|

By GREENBIRD56 - 8 Years Ago

|

That advertisement ought to be down in the classifieds, right? The Ebay price listing is $550...... whew!!!

Can you still buy new bushings for the Autolite style of OEM distributor (say 1959 model)? Re-bushing and setting the endplay has salvaged a lot of distributors over the years.

|

|

By GREENBIRD56 - 8 Years Ago

|

|

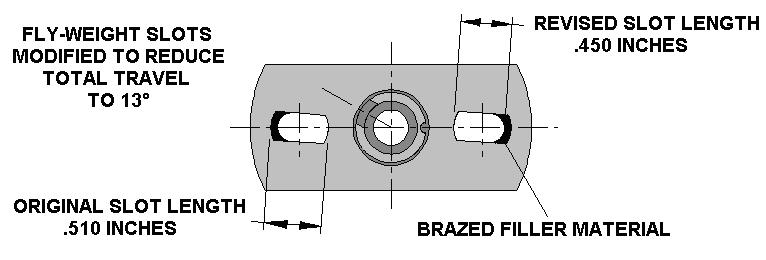

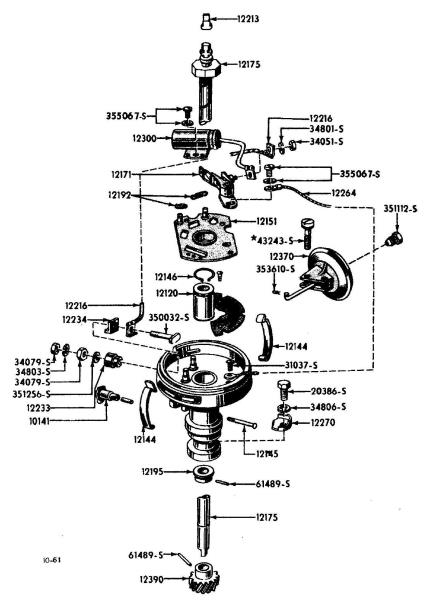

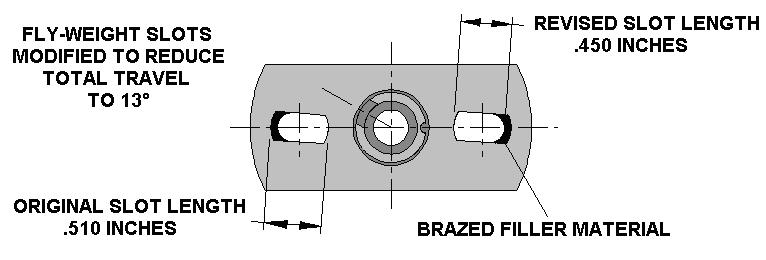

The best running set-up (all-around) I have is a 1959 Autolite style body with the "kidney" shaped flyweights. I came to me with an elongated flyweight travel slot in the upper rotor shaft. It had been designed by Ford to be used with a very short initial advance (3º-5º) - and then lots of centrifugal to reach whatever their target maximum was at the time, for the engine assembly it was installed in. I didn't want that on my engine as 10º initial seemed to work well and I wanted the limit to be 36º. Soooo.... you reduce the travel slot (in my case it was too long) to net a total travel of 13º in the distributor - 26º at the crank (with little or no wear on the pins). This required brazing up the end of the slot and then making a smooth radiused slot at the modified end.

The one in this photo looks a little different - it has the point cam machined off and the upper end modified to accept the "armature" of a Duraspark II system trigger.

|

|

By GREENBIRD56 - 8 Years Ago

|

|

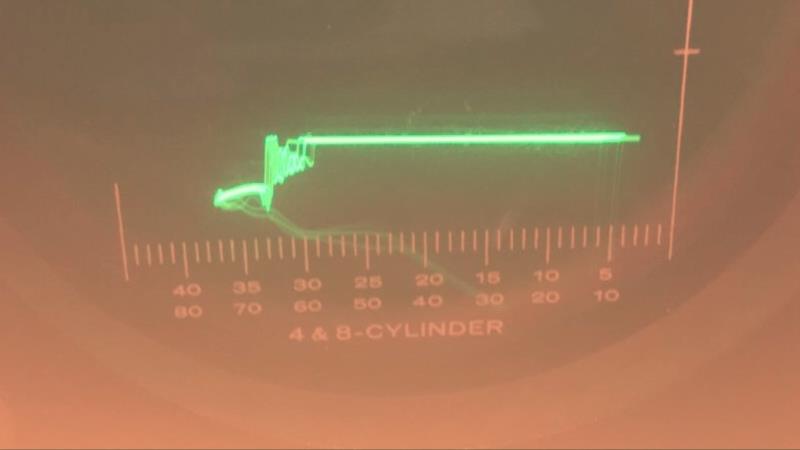

I can't tell you what's in there for springs now - too long since I had it apart. At one point I had two of the softer Ford springs in there - tried to get all of the advance in at about 2500 - but I know others have used lower rev's for full mechanical. Depends on the gas available and the cam (mine is a stocker). I'm also running mine with a vacuum pot limited to 7º - and feeding it manifold vacuum. Sitting at idle, advance is about 17º at the crank - and on my stock cam that nets 20 inches HG - best vacuum. it drops out to accelerate - then comes back in as the engine goes to "cruise" at higher road speeds. I prefer the manifold vacuum advance method and that's the way I set it up - other methods work as well.

