|

By martyk98 - 7 Years Ago

|

|

I'm looking for professional input. I have a very nice 368 block. Not looking to build a race engine but wondering what i can do to pump it up a little. Can I run roller lifters/cam?

|

|

By Joe-JDC - 7 Years Ago

|

|

What vehicle? Are you wanting to keep it original looking? If not, then a couple of spacers, and a SBC intake manifold help, and headers, pertronix ignition, and a good 750 cfm carb. I have ported several sets of the heads, and they respond well to that if you decide to wake the engine up. Simply adding a roller camshaft will not get you there. The cam cores are really difficult to find. Royce B. is the resident expert on the 368 Y. Joe-JDC

|

|

By KULTULZ - 7 Years Ago

|

|

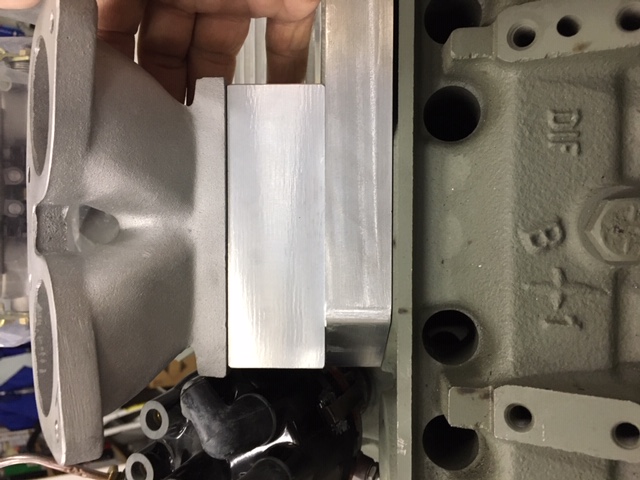

... a couple of spacers, and a SBC intake manifold help ...

Are these spacers available or do they need to be fabricated?

|

|

By Ted - 7 Years Ago

|

KULTULZ (11/8/2019)

... a couple of spacers, and a SBC intake manifold help ... Are these spacers available or do they need to be fabricated?

I haven’t seen those intake manifold adapter spacers being commercially available for the LYB engines but they could be out there. In looking at some of Royce Brechler’s modified LYB engines, they don’t look to be too difficult to fabricate. Here are some pics.

|

|

By KULTULZ - 7 Years Ago

|

THANX! again Ted ... really appreciated.

Those adapters are fairly gnarly looking. I assume they can be more blended in appearance.

It was found that the 303 OLDS had near matching ports and this allowed a HILLBORN INJ ASSY to be mounted on a LYB. But like the LYB, I can see no aftermarket 4V ALUM intake released for the OLDS.

|

|

By martyk98 - 7 Years Ago

|

|

I have one of those Hilborns stamped 303. It was on a 368 race engine I bought years ago. The block was junk but I kept all the aftermarket stuff. After reading more info I will probably stick with the stock engine rebuilt. I've done a little porting on the heads but have learned in the past that the smoother you make the runners, the more RPM's you need to make it work right. I wss hoping to find someone who could retrofit my Hilborn FI unit with EFI and make a nice engine for my 54 Merc.

|

|

By KULTULZ - 7 Years Ago

|

Read This - http://hilborninjection.com/faq/can-i-convert-my-old-mechanical-unit/

|

|

By martyk98 - 7 Years Ago

|

|

I've already talked to them. They won't do a retro, just sell you new equipment.

|

|

By RB - 7 Years Ago

|

If you have the 303 olds injector body they are easy to adapt to the Lincoln. I did it and It picked up 60 horse over the best factory manifold.But that was mechanical injection, not EfI

This guy can help you with adapting the Hilborn to EFI . https://foxinjection.com/. Alkydiggers.com can also do it

I have a couple old Edmunds dual carb intakes that would be OK for a warmed up stock engine one is ported by JDC and flows enough to make 350 or 375 horse. Forget the roller cam the view is not worth the climb, unless you address a lot of other areas that would be expensive, and negatively affect street manners. In fact even flat tappet blanks are very hard to find.. Regrinding your stock core will serve you just fine..Spend your money on head work ,increasing compression, and improving the intake manifold.. 400hp is not an unreasonable goal. I made my own intake spacers.. That is a big chunk of aluminum to make it work, but work it does. I merely calculated how thick the spacer needed to be, put a 368 gasket on one side and traced out the pattern, Then the SBC gasket on the other side and scribed that . Drill the holes to mount spacer to block, then manifold to spacer... I had JDC do the finish work, line up the ports and shape them to match up side to side.. It works well, but you better have a lot of hood clearance

|

|

By KULTULZ - 7 Years Ago

|

martyk98 (11/13/2019)

I've already talked to them. They won't do a retro, just sell you new equipment.

That's what I was trying to say but didn't post. When you go to their page, the first thing they say is no EFI retro-fit any longer -

Can I convert my old mechanical unit?

Although it is possible to convert your old Hilborn Injector to EFI, we have found that after spending the time and money required to accomplish this, it makes better financial sense to buy a new injector already set up for EFI. We’ve redesigned our original castings at the foundry level to accept all the necessary EFI components, which in the long run, can save you money by eliminating costly re-machining for conversion. Because of this, we do not offer machining conversion services at Hilborn Fuel Injection. However, most blown mechanical fuel injectors, whether scoop or hat style, can be easily converted to EFI.

|

|

By martyk98 - 7 Years Ago

|

|

or the info and advice. I have decided against rollers. The cam is at the shop, he'll bump it up to todays specs, I think he said 268. We'll get fitted pushrods and call it a day for the internals. Looking in to carb/FI options. I have lots of clearance in the compartment of my 54 Merc for anything that I want to do on top.

|

|

By KULTULZ - 7 Years Ago

|

That is going to be one beautiful ride ...

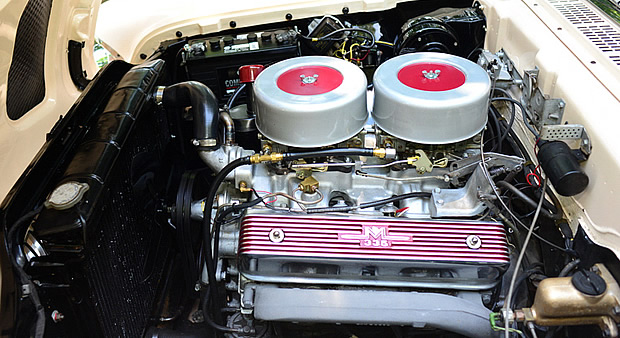

For any 368CI HP info, research the 1957 MERC TPK CRUISER and the 1957 MERC M-335 engine.

If you can see the cost, the conversion to EFI will be a show stopper.

|

|

By martyk98 - 7 Years Ago

|

|

How about 8 webers?

|

|

By KULTULZ - 7 Years Ago

|

Those will work ...

|

|

By martyk98 - 7 Years Ago

|

|

I've got an email in to Jim Inglese in Florida. He's the Weber Guru.

|

|

By martyk98 - 7 Years Ago

|

|

FYI-in case anyone is interested: Weber sold out years ago. Repos were made in Spain. New repos are knocked out in Asia. Quality is going downhill.

|

|

By KULTULZ - 7 Years Ago

|

|

FYI-in case anyone is interested: Weber sold out years ago. Repos were made in Spain. New repos are knocked out in Asia. Quality is going downhill.

Isn't it all?

Same deal. The SUMMIT carb is cast in China. I am not sure where it is machined, either there are here.

|

|

By martyk98 - 7 Years Ago

|

|

Well, I'm on m way with the 368 rebuild. Cam is back, Block cleaned, mag'd, honed. Waiting for crank. Valves are done. Probably have to get new rocker shafts. I have two sets and none of them look OEM. Won't know what size pushrods to get until we assemble. I'm sure I will get the 368 to Ford AOD tranny kit. Not cheap but exactly what is needed. We were going thru a lot of head scratching with matching up flywheels, balancers, and starters. This kit takes all that out by including everything you need to marry them up. Plan B with carburation would be 8 singles versus 4 weber types. Either way, some intake modifications will have to be researched. Anyone interested in parts, let me know, I'll have an extra cam and crank, piston rods, valves, etc.

|

|

By martyk98 - 7 Years Ago

|

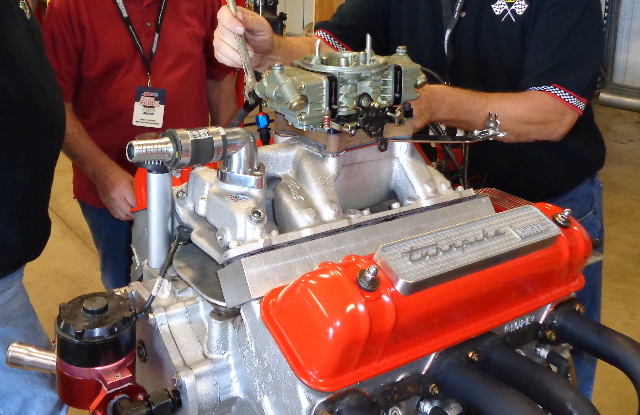

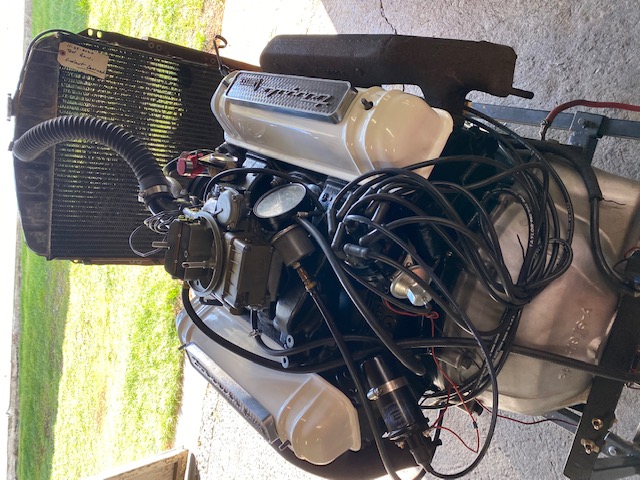

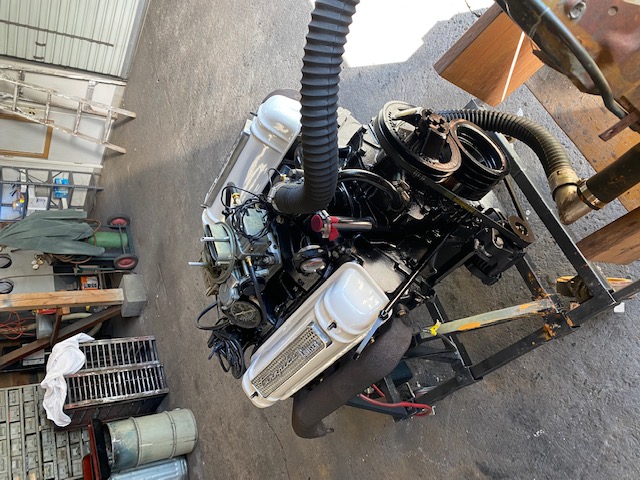

Let the fun begin. Cam and bearings are in. Plugs and slugs. Waiting on rings. Over 2 weeks from Speedway? I sanded the casting marks off the front of the block, timing chain cover and water pump. Hopefully when I paint them gloss black they will look OK. Plan on running webers, a magneto, and Turnpike Cruiser valve covers.

|

|

By RB - 7 Years Ago

|

Looks good Marty..

