|

Author

|

Message

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Ted (6/18/2020)

1946international (6/15/2020)

8. any other things that I have not heard of?Drain any old fuel from the gas tank with any new engine build or any engine that has sat dormant for awhile. Old fuel can create a ‘varnish’ or a gummy coating on the valve stems and this causes the valves to stick once the engine has cooled after its initial run in. Bent pushrods are the first indication of this and broken rockers are a real possibility when the pushrods have been upgraded to the stronger tubular styles. Thanks but there is no stale gas in this car... it gets driven a lot. the car is a blast and sounds great. The only reason I'm building another motor is that the one in the car needed to be bored and I just put it back without doing it. this way I can have this motor together for a quick weekend swap. Speaking about cars or motors sitting around, There is a good chance this motor will sit after being assembled, should I break in the cam and then let it sit or not start it until it gets installed in the car? I guess the cam will get installed in the motor in the next 30 days and the rest of the motor completed by the end of September but not installed in car until January.

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/18/2020)

Speaking about cars or motors sitting around, There is a good chance this motor will sit after being assembled, should I break in the cam and then let it sit or not start it until it gets installed in the car? I guess the cam will get installed in the motor in the next 30 days and the rest of the motor completed by the end of September but not installed in car until JanuaryMy preference is for freshly rebuilt engines not to be fired up until ready to be installed and driven. Starting them up and then letting them sit for awhile before driving removes the break in lube from the various parts which then makes these engines susceptible to accelerated wear or failure when restarted later. Regardless of how long an engine sits before starting it up, it’s important that it be stored in an area that does not experience any condensation buildup that occurs due to dew point temperatures taking place. Any engine not stored in a climate controlled area is subject to condensation issues during both the Fall and Spring seasons.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/18/2020)

I have had three Y block motors apart and none of them have had that "oil trough". I have seen the threaded hole that mounts it, In fact I first saw one on a thread here and asked what it was.... anyway I don't have one so I have to ask, is the hole worth it if I don't install a "oil trough". And as I have seen most of these holes drilled under the cam plate how does oil come out to do any good? would it be better to drill the hole a little lower?While the oil trough on the front of the block behind the timing set is a nice feature to have, it’s not a must. It was originally designed to work in tandem with the oil coming from the forward facing valley hole in the block that was getting its oil supply from the rocker arm overflow tube. Ford discontinued the oil troughs early during the 1957 run but I’ll add them to engines when they are available.

If doing the drilled hole behind the thrust plate, it’s important that the hole be under the thrust plate and not below it. By having the hole behind the thrust plate, the plate can be grooved appropriately to direct the oil to the side rather than shooting straight forward which can potentially flood the front seal area. The sideways movement of the oil will do more good for oiling the timing chain than a forward movement of the oil. An advantage to having the hole under the plate is that the groove on the plate is the final determination of the amount of oil being moved at that point rather than the freshly drilled hole under the cam journal hole.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Great, thanks. when you say grind the groove to direct the oil to the side, you are saying the right and left side of the motor, not grind it down towards the crank right?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/22/2020)

Great, thanks. when you say grind the groove to direct the oil to the side, you are saying the right and left side of the motor, not grind it down towards the crank right?My preference when doing this particular modification is to have the oil coming out towards the oil filter side of the engine. That would appear to be the shortest path based on how the cam retainer plate attaches to the block. Don’t get carried away with the sizing of the drilled hole in the block or the groove in the back side of the retaining plate. It doesn’t take much oil at this point to be effective.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/15/2020)

6. how important is it to have the posted heads? I have a set of each but the posted set will need more work and you know these motors are not cheap. Both sets are uncut and I'm running stock pistons. both sets are the big valve heads.If you already have a rebuildable pair of posted ECZ-G heads, then those are the heads to work with versus using an unposted pair. Posted heads came about as a result of head gasket sealing problems on the stock engines using the early production ECZ-G heads. 312’s were just more problematic due to the increased compression ratio on those engines but the problem exists across the board regardless of cubic inches. The service manual recommends only a maximum of 0.010” be removed from the unposted ‘G’ heads when milling is required but I have managed to mill those heads as much as 0.025” on stock engine builds and get away with it. The air/fuel ratios and timing are important when it comes to using unposted heads as those heads do not tolerate the tune up deviating too far from perfect. I can speak from experience that milling those particular heads in the 0.050”-0.065” range is asking for trouble regardless of the tune up. The unposted heads are okay with stock compression ratios but do not tolerate any increases in the compression ratio that comes about as a result of zero decking, excessive milling of the decks and/or heads, cubic inch increases and/or pop up pistons. Adding the posts to unposted heads is a suitable fix for those G heads that were originally unposted.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/15/2020)

