|

By 1946international - 6 Years Ago

|

I just got my block ('57 292) back from the machine shop and will start to slowly put it back together. I know there are many mods that people do to the Y block most had to do with the oiling system, so I would like to get a plan on what to do with my motor and have it all in one place. so everyone feel free to chime in on their thoughts on any or all of the following.

1. should I close off the drain tubes on the rockers?

2. if I do block off the drain tubes, should I drill the small hole in the block at the cam plate?

3. I think I have heard about a "better" cam bearing that I should buy, what brand is that? The harder bearing that will not let the groove close up. and what about cutting a groove under the bearing, in the block itself?

4. I have a book that shows drilling holes close to the tappet bores in the valley to let oil drain down to the cam, should I do that? if so, won't that reduce the amount of oil draining down to the timing chain and dist gear?

5. steam holes, I think some have said not to do this as it may cause cracks in head or block but I'll be running this with a stock Model A radiator. the 292 in the car now has the steam holes drilled and stays cool. thoughts? Radiator fill is well above the motor.

6. how important is it to have the posted heads? I have a set of each but the posted set will need more work and you know these motors are not cheap. Both sets are uncut and I'm running stock pistons. both sets are the big valve heads.

7. Camshaft, should I cut the oil groove deeper? I have a lathe and this would be easy to do. I will be buying an aftermarket cam, while we are here, any suggestions?

8. any other things that I have not heard of?

Thanks for your thoughts and yes, I know most of this has been covered before I just thought it would be nice to get it all in one place

|

|

By Cliff - 6 Years Ago

|

|

Those engines ran for 100's of thousand miles with no mods for over 50 years, most of the things I see people do are of no value.

|

|

By Joe-JDC - 6 Years Ago

|

|

#4. If you look in your valley, there is a trough that channels oil to the front timing gear area. Elongate that hole so that the oil drains freely, and you should be ok. The holes in the valley for camshaft oiling need to be in a specific place, or you are slinging the oil in the wrong direction. The rest of your questions are dependent on how much time you are willing to spend for little return. Joe-JDC

|

|

By 1946international - 6 Years Ago

|

I tend to agree that most are not needed but the rocker shaft mods sound like a good idea. I know I have heard about the "harder" cam bearings and that would be worthwhile. While we talking about this, is there a place that I can buy bushings to repair the rockers? I think I could figure out a way to cut them out and was thinking that buying a bushing to push in would make the job much easier.

|

|

By Florida_Phil - 6 Years Ago

|

I am not a professional engine builder, I am a hobbyist. Over the years, I have incorporated many of the mods you mentioned in my YBlock builds. The long term effects of some of them, like cutting the block oil drain holes deeper, are hard to qualify. On a street engine, I doubt there is any discernible benefit. I always cut shallow grooves in the back of the plate that holds the cam in position. I feel this is a worthwhile mod.

There are many different ideas when it comes to modifying a YBlock top end oiling system. I have tried them all. The best idea I have seen so far is leaving everything stock and cutting the cam oil groove deeper. I believe Mummert came up with this idea, but I may be wrong. I have an Isky cam in my motor. When I purchased this cam, the oil grove was .018" deep. I cut the grove in a lathe to .030" deep. This significantly increased the oil flowing to the heads. So much so that I decided not to pressurize the rockers. I was afraid I would have too much oil in the heads, so I installed new oil drain tubes in the stock position. All this assumes your head oil holes are open and that you don't have anything blocking the flow. I have put about 3,000 miles on my new engine with practically no valve adjustments necessary.

My heads and rockers are bone stock 1957 non posted "G" heads. I took them off a 40,000 mile 1957 Station wagon with a 272. Other than a valve job and new rocker shafts, nothing fancy has been done to them. This particular YBLock is one of the best engines I have ever owned. It holds 20 pounds of oil pressure idling at a traffic light with 30 weight oil, my plugs are perfect and the engine revs smooth and vibration free.

In my opinion, the key to having a good engine is in the machine work. Finding someone who can perform quality machine work is difficult these days. Quality knowledgeable machine work is essential. Quality like I look for is not normally available at your down the street machine shop. I took my engine to a well known race engine shop to have my work done. I did everything the way they told me to and I couldn't be more pleased with the result.

|

|

By darrell - 6 Years Ago

|

|

as some have stated cutting the groove deeper in the cam is a good idea.if you buy a cam from mummert its already been cut.its the only mod i do.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/15/2020)

1. should I close off the drain tubes on the rockers?

I’ll start with #1. In stock form, the factory overflow tubes work fine with stock valve spring pressures. Because the Y was never blessed with hydraulic lifters, the rocker arms do have a period of relaxation whereas rockers with a hydraulic camshaft do not experience that same period of free floating. For the Ford Y and because there is that time frame where there is no pressure against the shaft, gravity free flow of oil to the rockers is sufficient. Other advantages of retaining the overflow tubes will include the shafts being completely full of oil with minimal air being entrapped and the constant oil flow through those shafts also helps in keeping the oil temperature lower which in turn minimizes sludge formation within the shafts. Any trapped air in any oil system and especially where heat is applied speeds up the oxidation process.