A small suggestion.. If you bought stock type replacement pistons you may find they are further down the bore when at Top Dead Center than the originals.. This is a common occurrence on most engines because the piston manufacturer wants a safety margin for the piston interfering with the valves or head.. If the replacement piston is further down the bore you may have unacceptable low compression as a result.. To compensate you would need a thinner head gasket or have the heads cut to reduce chamber volume. Good luck on completing the build. RB

|

|

By martyk98 - 7 Years Ago

|

|

We're using the original pistons and rods. This motor was well taken care of. The crank polished up with STD bearings, pistons with STD rings. The second motor I have was not taken care of. We're using that as a mock up for the new carburetor set up and motor mounts that we have to figure out. I haven't seen anyone putting a 368 in a 54 Merc Monterey. We won't be able to fabricate them until we get the Bendtsen Adapter hooked up to my AOD. We're looking at these carbs but I'm a little leary of Asian Webers.

|

|

By KULTULZ - 7 Years Ago

|

Its nice to have a spare block to help in fabricating mounts and heads to adapt an intake.

57 MERC used a 368. It also had two fours on an ALUM INTAKE (M-335) if you are interested.

I would hold onto those spare parts. You never know.

Is this going to be a show car or driver?

|

|

By martyk98 - 7 Years Ago

|

|

This is going in my 54 Merc Monterey. The car is already done, I just thought it would be cool to have an all Mercury car. We just made an engine stand so we can run the 368 once it's done before installation and fix any bugs before install. I'll post more pictures as we go along. Spent a couple of hours today sanding down a pair of ram horn exhaust manifolds before sending them to the coaters. I have about three pairs of Lincoln exhausts if anyone is interested. Also a power steering pump. I'm sanding down the water pump and timing chain cover also.

|

|

By yalincoln - 6 Years Ago

|

|

hi! 57 to 64 HD trucks used a late holley pattern intake with a normal rise so you can use any late holley, edelbrock, aftermarket carb or a holley throttle body injection for normal street driving! just another idea!

|

|

By KULTULZ - 6 Years Ago

|

|

|

By martyk98 - 6 Years Ago

|

|

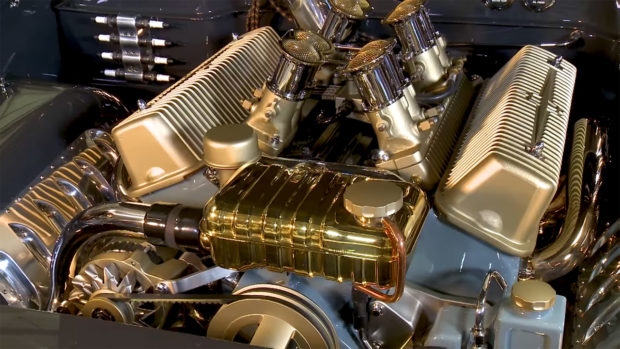

Beautiful motor "K". I'm going to lean away from a traditional intake and carb setup. 4 Weber 48 IDF's with a custom made intake system is the goal. Waiting on parts right now.

|

|

By KULTULZ - 6 Years Ago

|

|

Beautiful motor "K". I'm going to lean away from a traditional intake and carb setup. 4 Weber 48 IDF's with a custom made intake system is the goal. Waiting on parts right now.

I was just teasing you with eye candy.

Waiting to see what you come up with ...

|

|

By martyk98 - 6 Years Ago

|

|

Besides not getting parts delivered on time, now UPS says they dropped off my 4 Webers yesterday and they're not here. I have never lost a package because of the remote area I live in. Can't wait to see what their excuse is. I'm just having a difficult time with suppliers telling me they have the parts I want just to find out they are "out of stock".

|

|

By Joe-JDC - 6 Years Ago

|

|

A lot has to do with where you are standing when you take the picture. You need to think ahead of time where you want "up" to be in the picture. Joe-JDC

|

|

By KULTULZ - 6 Years Ago

|

It's either the browser or site. When I hit to enlarge, it shows correctly (FIREFOX).

I have occasional troubles here but believe it is my browser.

|

|

By martyk98 - 6 Years Ago

|

|

|

By martyk98 - 6 Years Ago

|

|

|

By martyk98 - 6 Years Ago

|

|

|

By martyk98 - 6 Years Ago

|

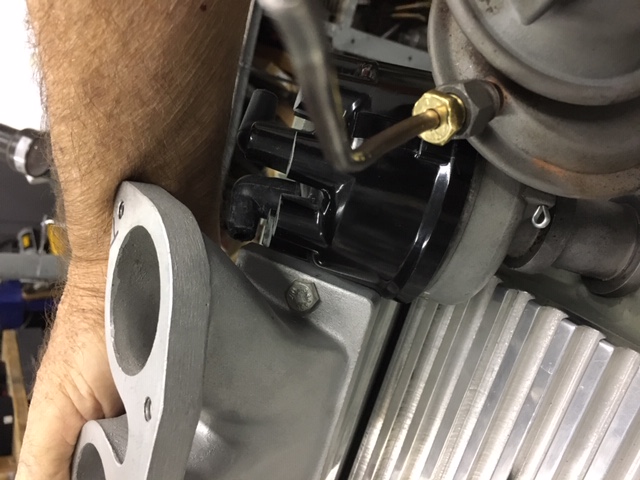

Got the Weber/SBC intake manifold today. Unbolted the weber plenum.

The diameters of the runners match the 368 heads within a 16th of an inch.

|

|

By martyk98 - 6 Years Ago

|

|

Advice is Wanted: I'm still looking for a new distributor. Should I go with a generic replacement with pertronix or a retro Mag look, or? 1" aluminum plates are at the machine shop getting milled to accept the plenum and water lines. Block is ready for test runs once we get the radiator hooked up, plug wires fitted and exhaust manifolds bolted on. Getting Close!

|

|

By FORD DEARBORN - 6 Years Ago

|

I would use a 57 or later distributor because it would look more natural. A Ford Y-block would work and much easier to find but would require replacing the drive gear with a Lincoln gear. I have converted a couple Lincoln stribs. for use in Ford y-blocks by doing the opposite. If you need a drive gear, let me know, I should have both. Just my 2 cents, JEFF...........

|

|

By mjs - 6 Years Ago

|

That drive gear is the same as a 390. I had to replace a couple and that is what it crossed over with. My local supplier (not NAPA, Oreilly's or

Autozone), had them in stock.

|

|

By martyk98 - 6 Years Ago

|

|

Thanks. I have the gears and the distributor. I thought someone might chime in and suggest something more exotic but I guess there really wasn't much exotic back then for these engines.

|

|

By martyk98 - 6 Years Ago

|

Just got the adapters back from my machinist friend, Harry. These go between the Weber intake runners and the head. A real professional job. Things are moving slow with this virus

|

|

By martyk98 - 6 Years Ago

|

ee ee

|

|

By martyk98 - 6 Years Ago

|

|

Our engine is running with stock intake and carb setup. After a few more runs, we'll take off the stock assy and put on the webers. We need to make fuel rails and throttle linkage. Any suggestions will be appreciated.

|

|

By martyk98 - 6 Years Ago

|

|

Well....Our engine is super hard to start and there is a lot of crank case pressure. We did put a little bigger cam in it but not dramatic. Resized pushed rods are also in. We're not sure if it's rings, cracked block, or what. Any ideas? Our next step is to check combustion pressure. Lots of blow by. Something"s wrong.

|

|

By Ted - 6 Years Ago

|

Are the piston ring end gaps adequate? Beyond that, I’ll suggest a cranking compression test. If you have leak down tester handy, that will be more definitive in isolating the problem to a single cylinder and exactly how bad the problem is if it is indeed a problem related to one cylinder and not all of them. Excessive leak down on all the cylinders will also point to a different set of fixes for the problem.

|

|

By martyk98 - 6 Years Ago

|

|

ALL cylinders have low compression. We're thinking the cam timing is off. With the change of cams to something a little hotter, we didn't change the dial in stock setting..We're going to investigate to see if we need to change that. If it improves the compression, we have found our gremlin. This is the second engine Jeff and I have built together, I don't think it is a builder problem. He's too anal. Thanks for getting back to me.

|

|

By DryLakesRacer - 6 Years Ago

|

|

Does it still have the carb and stock manifold? What changed from 4 days ago when you said it was running with no mention of a hard start. Was the 4 days ago start a typical one with a run to 2000 rpm and hold 20 minutes with a total timing check? Just asking..