|

|

By GREENBIRD56 - 8 Years Ago

|

|

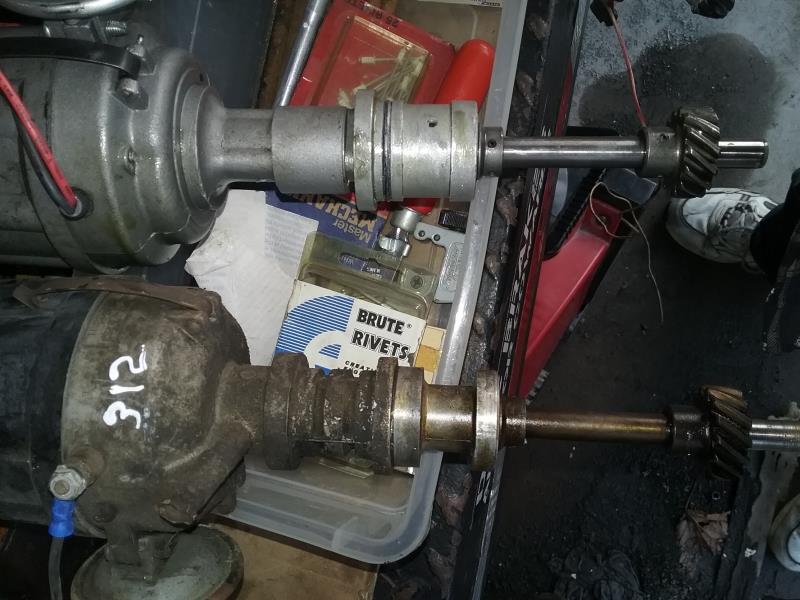

The single helical drive gear will make the shaft rise and fall on the endplay of the shaft. Wear of the pinion and cam gear will add to this...... due to the helix angle, the shaft will rotate ever so slightly with the rise and fall. The whole system of parts participates and it will also effect the electronic triggers.

|

|

By paul2748 - 8 Years Ago

|

Oldcarmark is correct - the instruction with my pertronix II said do not use the resistor with the Pertronix coil

oldcarmark (4/23/2018)

DryLakesRacer (4/23/2018)

Florida Phil...when it dies again I'll bet it's the Chinese condenser. Replaced twice on my 56 before I installed a Pertronics ll. Never a problem in 5 yrs now. I bought their correct coil also and used my existing ballast resistor. Good luck. If You are using the Coil that they recommend I believe You can bypass the Ballast Resistor so the Coil gets full 12 Volts. I have had this combination on mine for Years without the Ballast Resistor. Flamethrower Coil.

|

|

By paul2748 - 8 Years Ago

|

Has any one used a company name Philbin Rebuild Products in Oregon. They rebuild distributors.

|

|

By paul2748 - 8 Years Ago

|

Trucks?? In 1963 the only Y Blocks were the trucks.

Tedster (5/31/2018)

Went through my stash of parts and have two rebuildable cores, is there an application chart somewhere listing what these came out of exactly? C3TF A 12127 2MB C3TF K 12127 4FC

|

|

By monarch - 9 Years Ago

|

|

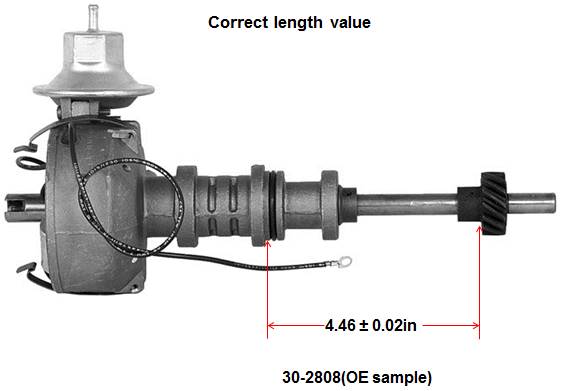

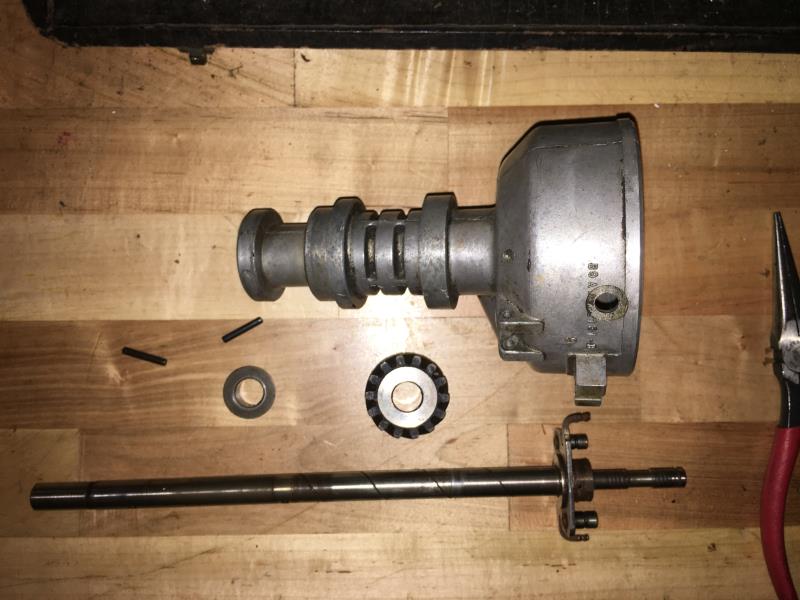

The distributor out of my 1957 Ford ( not loadamatics) has a shaft that is 6 inches long. ( from the part that touches the block to the end of the shaft. My replacement from Napa ( 48-2808) is only 5 3/4 inches long and the gear is off a 1/4 inch. Napa ordered me a second distributor and it to is 5 3/4 inches long. I have a friend who has some old cores and they are all 6 inches long including loadamatics. Question is are these Napa distributors compatible or are they all packaged wrong. I know these units are rebuilt from different years and parts but I would think the length and gear should be the same length. Thanks Bill