It’s when the valve spring pressures are increased significantly that I’ll consider pressurizing the rocker arm shafts. Another consideration is if bronze bushings are used at the rocker shafts versus if staying with iron on steel. Clearances at that point are also a consideration. When opting to use the roller rocker arms, I’ll pressurized the shafts as the rocker to shaft clearances are being targeted for 0.002”.

If using crap oil or the oil is not routinely changed, then it really doesn't matter what the oil system looks like at this point as accelerated wear will occur regardless.

I'm not the final word on how any of this in done so other options or ways of doing this are always welcome.

|

|

By 1946international - 6 Years Ago

|

Phil, Thanks, so you could see a big increase in oil at the rockers, that is good to know. I don't know what cam I will end up with but I'll cut the groove deeper like you did if needed. Any thoughts on the harder cam bearings?

Ted, so you sound like you are in the camp of not pressurizing the rockers unless I increase the spring pressure. On the 292 that is in the car now, I welded up the overflow tubes and drilled a very small hole in the ends. My thought here was to keep a little more oil in the shafts and still not shut off the oil to the timing chain and dist gear. After reading you last post, this may not have been the right thing to do as the rockers on that motor had been rebuilt with bronze bushings. is what your saying is that I should pressurize the shafts when running bronze bushings in the rockers?

|

|

By Florida_Phil - 6 Years Ago

|

1946international (6/16/2020)

Phil, Thanks, so you could see a big increase in oil at the rockers, that is good to know. I don't know what cam I will end up with but I'll cut the groove deeper like you did if needed. Any thoughts on the harder cam bearings? After I cut the cam groove deeper, I wanted to test it before final assembly. With the short block assembled and the oil pan full sitting on my engine stand, I used a speed handle to manually turn the oil pump. I was surprised to see oil shoot out the holes in the block. Cutting the grove has a significant effect on oil flow to the heads. I don't know what cam bearings were used as my machinist installed them. I have had problems with poorly installed cam bearings before. Often the cam would not turn without scraping the bearings, a tedious time consuming job. This time I gave the cam to the machinist so he could avoid having this issue.

|

|

By Daniel Jessup - 6 Years Ago

|

|

One thing I have done in a C2AE block that I have lined up to put in a 312 crank and some other good horsepower adders is a set of Durabond camshaft bearings from Verne Schumman that have BOTH and ID groove and an OD groove for oil feed. For all practical purposes, this is very close to the same idea of cutting the groove in the block deeper to increase the oil feed. As I recall, Verne had these especially made so I don't think they are available all over the place and such (unless someone knows otherwise). I do like McMaster's modification to the rocker arm assemblies as far as pressurizing. Also I have drilled the small hole up front behind the cam plate, grooved the plate itself, and added the trough (to feed the timing chain) to the C2AE block.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/15/2020)

3. I think I have heard about a "better" cam bearing that I should buy, what brand is that? The harder bearing that will not let the groove close up. and what about cutting a groove under the bearing, in the block itself?

For the harder cam bearing sets, I’ll use the Engine Tech #CC508. If I know that the cam tunnel alignment is going to be an issue as is the case with many of the ‘ECZ’ 312 blocks then I’ll opt for using Sealed Power, Melling, or Durabond cam bearings as these are much easier to carve on.

I cut all the center cam holes in the blocks with a groove for additional top end oiling. That's just the way I do it but other ways are also acceptable. Any excess flow of oil to the top end can be controlled with a restrictor at the rocker arm pedestals if necessary. As mentioned by others, a groove on the outside of the cam bearing or a deeper groove in the center cam journal also accomplishes the same thing. There are several fixes for potential top end oiling issues and any one of them gets the job done.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/16/2020)

Ted, so you sound like you are in the camp of not pressurizing the rockers unless I increase the spring pressure. On the 292 that is in the car now, I welded up the overflow tubes and drilled a very small hole in the ends. My thought here was to keep a little more oil in the shafts and still not shut off the oil to the timing chain and dist gear. After reading you last post, this may not have been the right thing to do as the rockers on that motor had been rebuilt with bronze bushings. is what your saying is that I should pressurize the shafts when running bronze bushings in the rockers?

I don’t see any major problems with what you have currently done. This is not rocket science and because the shafts are easily accessed on the car after it has been run, the oiling to the top end can be easily modified without a lot of difficulty if you don’t like what you see.

The rocker arm to shaft clearance is a key player in determining if the overflow tubes are to be retained when using bronze bushed rocker arms. On my end, 0.002” clearance requires that the rocker arms be pressurized when using the Harland Sharp bronze bushed roller tipped rockers. As the rocker to shaft clearances becomes larger (~0.004+) then gravity flow comes into play and especially if using a lighter weight oil. If pressurizing with excessive clearances, then oil flow can become excessive at the rockers depending upon what modifications took place at the cam journal to increase the oil flow to the top end. It’s not unusual to have to put an oil restrictor in each rocker arm shaft assembly to bring the oil flow back under control. In these cases, I’ll use a 0.078” restrictor.

|

|

By 1946international - 6 Years Ago

|

Ted, thanks. I think what I'll do is when I get to that point I'll look at the rockers in the other motor and see how they are wearing and make that decision then but I think I will cut the cam groove deeper, up to the spec Phil called out in needed.