|

|

By martyk98 - 6 Years Ago

|

We can't figure it out. It started up right away first time. After it got hot we shut it down fearing our temp gauge might be faulty. Tried to start it again and nothing. Messed with timing for a couple of hours and gave up. We went back yesterday and it was worse than before. Finally got it running but didn't like it. Did a compression check last night and every one of them is under 100. We did put in a hotter cam so we're going back to the drawing board and re-checking valve timing. Maybe we need to add/subtract a tooth.

|

|

By Joe-JDC - 6 Years Ago

|

|

Typically, retarded timing will cause the engine to run hotter than normal, and if it is getting worse, I would pull the distributor and look at the gear, and the pin holding the gear on the shaft. Next, would double check the camshaft install with degree wheel to make sure it is correct. Joe-JDC

|

|

By Ted - 6 Years Ago

|

|

Was fresh fuel being used when the engine was first started? If the gasoline was over 90 days old, it is suspect.

|

|

By RB - 6 Years Ago

|

Check the balancer for true top dead center.. Like Joe says, hard starting and hot exhaust says retarded ignition timing... Low cranking compression, if I had to guess, you are one tooth off on the timing marks and your intake valve is closing late..Was valve to block/piston clearance checked? Lincolns are particularly bad on the intake side . The valve hits the block with lift over .500 and it does not take much to tweak the valve head and lose some seal Do you have the specs on the cam you installed? If none of these things are at fault, sadly, the problem is much deeper

Definitely get a leak down tester.. it will tell you if the compression is escaping through intake or exhaust valve or getting past the rings

|

|

By martyk98 - 6 Years Ago

|

|

Thanks for all the advice. We are checking each and every idea. Gas is not an issue. Timing is our first thought, that's what is going on now. We had the timing marks spot on but maybe we needed to advance/retard one tooth because of the new cam grind. If the cam is more aggressive, should we advance the mark one tooth or retard? It's just me asking, Jeff probably already knows.

|

|

By RB - 6 Years Ago

|

One tooth of timing is way too much either way.. My guess is it one tooth off retarded. Make sure the timing marks are lined up so your cam is in the straight up position.. There are no adjustable cam components for these engines.. Is the cam reground stock?

If your timing marks on the damper are off due to the damper ring slipping, you will get an erroneous ignition timing reading. Try advancing the distributor while it is running. If the engine smooths out, give the engine what it wants not what the timing marks say. One more thing to check You may have a big vacuum leak somewhere which would make it hard to start and run hot due to lean fuel mixture.

Do you have hydraulic or solid lifters? If hydraulic, the rocker arm adjuster screws may have too much pre-load on the lifter and it is not letting the valves fully seat.. Just another item to check..

|

|

By DryLakesRacer - 6 Years Ago

|

|

I got an engine to run once being a tooth off and it was unbelievably bad. Back when it first started building performance engines I had to get a wider key and machine the sides to get an advance or retard; there were no notched crank gears or buttons for cams. and it was a pain. Thanks to my dads mill and his advice i was able to do it; then remember with no chain put it in backwards. I also does not sound right that a cam grinder would grind that much into any cam and only on a new casting or billet. Interesting reading and suggestions for sure...

|

|

By martyk98 - 6 Years Ago

|

OK, Timing: we have gone through the gambit of rotating the distributor and have found the "sweet spot" where it runs and idles OK. It is not a stock grind, a little more lift and duration went into it from a very reputable shop, not super aggressive. We put in longer pushrods to accommodate the cam. We're pretty sure the issue is here but are still working on it. Timing marks on the damper may be an issue with the new cam but our issue is bad compression numbers on all cylinders and hard starting. It's got to be in the valves. We did our own seating and grinding so we might end up swallowing our pride and taking them to a real shop for verification of our work. We could also end up going back to the stock grind, I have an extra cam. Funny, once we get this thing dialed in we're gonna take the top off and set up our webers and then back to the drawing board with linkage and fuel lines.. Trying to find a generic throttle linkage kit for the four twin stack webers has been impossible.

RB: hydraulic lifters, vacuum checks out at 20-21 with just a very little flutter.

|

|

By Joe-JDC - 6 Years Ago

|

|

Did you check your rocker arm ratio and valve tip relationship? With more lift, your longer pushrods may be bottoming out in those hydraulic lifters and holding the valves open a little when everything gets hot or heat soaked, losing compression. I would think the stock pushrod would be more appropriate with more camshaft, not longer ones. Joe-JDC

|

|

By martyk98 - 6 Years Ago

|

|

Good thought Joe, that's on our list. Fortunately there is a lot of play in the stock rocker arm adjustment. Maybe this engine wasn't meant to have a more aggressive grind.

|

|

By RB - 6 Years Ago

|

20-21 inches of vacuum is a lot.. That cam must not be a big step up from stock.. It seems that compression now is your main issue. I would start to maybe question your valve job. I know my attempts at home brew valve jobs have not had great results.. Before you pull the heads i would invest 40 bucks in a leak down tester and zero in on were the compression leakage is happening..

Nothing in the inherent design of the Lincoln Y block would prevent use of a hotter cam... As long as you account for valve clearance at max lift with the block and pistons.. I have Lincolns where I run over .600 lift and 250 duration.. But accommodations have to be made for valve clearances..I doubt too aggressive of a cam is your problem

|

|

By RB - 6 Years Ago

|

|

To piggy back on Joe's comments one thing you could try is to back off all the adjuster screws 1 or 2 turns and see what happens.. That would assure the hydraulic lifters are not bottoming out and holding the valves off the seat

|

|

By Ted - 6 Years Ago

|

All comments up to this point are valid. I’ll add a couple more.

That slow turnover of the starter can be a result of a dragging starter. Worn bushings in the starter can contribute to that. Performing an amp load on the starter while turning over the engine could help to clarify that.

If the compression tester is old or has been used on a hot engine, it can be giving erroneous readings. When getting abnormally low compression test readings, performing an accuracy check on the tester would provide some additional confidence in the readings.

|

|

By martyk98 - 6 Years Ago

|

|

Leak down test coming this week. You're right, the cam is not too aggressive. Gotta be dem damn valves.

|

|

By martyk98 - 6 Years Ago

|

|

Well...It's not the valves. It's the cam shaft. The new grind is so far off that it's affecting everything. There's only one cam shaft shop in the whole county so we're back to ground zero. Ted, if you know of a shop that can repair our CS, please let me know. Jeff has been checking around and we're not the only ones that are not happy. Rosen down in Cali is backed up over a month due to covid. In the mean time, we took the heads to a local old timer that's going to put hardened seats in them. Once we get a good cam shaft, I'm sure we'll be ready to go.

|

|

By RB - 6 Years Ago

|

|

What did you determine was the problem with the cam? Is it a regrind of a stock cam?

|

|

By Ted - 6 Years Ago

|

|

Like Royce, I would like to know more details on the camshaft and exactly what you found wrong with it. It strikes me odd that the engine initially cranked up and ran okay and now it’s not. This makes it appear that the camshaft has changed timing at the timing gear set and/or has lobes going away.

|

|

By martyk98 - 6 Years Ago

|

|

Yeah, the initial timing thing threw us too. Anyway, long story short, I went the the local cam shop and asked for a more "modern" grind that would give me a little more HP. What he gave me back was so far out of whack we can't imagine how the engine started in the first place. Only thing that comes to mind is when we were turning the distributor we must have found a small sweet spot that allowed the motor to start, never to be found again. Our heads came off with the cam tear out just to make sure there wasn't another problem, there wasn't. After dialing in the cam to see the numbers, Jeff was amazed with what he found. While the heads were off anyway, we decided to have hardened seats installed even though a leak down test showed we did a good job seating the valves in the first place. So I have two cams at the shop (same shop, there is no other) getting stock grinds, no more funny stuff. I'll post the numbers if you really want to see them.

|

|

By RB - 6 Years Ago

|

|

Boy that's a new one on me, a regrind being that far off... If you have never read up on degreeing in a cam it might be worth it to do that on your next install..Good luck...

|

|

By RB - 6 Years Ago

|

|

By the way, where are you guys located?

|

|

By martyk98 - 6 Years Ago

|

Puyallup, WA, a small town just SE of Tacoma. It's not us, it's the cam. I'm taking the blame for not getting the specs of what I wanted to the cam guy and just let him go on his own.

|

|

By RB - 6 Years Ago

|

|

I have worked with Oregon Cams and Delta cams up in that area.. Both seemed to do good work.. In fact I think Delta still has one of my cams for repair

|

|

By martyk98 - 6 Years Ago

|

|

They turned the two I gave them around in short order. Got them back yesterday. Not even a week. Between the two of them, I'm sure we'll be able to get rolling again soon on our project. Still looking for anyone with a lead on Weber linkage to handle the four we're putting on this thing.

|

|

By Oldmics - 6 Years Ago

|

I"d like to see the numbers. I assume these are the numbers you came up with while degreeing in the cam?

Its hard to fathom that a reground stick could be that wacked out ?

