|

Author

|

Message

|

|

NoShortcuts

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 1.4K,

Visits: 179.6K

|

Paul. IF you click the link below you'll view the complete information sheet that John Mummert includes for guiding those installing the longer ARP bolts or studs that are recommended.

http://www.ford-y-block.com/ARPmaininstall.htm

Looking back, production of the FoMoCo y-block began in the U.S. for the 1954 model year. For the engineers to decide in Spring of 1959 model year to increase the length of main cap bolts in the 292 and 312 ('59 & '60 Merc application!) engines was significant. Imagine how many 239, 256, 272, 292 and 312 y-block engine blocks had been made between 1954 and mid-1959 for the various Ford car, Ford pick-up truck, Thunderbird, Mercury, Edsel, Ford heavy duty truck, and various industrial and farm related applications. WoW! A number of y-block engines being re-manufactured by FoMoCo or by Ford Authorized Re-manufacturers had to be found with some pattern of cracking' in the main bearing block webbing area, Extending the length of the main bearing cap bolts was a solution. Seemingly simple enough, but not without expense for FoMoCo to implement. Necessary OR wise to-do for heavy duty applications like big, heavily loaded trucks OR for those actively exercising their engines capability with acceleration, elevated rpms, or load pulling ability. For those of us putting together anything more than a grocery-getter, if you're going through a pre B9AE engine block with main cap line honing, block squaring, cylinder boring, zero decking for pistons, rotating assembly balancing and the like, installing longer main cap bolts is something GooD to do. Studs are a little more effort to do, but . . .  .

NoShortcuts

a.k.a. Charlie Brown

near Syracuse, New York

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.3K,

Visits: 1.8K

|

I have a B9AE 292 block that was manufactured in June, 1959. Tomorrow, I will pull one of the main caps and check to see if the threads in the block go all the way to the top, If they do, I will assume that the block was drilled & tapped by Ford to accommodate the longer main-cap bolts.

I would like to install the ARP main-cap studs, and I'm aware of the need to clearance the rear-main-seal retainer, as addressed in John Mummert's video, "Building a Better 312", but there was no mention of having to shorten & notch the stud on the oil-filter side to prevent the blockage of the oil passage. Is this a necessary modification on the B9 and later blocks, or just for the earlier E-series blocks? If so, can it be avoided by using the ARP bolts instead of the studs?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

Ford normally used a grade eight castle head bolt on the rear mains which would allow the rear main seal retainer to clear thus leaving a full surface for the oil pan gasket. Depending upon the year model, the remaining main cap bolts may or may not be grade eight and the use of lock washers on the earlier engines further compounds the height problem. If using studs or non-stock main cap bolts in the rear main cap, then notching the rear seal retainer for bolt clearance is typically necessary. With a smaller head bolt such as ARP, then that notching is minimal. I am not a fan of using studs for either head bolts or main cap bolts for a street performance Ford Y. The torque values are different between studs and bolts and with that in mind, then the proper torque for the fastener should be adhered to when doing both the machine work and the assembly of the engine. For using studs in place of the main bolts, care must be taken that the threaded length that goes into the block does not protrude in the oil galleys at each main bolt hole on the oil filter side of the block. If staying with bolts, then swap out any non-grade eight bolts for grade eight bolts. Using too long a bolt or stud for the FYB main caps is a concern for all the threaded holes on the oil filter side of the block and not just the threaded hole at the oil filter as blocking the oil galley at any of those holes can occur. The other concern is using the later model longer bolts in the early blocks without first checking the threaded depth of the holes. Too long a bolt will simply bottom out prematurely and potentially cause the block to crack or break in that area. Easy enough to check the threaded depth length by first installing the bolts in the holes without the caps and then checking the under-head length of the bolts to the flat on the block where the main caps sit and comparing that number to the actual height of the caps. I do a similar check for the head bolt lengths which can get dicey at times. With the heads and head gaskets in place, the bolts are installed first without the head bolt washers and if the head bolts bottom out against the heads, then those same bolts will be fine with the head bolt washers installed. FYI, I install head bolt washers along with grade eight head bolts on all Y engines. The 1963 and 1964 Ford Y engines came factory equipped with grade eight head bolts which solved some of the head gasket issues when using the earlier grade five and grade six head bolts. Other comments always welcome so do not let this be the last word on the subject. This is just the way I do it.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.3K,

Visits: 1.8K

|

Thank you, Ted.