Should we get into the "steam" holes. I read your and other's posts about that and some like them but most don't. I'm leaning towards drilling them as they are drilled in my other motor and it stays cool. I do understand these holes don't have much cooling effect, they are more about filling the system. to make sure the system gets full with no air trapped, is that right? Inn my case, the radiator is way above the block so it should fill fine, so maybe I won't drill them.

|

|

By 1946international - 6 Years Ago

|

|

Just checked, Rock auto has those cam bearings for $27 not bad at all

|

|

By 1946international - 6 Years Ago

|

Joe-JDC (6/15/2020)

#4. If you look in your valley, there is a trough that channels oil to the front timing gear area. Elongate that hole so that the oil drains freely, and you should be ok. The holes in the valley for camshaft oiling need to be in a specific place, or you are slinging the oil in the wrong direction. The rest of your questions are dependent on how much time you are willing to spend for little return. Joe-JDC

"elongate that hole" I see the trough and my block has two holes that drain down to the chain. the holes are at a place that the oil will drain, not sure what you mean. I don't think I'll do the valley drilling, I don't know of Y blocks wiping cams so that looks like a fix looking for a problem if you know what I mean.

|

|

By 1946international - 6 Years Ago

|

|

Does anyone know of a supplier for bushings that can be used in the rockers? I guess I could just buy some bronze and make them but if there is a correct one out there I may be able to cut out the hole in some worn out rockers and just push the in.

|

|

By 2721955meteor - 6 Years Ago

|

i have a 292 with drain rocker tubes removed. , came grove enlarged new cm refaced lifters,289 valve seals. i ran the engine hot oil valve covers off,excelent supply of oil.the spinning pushrods cary oil into valley, as well as drain holes under the valve covers each end of the heads. this engine wasfreshend 3years ago and i use it lots in my1949 merchants f47.

my storey is most cam failures on Y blocks was but to poor lub to top end. the289 valve seals do a better job than the seals in oh kits.

no issues with timing chain frame lack of oil. just look at lube system in fes and sb fords 260/289. just my take on how to make aY with minor upgrades will last many miles. i run a 600cfm holley on a 57 4v intake, and dura spark conversion

|

|

By Ted - 6 Years Ago

|

|

1946international (6/15/2020)

2. if I do block off the drain tubes, should I drill the small hole in the block at the cam plate?

