|

By Frank from Texas - 11 Years Ago

|

My 312 Y-Block Mercury Montclair has a 12 volt generator system. I want to remove the generator and install an alternator.

Do I need any other parts other than the new alternator ? Mac's offers a conversion kit for $210.95.

Thanks

|

|

By Brodie55 - 11 Years Ago

|

http://forums.y-blocksforever.com/Topic63787.aspxere is what I used....highly recommended.

|

|

By bayboy - 11 Years Ago

|

|

use a GM delco 1 wire revamp old mounts or replace with aftermarket brackets and Bobs your uncle

|

|

By Rono - 11 Years Ago

|

|

Tuff Stuff markets a chrome GM 100 Amp 1 wire alternator that are pretty reasonable. I don't know if your 12V generator uses a voltage regulator or not, but with the 1 wire alternators you don't need them.

|

|

By iowa fords - 11 Years Ago

|

|

I make and sell a stainless set of brackets that will mount an alternator on lower right side. $120.

|

|

By miker - 11 Years Ago

|

|

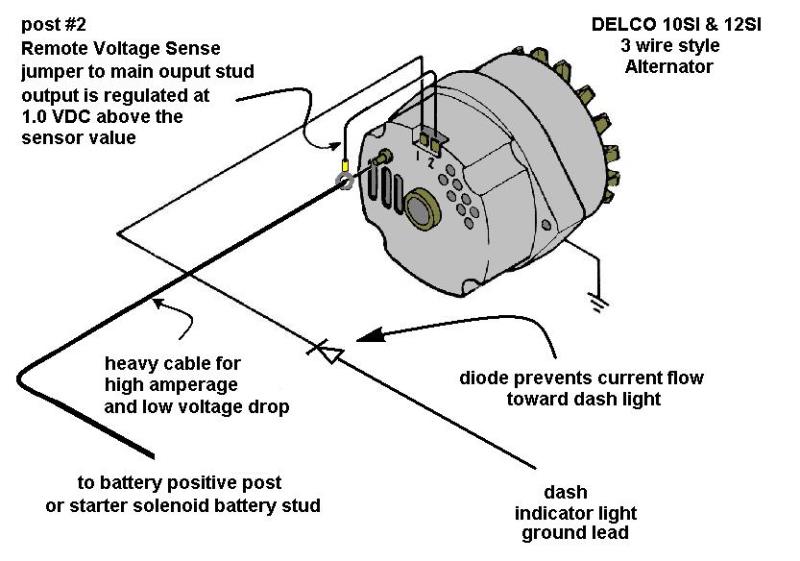

A one wire conversion produces charging voltage (nominally 13.7 or so) at the alternator. When I converted my 6 volt bird, I was only getting 12.7 at the battery, even with the larger wiring for 6 volts and cleaned connections. Going to a 3 wire set up saw 13.7+ at the battery. There's a reason GM, and others, designed those with three wires, even with the internal regulator.

|

|

By paul2748 - 11 Years Ago

|

I'm with Miker. I heard that you cannot get a one wire GM at just any parts store. I don't know if this is true any more, but the 3 wire ones you can get anywhere.

|

|

By charliemccraney - 11 Years Ago

|

I get the full 13.7v with a 1 wire. That's measured with a gauge wired to the fuse panel under the dash. Even at the fuel pump, toward the back of the bed, it's above 13 volts.

Not all 1 wires are the same. I have two, one is a Delco, converted to 1-wire. The other is a Powermaster, but it appears to be their own design, not a Delco logo anywhere. The delco needs to be rev'd to about 1500rpm to start charging. I never have to rev the engine for the Powermaster. My engine idles a little higher than a stock engine, so I'm not saying you absolutely won't have to rev yours, but it is much better about that than the Delco. Both provide full voltage.

Another thing at play is pulley diameter. Too large a pulley and the alternator will turn too slowly. If the vehicle is equipped with a 1/2" belt, then the alternator pulley is too big as it is impossible to get it small enough for a 2.5-3:1 ratio with the crank pulley. 3:1 is best for a stock engine or an engine with a near stock idle speed. Of course, the pulley should only have a significant effect at idle.

