|

Author

|

Message

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Well I have others, I may use a billet Mallory distributor that I have, this engine is 11-1 (a real 11-1) cast piston, stock crank and rods .060 over, the good stuff is the heads

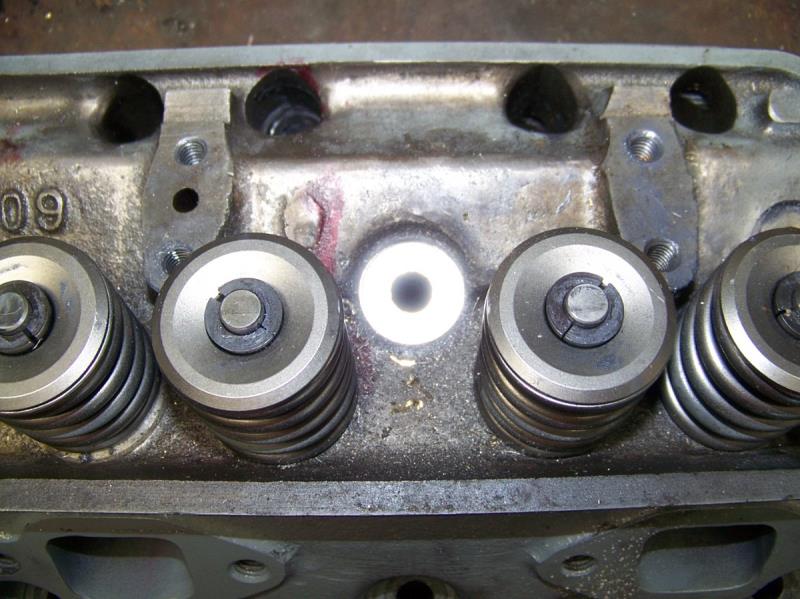

(speed master), these heads were a lot better than I expected, I bought them bare, when I checked the valve seats they were perfect, check the guides they were perfect, when I CCd the heads I had to cut one more than the other (about .013) the even up the chambers, 30deg intake seats, 45deg exhaust (Ferrea Valves), Isky springs and retainers (8005), the cam is a Howards Mech flat tappet, the Intake is a real Holman an Moody 2x4, 2 600 Holleys, all good parts in this engine, this is a street engine, I like the the old and the new mixed up.

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

After a lot of work today I had to remove one of the push rod tubes, and maybe one more, just to thick, I also see the head studs breaking through all the intake ports, I think I will make a half moon patch out of very thin stainless steel held in with JB Weld (push rod tubes), I also am of a mind to grind the intake ports and let the head studs show, I don't think the small amount of air transferring between the ports (top port to bottom port) will do anything, I couldn't get good pictures of the problems, funny thing, no problem with the head bolt holes on the bench, only after they were installed on the engine did they start to crack and show, I reached in with my finger nail and broke out a small piece of the port.

PS I guess sometimes you eat the bear and sometimes the bear eats you.

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Here's the material I'm using for the push rod tubes, I tried to form this by hand (to hard), Monday I will make a tool and form it on the lathe.

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Ok, here's the sleeves for the head bolt holes, they had to be tapped in, only the ends needed to be dressed, heads fit over the studs with no problem, also this is the push rod 1/2 moon sleeve, I wound it on the lathe then cut it to length, glued it with JB Weld.

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Installed and spot faced.

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

No photos today, time for final assembly, am checking all clearances 1 more time ( piston to head, push rods rubbing), so far all's good (I hope), next is the intake manifold (Lexan) have worked out

the nozzle placement (a lot of thought), will run a lot more pressure than most people and smaller nozzles, this helps the fuel to atomize better (raw fuel not running down the side of the port), going to Hawaii next week (!!!), no more work for a bit, will go to the swap meet in Hawaii (parts? well maybe a shirt),

|

|

|

|

|

Hoosier Hurricane

|

|

|

Group: Moderators

Last Active: 9 hours ago

Posts: 3.7K,

Visits: 323.4K

|

Cliff, are you sure you want to go to Hawaii with the Hurricane bearing down on it?

John - "The Hoosier Hurricane"

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

I paid for the trip last year so I'm going, how did you get those big rear tires under you car, my son is putting together a 1957 Fairlane 500 with a 428 that I built and it's about time to pick the wheels and tires.

|

|

|

|