|

Author

|

Message

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/15/2020)

3. I think I have heard about a "better" cam bearing that I should buy, what brand is that? The harder bearing that will not let the groove close up. and what about cutting a groove under the bearing, in the block itself?For the harder cam bearing sets, I’ll use the Engine Tech #CC508. If I know that the cam tunnel alignment is going to be an issue as is the case with many of the ‘ECZ’ 312 blocks then I’ll opt for using Sealed Power, Melling, or Durabond cam bearings as these are much easier to carve on.

I cut all the center cam holes in the blocks with a groove for additional top end oiling. That's just the way I do it but other ways are also acceptable. Any excess flow of oil to the top end can be controlled with a restrictor at the rocker arm pedestals if necessary. As mentioned by others, a groove on the outside of the cam bearing or a deeper groove in the center cam journal also accomplishes the same thing. There are several fixes for potential top end oiling issues and any one of them gets the job done.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/16/2020)

Ted, so you sound like you are in the camp of not pressurizing the rockers unless I increase the spring pressure. On the 292 that is in the car now, I welded up the overflow tubes and drilled a very small hole in the ends. My thought here was to keep a little more oil in the shafts and still not shut off the oil to the timing chain and dist gear. After reading you last post, this may not have been the right thing to do as the rockers on that motor had been rebuilt with bronze bushings. is what your saying is that I should pressurize the shafts when running bronze bushings in the rockers? I don’t see any major problems with what you have currently done. This is not rocket science and because the shafts are easily accessed on the car after it has been run, the oiling to the top end can be easily modified without a lot of difficulty if you don’t like what you see. The rocker arm to shaft clearance is a key player in determining if the overflow tubes are to be retained when using bronze bushed rocker arms. On my end, 0.002” clearance requires that the rocker arms be pressurized when using the Harland Sharp bronze bushed roller tipped rockers. As the rocker to shaft clearances becomes larger (~0.004+) then gravity flow comes into play and especially if using a lighter weight oil. If pressurizing with excessive clearances, then oil flow can become excessive at the rockers depending upon what modifications took place at the cam journal to increase the oil flow to the top end. It’s not unusual to have to put an oil restrictor in each rocker arm shaft assembly to bring the oil flow back under control. In these cases, I’ll use a 0.078” restrictor.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Ted, thanks. I think what I'll do is when I get to that point I'll look at the rockers in the other motor and see how they are wearing and make that decision then but I think I will cut the cam groove deeper, up to the spec Phil called out in needed.

Should we get into the "steam" holes. I read your and other's posts about that and some like them but most don't. I'm leaning towards drilling them as they are drilled in my other motor and it stays cool. I do understand these holes don't have much cooling effect, they are more about filling the system. to make sure the system gets full with no air trapped, is that right? Inn my case, the radiator is way above the block so it should fill fine, so maybe I won't drill them.

|

|

|

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Just checked, Rock auto has those cam bearings for $27 not bad at all

|

|

|

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Joe-JDC (6/15/2020)

#4. If you look in your valley, there is a trough that channels oil to the front timing gear area. Elongate that hole so that the oil drains freely, and you should be ok. The holes in the valley for camshaft oiling need to be in a specific place, or you are slinging the oil in the wrong direction. The rest of your questions are dependent on how much time you are willing to spend for little return. Joe-JDC "elongate that hole" I see the trough and my block has two holes that drain down to the chain. the holes are at a place that the oil will drain, not sure what you mean. I don't think I'll do the valley drilling, I don't know of Y blocks wiping cams so that looks like a fix looking for a problem if you know what I mean.

|

|

|

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Does anyone know of a supplier for bushings that can be used in the rockers? I guess I could just buy some bronze and make them but if there is a correct one out there I may be able to cut out the hole in some worn out rockers and just push the in.

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 927,

Visits: 190.0K

|

i have a 292 with drain rocker tubes removed. , came grove enlarged new cm refaced lifters,289 valve seals. i ran the engine hot oil valve covers off,excelent supply of oil.the spinning pushrods cary oil into valley, as well as drain holes under the valve covers each end of the heads. this engine wasfreshend 3years ago and i use it lots in my1949 merchants f47.

my storey is most cam failures on Y blocks was but to poor lub to top end. the289 valve seals do a better job than the seals in oh kits.

no issues with timing chain frame lack of oil. just look at lube system in fes and sb fords 260/289. just my take on how to make aY with minor upgrades will last many miles. i run a 600cfm holley on a 57 4v intake, and dura spark conversion

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/15/2020)