Perhaps in the future, when I have more electrical accessories, the one wire may not cut it. But so far, in well over 10 years of daily, year round, all weather driving, it has been flawless for the simple, mostly stock wiring.

|

|

By Brodie55 - 11 Years Ago

|

|

http://forums.y-blocksforever.com/Topic63787.aspx

|

|

By MoonShadow - 11 Years Ago

|

Don't the one wire alternators require you rev the engine to 2000 RPM or so to activate the stator on start up. Chuck

|

|

By charliemccraney - 11 Years Ago

|

Chuck, most probably don't require 2000rpm, but they generally do require a rev to start the charging. As I said from my personal experience, I've had one that I needed to rev to 1500 and another that actually requires no reving. I do not find it to be a problem in either case. The pulley ratio will have a lot to do with the engine rpm required to start charging since that ratio directly affects the alternator rpm.

The pulley ratios with both of those is about 2.6:1, with an engine idle speed of about 700rpm which translates to about 1820 alternator rpm..

|

|

By CK - 11 Years Ago

|

Also consider that the high ampere alternators are for later model cars which run everything electrically.

For example Fuel pump, EFI injectors and ECU etc. we're a carby engine is all ran as mechanical systems.

Unless your relocating the battery to the boot?

You should be able to find one at the wreckers which will put out 40A or thereabouts.

Consider all the extra energy it takes turning a hi output alt. when it's not needed.

Hope it goes well for you anyway.

|

|

By mgcookiewva - 11 Years Ago

|

I bought a one wire12 volt GM alternator form NAPA and a bracket from John Mummert for $100.00 that looks factory made and made for a very nice install.

Shouldn't matter if it's 272 or 312, I don't think.

|

|

By GREENBIRD56 - 11 Years Ago

|

Charlie is speaking words of wisdom when he says "think about the pulley ratio" - many of the aftermarket alternator suppliers just flat say to use a 3:1 . I finally found what I wanted at a swap meet - by measuring everything I could find. Several outfits offer a larger alternator pulley for high RPM drag use - but few offer one small enough for "parade" use. Keep looking until you get one in the ballpark - they're around.

The one wire design basically attaches the "feedback" wire of the 3 wire system, directly to the output wire of the alternator. Many of the internal regulators are designed to provide output roughly 1 volt more than the feedback. So the standard GM 3 wire is sampling voltage at the battery and calling for 1 volt more back at the output. The thing to know is - you have to have a rather large output wire to avoid a voltage drop back from the battery. Mine is #6 welding cable. If you have a "one wire" and it quits in outer Beaverchuck on Sunday afternoon - you could 'hotwire" a three wire from Auto Zone to do as shown below:

|

|

By charliemccraney - 11 Years Ago

|

There are actually quite a lot of options for Delco alternator pulleys and thanks to being for GM parts they are pretty cheap. I think alternators are pretty universal in that area so they may work for other makes as well.

In talking with Powermaster a few months ago, the smallest recommended diameter for a 3/8" V-belt pulley is about 2 3/8". Anything smaller and the belt starts to pucker as it wraps around the pulley. Because of that, you're not going to achieve 3:1 with a factory Y block damper. About 2.78 is the best you will get.

In talking with ASP racing about custom pulleys, the minimum diameter for a 1/2" pulley is about 2.75" because of the thickness of the belt and the clearance required for a socket for the nut. I don't know the diameter of a 1/2" belt damper but it can't be much larger than the 3/8" damper pulley, so if I assume the same diameter, that is a best of about 2.4:1.

For a 3/8" belt, their minimum is about 2.45" due to the same clearances that are required.

|

|

By miker - 11 Years Ago

|

Steve,

Your diagram shock loose some very old cobwebs in my brain. That's how we used to do 1 wire installations, before the 1 wire alternators with the voltage adjustment. And why we had low voltage at the battery. Your #6 cable plays into that also.

Not to hijack the thread, but we're having a 90 degree heat wave in Seattle. I put the hardtop back on the bird, and cranked the A/C to high. The voltage gauge read low for the first time. Both cooling fans, compressor, etc. Charlie and Steve, I guess I'd better go look at the pulley size, at that load I'm not making it at idle. Thanks.

|

|

By GREENBIRD56 - 11 Years Ago

|

|

Hi Mike - coming to Tucson one of these days? I've got one of those "notched" V-belts on mine - can't remember the brand - but it bends pretty tight without visible distress. The notches tend to make the belt flex a bit more like the rubber bands on the current serpentine designs.

|

|

By miker - 11 Years Ago

|

Steve, it's going to be 90 today up here, so I think I'll let you enjoy 101 and the monsoon for a while.