Oldmics

|

|

By martyk98 - 6 Years Ago

|

|

It appears the intake is the problem. It opens at 36 degrees BTDC and closes at 144 degrees ABDC. Exhaust is opening at 118 degrees and closing at 62.

|

|

By Ted - 6 Years Ago

|

|

Total agreement on the numbers being out of whack. What were the lobe lifts when those numbers were being recorded? As a general rule, lobe lifts are checked at 0.006" for hydraulic camshafts and 0.020" for solid lifter camshafts. I’m assuming that the exhaust is opening at 118° BBDC and closing at 62° ATDC? If that’s correct, then the duration for the exhaust is 360° while the duration for the intake is 344°. 360° is a full revolution of the crankshaft. If that 118 number you posted is 118° ATDC, then the exhaust is actually opening at 62° BBDC which would make more sense. Without clarification on the numbers, the problem lies with both the intake and exhaust lobes. Did you check the lobes on a cylinder on the opposite bank as there’s also the potential for the camshaft to be ground on the incorrect lifter bank angle which just compounds the problem.

|

|

By RB - 6 Years Ago

|

|

If you could post a copy of the cam card sent back from the grinder that would be helpful..

|

|

By martyk98 - 6 Years Ago

|

|

It's been too long since the grind, sorry, no card. As far as the exhaust numbers go, we have them at 116/65, just a little off from stock. We didn't go 100% on checking every cylinder. Once Jeff found the large discrepancy he knew where the problem was and pulled the cam. Stock grind going in. I was hoping for a few more ponies but I guess I'll have to settle for my amateur porting job. The last heads I did for my 56 Mark II came out great. These are Merc heads and had a little more casting to get rid of. Maybe it was just the supplier that was different, who knows. Uh-oh, you say, what did that knucklehead do to the heads? Not to worry, just made the gaskets and the holes match up on the intakes and exhausts. I know that sanding down the runners smooth only works best for high RPM builds.

|

|

By martyk98 - 6 Years Ago

|

|

We're up and running. Cam swap did the trick. All cylinders at 145. Now for the fun part(?) Fabricating the webbers with linkage, fuel delivery, and transmission linkage. Still looking for generic linkage and fuel systems on the internet.

|

|

By RB - 6 Years Ago

|

|

You will likely have to do your own linkage design with bell cranks heim joints and turn buckles.. Kinsler fuel injection has all kind of weird hardware to make their injector linkages work. You might look at their catalog.. You might also get some help from Alkydigger .com he does custom linkage setups for Hilborns which pose similar problems as your webers. Glad you got that 368 running Now let's make some horsepower!

|

|

By martyk98 - 6 Years Ago

|

|

Vacuum is going to be an issue. With my custom made adaptors which fit between the runners and the heads, there's no good place to get vacuum. I know external is an option but checking vacuum for tuning has got to be in the equation somewhere.

|

|

By charliemccraney - 6 Years Ago

|

|

Do Webbers not have vacuum ports for that purpose?

|

|

By RB - 6 Years Ago

|

|

To get an accurate vacuum reading you need to have a common plenum. With IR type induction you can't get a good reading because of the pulsing of the intake tract... The same problem comes up with IR injectors converted from mechanical to EFI.. It is solved by tapping an 1/8 pipe fitting (or smaller into each injector then running the lines to a small common plenum, then taking the vacuum readings off of that. I will see if I can find a picture for you

|

|

By RB - 6 Years Ago

|

|

https://www.alkydigger.net/proddetail.php?prod=AD-Vacuum

|

|

By Ted - 6 Years Ago

|

For balancing Weber carbs, I use a Unisync tool. Works also for individual throat fuel injection or those manifolds where the carb venturies are being aimed at specific cylinders such as when using the Man-A-Fre manifolds.

|

|

By martyk98 - 6 Years Ago

|

|

That would be fine if I had a full intake manifold. I'm working with a 368 that has a valley pan. Fitting a vacuum line in to all eight plenums poses a huge issue with fuel and throttle linkage also to be addressed.

|

|

By miker - 6 Years Ago

|

|

Marty, I just went thru a similar exercise on an Algon FI unit for my Yblock. I don't want to hijack your thread, send me a pm and I'll tell you what I learned if you're interested.

|

|

By martyk98 - 6 Years Ago

|

|

I would love to PM you but I'm getting a "cannot do" error when I try. Might be my iMac/Safari setup, it's also hard to get pictures sometimes . Anyway, my email is martyk2133@gmail,com. I am eager to hear your experience. PS Been up to the shop in Auburn and that guy is WAY past expensive, he quoted me $25-30K to do the engine. You are also correct, he does really good work. NO such thing as hijacking here. Everyone is welcome to join in. Personal experiences shared by all is the way we learn from each other. I have a bunch, most of which you can file as "I wouldn't have done that"!!!

|

|

By martyk98 - 6 Years Ago

|

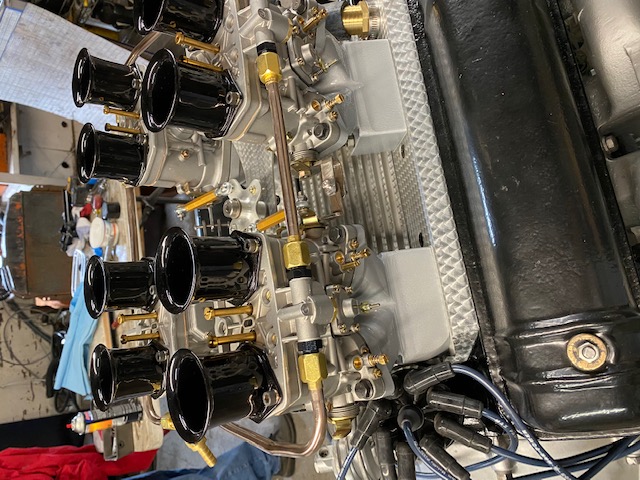

Here's the start of my Weber makeover.

|

|

By martyk98 - 6 Years Ago

|

|

|

By martyk98 - 6 Years Ago

|

|

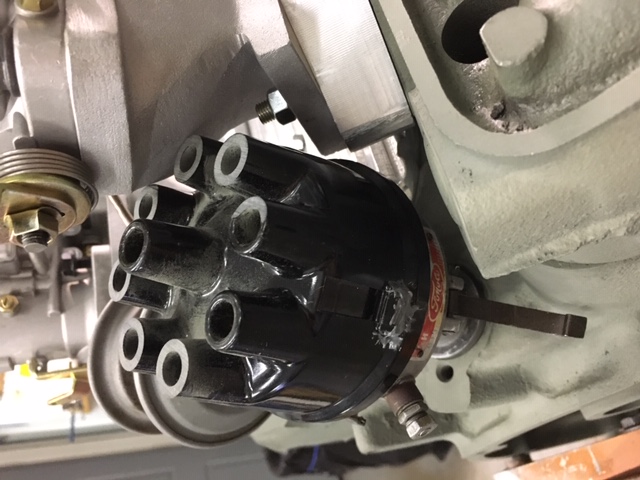

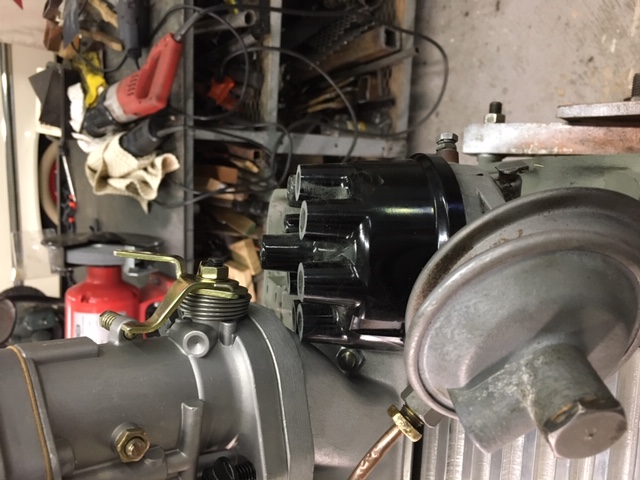

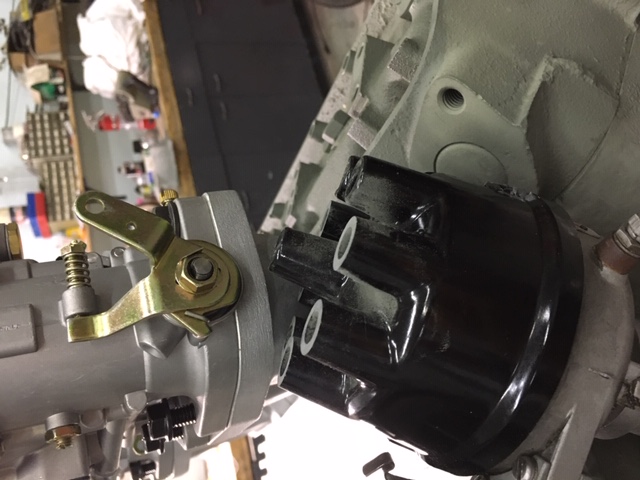

The rear Weber on the distributor side makes my stock cap not fit. Does anyone know of a low profile distributor or cap? Are 272 distributors the same height?

|

|

By RB - 6 Years Ago

|

|

Look for a marine cap for a Ford distributor. I think MSD or Mallory have them The terminals come out the side instead of the top of the cap Also the early Load O matic distributors have a shorter cap

|

|

By RB - 6 Years Ago

|

|

Another option would be to hunt down a Mallory model YL distributor for a Y Block.. They are a smaller diameter than the Ford distributor

|

|

By martyk98 - 6 Years Ago

|

|

Thanks for the info. As you know, searching for anything Y block on the internet is extremely frustrating. More stuff completely unrelated to what you're searching for appears, mostly scruby and SBF. The internet wants to ignore the term Y block. I would love to get the crab cap for my existing distributor but none of these websites tell me if it will fit mine. Try to call and get info? also not so easy, Covid is giving a lot of these suppliers a chance to fire employees and cut costs. Hold, leave a message, don't answer, I don't know, etc. I'd bet money that there wasn't a crab cap made for the 368 distributor and I think the 393-312 is a different diameter. There are many Mallory YL model numbers. Any help with the number I need would be appreciated. I'd pull my hair out but I only have a couple left. Something else I'm noticing, crab caps look like they don't fit on distributors with dual vacuum advance.

|

|

By RB - 6 Years Ago

|

Are you using the 56 dual advance Load a Matic distributor? If so it will be totally incompatible with your Weber setup.. The Ford/Merc 57 and up distributors are the same, Y Block and 368. Only the cam gear is different. The 57 and up takes the same cap as all other Ford distributors up to about 1975 when they went to the wide terminals and Duraspark I believe all Mallory YL distributors have the small dia cap. You just need to find one for a Y block Try the HAMB website.

Try mmancini@vintageignition.com He specializes in Mallory.