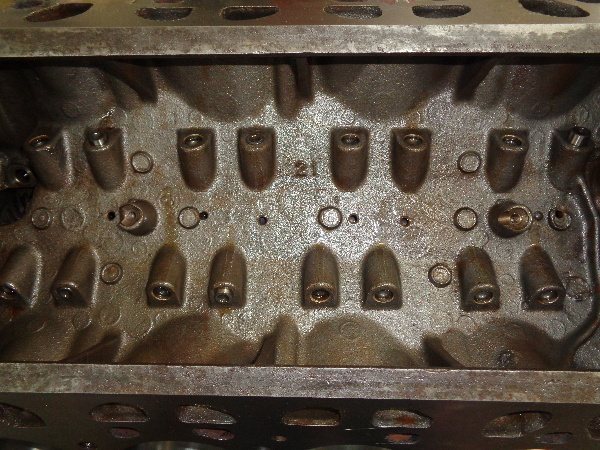

4. I have a book that shows drilling holes close to the tappet bores in the valley to let oil drain down to the cam, should I do that? if so, won't that reduce the amount of oil draining down to the timing chain and dist gear?I’m guessing you are looking at the ‘James Eickman’ book? Since the 1984 publication of that book, it’s been shown that the added holes actually have the reverse effect in that oil is relieved from the cam tunnel area rather than suplementing the amount of oil going to the camshaft. Testing on the dyno with a clear cover over the valley shows an abundant amount of oil coming up out of those drilled holes rather than oil in the valley draining into them. Drilling those additional holes does not take away from the oil feeding the timing chain and gears as that oil is being supplied by a separate trough in the valley area. If there’s any reason to add the holes, it would be to relieve crankcase pressure in the oil pan area as there are only three holes from the factory in the block to allow that pressure to be relieved to the topside of the engine. I’ll drill holes in the valley for pressure relief purposes but I’ll only drill those holes over lobes supplying oil to lifters on the left (U.S.A drivers’ side) bank. This modification is only performed on performance engines where excessive crankcase pressure could potentially be a problem when running at full throttle. Stock engines do not need any added holes to the valley. Here’s a picture of what I do on the performance Y engines in regards to added holes in the valley.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

1946international (6/15/2020)

8. any other things that I have not heard of?Watch out for the length of any new or replacement flywheel or flexplate bolts. If they are too long, they will contact the back of the block and the rear main seal holder. If the bolts do this, then premature damage to the center main (thrust bearing) is likely.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Ted (6/22/2020)

1946international (6/22/2020)

Great, thanks. when you say grind the groove to direct the oil to the side, you are saying the right and left side of the motor, not grind it down towards the crank right?My preference when doing this particular modification is to have the oil coming out towards the oil filter side of the engine. That would appear to be the shortest path based on how the cam retainer plate attaches to the block. Don’t get carried away with the sizing of the drilled hole in the block or the groove in the back side of the retaining plate. It doesn’t take much oil at this point to be effective. Great, I think the size hole I have see talk about is 0.060"

|

|

|

|

|

1946international

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 107,

Visits: 21.5K

|

Ted (6/22/2020)

1946international (6/15/2020)

6. how important is it to have the posted heads? I have a set of each but the posted set will need more work and you know these motors are not cheap. Both sets are uncut and I'm running stock pistons. both sets are the big valve heads.If you already have a rebuildable pair of posted ECZ-G heads, then those are the heads to work with versus using an unposted pair. Posted heads came about as a result of head gasket sealing problems on the stock engines using the early production ECZ-G heads. 312’s were just more problematic due to the increased compression ratio on those engines but the problem exists across the board regardless of cubic inches. The service manual recommends only a maximum of 0.010” be removed from the unposted ‘G’ heads when milling is required but I have managed to mill those heads as much as 0.025” on stock engine builds and get away with it. The air/fuel ratios and timing are important when it comes to using unposted heads as those heads do not tolerate the tune up deviating too far from perfect. I can speak from experience that milling those particular heads in the 0.050”-0.065” range is asking for trouble regardless of the tune up. The unposted heads are okay with stock compression ratios but do not tolerate any increases in the compression ratio that comes about as a result of zero decking, excessive milling of the decks and/or heads, cubic inch increases and/or pop up pistons. Adding the posts to unposted heads is a suitable fix for those G heads that were originally unposted. both the posted and unposted heads I have, have not been cut so I would hope it would not take too much to get them flat. That and the fact that this will be a stock style piston, so close to stock compression ratio, it is bored 0.040". I should be ok with the unposted heads. Can you add anything to the "adding posts to unposted heads" fix. I was thinking about if that was possible.

|

|

|

|