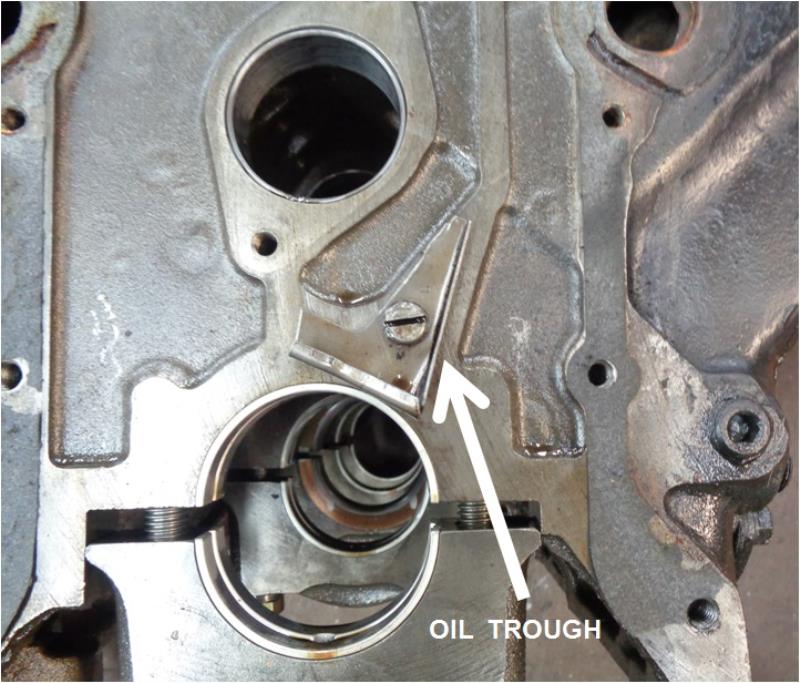

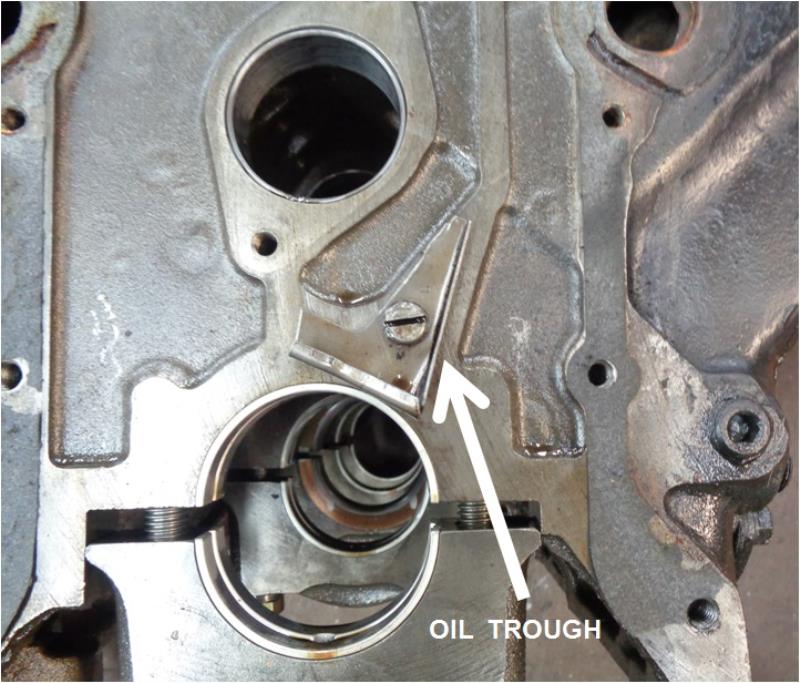

2. if I do block off the drain tubes, should I drill the small hole in the block at the cam plate?I have done this modification and it does restore the oil flow going to the timing set that is cut off when the passenger side (right side for the Aussies) rocker shaft overflow tube is eliminated or blocked off. I’ll add that I do install the ‘early production’ oil trough behind the timing gear set when doing this oiling modification as that trough just insures that more of the oil does gets redirected to the chain rather than slip in behind it. I’ll credit Tim McMaster for coming up with idea of adding the oil hole behind the cam thrust plate. Here's a picture of the aforementioned oil trough.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/15/2020)

8. any other things that I have not heard of?Drain any old fuel from the gas tank with any new engine build or any engine that has sat dormant for awhile. Old fuel can create a ‘varnish’ or a gummy coating on the valve stems and this causes the valves to stick once the engine has cooled after its initial run in. Bent pushrods are the first indication of this and broken rockers are a real possibility when the pushrods have been upgraded to the stronger tubular styles.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Ted (6/18/2020)

1946international (6/15/2020)

2. if I do block off the drain tubes, should I drill the small hole in the block at the cam plate?I have done this modification and it does restore the oil flow going to the timing set that is cut off when the passenger side (right side for the Aussies) rocker shaft overflow tube is eliminated or blocked off. I’ll add that I do install the ‘early production’ oil trough behind the timing gear set when doing this oiling modification as that trough just insures that more of the oil does gets redirected to the chain rather than slip in behind it. I’ll credit Tim McMaster for coming up with idea of adding the oil hole behind the cam thrust plate. Here's a picture of the aforementioned oil trough.

I have had three Y block motors apart and none of them have had that "oil trough" I have seen the threaded hole that mounts it, in fact I first saw one on a thread here and asked what it was.... anyway I don't have one so I have to ask, is the hole worth it if I don't install a "oil trough" And as I have seen most of these holes drilled under the cam plate how does oil come out to do any good? would it be better to drill the hole a little lower?

|

|

|

|