|

Author

|

Message

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

Chuck, most probably don't require 2000rpm, but they generally do require a rev to start the charging. As I said from my personal experience, I've had one that I needed to rev to 1500 and another that actually requires no reving. I do not find it to be a problem in either case. The pulley ratio will have a lot to do with the engine rpm required to start charging since that ratio directly affects the alternator rpm. The pulley ratios with both of those is about 2.6:1, with an engine idle speed of about 700rpm which translates to about 1820 alternator rpm..

Lawrenceville, GA

|

|

|

|

|

CK

|

|

|

Group: Forum Members

Last Active: 10 Years Ago

Posts: 152,

Visits: 1.1K

|

Also consider that the high ampere alternators are for later model cars which run everything electrically.

For example Fuel pump, EFI injectors and ECU etc. we're a carby engine is all ran as mechanical systems.

Unless your relocating the battery to the boot?

You should be able to find one at the wreckers which will put out 40A or thereabouts.

Consider all the extra energy it takes turning a hi output alt. when it's not needed.

Hope it goes well for you anyway.

|

|

|

|

|

mgcookiewva

|

|

Hitting on all eight cylinders

Group: Forum Members

Last Active: 11 Years Ago

Posts: 3,

Visits: 3

|

I bought a one wire12 volt GM alternator form NAPA and a bracket from John Mummert for $100.00 that looks factory made and made for a very nice install.

Shouldn't matter if it's 272 or 312, I don't think.

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.7K,

Visits: 102.7K

|

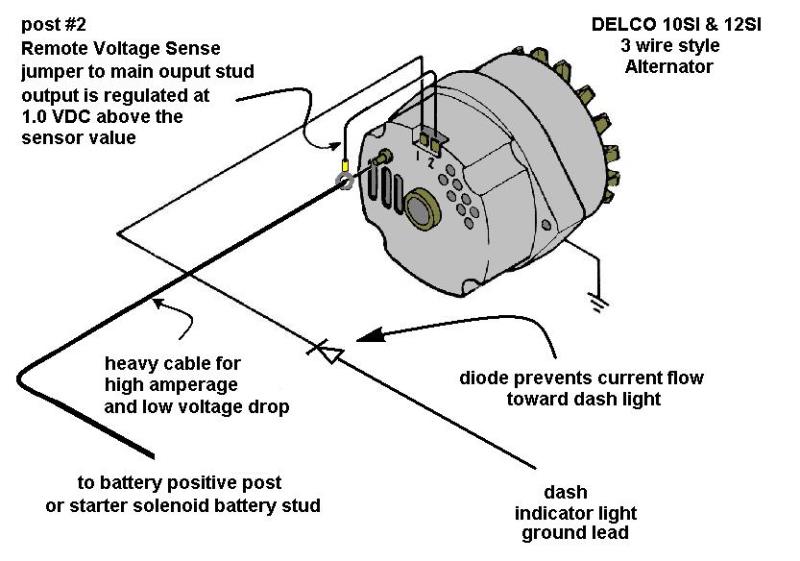

Charlie is speaking words of wisdom when he says "think about the pulley ratio" - many of the aftermarket alternator suppliers just flat say to use a 3:1 . I finally found what I wanted at a swap meet - by measuring everything I could find. Several outfits offer a larger alternator pulley for high RPM drag use - but few offer one small enough for "parade" use. Keep looking until you get one in the ballpark - they're around. The one wire design basically attaches the "feedback" wire of the 3 wire system, directly to the output wire of the alternator. Many of the internal regulators are designed to provide output roughly 1 volt more than the feedback. So the standard GM 3 wire is sampling voltage at the battery and calling for 1 volt more back at the output. The thing to know is - you have to have a rather large output wire to avoid a voltage drop back from the battery. Mine is #6 welding cable. If you have a "one wire" and it quits in outer Beaverchuck on Sunday afternoon - you could 'hotwire" a three wire from Auto Zone to do as shown below:

Steve Metzger Tucson, Arizona

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

There are actually quite a lot of options for Delco alternator pulleys and thanks to being for GM parts they are pretty cheap. I think alternators are pretty universal in that area so they may work for other makes as well. In talking with Powermaster a few months ago, the smallest recommended diameter for a 3/8" V-belt pulley is about 2 3/8". Anything smaller and the belt starts to pucker as it wraps around the pulley. Because of that, you're not going to achieve 3:1 with a factory Y block damper. About 2.78 is the best you will get. In talking with ASP racing about custom pulleys, the minimum diameter for a 1/2" pulley is about 2.75" because of the thickness of the belt and the clearance required for a socket for the nut. I don't know the diameter of a 1/2" belt damper but it can't be much larger than the 3/8" damper pulley, so if I assume the same diameter, that is a best of about 2.4:1. For a 3/8" belt, their minimum is about 2.45" due to the same clearances that are required.

Lawrenceville, GA

|

|

|

|

|

miker

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.9K,

Visits: 194.9K

|

Steve,

Your diagram shock loose some very old cobwebs in my brain. That's how we used to do 1 wire installations, before the 1 wire alternators with the voltage adjustment. And why we had low voltage at the battery. Your #6 cable plays into that also.

Not to hijack the thread, but we're having a 90 degree heat wave in Seattle. I put the hardtop back on the bird, and cranked the A/C to high. The voltage gauge read low for the first time. Both cooling fans, compressor, etc. Charlie and Steve, I guess I'd better go look at the pulley size, at that load I'm not making it at idle. Thanks.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.7K,

Visits: 102.7K

|

Hi Mike - coming to Tucson one of these days? I've got one of those "notched" V-belts on mine - can't remember the brand - but it bends pretty tight without visible distress. The notches tend to make the belt flex a bit more like the rubber bands on the current serpentine designs.

Steve Metzger Tucson, Arizona

|

|

|

|

|

miker

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.9K,

Visits: 194.9K

|

Steve, it's going to be 90 today up here, so I think I'll let you enjoy 101 and the monsoon for a while.

If you're taking about the v belts with the "notches" on the outside, that's what I've got. It doesn't appear to be slipping. I don't run the A/C that often, normally the tops off in the summer. So this heat wave is the first time I've run into this. Could also be the alternator is right on the edge of capacity. When I looked closer, the voltage is ok on low speed fan, marginal on medium, and low on high. I'll have to find the paperwork and check the output on this unit.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

Dayco have notches on the outside. Keep in mind that the dyno sheet for the alternator will be in Alternator rpm. If the 'bird pulley is the same diameter as the cars, then it is 6 5/8". Measure the alternator pulley. Crank pulley / alternator pulley is your ratio, multiply that by your engine idle speed and that is the alternator idle speed. See how that compares to the info on the paperwork.

Lawrenceville, GA

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.8K,

Visits: 306.3K

|

Here is a FORD Y-BLOCK dedicated (1G) BRKT ASSY -

____________________________

|

|

|

|