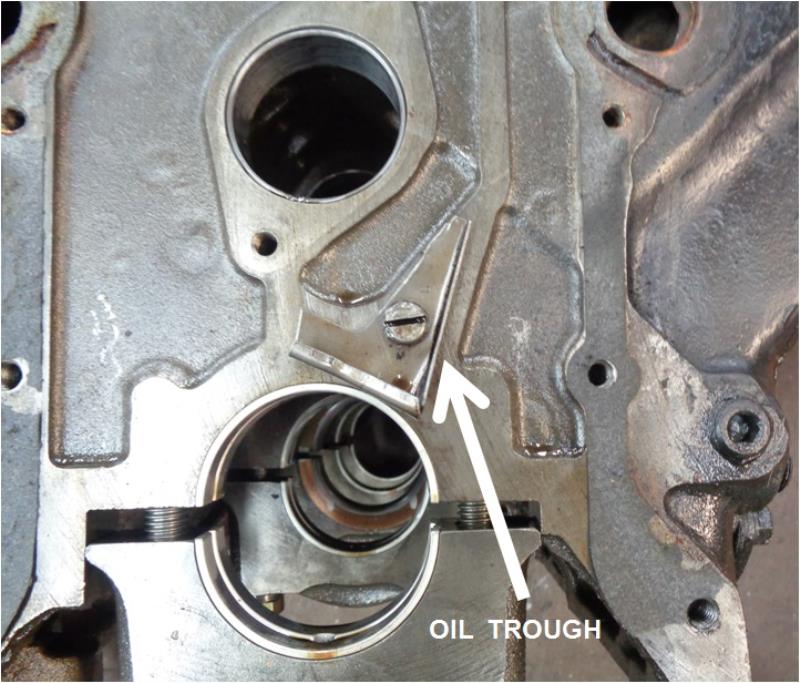

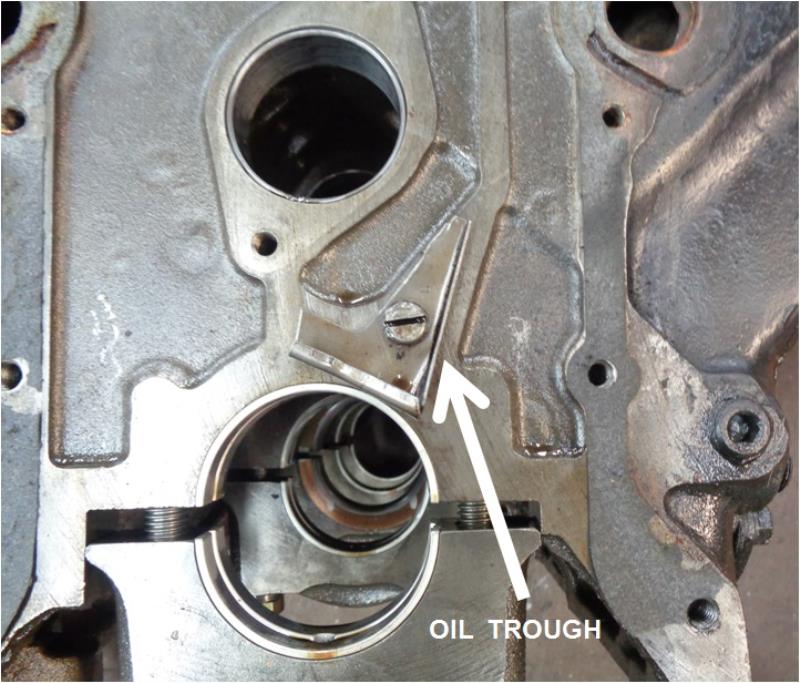

I have done this modification and it does restore the oil flow going to the timing set that is cut off when the passenger side (right side for the Aussies) rocker shaft overflow tube is eliminated or blocked off. I’ll add that I do install the ‘early production’ oil trough behind the timing gear set when doing this oiling modification as that trough just insures that more of the oil does gets redirected to the chain rather than slip in behind it. I’ll credit Tim McMaster for coming up with idea of adding the oil hole behind the cam thrust plate. Here's a picture of the aforementioned oil trough.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/15/2020)

8. any other things that I have not heard of?

Drain any old fuel from the gas tank with any new engine build or any engine that has sat dormant for awhile. Old fuel can create a ‘varnish’ or a gummy coating on the valve stems and this causes the valves to stick once the engine has cooled after its initial run in. Bent pushrods are the first indication of this and broken rockers are a real possibility when the pushrods have been upgraded to the stronger tubular styles.

|

|

By 1946international - 6 Years Ago

|

Ted (6/18/2020)

1946international (6/15/2020)

2. if I do block off the drain tubes, should I drill the small hole in the block at the cam plate?I have done this modification and it does restore the oil flow going to the timing set that is cut off when the passenger side (right side for the Aussies) rocker shaft overflow tube is eliminated or blocked off. I’ll add that I do install the ‘early production’ oil trough behind the timing gear set when doing this oiling modification as that trough just insures that more of the oil does gets redirected to the chain rather than slip in behind it. I’ll credit Tim McMaster for coming up with idea of adding the oil hole behind the cam thrust plate. Here's a picture of the aforementioned oil trough.

I have had three Y block motors apart and none of them have had that "oil trough" I have seen the threaded hole that mounts it, in fact I first saw one on a thread here and asked what it was.... anyway I don't have one so I have to ask, is the hole worth it if I don't install a "oil trough" And as I have seen most of these holes drilled under the cam plate how does oil come out to do any good? would it be better to drill the hole a little lower?

|

|

By 1946international - 6 Years Ago

|

Ted (6/18/2020)

1946international (6/15/2020)

8. any other things that I have not heard of?Drain any old fuel from the gas tank with any new engine build or any engine that has sat dormant for awhile. Old fuel can create a ‘varnish’ or a gummy coating on the valve stems and this causes the valves to stick once the engine has cooled after its initial run in. Bent pushrods are the first indication of this and broken rockers are a real possibility when the pushrods have been upgraded to the stronger tubular styles.

Thanks but there is no stale gas in this car... it gets driven a lot. the car is a blast and sounds great. The only reason I'm building another motor is that the one in the car needed to be bored and I just put it back without doing it. this way I can have this motor together for a quick weekend swap.

Speaking about cars or motors sitting around, There is a good chance this motor will sit after being assembled, should I break in the cam and then let it sit or not start it until it gets installed in the car? I guess the cam will get installed in the motor in the next 30 days and the rest of the motor completed by the end of September but not installed in car until January.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/18/2020)

Speaking about cars or motors sitting around, There is a good chance this motor will sit after being assembled, should I break in the cam and then let it sit or not start it until it gets installed in the car? I guess the cam will get installed in the motor in the next 30 days and the rest of the motor completed by the end of September but not installed in car until January

My preference is for freshly rebuilt engines not to be fired up until ready to be installed and driven. Starting them up and then letting them sit for awhile before driving removes the break in lube from the various parts which then makes these engines susceptible to accelerated wear or failure when restarted later. Regardless of how long an engine sits before starting it up, it’s important that it be stored in an area that does not experience any condensation buildup that occurs due to dew point temperatures taking place. Any engine not stored in a climate controlled area is subject to condensation issues during both the Fall and Spring seasons.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/18/2020)

I have had three Y block motors apart and none of them have had that "oil trough". I have seen the threaded hole that mounts it, In fact I first saw one on a thread here and asked what it was.... anyway I don't have one so I have to ask, is the hole worth it if I don't install a "oil trough". And as I have seen most of these holes drilled under the cam plate how does oil come out to do any good? would it be better to drill the hole a little lower?

