|

Author

|

Message

|

|

simplyconnected

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 302,

Visits: 835

|

HoLun (4/4/2009)

the thing is, my block is not align bored, I dont know why it has that much slack in the chain, I am gonna email rollmaster and see if i can get the shorter chain only before i try a new stock HP set.

also, how do i determent slack vs length to purchase?

when I swap out to the lighter springs i made sure the weights pivot freely, and i have verified with a timing light that at 500 rpm the weights are not moving, so the only thing i can think of now its the slack of the chain. or there might be too much backlash on the disturbitor gearIf your main bearing caps and saddles have not been altered by align-boring, a stock chain set should work just fine. I don't know why your new chain should be sloppy. New chains I installed were 'a fight' to get the cam sprocket on the camshaft (then you have that confounded cam key or bushing to contend with).

Perhaps you got ahold of a non-stock, or wrong chain set. Again, new timing sets are tight. For an align-bored block, it wouldn't take much for the factory to oversize the sprockets to correct for a sloppy chain.

Royal Oak, Michigan (Four miles north of Detroit, and 12 miles NORTH of Windsor, Canada). That's right, we're north of Canada.Ford 292 Y-Block major overhaul by simplyconnected

|

|

|

|

|

2DRHRDTP57

|

|

|

Group: Forum Members

Last Active: 10 Years Ago

Posts: 207,

Visits: 1.8K

|

Hey guys, interesting thread, one thing I know is I never stop learning reading these threads, there is a wealth of espertise here. I purchased a double roller from Mummert a rollmaster product, and like other comments in this thread it was tight to get on the shaft and very little slack once installed.

I would check that they have supplied a correct part, as i commented mine was not slack at all.

Hope this helps,

1957 ________________ Ford

\___((_______________))___/

(@)________V__________(@)

[________I_____I_________]

__[__]__ o_______o___[__]___

Y Blocks, The New Flathead!

|

|

|

|

|

pcmenten

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 375,

Visits: 1.1K

|

Thank you Ted. Always very informative.

Three items;

Spark scatter - seems like a crank trigger would help in that area. But I would be more concerned with 'cam scatter', or the inaccuracy of the valve events due to the chain jumping around.

Chain tension - I worked on a Toyota 18R that had a very long timing chain. It has a tensioner that pushes a shoe against the long stretch of chain. Smokey Yunick talks about watching the timing chain on a Scrub jumping around like a snake at 7000 RPMs. (Wow, talk about spark scatter). I still don't understand why there aren't aftermarket chain tensioners for V8's. Seems like a simple idea.

Oiling - only the passenger side has an overflow tube that dumps out to the timing chain. Perhaps the driver's side could be pressurized and the passenger side left to flow.

Also oiling, my 56 Fairlane with a Thunderbird 292 V8 came stock with a little tray that bolted underneath the chain to help direct oil onto the chain. Any issue with that? Seems like a roller chain would especially benefit from good lubrication.

And finally, the passenger side overflow tube just directs oil down a hole in the head. Perhaps an extension of that tube that continues through the valley and out the front, over the chain would be helpful.

Speaking of over the chain, perhaps it would be helpful to modify the front of the block to ensure that oil lands on the chain, not just flow down past the chain.

Oh, and an afterthought - beehive springs run at lower pressures. Seems like that would play into the whole chain-stretch equation. Also, lightened valve train components reduce spring pressure requirements; titanium retainers, aluminum rockers, titanium pushrods, hollow lifters.

Best regards,

Paul Menten

Meridian, Idaho

|

|

|

|

|

LON

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 523,

Visits: 3.7K

|

Rollmaster timing chains are (were ? ) made here in Qld .I heard a rumor that they were not making any more for Y-Blocks . I used one in the Vicky and the Rod .I'll try and find out if production has stopped . Why hasn't someone made a timing belt for Y-blocks .You can get them for SBF and that other brand ,so why not for Y-Blocks ??????????? I don't see a big difference . Lon

yblocksdownunder

|

|

|

|

|

HT32BSX115

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 452,

Visits: 24.4K

|

LON (4/5/2009)

Rollmaster timing chains are (were ? ) made here in Qld .I heard a rumor that they were not making any more for Y-Blocks . I used one in the Vicky and the Rod .I'll try and find out if production has stopped .

Why hasn't someone made a timing belt for Y-blocks .You can get them for SBF and that other brand ,so why not for Y-Blocks ??????????? I don't see a big difference .