If you're taking about the v belts with the "notches" on the outside, that's what I've got. It doesn't appear to be slipping. I don't run the A/C that often, normally the tops off in the summer. So this heat wave is the first time I've run into this. Could also be the alternator is right on the edge of capacity. When I looked closer, the voltage is ok on low speed fan, marginal on medium, and low on high. I'll have to find the paperwork and check the output on this unit.

|

|

By charliemccraney - 11 Years Ago

|

Dayco have notches on the outside.

Keep in mind that the dyno sheet for the alternator will be in Alternator rpm. If the 'bird pulley is the same diameter as the cars, then it is 6 5/8". Measure the alternator pulley. Crank pulley / alternator pulley is your ratio, multiply that by your engine idle speed and that is the alternator idle speed. See how that compares to the info on the paperwork.

|

|

By KULTULZ - 8 Years Ago

|

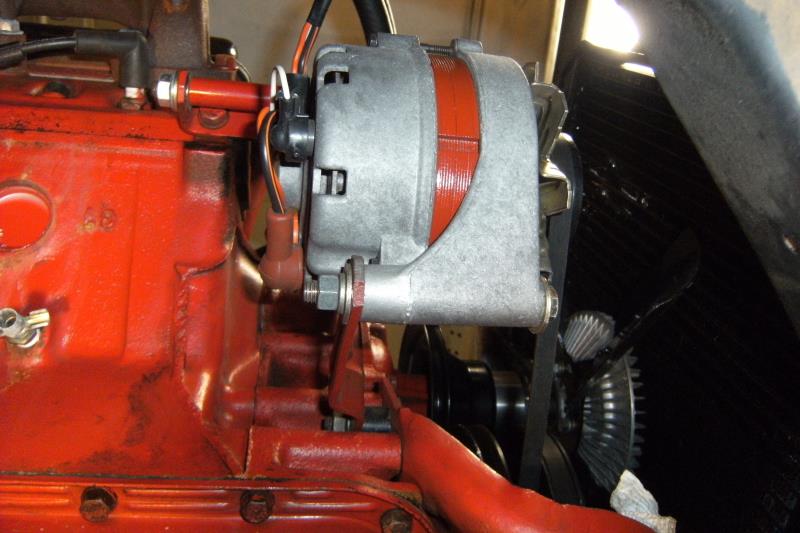

Here is a FORD Y-BLOCK dedicated (1G) BRKT ASSY -

|

|

By Rusty_S85 - 8 Years Ago

|

KULTULZ (12/9/2018)

Here is a FORD Y-BLOCK dedicated (1G) BRKT ASSY -

Nice, just curious why not go with the powermaster powergen and reuse the OE brackets?