While the oil trough on the front of the block behind the timing set is a nice feature to have, it’s not a must. It was originally designed to work in tandem with the oil coming from the forward facing valley hole in the block that was getting its oil supply from the rocker arm overflow tube. Ford discontinued the oil troughs early during the 1957 run but I’ll add them to engines when they are available.

If doing the drilled hole behind the thrust plate, it’s important that the hole be under the thrust plate and not below it. By having the hole behind the thrust plate, the plate can be grooved appropriately to direct the oil to the side rather than shooting straight forward which can potentially flood the front seal area. The sideways movement of the oil will do more good for oiling the timing chain than a forward movement of the oil. An advantage to having the hole under the plate is that the groove on the plate is the final determination of the amount of oil being moved at that point rather than the freshly drilled hole under the cam journal hole.

|

|

By 1946international - 6 Years Ago

|

|

Great, thanks. when you say grind the groove to direct the oil to the side, you are saying the right and left side of the motor, not grind it down towards the crank right?

|

|

By Ted - 6 Years Ago

|

|

1946international (6/22/2020)

Great, thanks. when you say grind the groove to direct the oil to the side, you are saying the right and left side of the motor, not grind it down towards the crank right?

My preference when doing this particular modification is to have the oil coming out towards the oil filter side of the engine. That would appear to be the shortest path based on how the cam retainer plate attaches to the block. Don’t get carried away with the sizing of the drilled hole in the block or the groove in the back side of the retaining plate. It doesn’t take much oil at this point to be effective.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/15/2020)

6. how important is it to have the posted heads? I have a set of each but the posted set will need more work and you know these motors are not cheap. Both sets are uncut and I'm running stock pistons. both sets are the big valve heads.

If you already have a rebuildable pair of posted ECZ-G heads, then those are the heads to work with versus using an unposted pair.

Posted heads came about as a result of head gasket sealing problems on the stock engines using the early production ECZ-G heads. 312’s were just more problematic due to the increased compression ratio on those engines but the problem exists across the board regardless of cubic inches. The service manual recommends only a maximum of 0.010” be removed from the unposted ‘G’ heads when milling is required but I have managed to mill those heads as much as 0.025” on stock engine builds and get away with it. The air/fuel ratios and timing are important when it comes to using unposted heads as those heads do not tolerate the tune up deviating too far from perfect. I can speak from experience that milling those particular heads in the 0.050”-0.065” range is asking for trouble regardless of the tune up. The unposted heads are okay with stock compression ratios but do not tolerate any increases in the compression ratio that comes about as a result of zero decking, excessive milling of the decks and/or heads, cubic inch increases and/or pop up pistons. Adding the posts to unposted heads is a suitable fix for those G heads that were originally unposted.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/15/2020)

4. I have a book that shows drilling holes close to the tappet bores in the valley to let oil drain down to the cam, should I do that? if so, won't that reduce the amount of oil draining down to the timing chain and dist gear?

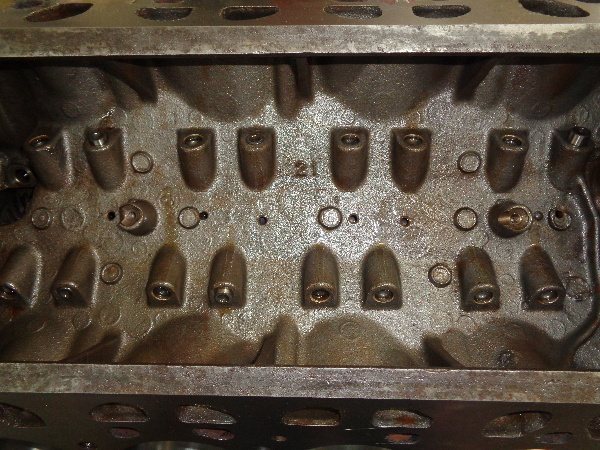

I’m guessing you are looking at the ‘James Eickman’ book? Since the 1984 publication of that book, it’s been shown that the added holes actually have the reverse effect in that oil is relieved from the cam tunnel area rather than suplementing the amount of oil going to the camshaft. Testing on the dyno with a clear cover over the valley shows an abundant amount of oil coming up out of those drilled holes rather than oil in the valley draining into them. Drilling those additional holes does not take away from the oil feeding the timing chain and gears as that oil is being supplied by a separate trough in the valley area.

If there’s any reason to add the holes, it would be to relieve crankcase pressure in the oil pan area as there are only three holes from the factory in the block to allow that pressure to be relieved to the topside of the engine. I’ll drill holes in the valley for pressure relief purposes but I’ll only drill those holes over lobes supplying oil to lifters on the left (U.S.A drivers’ side) bank. This modification is only performed on performance engines where excessive crankcase pressure could potentially be a problem when running at full throttle. Stock engines do not need any added holes to the valley. Here’s a picture of what I do on the performance Y engines in regards to added holes in the valley.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/15/2020)

8. any other things that I have not heard of?

