|

By 1960fordf350 - 9 Years Ago

|

Just joined over here, been over at FTE for years.

Hopefully I'm gonna build a fresh engine for my F350. I've been planning on doing this for a good couple years. (best laid plans!)

1st in need to figure out my rpm's I'm running out on the highway. Gear changes make my speedo totally inaccurate, that, and the fact it bounces up and down about 10mph as your driving. The 2nd is my weight. It's a 350 dually flatbed, and the flatbed is homemade diamond plate and heavy. Plus I do carry stuff on the back for show.

I have tires with 31in outside diameter. The diff is running a 5:14 gear. Plus I'm running an auxiliary tranny with a 17% overdrive. Can someone help me with the formula for what rpm's I'd be running at 65mph?

I'm collecting parts and ideas. I was looking at 312 cranks to stuff in my 292 block. I was also looking at mummerts rods that convert 292 crank to a 312. Anyone have experience with them? I have a shortblock still together that has an ec crank in it. I also have the running 292 still in the truck. So I have another crank there too. I plan to bore the block to at least 312, maybe more. I plan to still run the 2 barrel intake on it. It's running a holley 2 barrel with the oil bath air cleaner. I'm running dual exhaust already, eventually I'm hoping to put rams horns on it. I have a pair of ECG-D heads on the shelf, and if I remember right, the engine in the truck has C1TE heads.

OK throw some ideas and info at me

Pat

|

|

By miker - 9 Years Ago

|

Here’s an rpm calculator, you’ll have to do your own math for the o/d since it’s an odd ratio. I think you’re 4.3 or 4.4 if I did the math right.

https://www.ringpinion.com/calculators/Calc_RPM.aspx

I’ve done a couple offset ground 312 cranks, one in a 312 and one in a 292. 340 and 320 cid respectively. The 340 required clearancing the rods to the cam. They’re in a light car, I don’t know how the smaller rod bearings would hold up under a truck load. That would be a question for guys like Mummert or Ted Eaton.

|

|

By 1960fordf350 - 9 Years Ago

|

Thanks for that link Miker. I looked it up and tried to use it. Not quite accurate, but close. I looked back at the papers on the auxiliary, its .85 not what I originally thought. That website won't let me plug it in. It uses its own overdrive ratio of .80 Using that ratio my engine is turning 2897rpm at 65mph. So with my .85 I'll figure 3,000rpm. It shows 3621rpm for straight thru ratio of 1:1. When I 1st bought the truck it had a 5:83 differential in it. That calculator shows 4100rpm at 65mph for a straight transmission. That's screaming!!

So I went out today and scored a brand new set of service heads!! Still in the ford boxes. They are C3TZ-6049-FG heads. For some reason the F is not printed on the box, but is cast FG on the heads. Any ideas about them? I'm considering all new valves for these heads. Definetly gonna install hardened seats in the exhaust.

|

|

By miker - 9 Years Ago

|

Just run your o/d ratio by the 5:14 you’ve got, and then plug that in to the appropriate box in the formula. Should be right on.

Here’s the head casting info from Mummert’s site. It all clear at the bottom of his home page

http://www.ford-y-block.com/cylinderheadchart.htm

|

|

By Ted - 9 Years Ago

|

Welcome to the site.

Increasing the compression ratio is the easiest route for a torque increase. That can be done by decking the block and/or milling the cylinder heads. After that, consider a camshaft with an increase in intake duration. The 1958-1964 factory camshaft grinds are pretty dismal from a performance standpoint so almost any upgrade in this area will help. Even the stock 1957 grind would be a significant upgrade over the 60-64 truck grinds. Consider some mild port work to both the heads and intake manifold as this will also be beneficial even though you are keeping the two barrel carb. But also consider a larger two barrel carb as the original carburetors are conservatively sized.

Compression ratios are dependent upon the combustion chamber volumes and as such, the cylinder heads after 1960 concentrated on larger chambers in order to lower the compression ratio. Stepping up to a set of 1956 cylinder heads with the intermediate intake valve sizes would also help in lieu of the C1TE or ECG heads. ECZ-G or ‘113” heads (1957-1959) with the even larger 1.92” intake valves would be even better but prepared to look for these if you don’t have any handy. And last but not least, consider upgrading to a set of 1.54:1 rockers instead of the stock 1.43:1 rockers.

|

|

By 1960fordf350 - 9 Years Ago

|

Thanks for chiming in Ted. I know you go through these questions all the time. It's 50 outside in Parma today, so I went out to the garage. Upon further investigation, I found C1TE cast in the heads on the side that the head gaskets seal. Then I have the ECG-D heads on the shelf. Which ones would I be better to throw money at? Then I moved on to the 292 I have on the engine stand. I picked it up a couple years ago as scrap. It had been supposedly drag raced, who knows. It has an EC crank and EBU rods, but the pistons stick out of the block .0021. They had double stacked head gaskets on it. I pulled the front apart this morning and pulled the cam. I was thinking of some radical thing. NOT!! Lol Its got a FoMoCo cam in it. The only id numbers on it are behind the 1st lobe at the front of the cam. The 1st number is

67, when you roll it over 180* it has an 81. Anyways, doubt I'll use that one.

|

|

By Ted - 9 Years Ago

|

|

1960fordf350 (12/19/2017)

....Upon further investigation, I found C1TE cast in the heads on the side that the head gaskets seal. Then I have the ECG-D heads on the shelf. Which ones would I be better to throw money at?