Look for a YL 387A

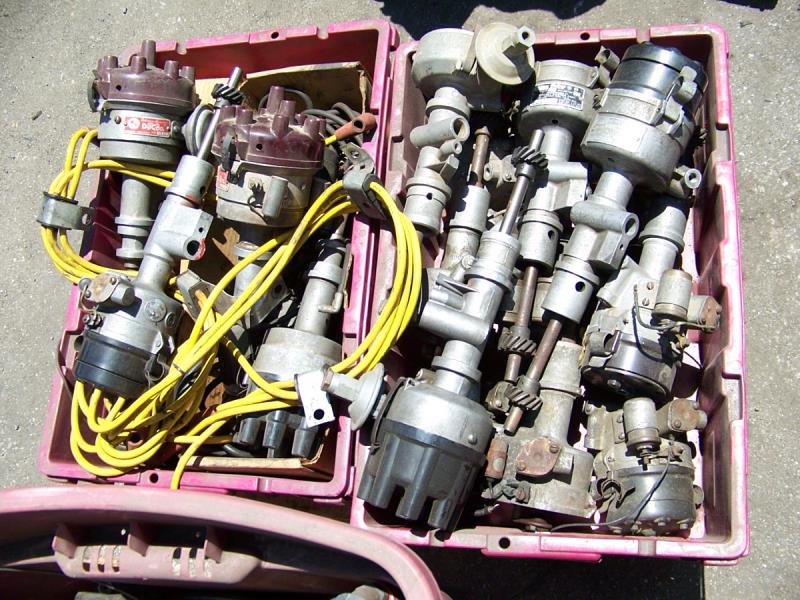

If possible post a picture of your distributor and how it interferes with the carb.

|

|

By martyk98 - 6 Years Ago

|

aas aas

|

|

By charliemccraney - 6 Years Ago

|

That is the earlier distributor, which will need to be replaced.

Would a spacer between the carburetor and adapter give the room needed for the cap to fit?

|

|

By 2721955meteor - 6 Years Ago

|

|

you might find a early truck engine, as,some of them had gear driven tack. aswell as a industrial 317 which is same as your engine except they had gear driven camshaft and smaller cubes. there where lots of these engines in washington state as well as bc canada,used in induct. swell as trucks

|

|

By martyk98 - 6 Years Ago

|

|

If I install a spacer on one then I 'll need to space all (linkage). Now I'm looking at space for the hood to come down. You might have something there though. They would have to be under the riser/plenum.

|

|

By RB - 6 Years Ago

|

|

I see your problem.. And it is a tough one. It's not the carb interfering it is the adapter.. The early distributor is actually shorter than the late one so using the 57 distributor probably makes the problem worse. A Mallory YL small cap MIGHT clear the adapter.. Otherwise the only solution I see it to make a spacer to put underneath the adapter..You can use that distributor you have but you will have no advance curve at all.. There are some more complicated solutions bu it gets into heavy mods on the distributor or redoing the distributor drive and moving it to the front of the motor

|

|

By martyk98 - 6 Years Ago

|

|

I'm going to try Charlie's idea first. It's the cheapest and seems to have the answer. I ordered the block of aluminum I need and getting it machined is no issue, all it takes is money, right? Changing out the distributor to a later model is also in the cards. It's hard to check hood clearance but it appears I"ll have enough room.

|

|

By Joe-JDC - 6 Years Ago

|

|

Now that you see the problem, I would start over with two new spacers, and move the intake ports over and angle them towards the heads to give you more room for the sparkplug wires to fit in that cap. It is a bit of work, but the finished product would have more hood clearance, and might help with linkages, etc.. Joe-JDC

|

|

By Lord Gaga - 6 Years Ago

|

|

Was there a "crab" cap available ever?

|

|

By martyk98 - 6 Years Ago

|

|

I have never seen a crab cap for this distributor. Joe: I'm not seeing your vision on this one. If I change any angle on the adapters will the carbs still be straight up?

|

|

By charliemccraney - 6 Years Ago

|

I think he's talking about the aluminum blocks you made, spanning the entire intake flange on each head. Make those again, but shift the rear carb forward, which will require that the ports be angled to meet the ports in the head.

|

|

By Joe-JDC - 6 Years Ago

|

|

The two aluminum spacers. Move the two rear ports forward on both sides the same amount to look normal. You are going to need space for the plug wires and boots on top of whatever cap you use, so use a cap with wires in place and see just how far you would need to slide the Webers/carbs spacer on the long spacer forward to clear, and see if it is possible to blend that amount to the heads. I have moved ports a lot on spacers and blended them, not ideal, but it could possibly work for you. You can remove a good deal of the carb spacer bosses, also without ruining their integrity. Joe-JDC

|

|

By martyk98 - 6 Years Ago

|

|

Going with Charlie's plan A first. Plate aluminum is at the machine shop.

|

|

By martyk98 - 6 Years Ago

|

Well, the blocks will do the trick. I need to massage them a little to make it more attractive but at least I can get the distributor on and moving freely. Still looking for the right distributor, may just have to use an old 292-312 stocker. Can't find a Mallory 387A anywhere.

|

|

By martyk98 - 6 Years Ago

|

|

Just purchased a 57-63 Ford Distributor with combo mechanical and vacuum advance. Should do the trick.

|

|

By Cliff - 6 Years Ago

|

387 A is a Y Block marine distributor, if that's what you want E Mail me $100.00 plus shipping (this is a dirty used part) 387 A is a Y Block marine distributor, if that's what you want E Mail me $100.00 plus shipping (this is a dirty used part)

Liqu@aol.com

|

|

By martyk98 - 6 Years Ago

|

|

Thanks Cliff, should clean up nice.

|

|

By Cliff - 6 Years Ago

|

I have a few more

|

|

By martyk98 - 6 Years Ago

|

|

Nice collection!

|

|

By martyk98 - 6 Years Ago

|

Well, the Mallory distributor isn't going to work. It's just as tall as the 57-62 Ford distributor which doesn't quite clear the intake plenum. I guess we are forced to use the stock 368 dual diaphragm (never knew there was a G in that word). Now I have two vacuum advance lines to run into 8 single throated carbs. Figure that one out!

FYI the height difference is in the base of the distributor where the points are, not the cap. Diameters of all three are almost the same.

|

|

By Cliff - 6 Years Ago

|

Mallory has a crab cap that is a lot shorter.

https://www.ebay.com/itm/Mallory-Crab-Distributor-Cap-plus-Rotor-Fits-Fords/143714160675?hash=item2176081023:g:ZnkAAOSwvJFfToKn

|

|

By paul2748 - 6 Years Ago

|

Isn't that just for the front mounted flathead engines?

|

|

By Lord Gaga - 6 Years Ago

|

|

I'll bet a clever person could make that cap fit.

|

|

By Cliff - 6 Years Ago

|

Better look

http://www.supermotors.net/getfile/481498/fullsize/mallorycrabcap.jpg

|

|

By Cliff - 6 Years Ago

|

The 8 cylinder flat (crab) cap sold by Mallory is simply a red version of the stock 1942-48 flat head Ford V8 distributor cap. Mallory was the OEM supplier of the distributor to Ford during that time. (Mr. Mallory and Henry Ford played a lot of golf together I hear).

Mallory is again making flat head Ford V8 distributors for the aftermarket and the same cap that was designed in the early 1940's is still in use (may even be the same mold).

In addition to using them on flat head Ford's, Mallory found that the cap can be adapted to many of the 1970's and later Mallory aftermarket distributors (except the Comp9000 versions) by machining the top of the bowl a little smaller and using a special custom rotor. The most common uses of the flat cap at Mallory (other than flat head Fords) are marine engines and engines with blowers because both applications commonly have clearance problems with the standard Mallory cap. The new Mallory catalog still lists several "blower" distributors and many marine distributors that use the flat cap. Unfortunately the FE Ford versions are no longer listed but any standard bowl mallory distributor can be sent to Mallory and refitted with a flat cap. (the service department does it all the time).

The basic part number for the flat cap is 221A. But there are several versions such as 221, 221A, 221B etc. The standard 221A is the one designed for the flat head. Most of the others are just modified versions of the standard cap. For instance, the standard 221A cap has the cylinder numbers molded into the cap which doesn't work out correctly if you install the cap on an engine that has a different firing order than a flat head. So 221 is the same as 221A but with the numbers milled off and a vent hole added. 221B has the numbers milled off but no vent hole as it is used for marine applications.

The 221A was designed in the early 1940's when compression ratios were lucky to be 7 to 1 and octane was around 76. Therefore cylinder pressure and ignition voltage was low. The cap is made out of "bakelite" which was good in it's day but not too impressive today. There are no arc prevention ribs inside the cap like most modern caps.

Will you have crossfire if you use a 221A style flat cap? Maybe not but since they are made from an inferior material which cracks very easy, and there are no ribs inside, you are much more likely to have crossfire than if you were using a more modern cap.

There are alternatives. Mallory also sells a flat cap part number 221F which is listed as the flat cap for magnetos. It will fit in place of the other 221 caps but is a more modern design with ribs and made of modern materials. It is also harder to find and costs twice as much. MSD now also makes a flat cap of modern design and modern materials. The MSD version even has male spark plug terminals. It will fit in place of any of the Mallory 221 caps. It too is pricey but if I had to use a flat cap on a high compression or blown motor, I would only use Mallory 221F or the MSD version. I've seen too many crossfire and cracking problems with the original flat head 221 design.

Just another history lesson from your humble Mallory engineer.

I copied this from the FE Web Sight- ;">

;">f100cleveland |

|

By martyk98 - 6 Years Ago

|

|

At a closer look, I think we can all agree the diameter of the crab cap in substantially larger than a regular cap. I have height and width restrictions on my build. My stock 368 dual diaphragm is going to be the unit of choice and I'll figure out the dual vacuum issue by tinkering with the running engine.

|

|

By wrcannon1 - 6 Years Ago

|

Wow! There are two Ducoil distributors in that collection.