|

|

By monarch - 8 Years Ago

|

|

Got 4 distributors from Napa. They all had the wrong shafts. Not Napas fault all ordered with right part number. Have since found a core that needs rebuilding. Now to find a shop that does in house rebuilding locally. Has a few missing pieces but is the right distributor. Thanks Bill

|

|

By PF Arcand - 8 Years Ago

|

Mark: Yes, incorrect assembly, but if I have it right, it's apparently because they are mistakenly using SBF shafts or distributor parts due to a shortage of original cores.

|

|

By PF Arcand - 8 Years Ago

|

Mark: you mentioned the pre 1957 Load o Matic distributors. Does anyone know if the shafts interchange with later units? And would they fit the SBF housings? If so, that would be a way to get usable cores into rebuilders hands. There must be some Load o Matics around gathering dust.. Also Mark, you mentioned Autoline, are they still operating in Canada?

|

|

By Y block Billy - 9 Years Ago

|

I recently had a similar problem with a 57 Tbird I worked on, checking the distributor out the advance was chewing into the bottom of the housing and it was full of aluminum shavings, when investigated it was found that someone had installed a thick gasket under the distributor flange where it rest on the block. This caused the gear to not rest on the pad in the block down by the oil pump shaft. Rotational forces on the gear were pulling down on it creating the wear in the housing. Like John states is is important that the gear rest on the block then check up and down movement of shaft in distributor. Being a Tbird with tack drive there was no other option but to make it work! unobtainium!

|

|

By KULTULZ - 8 Years Ago

|

oldcarmark (5/22/2018)

You are correct Jim. It is 1/4 Inch shorter as shown in pictures-not 1/2". The Gear is higher on the Shaft than original. Even at 1/4" shorter its still not engaging the Oil Pump Shaft by much. As I mentioned the Ones that were made in USA before they shifted Production to Mexico were correct Length at 6" and the Gears were properly located. I have not heard of One made in Mexico yet that has correct Dimensions. Cardone just seems to want to ignore the Problem. Buyer beware!

Here is the problem(s) as I see it.

CARDONE is using SBF distributor cores. The actual housing will fit the FYB, the distributor shaft is shorter than the FYB. While the drive gear can be re-positioned (verify this when removed from box) on the SBF shaft, the dist shaft will be too short to engage the driveshaft fully. Also, the end of the shaft is mildly tapered to allow fairly easy dist install, so then there is even more slop.

FORD made a running change in 60/61 regarding oil pumps and the later pump (C1AE 6600-B) requires a longer driveshaft.

Pre 1960/61 used shaft B9A 6A618-A (L= 8 1/16") while 61/ used shaft CIAE 6A618-A (L= 8 1/4"). Both are still available from vendors.

Either maybe go with this or find a good FYB core and have it professionally gone through. While CARDONE was once a quality re-builder, it seems they have no real concern now. They also seem to be doing only cosmetic rebuilds so you will have no idea of what curves you will end up with (or quality of IGN parts).

PREVIOUS THREAD- http://forums.y-blocksforever.com/Topic13087-2.aspx

|

|

By KULTULZ - 8 Years Ago

|

Ted (6/7/2008)

DANIEL TINDER (6/4/2008)

Ted,

I located and reread the excerpt on pump shafts from "Engine Builder's Handbook", by Tom Monroe. I had remembered incorrectly, as it was NOT cam gear wear that he was concerned with, but shaft breakage due to increased shock loading of the ends (which are still the same size, though the shaft itself is larger and less flexible).

Glad to hear your experience with heavier, after-market shafts has been positive. I will thus feel more secure in using the one I have for my grocery-getter rebuild. His theory does seem to make sense, but may only apply to Hi-Po race motors running very heavy oil and tight, high volume pumps?The ¼” hexagon aftermarket oil drive shafts are indeed more prone to breakage at the ends but that’s to be expected with the design where it steps down at the ends whereas the stock ¼” shafts are known for their ability to twist like a pretzel before snapping. But the shafts never break because of a defective or weakened shaft but generally because of the oil pump locking up. As a rule, the aftermarket shafts are strong enough that snapping the roll pin in the distributor gear can take place before a shaft failure which is a good safety fuse versus a shaft that simply twists until it breaks and the engine keeps running. The original thought process on the heavier shafts was to reduce the harmonics being transmitted to the distributor thereby reducing spark scatter at the higher rpms. This was very important with point distributors and although not as big a player with the more modern electronic distributors, is still worth considering in this regard.

I don't positively know if this will solve the problem(s) being experienced with the SBF replacement distributor from CARDONE but there is a longer shaft (OEM - NOS) available as well as performance aftermarket.