If wanting an increase in the torque values, then consider using the ECG heads as the combustion chamber design in those are more conducive to promoting additional turbulence at low rpms.

|

|

By PF Arcand - 9 Years Ago

|

About the pistons sticking out of the block. Possibly the block has been decked excessively? Or, and I may be corrected on this, it may have been re assembled with truck pistons that have a different wrist pin height.

|

|

By 1960fordf350 - 9 Years Ago

|

That was my thought about pin height. I believe that HD pistons used a different height pin. The pistons have a 30 in the top, but I haven't popped one out to see if its an oversize. I don't plan to rebuild that block. I plan on rebuilding the block that's still running in the truck. For right now I'm concentrating on the top end. I checked the rocker arms I have, they are ECG 6564 rockers. They are not loose on the shafts. The shafts don't look scored either. So I call that a score! Now for the heads. I was looking at the valves. I don't have any micrometers. Will the 1.78 intake valve sit down in the 1.64 hole? I was able to take a intake valve from the ECG-D head and it fit right in the new head. So now I don't know what head I have. I can't see any posts in through the holes in the head.

|

|

By 1960fordf350 - 9 Years Ago

|

Happy New Year!! Having some time off I've been playing with my project. I finally popped the pistons out of the block I have on the stand. My neighbor has a harbor freight micrometer I borrowed. Not the best, but close. I'm getting 1.75 for the center of the pin to the top of the piston. So, the block has been decked. I'm wondering if the stacked head gaskets had more to do with the intake not meeting the heads with the block decked that far. I didn't have an intake with the engine when I bought it.

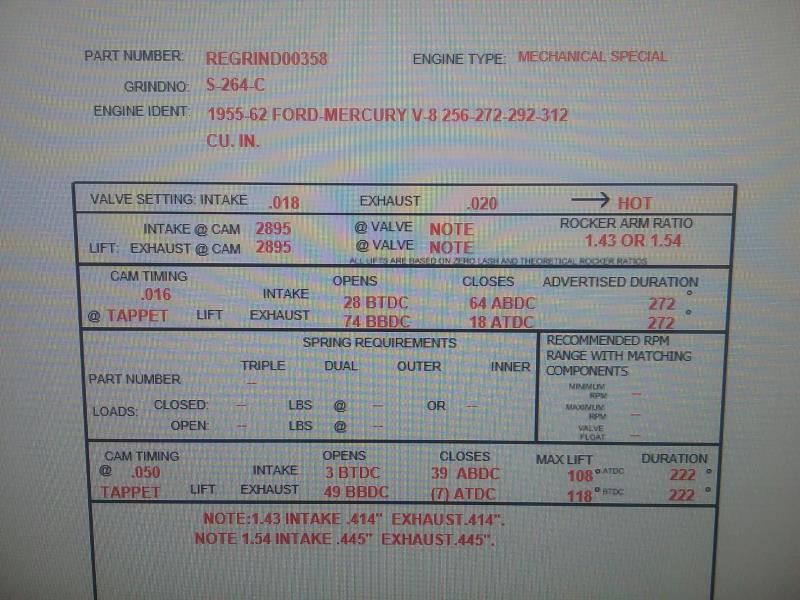

Has anyone used one of Mummert's reground cams? I found a page where he has reground cams and lifters for $175 He only has 2 grinds. 256 and 264 advertised duration.

But that's a good deal in anyones book.

|

|

By OlWeldinrig - 8 Years Ago

|

|

Any pictures of chamber in the "D" heads?I am curious because I have one D with a 58 style chamber and one stamped "D" head with a 57 style chamber.Both came off a 56 big truck engine,obviously one was changed at some point.

|

|

By 1960fordf350 - 8 Years Ago

|

|

A big truck? Is it a 292 or a Lincoln Y ? Lincoln y is a different animal.

|

|

By Ted - 8 Years Ago

|

|

1960fordf350 (12/19/2017)

...... It has an EC crank and EBU rods, but the pistons stick out of the block .0021. They had double stacked head gaskets on it.......