Way cool!

|

|

By martyk98 - 6 Years Ago

|

|

we are at a slight stand-still with linkage. Jim Inglese says he hasn't got time to fill my order.

|

|

By martyk98 - 6 Years Ago

|

|

Don't give up on me, I might have found a local that can help with my linkage issue. He comes highly recommended as a fabricator.

|

|

By martyk98 - 6 Years Ago

|

|

I found my man. He'll be taking my assembly after the holidays. He's gonna fabricate linkage, fuel rails, and vacuum lines.

|

|

By martyk98 - 5 Years Ago

|

|

The 16th is the big day. I bundle everything up and take it to Tacoma. All that will be left to do (hopefully) is finding the tranny adapter for my AOD. Bendtsen is $2K, i'd like to find one cheaper.

|

|

By martyk98 - 5 Years Ago

|

|

Engine, carbs and accessories delivered. Now I wait for results.

|

|

By PF Arcand - 5 Years Ago

|

Marty; Don't know, but have you tried garycroan@gmail.com in CostaMesa, re the adaptor for your AOD ? or at 949-722-1122.. I think he operates as Bristol Services?

|

|

By martyk98 - 5 Years Ago

|

|

Funny you should mention Gary. Earlier, (2019) he tried to give me a 368 engine but I couldn't make arrangements to pick it up, it was too far away. I really hated to pass it up but such is life. Thanks for the info, when I get closer to the completed engine, I'll give him a call. I think Bendtsen is at $1300 complete with starter. Once my fancy 8 stack Weber system is complete, we'll hook it up to our running 368 and hopefully get it running right. I feel fortunate that I have the resources available to attempt this kind of project. It will definitely be a first.

|

|

By yalincoln - 5 Years Ago

|

|

hi! do they make an adaptor for a FE? check with Royce but i believe it might work!

|

|

By martyk98 - 5 Years Ago

|

|

are saying an FE adapter with fit a 368?

|

|

By Ted - 5 Years Ago

|

My understanding is that the LYB bell housing bolt pattern is on a slightly smaller bolt circle than what’s found on the FE. I’ve heard of people simply slotting the FE bell housing bolt holes inward and making them work on the LYB engines. ........But depending upon the dowel pins and how they are located in the different blocks, it may be difficult to get the transmission properly aligned with the crankshaft. I have no personal experience with this. Anyone with more information is welcome to chime in.

|

|

By RB - 5 Years Ago

|

|

Several people have jiggered the holes and removed the dowel pins on a FE bell housing to make it bolt up to a Lincoln Y..I never have, as you would have to spend a lot of effort centering the transmission with the crank.. For an automatic I used a Merc-o-matic bell to a 368 and modified it for a C4. For a stick I took a heavy truck bell and adapted that to a T-85 . A Scrub HD Saginaw 3 speed will adapt pretty easily to the truck bell.

|

|

By martyk98 - 5 Years Ago

|

I just received the first picture of my Weber 368 project. I like the innovation

. .

Intake on the left is just welded (was 2 pieces) , on the right, sanded down

|

|

By martyk98 - 5 Years Ago

|

Just finished my first attempt at engine turning. This valley pan was easy compared to the problem I'm going to have figuring out complex angles on the intake runners.

|

|

By martyk98 - 5 Years Ago

|

Before and after

|

|

By martyk98 - 5 Years Ago

|

|

Just when you all thought I have given up or left the site, I'm still here. Been kinda lazy with this project but went out today and clear coated the engine turned parts, reblasted the other aluminum pieces and am on the hunt for the right aluminum paint for the intake runners. I'm looking at VHT SP106 flat silver right now but not sure if it has too much blue in it. I'm going to try Rustoleum Silver Caliper Paint tomorrow. After that and this heat wave we're going to have, it will back to the wrenches getting the intake/carb put together and running. Stay tuned.

|

|

By ian57tbird - 5 Years Ago

|

|

Just a suggestion, I have seen a couple of engines done with a 2k paint that looks good. The advantage is carby cleaner and most other solvents wont bother it.

|

|

By martyk98 - 5 Years Ago

|

|

Thanks for the tip, what I don't see is any shade of aluminum color. Unless you're not talking about POR.

|

|

By ian57tbird - 5 Years Ago

|

|

2K or 2 Pack describes coatings that require a hardener or catalyst, which is commonly used in car body shops. Once it hardens, it provides a much stronger substrate less susceptible to damage from chemicals. All shades of silver are available and mixed to your requirements, but would require you to use a spay gun for application. Not sure what you mean by POR.

|

|

By martyk98 - 5 Years Ago

|

Google POR. I used some of their clear on my engined turned pieces and it came out really good. That's a two part also. Spraying is easy, Home Depot sells the mini portable cartridge kit for $7 with the jar to mix your paint. Easy peasy, spray and throw away.

|

|

By martyk98 - 5 Years Ago

|

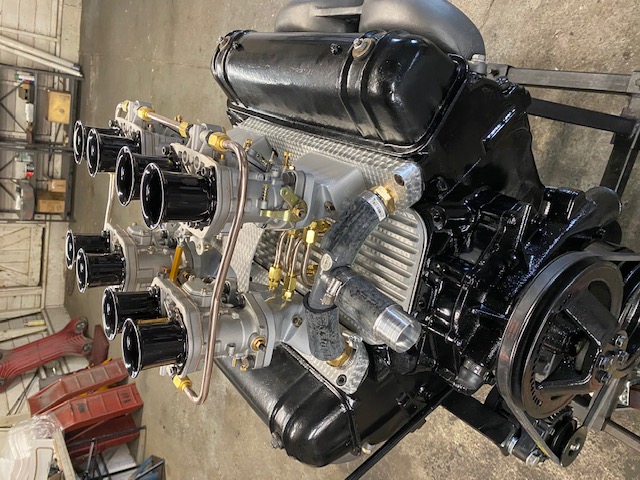

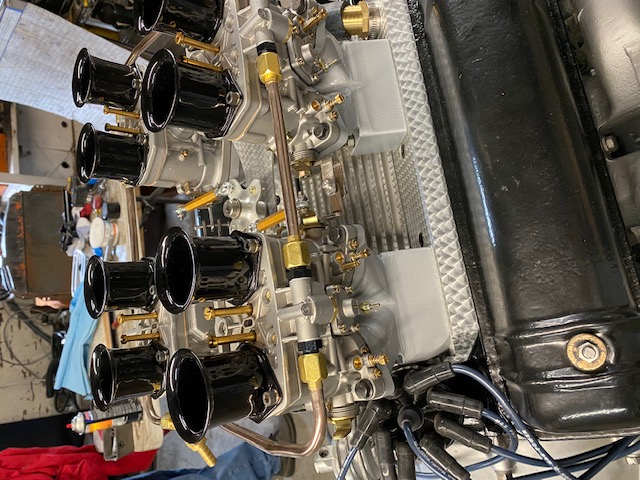

OK, now that our hot summer is fading fast, it's time to get moving on the 368/Weber Carb build. Got the old intake, carb, valley pan and accessories off, now putting on the goodies.   t t

|

|

By martyk98 - 5 Years Ago

|

|

The Valley pan has another pan under it so the vacuum lines work equally. The head adapters are there to accept the plenum for the Webers and deal with the coolant holes. I wish I was a better engine turner but I couldn't find a decent way to get the "swirls" to work, too many different angles to work with so I painted and clear coated them silver. I forgot to get carb gaskets so were on hold for them, the low pressure fuel gauge, and a 1-1/4 T to combine the water lines together . Any suggestions on how to plug up the blow-by tube hole? Maybe just a freeze plug? We are installing a blow by tube where the fuel pump was and going with electric fuel pump. We'll wait until we get it running before adding the powder coated Turnpike Cruiser valve covers. I'm not so keen on the brass fittings, kinda wish we had stainless but that's the way it goes. The Webers have a 1.8" throat on the stacks and I cannot find a suitable filter or screen for them, still looking. Anyone have an idea? BTW, I used generic appliance epoxy paint for the block, it came out good.

|

|

By DryLakesRacer - 5 Years Ago

|

I’d get a bottle or 2 of brush on clear coat for the brass/copper. The color match companies offer it and as long as everything is tight and you like it you can keep it nice by just wiping it off. This company makes pretty good paint products. Automotive touchup

|

|

By paul2748 - 5 Years Ago

|

Right side up

|

|

By martyk98 - 5 Years Ago

|

Good idea, I think my POR clear will do the same

|

|

By martyk98 - 5 Years Ago

|

Carbs, wires and throttle linkage on. Working on the water lines next.

|

|

By martyk98 - 5 Years Ago

|

|

Still working on the coolant lines but we did get the fuel pump on with the pressure regulator. We briefly started the engine today and didn't have any fuel leaks. Fuel to all 8 carbs and actually got an idle right away.

|

|

By martyk98 - 5 Years Ago

|

|

no work on the engine lately, my partner had eye surgery and is mending. We have all the pieces we need to finish testing. Once we're convinced we have it dialed in, we will pull the 302 and put her in the 54 Merc. Finding a dual port inlet radiator with transmission cooler is proving to be difficult. Champion wants a small fortune to customize one. Will probably be able to find one so we won't have to combine the water ports in to one. Separate 1-1/4" inlets is the desired set-up with a trans cooler built in. So far all I have seen is for a 54 Ford truck which is a different size than the sedan.

|

|

By martyk98 - 5 Years Ago

|

|

After running the motor for a time, we are discovering the vacuum advance distributor is not delivering enough advance for our set-up. Replacing the OEM one with an aftermarket mechanical is not possible because of lack of room with the Weber set-up. It's just too darn tight to get a new style distributor in there. We're looking for someone that can convert our vacuum one to mechanical. Any suggestions would be appreciated.

|

|

By charliemccraney - 5 Years Ago

|

|

You could use the vacuum distributor to trigger an external, programmable ignition box.

|

|

By Dobie - 5 Years Ago

|

|

Or switch to a post-'56 Y-block distributor, just change from the 14 tooth Ford drive gear to the 15 tooth Lincoln drive gear. The distributor is one of the few parts that interchanges between the LYB and the Ford/Mercury Y-block.

|

|

By FORD DEARBORN - 5 Years Ago

|

|

It looks like the problem is any distrilblutor other than a load o matic will be too tall for your build. As Charlie suggested, use your present distrubutor to trigger one of the available programmable boxes. I believe Pertronix makes a unit for the LOM distributor. That being said, I have used a Pertronix to trigger a 6A MSD box - worked perfect so I'm thinking that a simple Pertronix should be able to trigger other boxes that would be suitable for your purpose. That would be a simple straight forward method but there are olther systems available that use a trigger wheel mounded to the damper pulley etc.. Will be interesting to see what you come up with..............

|

|

By martyk98 - 5 Years Ago

|

|

Well, we thought it over and after weighing all the options, decided to go with the guy in Oregon that converts the Load-o-matic to mechanical. His final product is tailored to what we have for engine, carbs, and transmission so the unit should cure our advance issues with the 8 stack system. We won't know anything more until he examines our unit and can reassure us the new one will be the same size or smaller.

|

|

By KULTULZ - 5 Years Ago

|

|

... decided to go with the guy in Oregon that converts the Load-o-matic to mechanical.