IMO, if someone while assembling an engine, can verify correct driveshaft length within correct dimensional specs with an OEM FYB DIST AND the CARDONE SBF (w/ correct driven gear position) replacement and post the findings, it will alleviate doubt.

If the shorter driveshaft either slips out or breaks while running, you know what can happen.

|

|

By KULTULZ - 8 Years Ago

|

Hoosier Hurricane (5/23/2018)

I have a comment on this shaft length issue. Did you ever notice that the bottom of the driven gear is machined? I think this is because the machined surface mates with the machined surface in the block. The angle of the teeth on the camshaft would tend to push the distributor gear down and the machined surfaces would become a thrust surface. If the gear location is 1/4" short, not only would the gear mesh be off, but the thrust surfaces would not touch. The thrust surface would become the bottom of the distributor housing bowl and the flange on the shaft. That area is typically not well lubed, so wear will be present. Just my 2 cents. Correct. There have been several descriptions of the bottom of the bowl having been eaten and leaving shavings.

|

|

By KULTULZ - 8 Years Ago

|

Kahuna (5/26/2018)

Further on this issue:

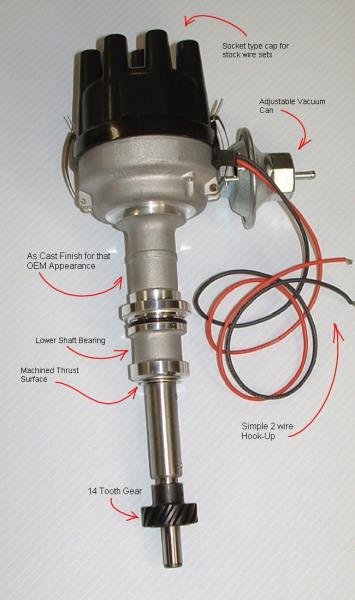

Is the problem that cores aren't available, or, is it that no one else rebuilds these things? The problem is CARDONE is using SBF cores for rebuilding. The true problem is that the actual distributor shaft is shorter for the SBF than the FYB and the distributor gear is usually not located correctly on the rebuilt distributor shaft. That is the true problem. There must be a true shortage of original FYB cores. The lengthened driveshaft (with correct location of gear) I referred to in a previous post would be meant to correct only the CARDONE rebuilds. But CAREDONE does not seem to care. They were once a quality rebuild supplier but after discovering all of this will make a wide swath around them. The only remedy (IMO) is to source and have a correct period FYB distributor professionally rebuilt or go with a quality aftermarket distributor ($$$) if not concerned with originality.

|

|

By KULTULZ - 8 Years Ago

|

oldcarmark (5/28/2018)

I want an original looking One not One of the new Aftermarket Ones especially at the Price they are. I have a Cardone 30-2808 in my other 56 and have for Years with no problem. A bigger concern is what do You use down the Road if they are hard to find now??? Most likely the CARDONE you have is a correct FYB rebuild (pre-FYB core shortage). Check the I.D. NOS. on the housing. Like a previous poster stated, rebuilding one yourself is not all that difficult but sourcing quality replacement parts and setting curve(s) without a distributor machine, while not impossible, would require a lot of effort. I doubt CARDONE goes that far for you. They reach into their CHINESEIUM parts bins and slap it together.

|

|

By KULTULZ - 8 Years Ago

|

Tedster (5/31/2018)

Went through my stash of parts and have two rebuildable cores, is there an application chart somewhere listing what these came out of exactly? C3TF A 12127 2MB C3TF K 12127 4FC

Yes, but the ID Chart will be found in the TRUCK MPC for that period. Both are truck applications.

2MB and 4FC are date codes.

|

|

By KULTULZ - 8 Years Ago

|

"Well that's really the issue isn't it. Sometimes they don't use Ford part numbers or just make up their own. So it's left to the repairer to try and figure out what's what and what will actually work."

They can't use actual FORD P&A (or ROTUNDA - AUTOLITE - MOTORCRAFT) numbering because of copyright infringement unless NOS or FORD AUTHORIZED REPRO.

The FORD P&A SYSTEM is very orderly/precise whereas these sellers shotgun information and you have to scroll through page after page to find what you are looking for (if you ever do). Also showing an actual FORD PN would give you the idea the part is genuine when it is actually Chineseium.

|

|

By KULTULZ - 8 Years Ago

|

"The bushing is solid steel and hard like tool steel and no way for the oil to get to the ID from the oil cup. We then split the dizzy in half length wise right through the oil passage. At the bottom of the oil passage there is a small chamber area for the oil that goes around the OD of the bushing, what good does that do?

Was there ever a time maybe in earlier years the that oiling through the cup actually oiled the bushing?"

There should be a spiral on the shaft itself which should bring the oil to the bushing-

Some styles had the cup and other styles had a wick under the rotor button you were supposed to oil when servicing.

|

|

By KULTULZ - 8 Years Ago

|

Bushings- B8QH 12102-A - C5AZ 12120-A - C5AZ 12132-A

The SHOP MANUAL shows how to remove and replace with SPECIAL SERVICE TOOLS but they can be duplicated.

|

|

By KULTULZ - 8 Years Ago

|

Basic PN 12210 is the points actual cam. Do you need the cam or rotor (12200)?