Did you mean 0.021” rather than 0.0021”? If the number is 0.021” out of the hole, then that likely indicates at least 0.050” cut from the decks.

|

|

By 1960fordf350 - 8 Years Ago

|

A surgeon never says OOPS!! BUT, I'm not a surgeon. Guess I got carried away with the 0's. And yes, I meant 0.021. At 0.0021 I doubt you'd ever had problems with the pistons just cause of the head gasket thickness.

Olweldingrig I will post a couple pics of those heads maybe Thursday. Got to go see mom tomorrow before work. Plus its 5 degrees outside tonight!! LOL

|

|

By 1960fordf350 - 8 Years Ago

|

OK Here's a pic of 2 heads. Used one is the D head. The other is from the set of new heads I bought.

|

|

By 1960fordf350 - 8 Years Ago

|

|

I've been reading a lot of posts on here. Lot's of information and ideas. Ted has mentioned a few times about using metric rings for less drag in the bores. Can they be used with the standard rebuild pistons for a Y? Since I'm going to build a torque engine and not a screamer, is there an advantage to it? I now have a 312 crank and rods. Is there any off the shelf pistons that will work on my rods without throwing a bunch of money at it? I plan on pulling my 292 and boring it. I'm going to have the crank turned to the 292 mains.

|

|

By charliemccraney - 8 Years Ago

|

By standard piston, I think you mean a piston made to original specs. In that case, metric rings will not work because the groove will be too wide.

The thinner rings will help for torque. Horsepower is a function of torque. Everything else equal, more torque = more horsepower. Whether it is a "screamer" will depend largely on the cam.

I think Mummert stocks modern design pistons that fit stock rods and strokes.

|

|

By NoShortcuts - 8 Years Ago

|

Pat. In having the 312 crank machined for your 292 block, yes, you need to have the main bearing size changed, but remember to have the rear seal diameter and the oil slinger size changed to 292 dimensions, too.

Click the link below to see the dimensional info supplied by John Mummert's wed site to provide your machine shop.

http://www.ford-y-block.com/crankshaftid.htm

Hope this helps!

|

|

By 1960fordf350 - 8 Years Ago

|

Well, progress is hopefully on its way. I picked up a never run 312 that has a cracked block. .060 over pistons, rollmaster chain, and some other new stuff. I disassembled it and pulled the cam. It's a crane cam. I emailed their tech people about the specs. They replied with a copy. Can anyone give me their opinion if its gonna be a good match for my F350? My highway cruising is at about 3,000rpm. Figure 5,000lb for truck.

|

|

By Lou - 8 Years Ago

|

|

1960ford350 you are building a truck engine, not a hotrod engine, you need torque and reliability, good gas mileage wouldn't hurt either. Start thinking truck, not hotrod.

|

|

By Genuinerod - 8 Years Ago

|

|

The numbers are almost the same as the Ford "F" code supercharged cam (B7A-6250-C). I believe you will feel the difference in the upper RPM (3000+). The sheet didn't say what LC was, but the Ford cam was 112 which would give you a little more vacuum. You may not have the pull at low RPM but it will a big upgrade over stock.

|

|

By GREENBIRD56 - 8 Years Ago

|

Seems to me - Hoosier recommended that a good 312 crank stay in a block machined for the larger mains. Even if it meant having a 292 block opened to the larger size during the machining process, squaring up the block.

There is some serious mechanical wisdom in that philosophy - the larger diameter journal is much, much stronger, especially when forged cranks aren't exactly "available".

|

|

By 1960fordf350 - 8 Years Ago

|

If I line bored the block to the 312 diameter, wouldn't I be back at that chance of cracking a web? Since I'm never going to spin this thing 6,000rpm is that smaller main going to really effect me? Tim McMaster's 58 F100 has been running around for years using a 313cu that he turned down the crank and bored the block. Plus he hauls a 1900lb camper on it. So I'd say his weight is fairly close to mine. I haven't had any machine work done yet, so I'm open to going either way.

Back to the cam. Since the engine came with a rollmaster chain, I can degree it where I want. So if I advance it, I will get more torque, no? The specs I received from crane show using either sets of rockers, I have both sizes on my shelf. The question still being, is this cam too big for my application?

|

|

By charliemccraney - 8 Years Ago

|

The smaller mains should be fine. The 312 crank may technically be stronger but the smaller main cranks have proven to hold up in race and performance street applications. Other considerations when using 312 mains is bearing availability and cost.

Not sure about the cam. I do have the repop cam that Mummert produced a long time ago and it is a little bigger. with that, it is noticeably lacking for off-idle torque, for truck use, even in a 3675lb with me in it F100. Your cam being a little smaller, and with the shorter gearing of the F350 might work out, but it will probably be at the very edge of what is acceptable for your planned use. Ask Crane what they have to say about it.

|

|

By GREENBIRD56 - 8 Years Ago

|

|

There are all sorts of examples of both methods - that worked OK. I believe the web problems were with 312 blocks that had improper hole depths for the main bolts - not so much with the 292's.

|