LonA timing BELT to replace the gears and chain/rollers? That would be some tiny little belt! do you have a link to a picture? I guess the "other" choice (since no one has mentioned it) would be a gearset. Most people don't like them because they're noisy and adds to the "moving parts" count..... Hmm, Found one on EBAY $500 or so. Found a few more on the net via a search.....$1000 or more for the kit. Sort of makes it pretty expensive. I wonder if it would be worth it. Someone of course, would have to make them for the Y. With the limited number it would be like aluminum heads.....the production run would be small and prohibitively expensive...... People probably wouldn't buy them... Cheers, Rick

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1955 F-600/272/E4OD// Disclaimer: No animals were injured while test driving my F-600 except the ones I ran over intentionally!

---------------------

This post was created using OpenSuSE Linux x64 and Firefox

|

|

|

|

|

oldcarmark

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 3.7K,

Visits: 32.6K

|

I noticed on the Elgin timing gear seat the Ford part#s the prefix B6T indicates a truck application.Were the larger trucks with a Y-block manufactured with the double wide timing gear set originally hence the "heavy duty" designation?

|

|

|

|

|

aussiebill

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 1.8K,

Visits: 11.4K

|

Hi, here in Australia , the 1st 292,s were in 59 f600 trucks, there was the fabled HD 292 in some and resulted in the steel crank, rods, and double row timing chain mentioned earlier,the hunt was allways on for one of these, and could mostly be identified by spider wheels and 2 speed diff. I,M not sure taking the theory of these chain differences to the finest point achieves much, ford surely wouldnt have designed the double row setup at the time if it was,nt suitable. but i,ve ran em all for 40 yrs and nowadays we just dont do the everyday miles we did as teenagers etc. just a note on Rollmaster chains, be aware the Nitrided version crank gear requires a light polishing to fit to crank as size has shrunk due to the treatment. Regards aussiebill.

AussieBill YYYY Forever Y Block YYYY AussieBill YYYY Forever Y Block YYYY Down Under, Australia

|

|

|

|

|

LON

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 523,

Visits: 3.7K

|

Bill , Thanks for reminding me about the Nitrided gears .Had a slight fitment problem with the Vicky .From memory it was .003 .I tried to phone my mate Scott Sterling today to see if they are still being made ,will try again tomorrow . Lon

yblocksdownunder

|

|

|

|

|

speedpro56

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.3K,

Visits: 9.2K

|

My rollmaster chains are oiled this way. Place the cam sprocket in place, there's an oil galley between the crank and cam. On the oil galley mark the spot with a magic marker put a dot where the cam sprocket teeth are. That's where you drill an approx .030 hole for oil to spray onto the sprocket teeth to oil the chain  . I did away with the overflow tubes too pressurized the rockers and have no more galled shafts. I also use a restricter in place to restrict the oil to the rockers.

-Gary Burnette-

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 8 hours ago

Posts: 7.5K,

Visits: 205.9K

|

pcmenten (4/5/2009)

.....the passenger side overflow tube just directs oil down a hole in the head. Perhaps an extension of that tube that continues through the valley and out the front, over the chain would be helpful.The passenger side rocker overflow tube does direct the oil to an engineered path in the block to the timing chain area. When examining the front area of the lifter valley in a Y block, you’ll see a designed and cast in path or channel where the oil from this particular overflow tube gets redirected to the timing chain area.

pcmenten (4/5/2009)

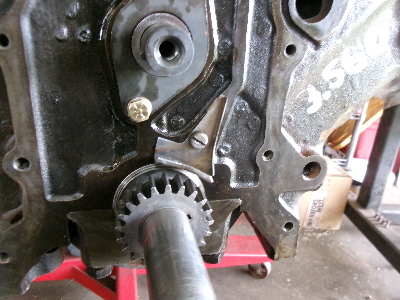

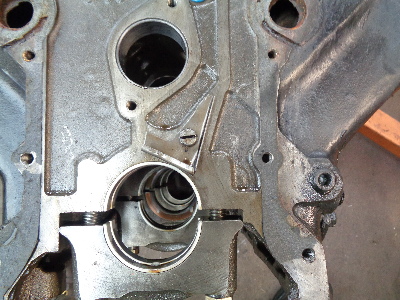

Speaking of over the chain, perhaps it would be helpful to modify the front of the block to ensure that oil lands on the chain, not just flow down past the chain.The aforementioned oil trough bolted on the front of the block does a good job of directing the oil to the lower timing gear sprocket and chain which then gets carried back up to the cam gear. This trough was eliminated in 1956 but I’ve built a jig that allows these to be put back on the later model engines in the correct factory specified position. Here’s a couple of pics of the oil trough for those that have never seen one.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|