|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 160,

Visits: 31.8K

|

we're still here. Being lazy about finishing up the engine. It's 90+ in the shop so nothing going on until it cools.

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 160,

Visits: 31.8K

|

well, we installed the rebuilt distributor. It ran for about 15 seconds before the roll pin that connected the gear to the shaft broke in three pieces. When we tried to fix it, the holes didn't line up?? The roll pin pieces just fell out of the gear and shaft telling us because the holes didn't line up correctly, they installed a smaller roll pin which couldn't handle the torque. We sent it back and haven't heard anything from them in a week. If it ain't one thing, it's two!!!

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

Did you try rotating the gear 180° on the shaft to see if the holes would line up? The holes are typically off center requiring the gear to be orientated a specific way on the shaft.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 160,

Visits: 31.8K

|

The whole shaft has been "redesigned" using a sleeve of some kind to support a replacement upper assembly to get the desired mechanical advance we need. The first time we sent it back they made the shaft too long, as reported in my previous posts. This time, they returned it with some hoaky roll pin connection that was misaligned and impossible to figure out how they made it work in the first place. Hence, the roll pin failing immediately. They've had it for a week now with no communication. Not sure what's going on.

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 160,

Visits: 31.8K

|

Well, this whole distributor modification thing has finally been completed. We would NOT RECOMMEND FBO Ignition out of Cottage Grove, OR, for any distributor work on an odd ball distributor like the 368. They were unprepared, uneducated, made several mistakes, and the overall quality of the fabrication was not what I call professional grade. We got it installed and it is working, but not out of the box. We had to "fix" a couple of things to make it work. They never offered to pay for return shipping, (twice), and returned the latest "fix" with the wrong gear. The next step is to take my bare block with oil pan to our work area and see if it fits without having to modify the oil pan. If anyone knows anything about swapping a 368 in to a 54 Merc or Ford (same frame) let me know. The existing 302, with front belly oil pan, just makes it. Not sure what will happen with the 368. The adaptor kit moves the engine forward about 2 inches, so we'll see. I think we're going to go with no fan blade and add electric fans on the front of the radiator. Our mock up engine stand has this and it has kept the engine very cool. I'll pat my friend, Jeff's back, for and excellent rebuild. The motor sounds and runs great.

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 160,

Visits: 31.8K

|

we have our engine tuned and ready. will start the swap after New Years.

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 160,

Visits: 31.8K

|

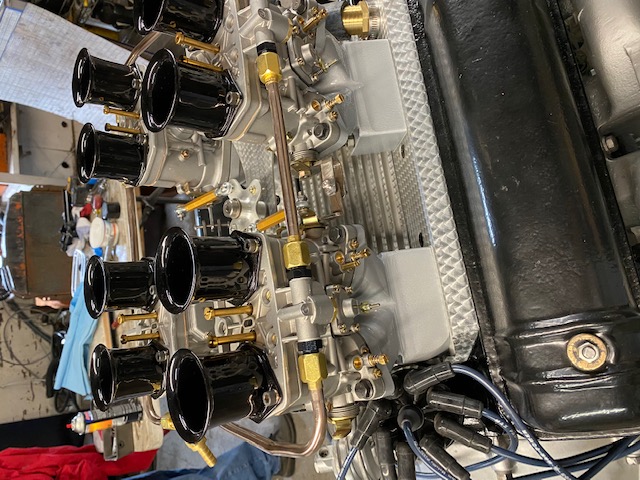

We started the final tune on the 368 with the Chinese knock off Webers. Had to fix one bad float out of the four. Having a hard time with fuel. We're sure we are flooding. Next time we'll turn them all the way in and then back off 1/2 and go from there. Fuel coming out from the tops when revving. We started taking the 302 out today. If all else fails, we can always put on the stock intake and add an FI unit.

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

You don’t mention if the fuel is coming out of the throats or the fuel bowl covers. That might give a better idea if it’s a float level issue or a camshaft issue. My experience with Weber carbs has them liking camshafts with wide lobe centerlines. I did try a 108° lobe center camshaft with the Weber carbs on a FE and there was some serious fuel reversion going. At the lower rpms and where the throttle was opened up, there would be a cloud of fuel shoot up above the carbs and then suck back down. Learned early on that those carbs prefer a minimum of 112° lobe centers and 114° is better.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 160,

Visits: 31.8K

|

Thanks Ted, we did modify the cam just a little but it's still pretty tame. Doing some more research we're finding out that multiple Webers take larger jets (which doesn't make sense to me). On line stats from reputable sources say 1.50 for one carb, 1.75 for two. Nothing about 4. Does this mean 2.0 or better? Do we need to replace all the different jets? There are three different jets and two venturi. Am I over my head? In the mean time, we have about 4 more bolts to take out before the 302 is free. P/S The amount of fuel coming up is minimal and only at high throttle input. The amount is not the same with all 4 units.

|

|

Group: Forum Members

Last Active: 5 days ago

Posts: 1.9K,

Visits: 194.9K

|

Marty, what size are those Webers. Bore and Venturi. It’s been over 40 years since I set ones up, and they were much smaller cylinder displacement to bore/venturi sizes. But IIRC they are completely different for initial set up on a carb per cylinder than they are on a plenum manifold.

I helped on a set for a sbf on a friend’s Cobra, but I gave him the books. Now I wish I hadn’t.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|