Watch out for the length of any new or replacement flywheel or flexplate bolts. If they are too long, they will contact the back of the block and the rear main seal holder. If the bolts do this, then premature damage to the center main (thrust bearing) is likely.

|

|

By 1946international - 6 Years Ago

|

Ted (6/22/2020)

1946international (6/22/2020)

Great, thanks. when you say grind the groove to direct the oil to the side, you are saying the right and left side of the motor, not grind it down towards the crank right?My preference when doing this particular modification is to have the oil coming out towards the oil filter side of the engine. That would appear to be the shortest path based on how the cam retainer plate attaches to the block. Don’t get carried away with the sizing of the drilled hole in the block or the groove in the back side of the retaining plate. It doesn’t take much oil at this point to be effective.

Great, I think the size hole I have see talk about is 0.060"

|

|

By 1946international - 6 Years Ago

|

Ted (6/22/2020)

1946international (6/15/2020)

6. how important is it to have the posted heads? I have a set of each but the posted set will need more work and you know these motors are not cheap. Both sets are uncut and I'm running stock pistons. both sets are the big valve heads.If you already have a rebuildable pair of posted ECZ-G heads, then those are the heads to work with versus using an unposted pair. Posted heads came about as a result of head gasket sealing problems on the stock engines using the early production ECZ-G heads. 312’s were just more problematic due to the increased compression ratio on those engines but the problem exists across the board regardless of cubic inches. The service manual recommends only a maximum of 0.010” be removed from the unposted ‘G’ heads when milling is required but I have managed to mill those heads as much as 0.025” on stock engine builds and get away with it. The air/fuel ratios and timing are important when it comes to using unposted heads as those heads do not tolerate the tune up deviating too far from perfect. I can speak from experience that milling those particular heads in the 0.050”-0.065” range is asking for trouble regardless of the tune up. The unposted heads are okay with stock compression ratios but do not tolerate any increases in the compression ratio that comes about as a result of zero decking, excessive milling of the decks and/or heads, cubic inch increases and/or pop up pistons. Adding the posts to unposted heads is a suitable fix for those G heads that were originally unposted. both the posted and unposted heads I have, have not been cut so I would hope it would not take too much to get them flat. That and the fact that this will be a stock style piston, so close to stock compression ratio, it is bored 0.040". I should be ok with the unposted heads.

Can you add anything to the "adding posts to unposted heads" fix. I was thinking about if that was possible.

|

|

By 1946international - 6 Years Ago

|

I have come to the conclusion that I won't drill the holes in the valley, others have also said it is not a good idea. Thanks for the info about it. also the tip on the flywheel bolts, I have the stock bolts but will check when they go in.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/22/2020)

Can you add anything to the "adding posts to unposted heads" fix. I was thinking about if that was possible.

See if one of these links to past threads regarding posted heads helps you out.

Advantages of posted heads

Identifying posted heads

Posting G heads (how to)

Posting G heads (tutorial)

|

|

By 1946international - 6 Years Ago

|

|

Thanks Ted for the info and I hope no one minds that I brought that 10 year old thread about posting heads back up to the top.

|

|

By Ted - 6 Years Ago

|

|

1946international (6/15/2020)

5. steam holes, I think some have said not to do this as it may cause cracks in head or block but I'll be running this with a stock Model A radiator. the 292 in the car now has the steam holes drilled and stays cool. thoughts? Radiator fill is well above the motor.

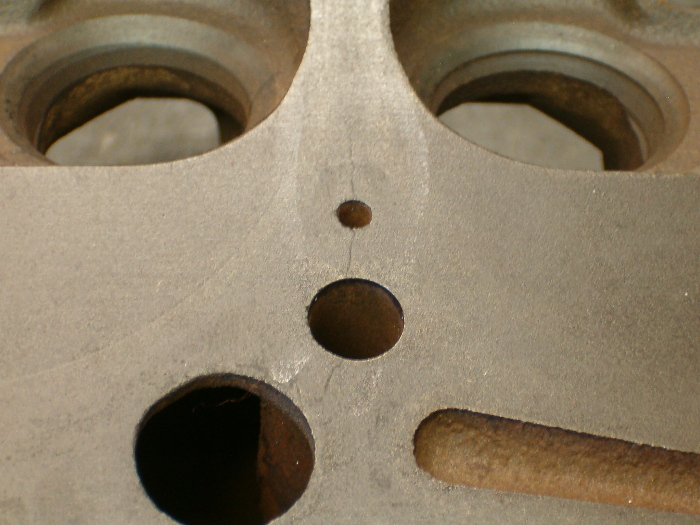

There's always controversy on this subject but here's my take on it. If the steam holes are present in both the heads and block, I’ll leave them. That doesn’t happen very often as I don’t have to build very many engines with late model heads. Under no circumstances will I drill a block that has no steam holes to accommodate steam holes in the heads. Because I deal with a large number of non-steam hole heads, I will use cast iron plugs in the block decks to do away with those steam holes when present before decking or machining the decks. Here’s a picture of a head with a crack going thru the aforementioned steam hole.

|

|

By 1946international - 6 Years Ago

|

Well, I guess that settles that! the block I'm building now has no holes and the unposted heads do not either, my posted heads on the running car have the holes. to tell you the truth I'm leaning on putting the money in the non-posted heads when I get to that point. I hope to be installing cam bearings and freeze plugs this weekend.