|

|

By Rusty_S85 - 8 Years Ago

|

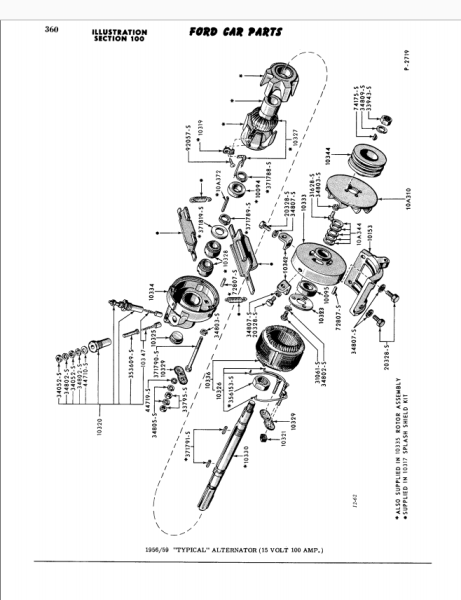

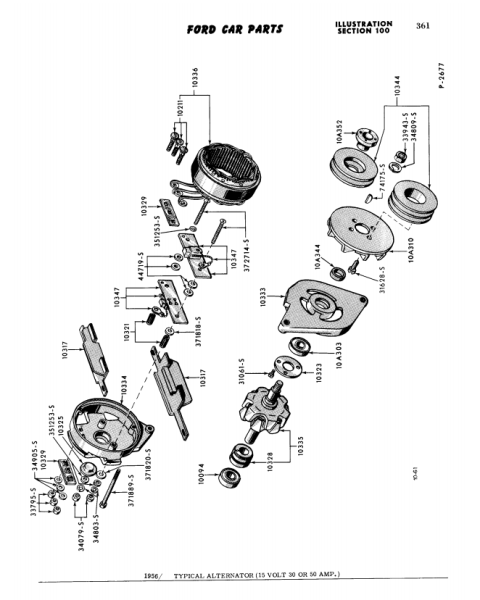

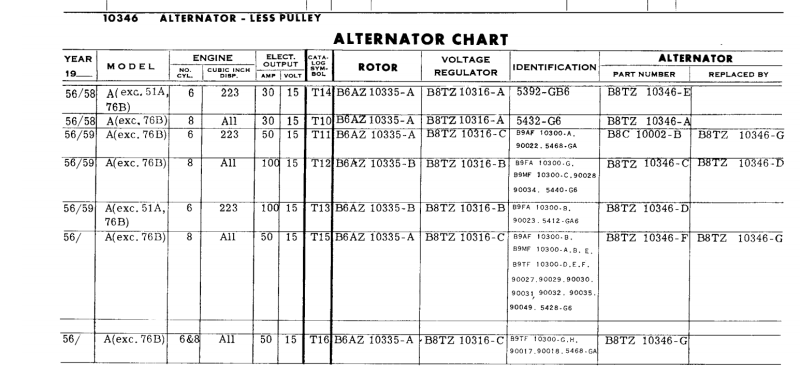

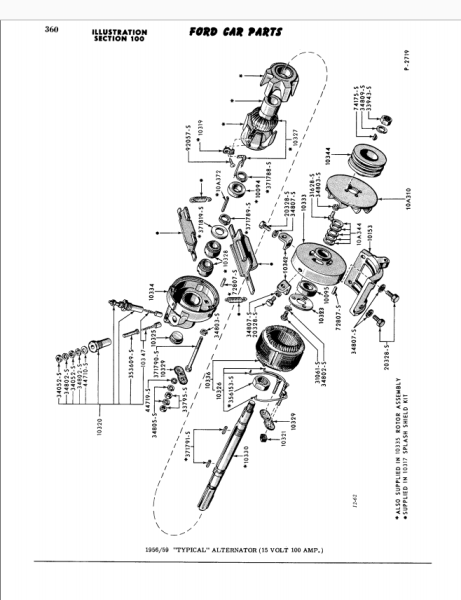

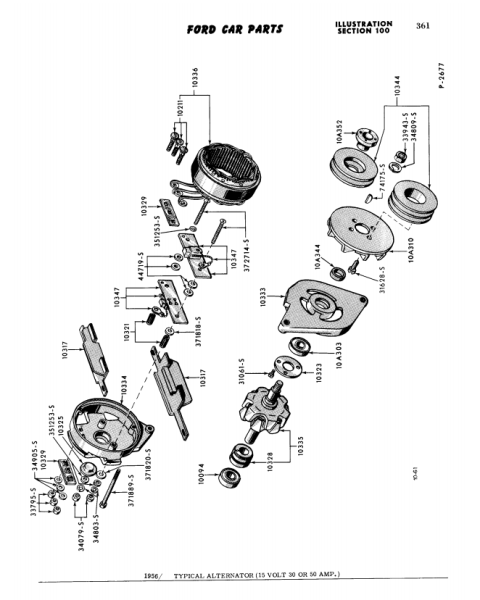

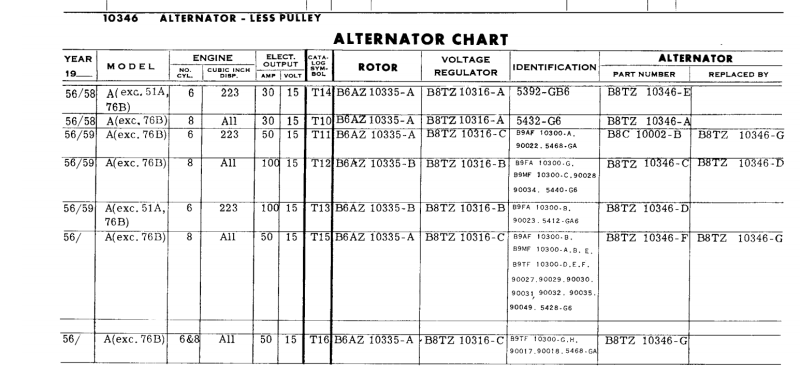

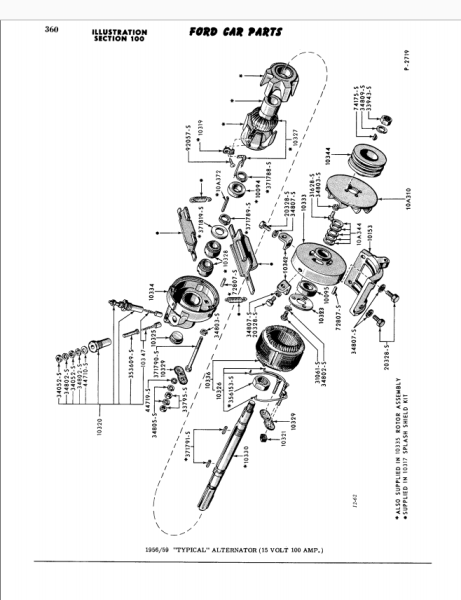

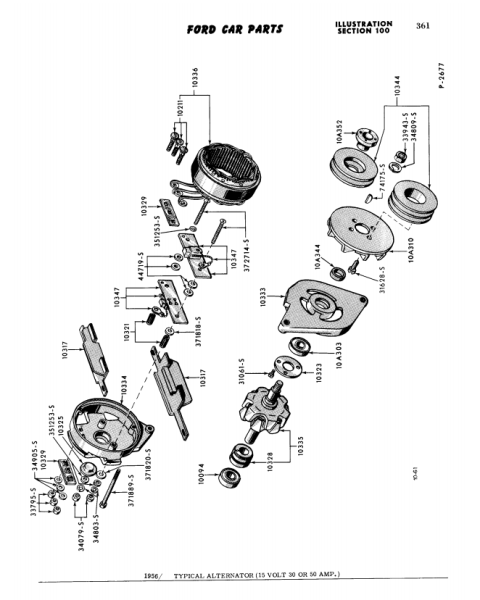

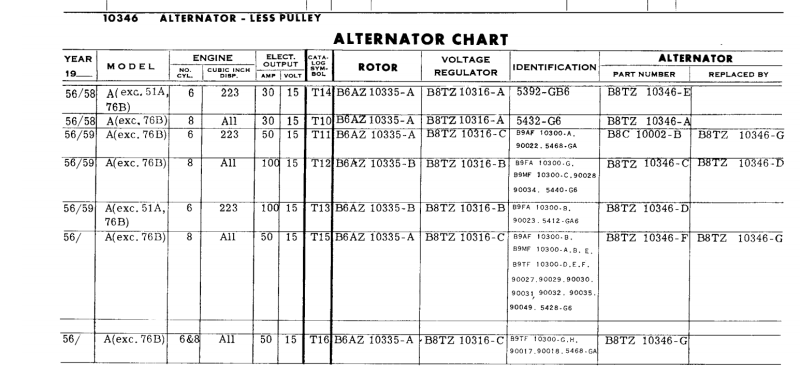

Why convert and go with a new alternator when you can get a OEM Ford Alternator used for 56-58 fords?

100A 15V alternator - 56/59

30A or 50A 15V Alternator - 56/

And part numbers for the alternator and regulator based off engine and year.

|

|

By oldcarmark - 8 Years Ago

|

KULTULZ (12/9/2018)

Here is a FORD Y-BLOCK dedicated (1G) BRKT ASSY -

That's a nice neat Installation. Is that something You came up with yourself or is it One You purchased?

|

|

By KULTULZ - 8 Years Ago

|

"That's a nice neat Installation. Is that something You came up with yourself or is it One You purchased?"

Guess it would have been thoughtful if I included the source ...

https://carcrap.net/product/272-292-312-ford-alternator-mtg-kit-y-block-thu/

|

|

By KULTULZ - 8 Years Ago

|

"Why convert and go with a new alternator when you can get a OEM Ford Alternator used for 56-58 fords?"