One thing that I hadn't considered until after my original post is the possibility of compromising the integrity of a main stud by cutting a v-notch in it to prevent an obstruction of the oil galley. If that's true, doesn't it defeat the purpose of using studs?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

55blacktie (1/26/2025)

One thing that I hadn't considered until after my original post is the possibility of compromising the integrity of a main stud by cutting a v-notch in it to prevent an obstruction of the oil galley. If that's true, doesn't it defeat the purpose of using studs?It’s important that the main cap bolt or stud does not protrude so deeply that it blocks the oil passage.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.3K,

Visits: 1.8K

|

If the rear-main-seal retainer has to be clearanced for ARP studs, does that increase the possibility of oil-pan leakage?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

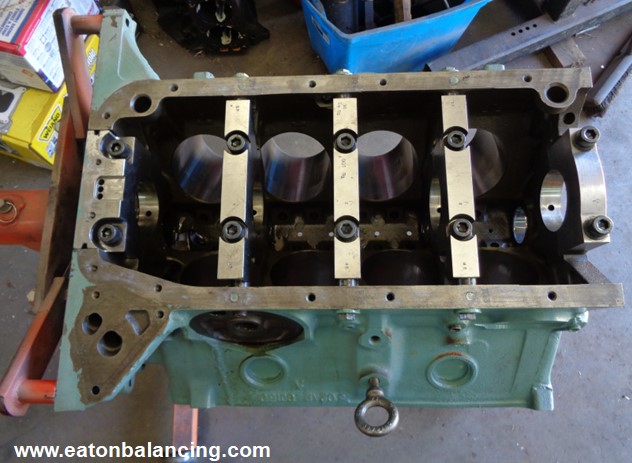

55blacktie (1/27/2025)

If the rear-main-seal retainer has to be clearanced for ARP studs, does that increase the possibility of oil-pan leakage?It does increase the potential for an oil leak. Part of that potential lies in whether the oil pan itself has to be modified to compensate for any main cap fasteners that extend past the gasket sealing surface. An option is to machine the tops of the rear main cap down at the bolt holes just enough to lower the fastener to permit the fasteners to fit either flush with the gasket surface or better yet, sits below the rear seal retainer so that the retainer itself does not have to be modified. Modifying or machining the tops of the fastener heads can also give some more working room in that area. There are several different ways to work around modifying the rear seal area for using different rear main cap fasteners. But unless you are planning on making in excess of 450HP, then the stock grade eight fasteners will prove to be more than adequate. Here's a picture of what I did for a Ford Y. I had a rear cap machined that eliminated the original rear seal retainer and instead had the rear seal combined with the rear main cap similar to what you see on a FE Ford engine (390/428).

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.3K,

Visits: 1.8K

|

Are the ARP Y-block main-cap bolts available in two different lengths? How long are the bolts for the 59-up 292 engines? When I bring my block home from the machine shop, I'll pull a bolt and measure it.

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.3K,

Visits: 1.8K

|

All of the main-cap bolts in my B9AE 292 block are exactly the same. I have to assume they are the original bolts because it's a standard-bore block, and the rod & main journals are also standard. The 1/2-13 bolts have an overall length of 3 inches (excluding the head); the thread length is 1 3/16ths, and the head diameter is 3/4-inch. The block has a separate aluminum real-main-oil-seal retainer that has to be removed before accessing the cap bolts underneath. A 12-point 3/8ths socket is required to remove/replace the retainer bolts. There are no washers.

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.3K,

Visits: 1.8K

|

Although the ARP main-cap-bolt heads are smaller (9/16ths) than the OEM bolt heads (3/4ths), it's still necessary to clearance the rear-seal cap in order for the cap to seat properly; it's close, but no cigar.

|

|

|

|