|

Author

|

Message

|

|

Joe-JDC

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 772,

Visits: 22.6K

|

I actually installed a plug in the rear main seal housing bolt holes and covered it with silicone and let it set up before installing the oil pan gasket. I also cut the clearance for the rear main cap bolts prior to installation. Made it easier to install the windage tray afterwards.  JDC

JDC

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.3K,

Visits: 1.8K

|

I used a grinding stone in a drill (my die grinder bit the dust). Even with a drill, there's no problem grinding the aluminum rear-seal cap. I did check the fit numerous times, making sure that I did not remove more material than necessary. The cap is now properly seated, and my work looks as good as any I've seen.

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.3K,

Visits: 1.8K

|

Although the ARP main-cap-bolt heads are smaller (9/16ths) than the OEM bolt heads (3/4ths), it's still necessary to clearance the rear-seal cap in order for the cap to seat properly; it's close, but no cigar.

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.3K,

Visits: 1.8K

|

All of the main-cap bolts in my B9AE 292 block are exactly the same. I have to assume they are the original bolts because it's a standard-bore block, and the rod & main journals are also standard. The 1/2-13 bolts have an overall length of 3 inches (excluding the head); the thread length is 1 3/16ths, and the head diameter is 3/4-inch. The block has a separate aluminum real-main-oil-seal retainer that has to be removed before accessing the cap bolts underneath. A 12-point 3/8ths socket is required to remove/replace the retainer bolts. There are no washers.

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.3K,

Visits: 1.8K

|

Are the ARP Y-block main-cap bolts available in two different lengths? How long are the bolts for the 59-up 292 engines? When I bring my block home from the machine shop, I'll pull a bolt and measure it.

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

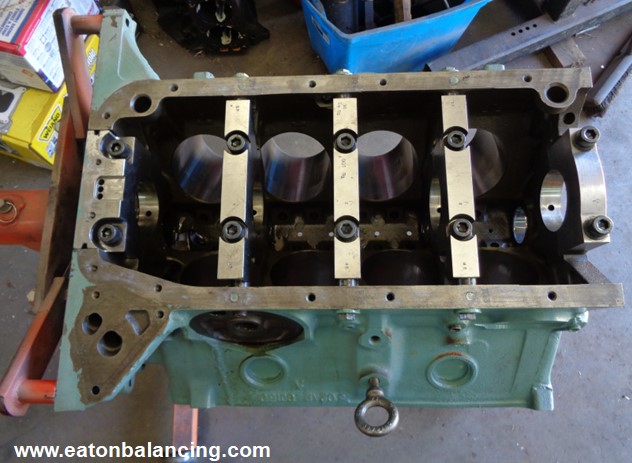

55blacktie (1/27/2025)

If the rear-main-seal retainer has to be clearanced for ARP studs, does that increase the possibility of oil-pan leakage?It does increase the potential for an oil leak. Part of that potential lies in whether the oil pan itself has to be modified to compensate for any main cap fasteners that extend past the gasket sealing surface. An option is to machine the tops of the rear main cap down at the bolt holes just enough to lower the fastener to permit the fasteners to fit either flush with the gasket surface or better yet, sits below the rear seal retainer so that the retainer itself does not have to be modified. Modifying or machining the tops of the fastener heads can also give some more working room in that area. There are several different ways to work around modifying the rear seal area for using different rear main cap fasteners. But unless you are planning on making in excess of 450HP, then the stock grade eight fasteners will prove to be more than adequate. Here's a picture of what I did for a Ford Y. I had a rear cap machined that eliminated the original rear seal retainer and instead had the rear seal combined with the rear main cap similar to what you see on a FE Ford engine (390/428).

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.3K,

Visits: 1.8K

|

If the rear-main-seal retainer has to be clearanced for ARP studs, does that increase the possibility of oil-pan leakage?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

55blacktie (1/26/2025)

One thing that I hadn't considered until after my original post is the possibility of compromising the integrity of a main stud by cutting a v-notch in it to prevent an obstruction of the oil galley. If that's true, doesn't it defeat the purpose of using studs?It’s important that the main cap bolt or stud does not protrude so deeply that it blocks the oil passage.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|