Those are LEECE-NEVILLE. They were used for POLICE/FIRE, etc. Would be hard to find today and the appearance is not good (IMO)

|

|

By oldcarmark - 8 Years Ago

|

Rusty_S85 (12/9/2018)

Why convert and go with a new alternator when you can get a OEM Ford Alternator used for 56-58 fords? 100A 15V alternator - 56/59  30A or 50A 15V Alternator - 56/  And part numbers for the alternator and regulator based off engine and year.

If You are going to go to the Trouble of Converting to an Alternator there's lots of Choices in makes and Amps.I did One on my last '56 using the old Style 3 Wire Ford Setup. I like the Bracket shown. Looks much more Professional than some of the manufactured Ones I have seen. I made my own using Information off the Web.Uses the Original Brackets with Threaded Rod and Spacers. Looked alright. Worked fine.

|

|

By Rusty_S85 - 8 Years Ago

|

oldcarmark (12/9/2018)

Rusty_S85 (12/9/2018)

Why convert and go with a new alternator when you can get a OEM Ford Alternator used for 56-58 fords? 100A 15V alternator - 56/59  30A or 50A 15V Alternator - 56/  And part numbers for the alternator and regulator based off engine and year.  If You are going to go to the Trouble of Converting to an Alternator there's lots of Choices in makes and Amps.I did One on my last '56 using the old Style 3 Wire Ford Setup. I like the Bracket shown. Looks much more Professional than some of the manufactured Ones I have seen. I made my own using Information off the Web.Uses the Original Brackets with Threaded Rod and Spacers. Looked alright. Worked fine.

Honestly, I would love to go with the GenerNator, but first time I contacted him he only offered one wire hook ups he wouldn't do one to hook up oem and use the external regulator, he proclaimed they were junk and didn't last. Funny considering all my vehicles my 56, 63, 78, and 82 year model vehicles with external regulators still sport the oem factory regulator. But I emailed him a few years later and he does it using the external regulator as the rewire point but it wont function and he can at extra cost include a light hook up so the gen light will function all for $895 without the gen light. Im like screw that I will just stick with my oem generator I could rebuild it thousands of times for the cost of that one genernator and then god knows what kind of dependability there is on that. at least if my generator goes out I can rebuild it or replace it, his you have to mail back to him as he custom makes it in your old oem case which means once he passes away you are screwed now.

Powermaster sells one now but its a one wire hook up but at first they didn't have a generator light hook up but now they offer it for around $500 but its still a one wire internally regulated alternator that wont hook up to OEM harnesses so makes it pointless to spend money on a reproduction wiring harness having to chop it all up.

|

|

By oldcarmark - 8 Years Ago

|

|

3 Wire Alternator works good. Gen Light works too.

|

|

By charliemccraney - 8 Years Ago

|

If you're wanting an original appearance then I can understand the high cost as that is a niche market. If you don't need it to look original, 127 options for an externally regulated alternator:

https://www.summitracing.com/search/part-type/alternators-and-generators/department/ignitions-electrical/voltage-compatibility/12/pulley-style/v-belt/regulator-style/external?N=4294944858%2B4294951516%2B4294944880%2B4294948909%2B4294921065&PageSize=100&SortBy=Default&SortOrder=Ascending&tw=alternator&sw=Alternators%20and%20Generators

Most brackets will be for a GM style alternator so you will probably have to modify something that is already made or make your own brackets for anything else.

|

|

By Rusty_S85 - 8 Years Ago

|

charliemccraney (12/9/2018)

That's the thing for me if I were to do it I want it to look like a generator. Which I can always run the powermaster powergen series they offer and chop the wiring up but I planned on buying all new wiring harnesses for the car as mine is old and brittle. Cant justify spending big money on a powergen and a new harness only to cut the harness up to wire up the powergen cause they don't offer a oem style hook up.

|

|

By miker - 8 Years Ago

|

|

Rusty, this is an aside to your last comment on a long thread. When I bought my first alternator conversion, part of the instructions were how to rewire at the voltage regulator. It basically turned it into a junction block, it no longer functioned. So there might be a way around cutting up the harness and still make it work. Been many years ago, I don’t remember the particulars.

|

|

By Rusty_S85 - 8 Years Ago

|

miker (12/9/2018)

Rusty, this is an aside to your last comment on a long thread. When I bought my first alternator conversion, part of the instructions were how to rewire at the voltage regulator. It basically turned it into a junction block, it no longer functioned. So there might be a way around cutting up the harness and still make it work. Been many years ago, I don’t remember the particulars.