Now who is that?

|

|

By martyk98 - 5 Years Ago

|

|

Outfit called FBO Ignition out of Cottage Grove, OR. They have a website on the internet.

|

|

By charliemccraney - 5 Years Ago

|

|

Oh, yeah, they do the conversion of Pertronix small block distributors, to fit Y Blocks. Haven't heard anything bad about them.

|

|

By KULTULZ - 5 Years Ago

|

|

Outfit called FBO Ignition out of Cottage Grove, OR. They have a website on the internet.

Well I'll be darned ...

I am aware of them but had no idea they could convert a LOAD-O-MATIC DIST to a DUAL ADVANCE.

I am reading this right?

BTW - ABSOLUTELY BEAUTIFUL WORKMANSHIP!

What is it going in and will it be a show car or driver?

|

|

By martyk98 - 5 Years Ago

|

It's going in my driver. 54 Mercury Monterey. I'll remove the 302 and keep the AOD. Already have the adapter, just want to make sure we fix all the gremlins before the swap. It's way easier to fix everything before it slips in to the engine bay. We need to fab motor mounts and check oil pan clearance and exhaust options. Fortunately we have a spare block to tinker with so all our hard work can go in after.

|

|

By KULTULZ - 5 Years Ago

|

The MERC is beautiful also. I think I am getting jealous ...

Will it be for show or a driver?

|

|

By martyk98 - 5 Years Ago

|

The original color was that soft green. Reminded me of the walls of my basic training barracks, YUK. I used vinyl paint from Wesco Auto Body Supply. It has held up very well. Just my driver. I have tried the show car thing before and didn't like the limits it put on me.

|

|

By martyk98 - 5 Years Ago

|

|

Just got off the phone with FBO Ignition. Don sez he can retro my distributor, use the original cap, and make it fit my application. Can't wait to see the finished product.

|

|

By martyk98 - 5 Years Ago

|

|

Distributor is home. Looks fantastic. Can't wait to see it installed and working.

|

|

By miker - 5 Years Ago

|

That’s a really impressive build. I’m thinking I may need to talk to you about your guy for that Algon unit I have.

I know your busy, but if you could get some pictures of the modified distributor and keep us informed, I for one would find it useful. Tach drive 57 units are unobtainium, and being able to modify a 55-56 unit for our ‘birds would be of real interest

|

|

By martyk98 - 5 Years Ago

|

|

I'll get some pictures to you tomorrow. I've been fighting a prostate and not quite feeling 100%.

|

|

By martyk98 - 5 Years Ago

|

OK Miker, here you go: He even ID'd the housing underneath for future reference.

|

|

By miker - 5 Years Ago

|

He give you the advance curve? Weights are under the plate I assume. Sure looks nice.

Thanks

|

|

By martyk98 - 5 Years Ago

|

|

Yes, he included a spec sheet.

|

|

By martyk98 - 4 Years Ago

|

|

Don't count us out. I've had a setback with prostate surgery and nasty weather. We will "endeavor to persevere".

|

|

By bird55 - 4 Years Ago

|

So, correct me if I am wrong. If I understand correctly, this is a 55-56 distributor LoadOMatic converted to Pertronics style? If so this will be a real boon to 55 and 56 tbird tach drive distributors. A lot of those are sitting on a shelf at a reduced price.

|

|

By FORD DEARBORN - 4 Years Ago

|

|

Just get yourself well - a speedy recovery....................

|

|

By martyk98 - 4 Years Ago

|

|

The distributor I had modified was a load-matic for a 56-57 368 Lincoln/Mercury, not a T bird. Different animals. Different block family. This was a 1956 distributor with vacuum advance that has been converted to mechanical with Pertronix. BTW, it's been 3+ weeks since my surgery and I'm healing up well, thanks.

|

|

By martyk98 - 4 Years Ago

|

|

Major Set-back!! We go to install our newly modified distributor to find out it doesn't fit. The company used the base for a Ford Y block and it doesn't fit the Mercury 368. Either his base was not machined correctly or the diameter on the Ford and Mercury Y blocks are different sizes. Anyone have any first hand knowledge? He has the only Load-matic distributor I had so I can't measure apples to apples when he keeps the base.

|

|

By charliemccraney - 4 Years Ago

|

|

Which part of it doesn't fit?

|

|

By FORD DEARBORN - 4 Years Ago

|

|

Not sure of what you have? I thought the loadomatic went out at the end of 56 production except for 6 cylinder engines. I am presently running a 57 368 tach drive from a 57 Mercury Turn Pike Cruiser in my Ford Y-block. Same casting and internals as the Ford/T-birc 57 tach drive and in that case, the shaft is the same also. The difference was the gear. I replaced the gear with a Ford 14 tooth Y-block gear and have been running this distributor for a number of years now. I have also done the same to a cast iron dual advance strib removed from a big Ford truck equipped with a 302 or 332 Lincoln Y-block. That strib had a governor which I removed. Maybe the gear is not in the proper location? To my knowledge and experience, the Lincoln Y-block and Ford Y-block distributors are interchangeable at least from 57 on except for the drive gear. Just to mention: There were 2 different drive gears used in the big Ford trucks with Lincoln Y-blocks. One was right hand teeth and the other was left hand teeth. Some of the Lincoln truck Y's were built with a gear driven camshaft which required a strib drive gear with teeth of an opposite angle so the strib would still rotate CCW.

|

|

By FORD DEARBORN - 4 Years Ago

|

|

Edit I only mentioned the 2 different gears because I know how easy it is to grab the wrong part from a bench covered with parts when assembling something. If you don't mind, post a pic of the modified distributor you are installing.............

|

|

By mjs - 4 Years Ago

|

|

I needed to replace the gear on my 368. As i recall when I called my local parts store they told me it was the same as a 390 and they had one on the shelf.

|

|

By martyk98 - 4 Years Ago

|

The housing is the problem. The diameter of the housing won't allow the distributor to set down in the hole of the block. Then the base of the housing is too large to properly seat on the block. There is a small machined flange on the block that needs to marry with the base to finish the install. We had the right distributor to send them, we had it running on the engine previously. I sent it back today so we'll hear something back next week. The housing is the problem. The diameter of the housing won't allow the distributor to set down in the hole of the block. Then the base of the housing is too large to properly seat on the block. There is a small machined flange on the block that needs to marry with the base to finish the install. We had the right distributor to send them, we had it running on the engine previously. I sent it back today so we'll hear something back next week.

|

|

By FORD DEARBORN - 4 Years Ago

|

|

Glad you found the problem I have on hand here both a Ford and Lincoln Y-block distributor. The diameter of the upper flange that positions the strib in the machined undercut in the block measures 1.750". The 2 lower pilot areas that enters the hole in the block measures 1.495". These are the measured dimensions of the Lincoln and Ford y-block distributor so both housings are dimensionally the same. And what's more, great to see you have recovered well and back in the engine game........................

|

|

By martyk98 - 4 Years Ago

|

|

Thank you. I sent the unit back on Saturday. He must have grabbed the wrong housing. My measurements on the one he sent me do not match yours, mine are larger. Thanks for the information.

|

|

By martyk98 - 4 Years Ago

|

Well.... It was more than just the housing. I sent it back and got it back without the cap. Put it in the block and it didn't fit. The tip of the shaft where the oil pump shaft enters was wider than the hole in the block. I managed to take it out and set it up so I could use some 80 grit on the shaft while I spun it with my drill. Within 10 minutes I had the shaft sanded down where it fit nicely in to the block hole. Then the next problem..... When I bolted down the distributor to the block the shaft quit turning because the gear was pressing too hard on the block down below where the shaft tip connected to the oil pump shaft. Back to FBO for modifications, again. There are several lessons to be learned here, let me list them. Pic 1 is the hole in the block that was too small. Pic 2 is the sanded shaft to make it fit. Pic 3 is the bottom of the gear that bites down on the block when bolted down. Well.... It was more than just the housing. I sent it back and got it back without the cap. Put it in the block and it didn't fit. The tip of the shaft where the oil pump shaft enters was wider than the hole in the block. I managed to take it out and set it up so I could use some 80 grit on the shaft while I spun it with my drill. Within 10 minutes I had the shaft sanded down where it fit nicely in to the block hole. Then the next problem..... When I bolted down the distributor to the block the shaft quit turning because the gear was pressing too hard on the block down below where the shaft tip connected to the oil pump shaft. Back to FBO for modifications, again. There are several lessons to be learned here, let me list them. Pic 1 is the hole in the block that was too small. Pic 2 is the sanded shaft to make it fit. Pic 3 is the bottom of the gear that bites down on the block when bolted down.

1-take plenty of pictures and measurements of your distributor

2-if you're the company that is making the changes, do the same before you tear it apart and modify anything.

3-never assume all the stories about distributors being swapped from one block to another are always true.

4-the 368 Lincoln/Mercury block is an ODD DUCK.

I don't blame FBO entirely for all the issues, my odd duck was something they haven't seen very much of. BUT, their lack of following #2 has resulted in some frustration that surely could have been avoided.