Thanks

|

|

By 1946international - 6 Years Ago

|

Well, not I can finely get back to putting this motor together and have gone as far as I can without a camshaft. So here it comes, can anyone help suggest a cam for this? What I have is a 292 with stock flat top pistons .040 over, the '57 big valve heads, '57 4 bbl stock intake and the stock #1272list Holley carb. I think this is a 450cfm carb but I may go to a 600 cfm Holley at some time. The car is a 1930 Model A with 3.73 gears and tall 30" rear tires and 3 speed T bird transmission. This will be use to drive around the street not a race car. any help would be appreciated. I have been looking at a Isky E4, I also see that John Mummert does not sell his two mildest cams any more the y265-s & y270-s but offers a y280-1-11 with a .500" lift, I think i'll have to cut the valve guides with that much lift so would like to stay away from that. Clay Smith has two that look good, the #c-265-0-b w/ 224* @ .050 & .440 lift, with 110*lsa, and #c-272-8-b w/ 224* @ .050 and .446 lift with 108* lsa .

any ideas?

|

|

By Cliff - 6 Years Ago

|

|

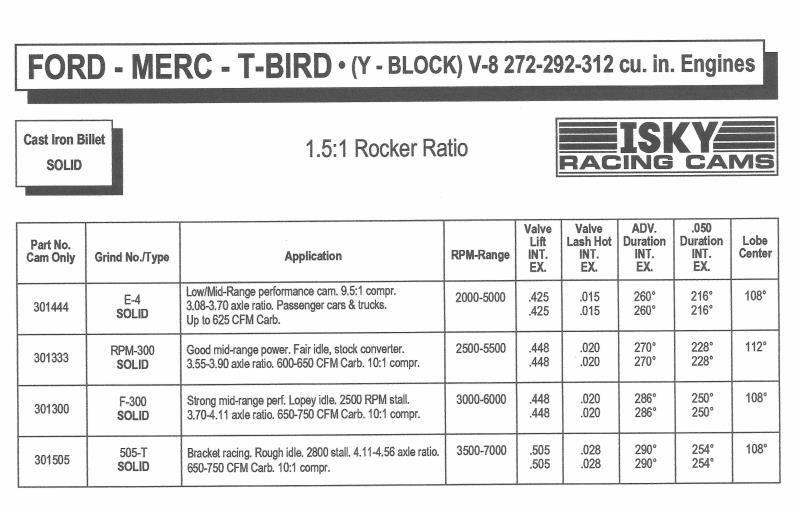

Isky E 4 is nice, or for a rumble the RPM 300

|

|

By 1946international - 6 Years Ago

|

|

what is a RPM 300?

|

|

By Cliff - 6 Years Ago

|

|

Isky RPM 300 cam

|

|

By 1946international - 6 Years Ago

|

|

OK thanks, I have that one on my list as # ISK301333 , that may be a little too much with a rpm range of 2500-5500

|

|

By Ted - 6 Years Ago

|

1946international (9/12/2020)

Well, now I can finally get back to putting this motor together and have gone as far as I can without a camshaft. So here it comes, can anyone help suggest a cam for this? What I have is a 292 with stock flat top pistons .040 over, the '57 big valve heads, '57 4 bbl stock intake and the stock #1272list Holley carb. I think this is a 450cfm carb but I may go to a 600 cfm Holley at some time. The car is a 1930 Model A with 3.73 gears and tall 30" rear tires and 3 speed T bird transmission. This will be use to drive around the street not a race car. any help would be appreciated. I have been looking at a Isky E4, I also see that John Mummert does not sell his two mildest cams any more the y265-s & y270-s but offers a y280-1-11 with a .500" lift, I think i'll have to cut the valve guides with that much lift so would like to stay away from that. Clay Smith has two that look good, the #c-265-0-b w/ 224* @ .050 & .440 lift, with 110*lsa, and #c-272-8-b w/ 224* @ .050 and .446 lift with 108* lsa . any ideas?

Much of this likely depends what you ultimately would like performance wise. The Isky E4 is a good all around camshaft with just enough rumble to let you know the engine has a camshaft in it. The Isky RPM-300 is definitely a better performer but is expected to be a tad softer in performance right off of idle and part of that will be associated with the 112° lobe centerline it is ground on. If I was special ordering this camshaft straight from Isky, I would specify that it be ground on 110° lobe centers. At 3000 rpm and with 112° lobe centers, it is expected to come on much stronger than the E4. My ’55 Customline with a 272 has the E4 and idles good while still being a good all around driver. The 312 I use as a dyno mule has the 238/238 Crower camshaft ground on 110° lobe centers and it also idles good with a noticeable rumble but is strong with mildly ported G heads well past 5500 rpm. The 312 dyno mule also uses a Mummert intake and 750 cfm Holley carb. Considering the weight of your car along with the transmission and gearing, I would lean towards the Isky RPM-300 with a 600 or 750 carb if looking for a good compromise between daily driver and good performance. Regardless of what camshaft you select, take the time to degree it in to insure it is installed exactly where it needs to be. 4-5° of advance is typically recommended with a new timing set in place.