Well if there is a way to use the OEM harness and just change the wiring at the oem regulator then I will have no problem spending $400 on the powermaster powergen alternator in the generator case, my problem is that's a one wire hook up and the new model you can get has an optional gen light terminal so it looks like the original generator with two studs on the top of the generator. Would also love for it to be like oem though where it has a power wire to activate the alternator. Ive had one wire alternators ive installed at work before that were hit and miss. some would start charging automatically at 1,000 rpm engine speed, others ive had you had to hit the throttle to 2,000 rpm to get it charging. For a cold engine I do not like going over 1,500 rpm when on choke so I would have to be assured that a 1,500 rpm cold idle would start the alternator charging before I am comfortable with buying a 1 wire setup.

|

|

By FORD DEARBORN - 8 Years Ago

|

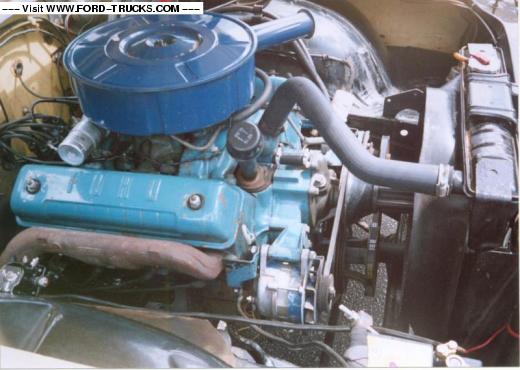

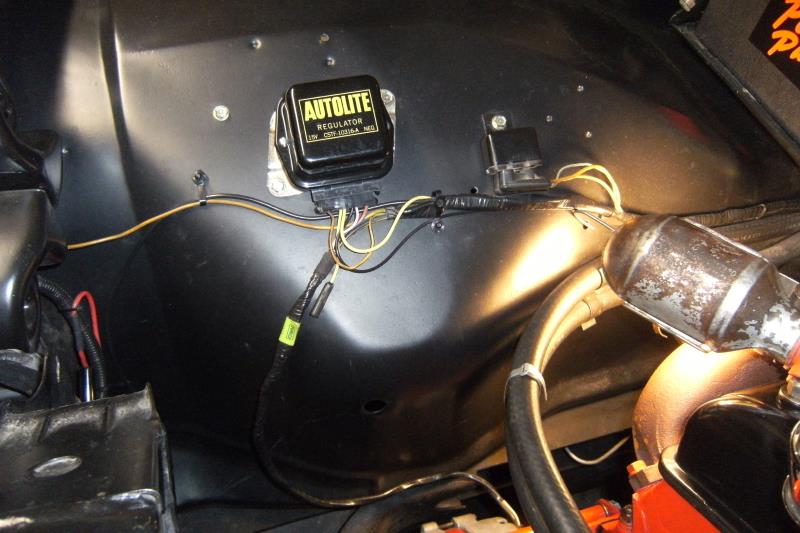

Greetings to all: Here is a G1 install in my '64 F100. The top 2 brackets have not been altered and are as came with the truck. The alternator pivot hole was drilled just large enough to accept a longer pivot bolt. The spacer between the ears of the bracket on the cylinder head is nothing more than a sized 3/8" I think, piece of pipe with a couple washers for shimming. (Been a few years since I did this.) The lower adjusting bracket is from a passenger car but had the best shape, offset and length to make this work. It's close to being maxed out but through trial and error, a belt was selected to make this work very well. The regulator is a Motorcraft electronic version with a '65 reproduction (Mustang) cover. There are numerous harnesses reproduced for he Mustang sold by NPD of which I chose the one that I thought would be good for this conversion. I did unwrap it and made a kind of hybrid harness to suit the truck. The wrapping material is also available from NPD along with the engineering tag. Since the subject came up again, I'll try to post a few pics. BTW, the Ford 3 wire system IMHO is second to none. Rock solid regulation sensing the voltage on the bus, not the alternator itself and it looks correct. Hope this helps, JEFF.......................

|

|

By Kahuna - 8 Years Ago

|

Rusty

I did as Miker on my 56 Ford using an original voltage regulator & making it into a non-funtioning terminal block.