I'm also sure that they could do a wonderful job on a more common distributor.

|

|

By FORD DEARBORN - 4 Years Ago

|

|

Sorry to hear about the additional problems. Hard to see the internal 1/4" hex inside the shaft end but it is there isn't it? From my limited dealings with Lincoln Y-block distributors, the dimensions are the same as that of the Ford distributor except for the gear. Since it appears the gear is binding on the machined surface in the block, then it is not set to the spec of 4.991 to 4.996 shaft extended down as shown in the Ford manual. The thrust should be minimum .021" with .030" acceptable. Also, make sure the internal 1/4" hex as mentioned above is indeed deep enough to allow the oil pimp drive shaft to penetrate as it should. Is the camshaft installed in the engine? If not, try installing a Ford Y distributor if you have one on hand to see how that fits in there. As stated in one of my earlier posts: I am at this time running a 1957 368 tach drive distributor in a 1964 Ford Y-block after changing only the gear. My point is the Lincoln Y and Ford Y distributors are dimensionally the same except for the gear. At least 1957 on.

|

|

By martyk98 - 4 Years Ago

|

|

I hear you. I think the issue is when they modified the shaft to fit the Pertronix base unit the made the shaft too long. Because I had to send the unit back to get it to fit my block, the length of the housing might be a little off from the stock height which could have thrown other measurements off as well. Eventually we will get this right. Their communication with me has been excellent. In no way are they ducking the issue and are standing behind their work. BTW, the hex shaft fits well.

|

|

By martyk98 - 4 Years Ago

|

|

That's one thing about being retired, you don't have to be in a hurry. We got the distributor back, is was their mistake. All fixed and installed. My partner and his wife picked up COVID somewhere and are hiding until his wife feels better. The shots have saved them from being really sick. We'll get the 368 running again soon. Dialing in 8 Webers is time consuming.

|

|

By 55blacktie - 4 Years Ago

|

|

8 Webers or 4 two-barrel Webers?

|

|

By martyk98 - 4 Years Ago

|

|

4 two barrels. My partner had COVID so between crummy weather and him we will be on standby. He's working on a 54 Corvette at the moment. Anyone know where we can get an oil pan, let me know. The one in the car has extensive damage. June 20, got the oil pan repaired by a local pro. 60 degrees 2 days ago, 85 this coming Saturday.?????/

|

|

By martyk98 - 4 Years Ago

|

|

we're still here. Being lazy about finishing up the engine. It's 90+ in the shop so nothing going on until it cools.

|

|

By martyk98 - 4 Years Ago

|

well, we installed the rebuilt distributor. It ran for about 15 seconds before the roll pin that connected the gear to the shaft broke in three pieces. When we tried to fix it, the holes didn't line up?? The roll pin pieces just fell out of the gear and shaft telling us because the holes didn't line up correctly, they installed a smaller roll pin which couldn't handle the torque. We sent it back and haven't heard anything from them in a week. If it ain't one thing, it's two!!!

|

|

By Ted - 4 Years Ago

|

Did you try rotating the gear 180° on the shaft to see if the holes would line up? The holes are typically off center requiring the gear to be orientated a specific way on the shaft.

|

|

By martyk98 - 4 Years Ago

|

|

The whole shaft has been "redesigned" using a sleeve of some kind to support a replacement upper assembly to get the desired mechanical advance we need. The first time we sent it back they made the shaft too long, as reported in my previous posts. This time, they returned it with some hoaky roll pin connection that was misaligned and impossible to figure out how they made it work in the first place. Hence, the roll pin failing immediately. They've had it for a week now with no communication. Not sure what's going on.

|

|

By martyk98 - 4 Years Ago

|

Well, this whole distributor modification thing has finally been completed. We would NOT RECOMMEND FBO Ignition out of Cottage Grove, OR, for any distributor work on an odd ball distributor like the 368. They were unprepared, uneducated, made several mistakes, and the overall quality of the fabrication was not what I call professional grade. We got it installed and it is working, but not out of the box. We had to "fix" a couple of things to make it work. They never offered to pay for return shipping, (twice), and returned the latest "fix" with the wrong gear. The next step is to take my bare block with oil pan to our work area and see if it fits without having to modify the oil pan. If anyone knows anything about swapping a 368 in to a 54 Merc or Ford (same frame) let me know. The existing 302, with front belly oil pan, just makes it. Not sure what will happen with the 368. The adaptor kit moves the engine forward about 2 inches, so we'll see. I think we're going to go with no fan blade and add electric fans on the front of the radiator. Our mock up engine stand has this and it has kept the engine very cool. I'll pat my friend, Jeff's back, for and excellent rebuild. The motor sounds and runs great.

|

|

By martyk98 - 4 Years Ago

|

|

we have our engine tuned and ready. will start the swap after New Years.

|

|

By martyk98 - 3 Years Ago

|

We started the final tune on the 368 with the Chinese knock off Webers. Had to fix one bad float out of the four. Having a hard time with fuel. We're sure we are flooding. Next time we'll turn them all the way in and then back off 1/2 and go from there. Fuel coming out from the tops when revving. We started taking the 302 out today. If all else fails, we can always put on the stock intake and add an FI unit.

|

|

By Ted - 3 Years Ago

|

You don’t mention if the fuel is coming out of the throats or the fuel bowl covers. That might give a better idea if it’s a float level issue or a camshaft issue.

My experience with Weber carbs has them liking camshafts with wide lobe centerlines. I did try a 108° lobe center camshaft with the Weber carbs on a FE and there was some serious fuel reversion going. At the lower rpms and where the throttle was opened up, there would be a cloud of fuel shoot up above the carbs and then suck back down. Learned early on that those carbs prefer a minimum of 112° lobe centers and 114° is better.

|

|

By martyk98 - 3 Years Ago

|

|

Thanks Ted, we did modify the cam just a little but it's still pretty tame. Doing some more research we're finding out that multiple Webers take larger jets (which doesn't make sense to me). On line stats from reputable sources say 1.50 for one carb, 1.75 for two. Nothing about 4. Does this mean 2.0 or better? Do we need to replace all the different jets? There are three different jets and two venturi. Am I over my head? In the mean time, we have about 4 more bolts to take out before the 302 is free. P/S The amount of fuel coming up is minimal and only at high throttle input. The amount is not the same with all 4 units.

|

|

By miker - 3 Years Ago

|

Marty, what size are those Webers. Bore and Venturi. It’s been over 40 years since I set ones up, and they were much smaller cylinder displacement to bore/venturi sizes. But IIRC they are completely different for initial set up on a carb per cylinder than they are on a plenum manifold.

I helped on a set for a sbf on a friend’s Cobra, but I gave him the books. Now I wish I hadn’t.

|

|

By martyk98 - 3 Years Ago

|

|

Hi Mike- They are 48 IDF Chinese Weber knock offs. I was told yesterday that Weber replacement parts don't fit. We have decided to tune them the best we can, install the engine, and then find a reputable tune-up shop and hope they can fine tune. Our biggest issue is the stumble from idle to full throttle. The engine actually shuts down. Not sure if its lack of air, too much gas, or what.

|

|

By martyk98 - 3 Years Ago

|

Out with the 302, fitting the adaptor to our extra block. We're being halted for motor mounts. Any ideas? I can't even find a set; all I see is rubber parts.

|

|

By miker - 3 Years Ago

|

Any chance you can get a couple air fuel meters, one on each bank? If it’s on an engine dyno, it’s much easier to get close than it will be in the car and on a chassis dyno.

What little I remember about the Webers was the real key was having them shipped with the correct emulsion tubes. The jet changes, main and idle, were pretty easy for fine tuning. I was lucky, the ones I had (IDA’s on a flat 4 air cooled) were done by a CA company who did it all the time. Same with whatever my friend had on the 302 in the Cobra. Most of the work was syncing the linkage at idle and just off idle.

Hope it goes well for you, that’s quite the impressive set up.

|

|

By martyk98 - 3 Years Ago

|

|

Our build has come to an end. One of the bronze guides wasn't fitted properly and bent a valve. After pulling the heads off we found some contamination in #3 cylinder. The whole engine needs to be rebuilt probably .30 over. We're not willing to spend another $2500. Anyone interested in 368 parts? LOL. Also, FYI, with the Bentson adapter to marry the 368 up to my Ford AOD tranny, it pushes the engine so far forward that I would either have to push everything back an inch or find a 2" radiator just to get the water pump to fit without the fan. We thought we had it measured correctly but we were an inch off in final length. It was hard to get exact measurements until we put the spare block in and discovered the issue. I might have tried to shoehorn it in with a custom 2 core radiator but when we discovered the internal damage, we decided to throw in the towel. Getting the Webers to work was also difficult, we were pouring gas into the engine like crazy with no end in sight unless we wanted to spend countless dollars in jets hoping they would fit these chinese knock-offs. No one wanted to admit what brand they are to get parts and fishing around for these jets could have been futile. Moral of the story: be happy with what you got if it's running fine. The 302 will be going back in.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

Very sorry to read this. You fellas poured in way too much effort to just walk away. That Lincoln Y is a super georgous and very unique engine that would make your car one of a kind. Maybe consider a more traditional build but with a mild custom cam and cruise-o-matic or???? I think there's still a lot of good there to work with. You have shown a lot of attention to detail so why not keep the 368?

|

|

By martyk98 - 3 Years Ago

|

|

we're considering it but probably not. I need an exhaust valve. EGGE has one but they want $21 shipping for a $29 valve. I have a hard time with that. I was wondering if there were any other valves that I could use.

|

|

By martyk98 - 3 Years Ago

|

|

Hey Ted, gotta extra exhaust valve you want to part with? Marty

|

|

By martyk98 - 3 Years Ago

|

|

Got a valve and gaskets. We're going to try to put this back together with stock intake and see what the compression looks like.

|

|

By martyk98 - 3 Years Ago

|

|

Everything put back together. The engine runs fine but we still have to do a compression check.

|

|

By martyk98 - 3 Years Ago

|

compression check went good, we're sure it was low earlier due to fuel mixed in the oil from the Webers Carbs. More run time will allow the rings to seat better with the fresh oil. We put the 302 back in the car and the 368 is now up for sale. $3000 complete less teapot factory carb. Turnpike valve covers and ceramic coated Y exhausts if you don't like the stockers. Vacuum is 19.

|

|

By RB - 3 Years Ago

|

|