|

Author

|

Message

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.7K,

Visits: 102.7K

|

There are all sorts of examples of both methods - that worked OK. I believe the web problems were with 312 blocks that had improper hole depths for the main bolts - not so much with the 292's.

Steve Metzger Tucson, Arizona

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

The smaller mains should be fine. The 312 crank may technically be stronger but the smaller main cranks have proven to hold up in race and performance street applications. Other considerations when using 312 mains is bearing availability and cost. Not sure about the cam. I do have the repop cam that Mummert produced a long time ago and it is a little bigger. with that, it is noticeably lacking for off-idle torque, for truck use, even in a 3675lb with me in it F100. Your cam being a little smaller, and with the shorter gearing of the F350 might work out, but it will probably be at the very edge of what is acceptable for your planned use. Ask Crane what they have to say about it.

Lawrenceville, GA

|

|

|

|

|

1960fordf350

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 110,

Visits: 2.9K

|

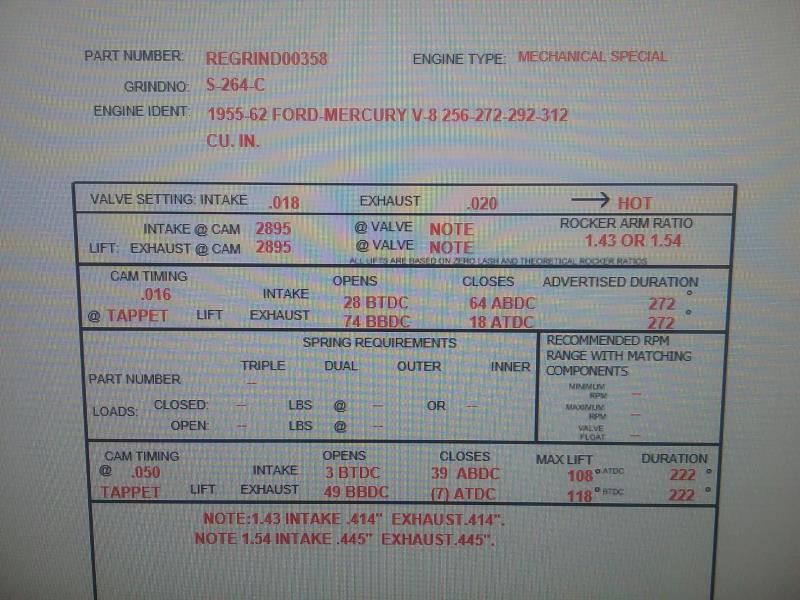

If I line bored the block to the 312 diameter, wouldn't I be back at that chance of cracking a web? Since I'm never going to spin this thing 6,000rpm is that smaller main going to really effect me? Tim McMaster's 58 F100 has been running around for years using a 313cu that he turned down the crank and bored the block. Plus he hauls a 1900lb camper on it. So I'd say his weight is fairly close to mine. I haven't had any machine work done yet, so I'm open to going either way. Back to the cam. Since the engine came with a rollmaster chain, I can degree it where I want. So if I advance it, I will get more torque, no? The specs I received from crane show using either sets of rockers, I have both sizes on my shelf. The question still being, is this cam too big for my application?

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.7K,

Visits: 102.7K

|

Seems to me - Hoosier recommended that a good 312 crank stay in a block machined for the larger mains. Even if it meant having a 292 block opened to the larger size during the machining process, squaring up the block. There is some serious mechanical wisdom in that philosophy - the larger diameter journal is much, much stronger, especially when forged cranks aren't exactly "available".

Steve Metzger Tucson, Arizona

|

|

|

|

|

Genuinerod

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 120,

Visits: 33.3K

|

The numbers are almost the same as the Ford "F" code supercharged cam (B7A-6250-C). I believe you will feel the difference in the upper RPM (3000+). The sheet didn't say what LC was, but the Ford cam was 112 which would give you a little more vacuum. You may not have the pull at low RPM but it will a big upgrade over stock.

|

|

|

|

|

Lou

|

|

|

Group: Forum Members

Last Active: 8 days ago

Posts: 563,

Visits: 8.4K

|

1960ford350 you are building a truck engine, not a hotrod engine, you need torque and reliability, good gas mileage wouldn't hurt either. Start thinking truck, not hotrod.

|

|

|

|

|

1960fordf350

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 110,

Visits: 2.9K

|

Well, progress is hopefully on its way. I picked up a never run 312 that has a cracked block. .060 over pistons, rollmaster chain, and some other new stuff. I disassembled it and pulled the cam. It's a crane cam. I emailed their tech people about the specs. They replied with a copy. Can anyone give me their opinion if its gonna be a good match for my F350? My highway cruising is at about 3,000rpm. Figure 5,000lb for truck.

|

|

|

|

|

NoShortcuts

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 1.4K,

Visits: 179.6K

|

Pat. In having the 312 crank machined for your 292 block, yes, you need to have the main bearing size changed, but remember to have the rear seal diameter and the oil slinger size changed to 292 dimensions, too. Click the link below to see the dimensional info supplied by John Mummert's wed site to provide your machine shop. http://www.ford-y-block.com/crankshaftid.htmHope this helps!  NoShortcuts

NoShortcuts

a.k.a. Charlie Brown

near Syracuse, New York

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

By standard piston, I think you mean a piston made to original specs. In that case, metric rings will not work because the groove will be too wide. The thinner rings will help for torque. Horsepower is a function of torque. Everything else equal, more torque = more horsepower. Whether it is a "screamer" will depend largely on the cam. I think Mummert stocks modern design pistons that fit stock rods and strokes.

Lawrenceville, GA

|

|

|

|

|

1960fordf350

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 110,

Visits: 2.9K

|

I've been reading a lot of posts on here. Lot's of information and ideas. Ted has mentioned a few times about using metric rings for less drag in the bores. Can they be used with the standard rebuild pistons for a Y? Since I'm going to build a torque engine and not a screamer, is there an advantage to it? I now have a 312 crank and rods. Is there any off the shelf pistons that will work on my rods without throwing a bunch of money at it? I plan on pulling my 292 and boring it. I'm going to have the crank turned to the 292 mains.

|

|

|

|