If rotor, B7A 12200-A is the STD 1957/ .

|

|

By KULTULZ - 8 Years Ago

|

"...an earlier part number for the "upper" bushing (Y Block distributors have only one) is B7A-12120-A (replaced or superseded by B8HQ-12120-A)"

B8QH 12120-A

Where did you come across B7A 12120-A being replaced by B8QH 12120-A?

|

|

By KULTULZ - 8 Years Ago

|

"Can anyone shed some light on correct part numbers and availability? Is this another unicorn part??"

I hate to interfere, but you realize there are two distributor designs (1957-1959) and 1958/ )? There is a design change again in 1960 and again in 1965. While many parts are interchangeable, many are not.

You are working with a 1963 292 LT distributor? What is the ID NO.?

|

|

By KULTULZ - 8 Years Ago

|

"The question pertains to whether the distributor shafts available are serviceable for more years than Mac's or Carpenters allows.

I have a hard time trying to decipher sites such as those. If I need something, I search by the actual PN.

That being said, The B7A 12175-A shaft was used on the 292 through end of pass car production (1962). I cannot say for LT as I got rid of most of my reference materials years ago.

I will leave you alone now ...

|

|

By KULTULZ - 8 Years Ago

|

Tedster (5/31/2018)

KULTULZ (5/31/2018)[ 2MB and 4FC are date codes. Hm, I thought C3 was the date code, and T of course means truck etc., the shop manual sez K suffix designates 292 V8 but is silent on the rest.

C3 would refer to the 1963 model year the part was released for assembly. The other characters if stamped is the actual assembly date of the dist assy..

If you see a Casting I.D. No. on the distributor housing with a Basic PN 12143, that refers to the actual bowl casting I.D. and any Cast Date Code would be the casting date of the bowl.

The MPC would show more concise/up to date and detailed info (service upgrades/superscessions) over a Shop Manual. The Shop Manual will give you detailed service info (curves for instance) (along with Service Letters/TSB's) whereas the MPC will not.

Hope that came out understandable...

|

|

By KULTULZ - 8 Years Ago

|

Yes.

The 57/58 is unique as is 59/ (matches breaker plate style)

|

|

By KULTULZ - 8 Years Ago

|

"...they have the old, "fat comma" style advance weights in stock, though I can't find them on their site. B7A-12188-A The problem with these, is the slot pins, though made of hardened steel, get grooves worn into them.

The distributor cam itself though, the slots also show some wear. Probably be OK, but if anyone has access to the part # for these that would be great, I believe this was actually an Autolite distributor. 13L is stock I believe."

Go to the FTE site and post your question and DIST ID Nos and a fellow named NUMBER DUMMY should be able to give you the PN's and availability of the parts you want. I no longer have that period TRUCK MPC.

Any curving info you need will be in the appropriate year LT SHOP MANUAL.

|

|

By KULTULZ - 8 Years Ago

|

'Ya know...

A lot of the LOADOMATIC service parts are still available NOS if you know what you are looking for. If you are still a young fellow, it might be worth stocking up while you can... still available NOS if you know what you are looking for. If you are still a young fellow, it might be worth stocking up while you can...

|

|

By KULTULZ - 8 Years Ago

|

"Hm. I see where you're goin' with that. Can the '57 and later cam assembly and weights be swapped over? Breaker plate?"

No, the LOM DIST BOWL is smaller as is the dist cap.

CARDONE used to be a class act. I personally will avoid them like the plague nowadays.

|

|

By KULTULZ - 8 Years Ago

|

"In contract terms it falls under warranty of fitness for a particular purpose, and they can't just slap a sticker on the box "too bad so sad". Technically they would have to sell their products "As-is". The customer has an expectation that when he buys a Y block distributor, it's going to fit and is designed and constructed in a workmanlike way."

CARDONE DISTRIBUTOR 32-2808 DISCLAIMER-

WARNING-

" It is extremely important to match the replacement distributor to the original unit. Dimensions and gear description must be checked before installation. If the original shear pin or gear is worn or broken, then the oil pump and or gear must be replaced. Using the wrong distributor, worn drive gear , or defective oil pump drive will result in extensive engine damage and VOID THE WARRANTY."

In short, have a nice day.

|

|

By oldcarmark - 8 Years Ago

|

|

I sent an Email to the Tech Dept at Cardone asking about the Problem posted here. Asking if they were aware of the problem with Shaft Length and has it been corrected? Response was not having a problem and they are built to OE Specs. Maybe it was just One batch assembled wrong or have there been any recent problems with these? I have purchased 2 in the past and not had any problem with them except for one with excessive vertical free play which I corrected using Shims. Email- tech@cardone.com

