|

By Brent - 2 Years Ago

|

Valve lash is not holding steady after first few runs:

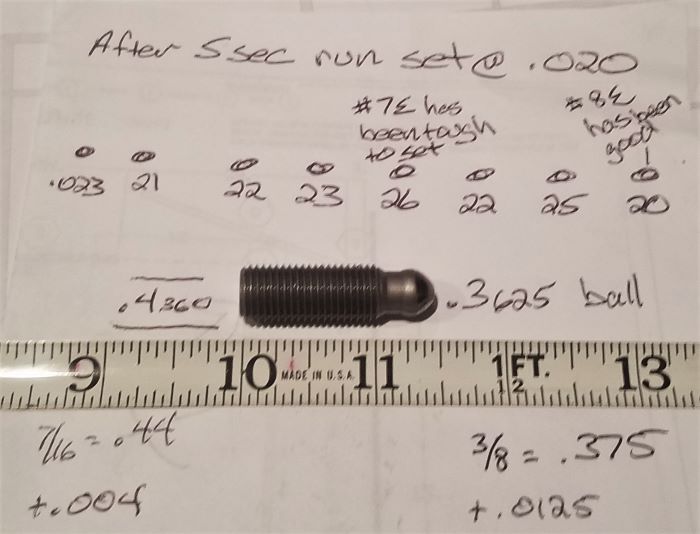

First run: lash opened .006 Second run: the same thing. Third run: I adjusted lash again at .020 cold and then ran the engine for 5 seconds. The lash has opened up again, this time after just a few seconds. I think that if there is something failing at this fast of a pace it would be gone/done already.

The threaded adjusters measure .4360 on the OD of the threads, the ECG rocker ID measures .4395 on the groove. That is a .0035 difference without the depth of the grooves added.

I found two postings that both mention either damaging the threads or using oversized adjusters. Any words of wisdom will be greatly appreciated.

Rocker adj nuts

Loose rocker adjusting screws. - 332-428 Ford FE Engine Forum

Harland Sharp makes these screws but I'm not sure they will fit, threads are +.004 wider and the ball is +.0125 wider, If the 1.200 is the length of just the threads seems like they should be a tighter fit: 7/16 - 20 x 1.200, 3/8 Ball, Ford FE

|

|

By famdoc3 - 2 Years Ago

|

|

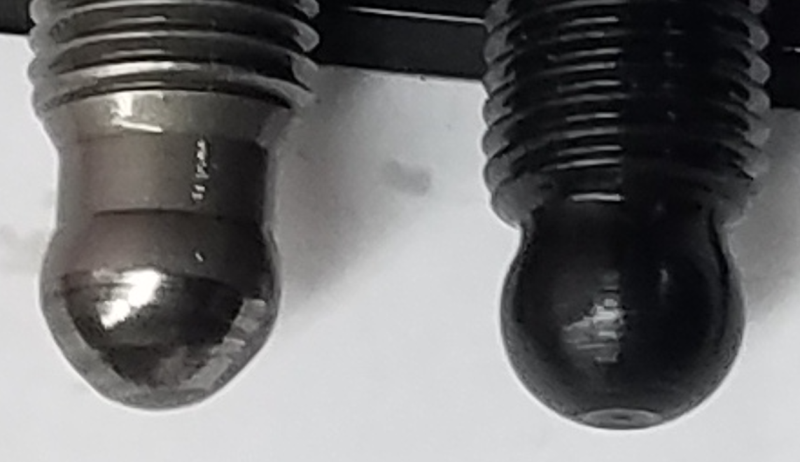

Look at the ball and the wear pattern. I suspect you have a pushrod to adjuster ball mismatch. I have made the same mistake before and thought it was that the balls were “soft”. Measure the two and I suspect you will have your answer.

|

|

By Brent - 2 Years Ago

|

The wear mark on the ball is pretty small on the tip and it's football shaped.

The Harland Sharp adjuster has a ball +.0125 wider which would produce a tighter fit in the cup.

|

|

By DryLakesRacer - 2 Years Ago

|

I would give Smith Brothers or Manton a call. I’ve worked with both over the years with push rods and both offered adjusters. They do offer adjusters that are cups and not balls but your really looking at the threads in the arm.

Have you screwed in a 7/16” fine thread bolt as a test to see if they are as loose as your adjuster now. Just a thought.

|

|

By Ted - 2 Years Ago

|

I'm assuming good oil flow at the rockers. I’ll suggest ‘bluing’ some of the pushrod cups and run the engine for about a minute and then checking the wear pattern at the pushrods. With a locking nut adjuster, I do not think the problem is in the threads but is instead at the adjuster ball to pushrod cup fitment.

|

|

By 2721955meteor - 2 Years Ago

|

|

HAVE YOU REMOVED THE SPILL TUBES,AND BLOCKED THE HOLE IN THE STAND.IF YOU ARNT GETTING GOOD OILFLOW AT EVERYROCKER,NEXT YOU MAY BELOOKING FOR A NEW CAM ETC

|

|

By Daniel Jessup - 2 Years Ago

|

|

From the pictures you have posted, your ball end of the adjuster is not riding true in the cup of the push rod. Once you have some wear between those two parts because the ball is trying to seat, that is what is giving you the extra lash.

|

|

By Brent - 2 Years Ago

|

The supplier told me that the problem is that the cup is not machined perfectly and the roughness in the cup is grinding the ball.

