|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

|

|

Group: Forum Members

Last Active: 9 days ago

Posts: 799,

Visits: 113.5K

|

Did you produce the red and black enclosures with a 3D printer? Good to see you're back at it....

64F100 57FAIRLANE500

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

No, bought them on E bay, yes I'm back working on my car.

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

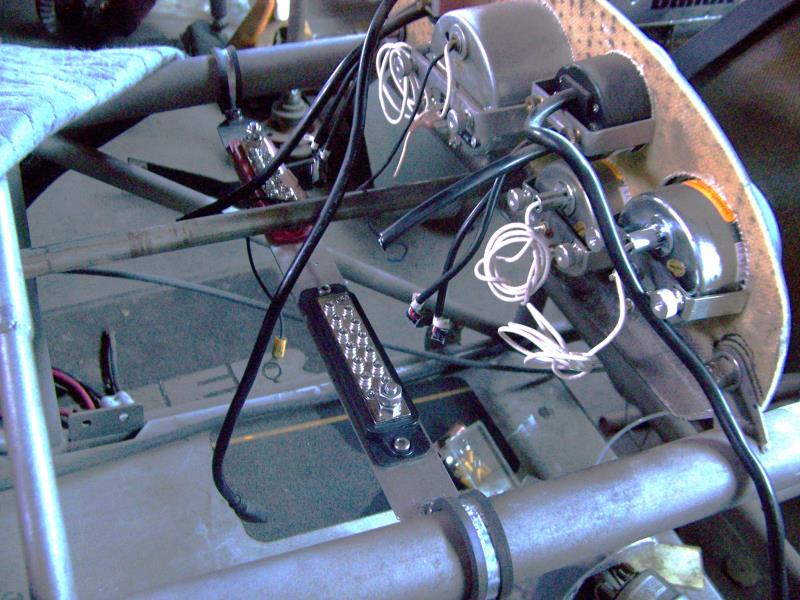

Done

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

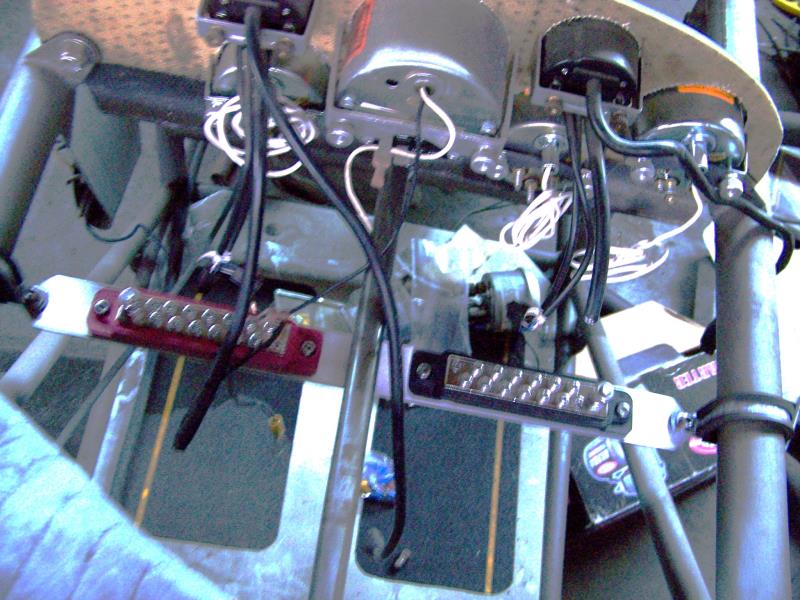

Installed

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Look what I bought, it's brand new, never mounted

|

|

Group: Forum Members

Last Active: 3 days ago

Posts: 1.9K,

Visits: 194.9K

|

Usually we’re asking for pictures. We got pictures, so how about more information.

Thanks

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Latham Supercharger, setup for a Y Block Ford, it took me 2 years to buy this

|

|

Group: Forum Members

Last Active: 3 days ago

Posts: 1.9K,

Visits: 194.9K

|

Thanks Cliff. That quite the set up. An eye catcher for sure.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

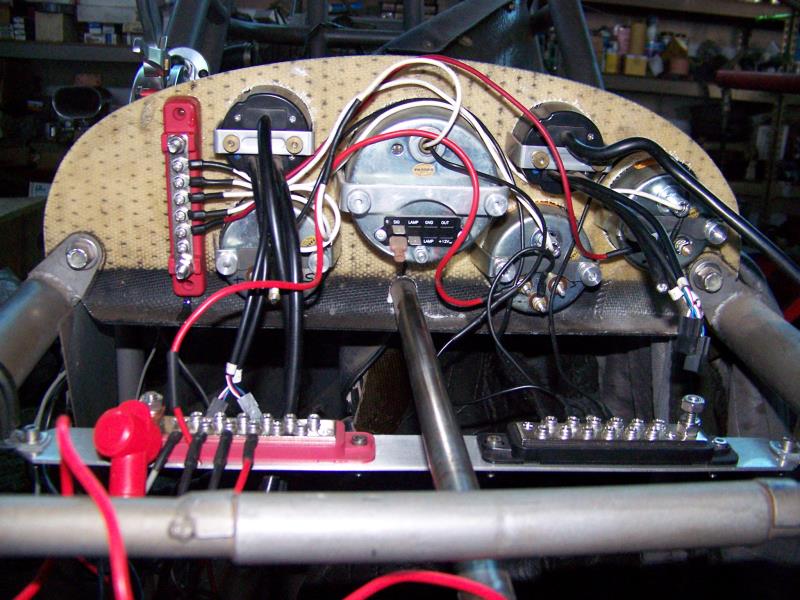

Still working on the dash, lots of wires

|