|

|

By oldcarmark - 8 Years Ago

|

|

$200.00 + Core seems to be around the Average Price.There's several listed on Ebay with some even higher than $200.00. Rock Auto sells them for a little less than $200.00 + Core but they are Carcone Units too. There is a shortage of Cores because they never get the 57+ Ones turned back in. A couple of Years ago there were no rebuilts available from Carcone for awhile because they ran out of Cores.I don't know of anyone else selling rebuilt Ones except Carcone. If You go on Ebay there are new Ones from Offshore with Electronic Ignition available. Anyone tried One of these? When I contacted Carcone by email a few Weeks ago they claimed they were not aware of any Problems with these 30-2808 Units. Shortage of correct Cores right now does not bode well for the Future needs. About a Year ago there was another Supplier on Rock Auto who claimed that they had brand new Distributors for Y Block. When I contacted them directly to verify that the Units were for Y-Block they realized they were not. The Listing is gone from Rock Auto. Only the Carcone Units are listed. The only real difference between the Y Block Distributors and most other Ford Distributors is the length of the Shaft. Gears are different but thats not a problem to get correct Gears. If You look at the ID # on the Housing of the 30-2808 Exchange Units they are from several different Years and Applications. The housings are the same for Years. The Shaft is different for Y Blocks. I have used 2 Carcone exchange Units without a problem with shaft length or Gear Location but both were purchased more than a Year ago. The problem with Shaft Length an Gear location seems to be within last 6 Months.Maybe Carcone is now having these redone Overseas like a lot of other Automotive Suppliers and that's where the Problems are coming from??? There are a lot of Offshore Condensors that are Garbage as We are finding out. By the way the correct Part # for the Carcone Y-Block Unit is 30-2808. I see some different #;s in prior Posts which I think are incorrect for our Y-Blocks.

|

|

By oldcarmark - 8 Years Ago

|

|

........The Shaft is different for Y Blocks. The correct Part # for these Cardone Distributors is 30-2808. I see a different # in previous Posts.

|

|

By oldcarmark - 8 Years Ago

|

I contacted Cardone about a Month ago regarding these 30-2808 Distributors being assembled wrong. They denied there was a problem. I bought One last Week and sure enough the Dimensions are wrong. I took Pictures comparing the originals to the Exchange Units showing where the Dimensions are wrong. I sent a detailed Email to Tech Dept at Cardone again Today. Now they are going to have whoever is responsible tor Quality Control look into it. Hope they agree and Fix the Problem. I have searched extensively and there is no other Source for these unless You go aftermarket high $ Units.

|

|

By oldcarmark - 8 Years Ago

|

More Pictures

|

|

By oldcarmark - 8 Years Ago

|

DryLakesRacer (4/23/2018)

Florida Phil...when it dies again I'll bet it's the Chinese condenser. Replaced twice on my 56 before I installed a Pertronics ll. Never a problem in 5 yrs now. I bought their correct coil also and used my existing ballast resistor. Good luck.

If You are using the Coil that they recommend I believe You can bypass the Ballast Resistor so the Coil gets full 12 Volts. I have had this combination on mine for Years without the Ballast Resistor. Flamethrower Coil.

|

|

By oldcarmark - 8 Years Ago

|

|

Whats the complete Part # ? I can check Parts Catalog and see what they fit.

|

|

By oldcarmark - 8 Years Ago

|

57RancheroJim (8/19/2018)

That must be an error in the shop manual, see those all the time. When revisions and corrections are made the dealers get a service bulletin, we don't.. Yes the bushing goes down to a lip, if my old camera will cooperate today I'll try to take a picture of the housing my friend and I cut in half. Were did you find the new bushing? MACs listing for many parts are screwy at best... I'm only guessing but I would think the 60-64 would be the same, and I only say that because I have a 59 that is different. The plate that the springs attach to is three pieces riveted together, of course I can't guarantee that is 100% original. Also it doesn't use the 3 little nylon buttons for the breaker plate to slide on, it has brass screws..

You might also check out Green Auto Parts or Sales. They have a huge Inventory of Obsolete Parts. If it doesn't show on their inquiry site U might contact them direct and see what they have.

|

|

By oldcarmark - 8 Years Ago

|

|

I thought I was done adding my 2 Cents worth to this Topic but I just did a search for the Cardone 30-2808 which was the original cause for this Topic. They don't appear to be available from anyone who usually sells them. Is it possible that Cardone is now admitting there is a Problem with the Frankenstein Distributors they tried to produce using the wrong Shafts? Everywhere I checked online they are "not available". About Time they stopped selling them if that is the Reason they are not available.

|

|

By oldcarmark - 8 Years Ago

|

. squote]Tedster (8/8/2018)

Hm. I see where you're goin' with that. Can the '57 and later cam assembly and weights be swapped over? Breaker plate? I wrote one seller about their 30-2808 wares, explained the problem. "Hi, I would suggest orderingg this part and if the measurements are not correct then return it. We do not do measurements, as we cannot gaurantee accuracy. So hope that that suggestion helps" They can't be trusted with a crayon, a tape measure is a bridge too far, I guess.

There is no point in contacting the Seller of these 30-2808. They all come from Cardone and that's where the Problem is.. I contacted Cardone several Times regarding the "problem" with these 30-2808 Distributors. They are ADAMANT that there is nothing wrong with them and basically get LOST and stop bothering us. Nice Eh? Stay way from their Junk unless U want to end up with Engine Damage. I also contacted Pertronox with the suggestion that they might want to look at producing stock Type Distributors for Y-Blocks. No response from them.

|

|

By oldcarmark - 8 Years Ago

|

|

.Doing some reading online I believe the Bushings have to be honed to fit the Shaft once they are installed..

|

|

By oldcarmark - 8 Years Ago

|

|

They may fit fine before they are pressed in but likely will be a tighter fit once pressed in. I purchased a NOS original 60-64 Light Truck 292 Y-Block Distributor on Ebay on Wed .Autolite DA-647 in the Box. Not rebuilt but later brand new Ford replacement Distributor with the Triangular shape Body below the Bowl. Surprised nobody beat Me to it. I don't need it right now but the way things look as far as getting replacements I thought it a good Idea to grab One while One is available.