I have Smith Bros. rods on the way and Harland Sharp had some fat adjusters (.438) with 3/8” ball. Both made in the USA!

famdoc3, you nailed it. , DryLakesRacer I could not find a fatter bolt to try, they are all skinnier, real good idea. The mfg leads helped. Ted, as always, many thanks! 2721955meteor, when I had the covers off and primed the system there was oil at all of the rockers, after the short runs upon inspection everything appears wet. Daniel Jessup, the wear was opening the lash so quickly it seemed dangerous to keep running it. As a result of this group, I have again made another step in the right direction.

I hope you all have a great day!

|

|

By DryLakesRacer - 2 Years Ago

|

|

I’m assuming the Smith Brothers push rods have cups that accept a 3/8” ball and the ball will sit in the bottom of the cup with clearance on the sides. I don’t know about your assembly habits but I recently had both my heads off for a valve seal change along with other repairs and lubed the top and bottom of the push rods with assembly lube. My racing GMC 6’s are made the same and it’s a precaution I take when servicing the engine. I hope it all works out and your problem is solved.

|

|

By Brent - 2 Years Ago

|

The new adjusters arrived: 3/8” ball x 7/16-20 “oversized” (these fit the rocker arms much better.) The ball fits the cup in the new pushrods perfectly. The ball on the new adjusters is round; the failed adjuster balls are ground down and are not round.

I am planning to work through the install one cylinder at a time, replacing the intake when the exhaust valve is just opening and the exhaust when the intake is almost closed. I think the rocker arms will move to the side to allow the pushrods to clear except at the four ends the rockers wont slide to the side, It seems to me that I should remove the cotter pin from the end of the shaft to allow the rockers on the ends to be moved for new pushrod install, or, is there a better way?

|

|

By Ted - 2 Years Ago

|

There’s no need to remove the cotter pins from the shafts to install the adjusters in the end rocker arms assuming there is enough wiggle room to replace the pushrods. There’s always the possibility that the rocker arm shaft assemblies will need to be loosened up to change out the pushrods. Let us know on that one. Aluminum heads are easier than cast iron heads in that regard.

On my end, it is simpler and quicker to just change out both rocker arm adjusters on a given cylinder by having the engine at the top of the compression stroke on that cylinder. At TDC on the damper, either the #1 or #6 cylinder will be on its compression stroke and once you determine which of those two cylinders is at compression, that’s a good starting point. In your case, the cylinder with lash on both the valves would be the one at its compression stroke. I start at the #6 cylinder regularly on most engines setting the valves just to eliminate an additional rotation of the crankshaft to get to #1 in those cases where #6 is at the compression stroke and not the #1 cylinder. Rotating the engine in 90° increments and following the firing order will save time versus doing it the EOIC method and much easier to keep up with where you are.

|

|

By Brent - 2 Years Ago

|

|

The #5 exhaust pushrod will not clear the rocker arm, it's only a 1/16" or less but I can't get it to clear. Is it better to remove the cotter pin and wiggle the rocker to the side or lift the entire rocker assembly? If lifting the assembly, I am concerned about getting it torqued back down with the rockers in contact with the springs. I should be able to loosen all of the adjusters and then rotate the engine to the correct positions to get each cylinder to the full compression cycle, but I am leery of not having the rockers as they are adjusted to indicate that I am in the right position, rocker arms not in contact with springs, and then replace pushrods and adjusters and adjust the lash of a particular cylinder.

|

|

By charliemccraney - 2 Years Ago

|

If you loosen the rocker hold down bolts and nuts, there may be enough wiggle room. And if that doesn't work, you can remove the shaft assembly to install the pushrods and tighten it down with the pushrods in place. Since there will be tension on the shaft, you want to be sure to tighten them evenly but it should not be a problem. I've done that numerous times.

|

|

By Brent - 2 Years Ago

|

|

Is there any reason not to remove the cotter pins and then wiggle the exhaust rocker arms at 1-4-5 & 8? It seems to me much easier than lifting the entire assembly for just those 4 rocker arms, I think the rest of them will move easily out of the way with the assembly in place.

|

|

By charliemccraney - 2 Years Ago

|

Removing the cotter pins should work, too. Do it however you are the most comfortable. I find it easier to remove the assembly rather than replace the cotter pins with the shaft on the engine.

|

|

By Brent - 2 Years Ago

|

I installed the new pushrods and adjusters; pulling the cotter pins at the exhaust rocker arms #1-4-5 & 8 is a cinch, every other rocker arm moves freely to the side. The engine sounds so much better, what a relief. The old pushrod cups are rough on the inside and the adjuster balls grind inside of them. I am very thankful for everyone's help.

Now it's time to test the brakes!

|