I am also using all new original wiring harnesses throughout the car. Purchased from Mac's

I only had to splice or change the connection on one (1) wire to do so.

I am using an S-10 or S-12 alternator. Alternator came with the car, but was not mounted.

Other than the alternator itself, all wiring appears stock. (Well, maybe not to the purist, but damn close)

Jim

If I were more computer literate, I would be able to get you a picture.

My ONLY concern with what you are doing is the reliability of those modified generators,

but maybe my concerns are unfounded.

J

|

|

By the human wrench - 8 Years Ago

|

|

The latest Hot Rod magazine has a article on 3G Motorcraft alt. conversions. If you want to stay FoMoCo.

|

|

By Rusty_S85 - 8 Years Ago

|

Kahuna (12/10/2018)

Rusty I did as Miker on my 56 Ford using an original voltage regulator & making it into a non-funtioning terminal block. I am also using all new original wiring harnesses throughout the car. Purchased from Mac's I only had to splice or change the connection on one (1) wire to do so. I am using an S-10 or S-12 alternator. Alternator came with the car, but was not mounted. Other than the alternator itself, all wiring appears stock. (Well, maybe not to the purist, but damn close) Jim If I were more computer literate, I would be able to get you a picture. My ONLY concern with what you are doing is the reliability of those modified generators, but maybe my concerns are unfounded. J

That's my concern with a small time one man operation he gives a 3 year warranty but the guy is not young he is up in age pushing I want to say 70 almost. Means he wont be around forever and then you are screwed when his alternator conversion finally fails.

Plus there is the cost, I could get the Powermaster PowerGen series that they've had out for a few years they are a big company and don't seem to be going anywhere any time soon. The powergen how ever is designed as an alternator with a generator housing. Not a generator housing with custom alternator pieces fabricated for it like the other guy is doing. Price is a lot cheaper as well. I just need to look more at the wiring because I would like to keep it looking OEM while being more driver friendly.

Generator would probably be fine for me though considering the car doesn't have anything on it other than a radio and heater. I already installed LED lights in the dash so that saved me some current draw there, got some new warm white ones to install as the white ones I had on hand are pure white and they are just too white they look way too out of place.

|

|

By Rusty_S85 - 8 Years Ago

|

the human wrench (12/10/2018)

The latest Hot Rod magazine has a article on 3G Motorcraft alt. conversions. If you want to stay FoMoCo.

3G is a fairly old conversion now a days, I been planning on a 3G conversion on my old ford truck for the last 8 years now. Just never got around to it but will be doing it now how ever since I have to put a engine in. Nows the time to junk the 1G and get a 3G so my extra lighting can be supported without fear of overtaxing the 1G.

|

|

By paul2748 - 8 Years Ago

|

When I converted my 64 Fairlane to a alternator, I did the same thing. I got a diagram from the Fairlane clubs magazine. Didn't have to cut anything

miker (12/9/2018)

Rusty, this is an aside to your last comment on a long thread. When I bought my first alternator conversion, part of the instructions were how to rewire at the voltage regulator. It basically turned it into a junction block, it no longer functioned. So there might be a way around cutting up the harness and still make it work. Been many years ago, I don’t remember the particulars.

|

|

By cokefirst - 8 Years Ago

|

|

I have the Powermaster generator/alternator on my 1957 Skyliner. I bought the 2 wire set up so that it would turn off the dash gen light. I used the original harness. I had to cut the internals on the regulator so that there were no internal connections but by wiring it through the regulator, I have the look of a generator and regulator with the great output of an alternator system. I have factory air on my Skyliner, so it takes a two groove pulley. That was not a problem, as I simply took the pulley from the generator and put it on the Powermaster unit. The only problem I had was that the generator uses a woodruff key to engage the pulley. The Powermaster unit does not use a woodruff key and relies on nut tension to lock the pulley to the shaft. That means you have to put the nut on extra tight. I did not and had some slippage and poor charging until I figured it out. I notified them that a keyed shaft would be a good idea, but they said no one else complained so I am guessing they are not willing to go to the extra machining to make this match the generators. I love that way this looks and performs. So I am pleased. Yes. it is way more expensive than putting on a modern style alternator, but if you are going to a near stock look, this is it!

|