|

Author

|

Message

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

All I can determine is that the location of the collar itself sets the endplay if it is measured by pushing the distributor shaft up. I must be overthinking it. The manual isn't very clear though.

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: 9 days ago

Posts: 799,

Visits: 113.5K

|

Greetings to all: I think you all are on the right track. My way of doing something isn't always the best way for someone else. But yes, the collar stops the shaft fly weights from being pushed up against the bottom of the breaker plate, As 57RancheroJim stated, .024" sounds in the ball park. So, in this case, with the distributor fully seated in the block. there should be something LESS than the .024" thrust as when uninstalled. This ensures the bottom of the driven gear is indeed seated against the machined thrust surface in the block, the fly weight mechanism will not be contacting the bottom of the distributor bowl and the remaining thrust will ensure nothing will bind when up to temperature. Make sure your dial in on the distributor shaft tip and not the breaker point cam as the cam in the 57 & up distributors has some thrust also and will produce a false reading. With all things working properly, I too have never seen the stop collar contact the bottom of the distributor housing. Fellas, I'm not too good at explaining things but hope this may clear up the theory of this thrust business. JEFF.................

64F100 57FAIRLANE500

|

|

|

|

|

57RancheroJim

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 729,

Visits: 112.0K

|

Jeff,

I understand what you are saying and I agree.

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

I suspect that's why the Loadomatic distributor endplay can be checked with the distributor installed, but the '57 and later cannot.

If the distributor cam &c., is removed then a dial indicator would work fine when distributor is installed. Tracking now.

It may be the "holding tool" they describe in the dual strib manual procedure puts the distributor upside down or some BS like that, I wish they would have just written that the "gap between the collar and distributor base must be 0.022"- 0.032"

Now that all is right in the world, shimming clearance closer to the 0.022" side of things would make for steadier dwell when running points no? That is to say, a closer tolerance is better than the high side of things, assuming the gear is located accurately?

|

|

|

|

|

57RancheroJim

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 729,

Visits: 112.0K

|

Ted,

I may be wrong but if the shafts moves up and down a few thousands it wouldn't change the dwell, the point gap would remain the same but it would change the timing a small amount. Dwell would only change from side to side movement like with a worn shaft or bushing??

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

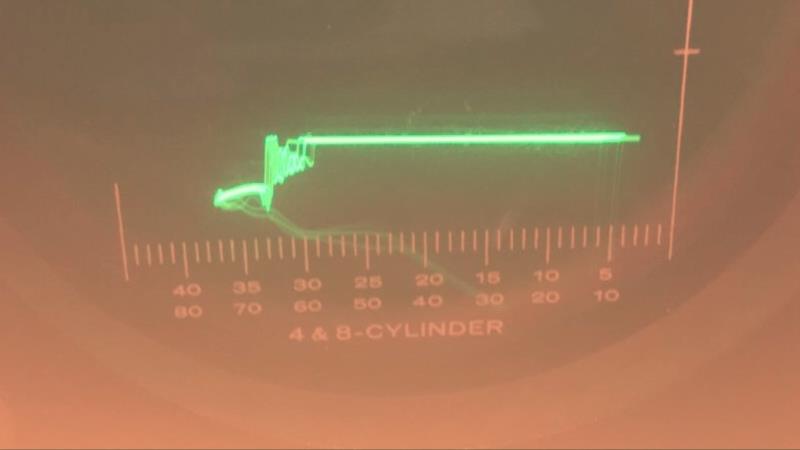

Yes, the wobble in the shaft is seen or measured easily on a scope when measuring dwell angle, is a better way to put it. Wobble and endplay, two different things, both bad. If the distributor cam surface is worn the points rubbing block will ride on a slightly different spot of the cam because of excess end play, that would change the point gap slightly. If the shaft is wobbling, it would also change the point gap. I think. Now this is from a Plymouth site, but the principle is the same. In the pic, the author suggests that no more than a .006" point gap change is allowable. That sounds like too much to me, but. See: http://www.plymouthcarclub.com/2018/02/replacing-distributor-bushings/  Heck, all I know is the ignition display when running a worn distributor and points looks like an unbalanced clothes washer on spin cycle! Here is a primary superimposed (I think), when using Pertronix. It's "OK"; spec is supposed to be no more than 2 or 3 degrees. When I tried points it was jumping all over the place. One thing I noticed too, is sometimes rotors don't fit tightly depending who made them. If they are loose that won't help anything either. It all adds up.