|

|

By oldcarmark - 8 Years Ago

|

|

I can't get a Link.Even using the Listing # won't show on Ebay. If You search ford 292 Distributor and look at the "Solds" its there. 4th or 5th Listing.

|

|

By oldcarmark - 8 Years Ago

|

|

The Seller listed it as a Ford 292 Distributor. If He had mentioned Y Block anywhere in the Listing it would have been gone quicker than I found it. The casting # on the Bowl identifies it as being produced in 1965 or After. I found several other sold Ones on the Internet with the same 1965 Casting Identification. They are for up to 1964 Ford Truck with Y Block. NOS Ford Service Parts. Nice to find a NOS One. I have a 390 Holley sitting in a Box that needs a rebuild. So now I have a Distributor also for when i do another Conversion. Done 3 so far. Forgot to mention- I asked If He was open to an Offer and He took $10.00 off the listed Price."Frosting on the Cake!".

|

|

By oldcarmark - 8 Years Ago

|

|

If U convert it to Pertronix You have remove it and enlarge the Hole for the Retainer that comes on the Pertronix feed Wire. I had to do that on the 1957 Distributor I just installed on my Car recently.

|

|

By oldcarmark - 8 Years Ago

|

|

Its hard to find good Cores that can be redone. Personally I prefer the post 62 or so with the Vacuum Advance that can be adjusted using an Allen Key.

|

|

By oldcarmark - 8 Years Ago

|

|

Rock Auto was selling the Cardone 30-2808 as recently as last Week.Now the Listing is rebuild and return your Core. I wonder if they have not had a bunch of returns when selling what Cardone is producing now???

|

|

By oldcarmark - 8 Years Ago

|

|

Thanks. It just pisses Me off because now I need One to use with the Holley 390 I already have and I can't find One. I want an original looking One not One of the new Aftermarket Ones especially at the Price they are. I have a Cardone 30-2808 in my other 56 and have for Years with no problem. A bigger concern is what do You use down the Road if they are hard to find now???

|

|

By oldcarmark - 8 Years Ago

|

|

I ended up buying One on Ebay. Original 1957 FEH which looks very good. Bushing has been replaced. Seller says it should be very useable as is. I am going to Covert it to Pertronix before I install it. Also ordered a brand new 390 Holley Carb. I converted my other 56 several Years ago and has been very reliable and certainly much more responsive than the original Loadomatic and Teapot.

|

|

By oldcarmark - 8 Years Ago

|

Tedster (5/29/2018)

The only caveat there, the internal rubber diaphragm is vintage 1957 as well, and may be dried out by now and crispy. Won't last long in service, maybe.

Thanks. The Seller assures Me it is working now. They are available in the event it does stop working. I am just happy to have found what looks like a very good original Distributor so I can get on with my Conversion.

|

|

By oldcarmark - 8 Years Ago

|

Kahuna (6/2/2018)

Is it possible to purchase just the vacuum advance units for an original 57 & up distributor? Thanks Jim

I just purchased an original 1957 Distributor. You might want to read my Post regarding this Type Vacuum Advance.. You can buy the Advance without the Spacers/Springs from amongst others Macs. If I read the Information from Steve "Greenbird56" correctly you can use the later Vacuum Advance if You also change the Breaker Plate to later Style.

|

|

By oldcarmark - 8 Years Ago

|

|

That's interesting because the Distributor Shafts are 1/2 " Shorter than the Original Units. So how much of the Oil Pump Shafts are actually being engaged by the Distributor Shaft? Not much by the sounds of it. I guess if You were to use a longer Oil Pump Shaft You could use these Distributors if You wanted to take a Chance that the Gear on the Distributor will work even though its not positioned correctly either. The Units they are selling do not match the Dimensions that Cardone itself says they should be.Not sure what the Alternative is because I won't be using One of these 30-2808. They seem to be selling a lot of them on Ebay. Cardone don't seem to care that the Units they are producing are not assembled correctly. Buyer beware as the saying goes!

|

|

By oldcarmark - 8 Years Ago

|

|

I don't know where the difference would be that allows it to still engage the shaft. The difference of 1/2 " shorter is from the Pad that sits on the Block to the end of Shaft. Look at the Pictures I posted a couple of Weeks ago showing the Measurement of the 30-2808 replacement and the Original I have. Doesn't make sense that it still engages Oil Pump Shaft.

|

|

By oldcarmark - 8 Years Ago

|

|

You are correct Jim. It is 1/4 Inch shorter as shown in pictures-not 1/2". The Gear is higher on the Shaft than original. Even at 1/4" shorter its still not engaging the Oil Pump Shaft by much. As I mentioned the Ones that were made in USA before they shifted Production to Mexico were correct Length at 6" and the Gears were properly located. I have not heard of One made in Mexico yet that has correct Dimensions. Cardone just seems to want to ignore the Problem. Buyer beware!

