Valve lash is not holding steady after first few runs:

First run: lash opened .006 Second run: the same thing. Third run: I adjusted lash again at .020 cold and then ran the engine for 5 seconds. The lash has opened up again, this time after just a few seconds. I think that if there is something failing at this fast of a pace it would be gone/done already.

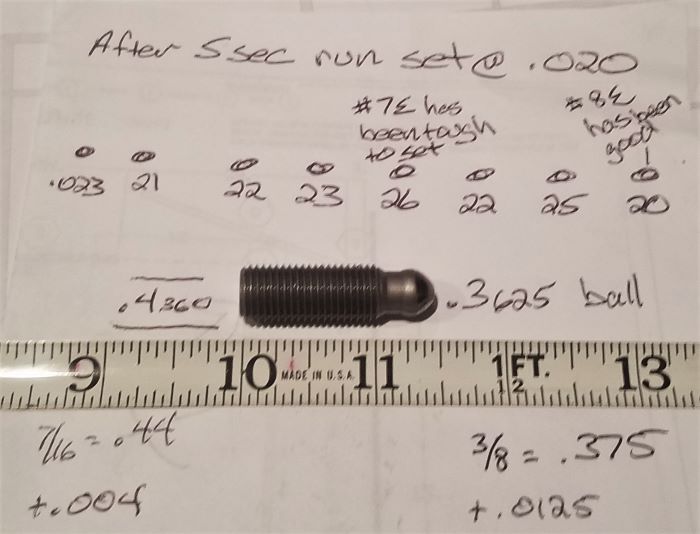

The threaded adjusters measure .

4360 on the OD of the threads, the ECG rocker ID measures .

4395 on the groove. That is a .0035 difference without the depth of the grooves added.

I found two postings that both mention either damaging the threads or using oversized adjusters. Any words of wisdom will be greatly appreciated.

Rocker adj nuts

Loose rocker adjusting screws. - 332-428 Ford FE Engine Forum

Harland Sharp makes these screws but I'm not sure they will fit, threads are +.004 wider and the ball is +.0125 wider, If the 1.200 is the length of just the threads seems like they should be a tighter fit: 7/16 - 20 x 1.200, 3/8 Ball, Ford FE

.150 Stroked Y-Block:327.25 ci @ >1hp per ci