|

Author

|

Message

|

|

Hoosier Hurricane

|

|

|

Group: Moderators

Last Active: 11 hours ago

Posts: 3.7K,

Visits: 323.4K

|

Cliff: I guess, since the car can no longer run NHRA stock class, I can tell how I did it. I had noticed how the inner wheel well leaned in a lot from the 1/4 panel, making the fit tight on the outside of the tread at the top. I cut the outer part of the inner fender along the outside of the seam where the inner and outer panels were joined. I separated the panel from the 1/4 panel, and fitted the inner half of a '56 inner fender in place, using the rh '56 panel on the left side and vice versa. That placed the weld on the outside of the original seam and invisible from the trunk A little undercoat hid the underside of the weld. This made the outer wall of the inner fender vertical instead of leaning in. The entire 1/4 panel and inner wheelhouse was then jacked out a little along the wheel opening. The inner flange junction to the trunk floor was hammered in flush with the frame rail. The springs were moved inboard a little too. It would be much simpler to just tub one now. Neither NHRA nor IHRA ever caught my modifications. The wheels are 10 x 15 with 6" backspace. Tires are Phoenix 10.5 x 29.5 x 15. Goodyear and Hoosier tires won't fit, the sidewalls are too wide. Clearance to the spring, frame, and outer panel are each no more than 1/2". Four link suspension keeps the axle from shifting side to side.

John - "The Hoosier Hurricane"

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Thanks John, I will pass this on to my son.

|

|

|

|

|

NoShortcuts

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 1.4K,

Visits: 179.6K

|

JOHN ! ! ! Has the statute of limitations expired on what you have shared with us OR will somebody be contacting you to repossess some of your trophies?

E-mail writings can be misleading. Know that I've been sitting here laughing after reading what you shared before I made the time to write back. I love this Internet Forum because of the great individuals who so generously share their expertise, knowledge, experiences, creativity, ingenuity, and hard-knocks with others.

Best Wishes, always!

Charlie Brown

NoShortcuts

a.k.a. Charlie Brown

near Syracuse, New York

|

|

|

|

|

miker

|

|

|

Group: Forum Members

Last Active: 3 days ago

Posts: 1.9K,

Visits: 194.9K

|

Love the story, John. The way racing was done in the day.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

Hoosier Hurricane

|

|

|

Group: Moderators

Last Active: 11 hours ago

Posts: 3.7K,

Visits: 323.4K

|

I forgot to mention that I rolled the inner edge of the wheel opening so there was no sharp edge in case the tire sidewall touched it. I did all that to try to stay even with the Camaros in my class. With their radiused wheel openings, all they had to do was raise the rear slightly to get 10 inch tires on. 8 inch was about all I could get in my stock wheel wells. All was equal when NHRA had their 7 inch tire rule, but when things changed to "any size tire that fit within the wheel well", I was at a disadvantage (temporarily). Also, the spring shift amounted to moving the perches on the axle in about 1/2 inch and crowding the springs inboard there and on their shackle bushings.

John - "The Hoosier Hurricane"

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

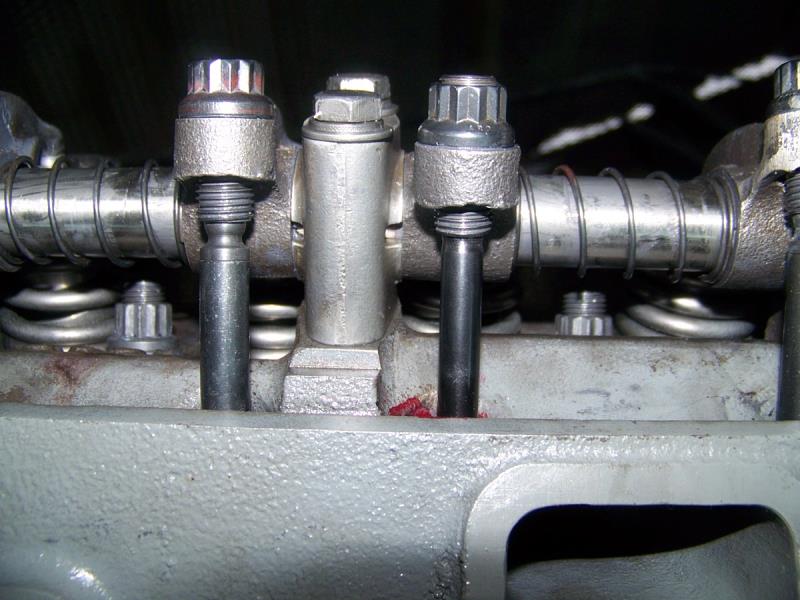

A little more, I bought 5/16 push rods, no more clearance problems, these are 8.500 long (.070 longer)   longer)

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Back working, cleaned the valve covers, bead blasted them, I cut the rails   out of them and found a lot of crap, so look good at your parts, a lot of dirt was under those rails

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

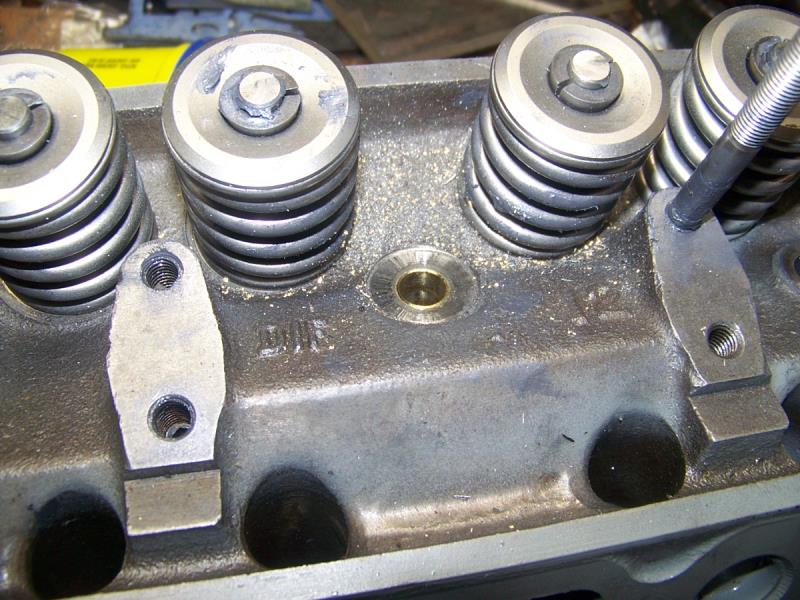

Sleeves added to second head

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Burning the night oil tonight, after all the work I did, I CCd the chambers one more time, 5= 72, 2=73, 1=74 it's going together for the last time, new push rods solved the clearance problems, piston to valve good, valve to block good, now for the bracket making, front motor plate, alternator bracket, fuel pump bracket, water pump cover, valley pan, rear motor plate, adapter Ford to powerglide, mount starter (?) and clean up the mess.

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

|

|

|

|