|

|

By 1946international - 6 Years Ago

|

|

Thanks for your thoughts, I guess it is coming down to the E4 or the RPM-3000. Can you confirm that the RPM-3000 is the ISK 301333? I also have to go back and check the cam card on the cam that is in the car now. I always thought it was too much cam as it did not pull real good until over 2500 RPM but that is with a Ford-o-matic and I did not degree it in. I will be sure to do that this time.

|

|

By Ted - 6 Years Ago

|

See if this helps.

|

|

By 1946international - 6 Years Ago

|

|

YES, like always, Thanks

|

|

By Florida_Phil - 6 Years Ago

|

I have an Isky 301333 cam in TBird. My engine is a near stock 1957 292 bored .060", iron 312 intake, Holley 4V and a manual transmission with O/D. I love this cam. It has a noticeable lope at idle, just enough so you can hear the cam pop through the tailpipes. Low RPM torque is good, mid range is outstanding. The only modification I made was to cut the cam oil grove to .030" deep. It pulls hard to 5,000 rpm. I have never revved my engine higher than that. If you want a quiet engine, this cam may not be for you. If you want a muscle car sound and feel, I think it's perfect.

|

|

By 1946international - 6 Years Ago

|

|

Great, Thanks Phil, you and Ted are making this easy.

|

|

By 1946international - 6 Years Ago

|

If I have not made it clear, I have a running 292 in the car now, i'm just building another one that will be a little better. So as far as cam selection goes,

What I have in the car now, .471 lift 224 In/230 Ex duration at .050 lift 108* LSA

The thing is this lift is way more than other cams I have found

ISKY 2000-5000rpm .425 lift w/ 216* duration at .050 lift 108*LSA

ISKY 2500-5500rpm .448 lift w/ 228* duration @ .050 112* lsa

ISKY 3000-6000rpm .448 lift W/250* duration 108* LSA

Clay smith 1800-5500rpm .440 lift w/ 224* duration 110* LSA

Clay smith 2000-5000 rpm .446 lift w/224* 108* LSA

Clay smith 2500-6200rpm .462 lift w/236* 108* LSA

Howard 1800-5000 rpm .463 w/ 220* 110* LSA

Howard 2800-5400rpm .515 w/238* 110*lsa

Now I have found some info on Isky’s site and Munnert’s site that says I must cut the valve guides when using a can w/ lift more than .450” as you can see the cam in the car is .471 lift and I did not cut valve guides and this set up has been on the car with two different heads.

I have also read that less LSA gives a more choppy idle, more lsa gives a smooth idle. I would hate to give up my idle sound. I guess the CompCams Camshaft I have in the car now is closest to the 2000-5000 RPM Clay smith cam but with less lift.

Any thoughts?

|

|

By Ted - 6 Years Ago

|

You will want to look at lobe lifts on the camshafts when comparing different cam grinders as everyone may not be using the same rocker arm ratio for the valve lift calculations. By looking at the lobe lifts, you can multiply it by whatever rocker ratio you are using to get a more accurate feel for what is happening at the valve. Keep in mind that you will want to subtract the valve lash from any calculated valve lift in order to know the actual valve lift.

As far as what your heads can handle in regards to valve lift, that is typically determined as they are being assembled. If they have been machined for positive type valve seals, then different shops machine the tops of the guides at different depths so that’s an unknown until you actually measure the retainer to seal clearance. Assume nothing.

|

|

By 1946international - 6 Years Ago

|

|

True but most if not all the cam specs I have listed calculated valve lift with 1.5 ratio rockers ( I think one did not specify ratio) and the heads that have been running with that .471 lift cam are stock heads with stock style valve seals. I'm thinking that the .471" lift number may be a misprint, guess I could measure valve travel and see. so is it true that on most Y block builds if you have more than .450 lift at the valve you will need to cut the guide some?

|

|

By Ted - 6 Years Ago

|

1946international (9/22/2020)

True but most if not all the cam specs I have listed calculated valve lift with 1.5 ratio rockers ( I think one did not specify ratio) and the heads that have been running with that .471 lift cam are stock heads with stock style valve seals. I'm thinking that the .471" lift number may be a misprint, guess I could measure valve travel and see. so is it true that on most Y block builds if you have more than .450 lift at the valve you will need to cut the guide some?

Stock ECZ-G and ‘113’ heads with the factory rotator valve spring retainers have ~0.430” between the retainer and umbrella seal. This is before any grinding on the valves and/or valve seats which will increase that measurement. If using a single piece retainer, the clearance between the retainer and seal will increase to ~0.460”.

These measurements only deal with what the cylinder head can tolerate in the way of valve lift. No safety margins for valve float are included. Additional consideration must be taken when dealing with the intake valve in relation to clearance at the edge of the cylinder wall. I typically use 0.535” of intake valve lift as the limit for that. How much the heads are milled and/or valve diameters can have that value varying.

|