in path or channel where the oil from this particular overflow tube gets redirected to the timing chain area.

pcmenten (4/5/2009)

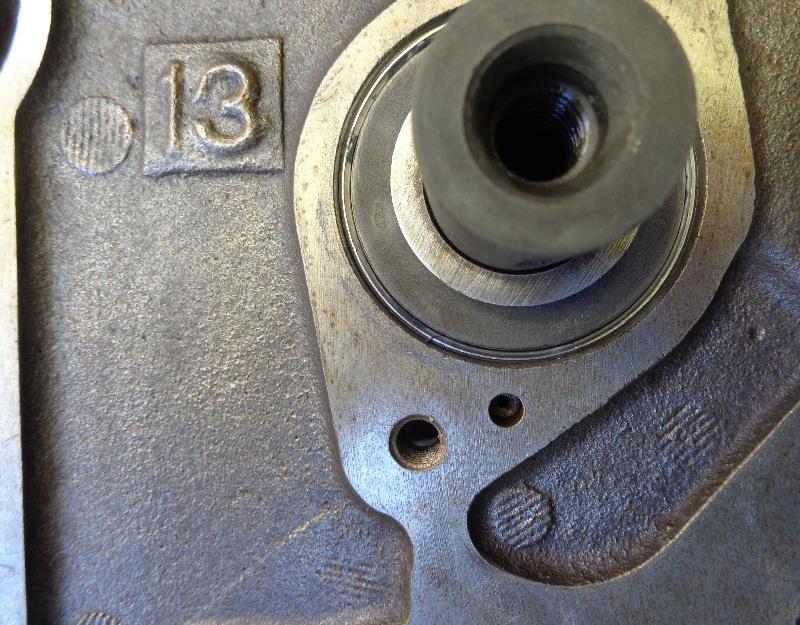

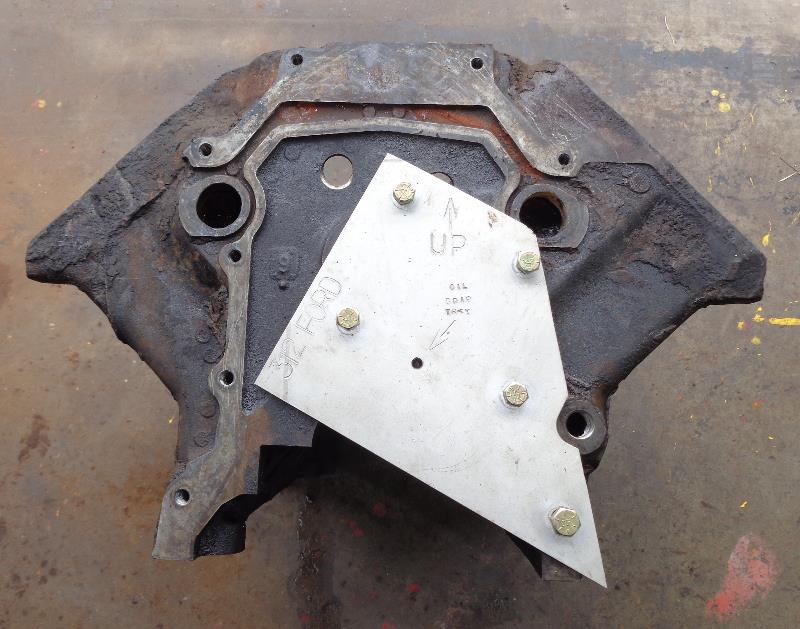

Speaking of over the chain, perhaps it would be helpful to modify the front of the block to ensure that oil lands on the chain, not just flow down past the chain.The aforementioned oil trough bolted on the front of the block does a good job of directing the oil to the lower timing gear sprocket and chain which then gets carried back up to the cam gear. This trough was eliminated in 1956 but I’ve built a jig that allows these to be put back on the later model engines in the correct factory specified position. Here’s a couple of pics of the oil trough for those that have never seen one.

|

|

By Ted - 17 Years Ago

|

|

LON (4/5/2009)

Why hasn't someone made a timing belt for Y-blocks .You can get them for SBF and that other brand, so why not for Y-Blocks ??????????? I don't see a big difference. Not as simple as it looks and involves some initial investment to make it happen. If it’s not being driven from a passion standpoint, then in many instances the payback is not justifiable. These belts are designed to run dry and not exposed to oil. This simply takes some special considerations to design a system for the Y that allows it to sit on the outside of the engine. And a water pump still needs to be bolted up to it. Doable but it’s one of those items that’s not justified in a majority of applications. It would likely need to look like this one for a small block Ford when it’s all said and done.

|

|

By Ted - 17 Years Ago

|

|

mctim64 (4/10/2009)

Also, here are the pics of the oil hole I drill in the front to lube the chain. I would have had it sooner but all the engines I have out in the garage are closed up and I hadn't taken any picture of this mod before. Tim. Thanks for sharing the pics of the oil hole behind the thrust plate. Another great alternative and adds to the list of options for oil mods. I agree with Tim in that the directing oil channel can go either in the block or in the rear of the thrust plate and be equally effective.

|

|

By Ted - 7 Years Ago

|

See if these two pictures help. The first picture shows the additional hole drilled into the block that intersects the oil gallery. That hole is larger at the surface and then much smaller where it breaks into the vertical oil galley. The second picture shows the thrust plate with the groove that redirects the oil flow so it’s sideways and thrown towards the chain.

|

|

By Ted - 7 Years Ago

|

|

jimcar-9 (10/29/2019)

Just to be clear, the slot in the trust plate will be pointing about 90 degree to the right (seen from the front of the engine)? Right ?

Any direction technically works but 90° to the right (looking from the front) is likely best.

How deep is the slot, in the trust plate, at the edge of the plate ?

0.030”-0.040” deep

|

|

By Ted - 7 Years Ago

|

KULTULZ (11/1/2019)

... my understanding is that the oil trough was only originally installed on production y-blocks in model years 1955 and 1956. I've sourced several of these in the past from discarded engines. The trough was originally secured to the engine block by a pan head machine screw. As I write this, I forget the thread size. Drilling and tapping the single hole in the correct block location is easily accomplished. Personally, I use medium strength blue Loctite when installing the single screw. Most would likely agree that isn't needed, but . . . The delete was part of the valve-train redesign(s) in 1956. It seems to me it would still be needed to direct oil to the chain rather than allowing it to just drop to the crank gear, especially with the modification TED EATON describes. Same as the upper oil deflectors being needed, especially if the rocker arm shafts are pressurized. I swear TED had either an article or offered the trough retro-fit. THANX! for the reply.

Due to server changes, some of the older and relevant pictures posted earlier in this thread are not being correctly linked which makes them currently unavailable.

Here’s are pictures showing the fixture I made to properly locate the required threaded hole in the block so that the 1954-1956 lower timing gear oil trough can be used.

|