|

|

|

|

|

57RancheroJim

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 729,

Visits: 112.0K

|

I agree, .006 sounds like too much. I do like their method of bushing removal.

|

|

|

|

|

57RancheroJim

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 729,

Visits: 112.0K

|

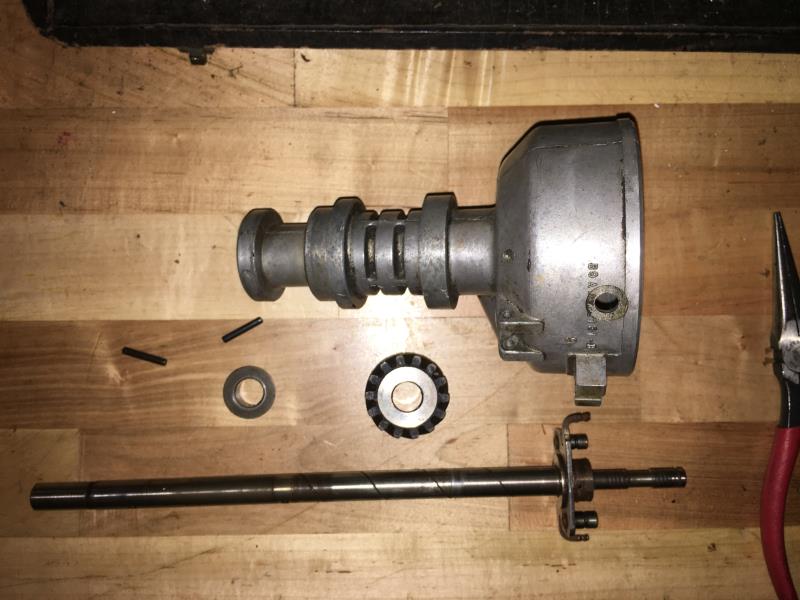

I finished up the distributor on Monday and started to install it yesterday using my old cap and rotor and noticed there was some wear marks on the top side of the rotor brass tip, also signs of it hitting the top of the inside of the cap, another WTF!

After measuring the height of the rotor with and without the Pertronix wheel over the point cam there was a .070 difference. I checked that measurement again with two different rotors, FOMOCO and a STANDARD, both measured the same. I ended up sanding the bottom of the rotor to bring it back to the same height as without the Pertronix wheel.

I finally got it fired up, set the timing and went for a ride and all is good...

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

That's weird. There sure is a lot going on inside these things that need to be looked at!

Cheap distributor caps might be out of round in terms of the terminal ring, or made with old worn tooling and the dimensions aren't correct. I doubt that's your problem though.

I bought a Standard FD125 cap a while back and was rewarded with sparkles of brass glitter sprayed all over the inside. Same deal, rotor tip getting a little too chummy with the terminals. I think it turned out just that the rotor wasn't fully seated. The cap itself, if it is installed cockeyed will interfere with the coil secondary voltages because the rotor gap varies across different cylinders.

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

I got a line on a vendor who says they have five NOS distributor cam rotors on hand, base # 12210 ; but, they are for a '57 T bird distributor. "I'm wonderin" if maybe that's a tach drive distributor, and (naturally) uses a different rotor, won't fit anything other than that year etc. Anytime some unicorn part shows up, it's always something like that. Anybody know?

What I could do maybe is get somebody to braze up the slots on this tired old rotor and grind back to original dimensions, similar to when limiting total advance. I should have another rotor cam around here somewhere, maybe it's in better shape but I can't find it. Dang gremlins.

|

|

|

|