Ah yes. Another night that I won't get to sleep early.

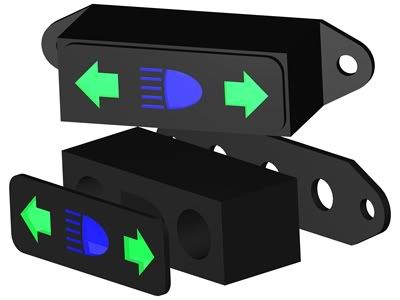

Here is my plan for the light panel.

The block in the center will be a white plastic. I figure that will help make the lights as bright as possible.

I'm thinking that the back piece will be aluminum and there will be a thin gasket of some sort between that and the block. The LEDs have thingies so that they can be mounted to a panel and they will fit in the 3 larger holes of the aluminum part. And the two smaller holes are for fastening to the instrument panel. I'm also planning to support the circuit board with the same fasteners and some spacers just thick enough so that the board is supported but not under tension.

The front is going to be clear. I just gave them color to make the rendering a little more dramatic. The plan is to use printer labels to print my templates, figure out some way to stick them to some polycarbonate and have them lined up properly, paint it white, then peel of the stickers. This part will be glued carefully to the white part.

Lawrenceville, GA