|

|

By oldcarmark - 8 Years Ago

|

|

It would be helpful to know that Information. Perhaps Ted could do a little checking when assembling one of the Y Blocks He rebuilds. I found an Article Ted wrote several Years ago regarding using different Drive Shafts when He modified an Oil Pump into a High Volume Pump. A different length Shaft was required to make it compatible with the Distributor. If Cardone is not going to fix the Problem then maybe We can figure out how to make them work. The big Problem really is that the correct Cores are hard to come by because they don't get turned back in. So I guess this is Cardone's Solution to the Core Problem. These 30-2808 Distributors can be recurved using Mr. Gasket Spring Kit., the Vacuum Advance is Adjustable, Aftermarket Electronic Ignition or Fords EEC Ignitions can be installed. They can be a low $$ upgrade over the original Loadomatic if they can be made to fit correctly as far as Dimensions and Shaft Length.

|

|

By oldcarmark - 8 Years Ago

|

|

Hi John. If You go back to Page 4, the Company making those Aftermarket Distributors are doing exactly that. Combining the lower Part of an original Y-Block Distributor with late new Production upper Distributors. They want to purchase any Cores just to get the lower Shafts.I wasn't sure if the lower end of Shaft rides on the Block. That being the Case the Shorter Shafts will not work even with a longer Oil Pump Shaft. So much for that Idea. Thanks for the Info.

|

|

By oldcarmark - 8 Years Ago

|

nt[quote]john2747 (5/24/2018)

Go back to page # 1.I am a retired machinist worked in a machine shop for 44 yrs.I have worked with some very talented welders,I doubt that any of them would claim they could weld two shafts together and maintain a .005" tolerance in length.If it has ever been done it was due to lots of talent.Both length and straightness would be a big challenge.The measurement is taken properly from bottom of distributor housing flange to the bottom of machined pad on the bottom of the gear,not to the bottom of the gear teeth.I have built tach drive distributors from scratch using some original parts.A SBF distributor shaft is about .958" too short to use in a y-block.Like they say there is no substitute for length.SBF distributors can not be reconfigured to ford spec's for y-blocks,it is simply impossible without making the shaft longer That picture from Cardone is simply ridiculous,the measurement to the top of the gear is meaningless,distributor gears differ in height from different producers only the bottom pad on the gear comes into play. john2747

You make some good Points John. The Company making the Aftermarket Distributors are using a machined Sleeves to join the Hybrid Shaft together. I can see that working if the machining is Accurate. I don't have much faith in the Examples Cardone is using when they claim their Inventory of 30-2808 is "fine". They just don't seem to care. Avoid their Distributors unless You want problems not too far down the Road.

|

|

By oldcarmark - 8 Years Ago

|

|

Looks like. 30-2808 is Carcones #. Measure from under the Pad that sits on the Block when the Distributor is seated and the end of the Shaft. Needs to be 6". If its 5 3/4 its too short. Send it back. I noticed a Seal on that One where it sits in Block. Y Blocks don't use a Seal or Gasket there. Just Metal to Casting. I emailed Carcone Tech again Friday to ask if anything is being done to correct the Problem. See if I get a Response.

|

|

By oldcarmark - 8 Years Ago

|

|

I don't think You have one of the Problem Units. Problem started about a Year ago. Cardone moved Production from US to Mexico about the same Time.I bought One about 14 Months ago which was US Production. It was fine .Is Your Shaft 6 inches from bottom of the Pad to the end of the Shaft? It will be very clear if its 1/4 Inch Shorter. The Instructions with new Rebuilt Units states very clearly to check New Unit against Original for Dimensions.

|

|

By oldcarmark - 8 Years Ago

|

|

Maybe that's why it's on Ebay as a resale. If U look at the Box it say's "Made in Mexico". Cardone's not taking responsibility if it Screws up your Motor because its too short. U are supposed to check Dimensions before installing.

|

|

By oldcarmark - 8 Years Ago

|

|

.I just got an email from Carcone Tech Dept. "Our Stock is all good." Thanks for your Business. Now I don't know if they have corrected the Problem or are just going to ignore it and hope We go away and stop bothering them. Not sure to whom the next Complaint goes to at Carcone. Maybe they just need a new Tape Measure in the Quality Control Dept!

|

|

By oldcarmark - 8 Years Ago

|

|

Can Someone tell me how much ( Length in Inches) of the Oil Pump drive Shaft is actually inside the Distributor Shaft when assembled on the Engine. If you look at a used Shaft You can see the wear Mark on the Shaft. I am still discussing the Distributor Problem with Cardone Tech.

|

|

By oldcarmark - 8 Years Ago

|

They sent Me a Picture showing the Dimensions that their 30-2808 is supposed to be. Its the same as original with the exception of the 1/4 inch short on the Bottom. Problem is the Dimensions in their Sample Picture do NOT match the Distributor I received and then returned. I would really like to get them to take this seriously and fix the Problem. They are really the only Source for Stock Type replacement Y Block Distributors. If We can't use One of theirs what are We supposed to use unless You want to spend a lot more Money for the new Aftermarket One's? I have requested that they send Me picture with 2 other Dimensions. Pad to bottom of the Gear and Pad to end of Shaft. They sent Me a Picture showing the Dimensions that their 30-2808 is supposed to be. Its the same as original with the exception of the 1/4 inch short on the Bottom. Problem is the Dimensions in their Sample Picture do NOT match the Distributor I received and then returned. I would really like to get them to take this seriously and fix the Problem. They are really the only Source for Stock Type replacement Y Block Distributors. If We can't use One of theirs what are We supposed to use unless You want to spend a lot more Money for the new Aftermarket One's? I have requested that they send Me picture with 2 other Dimensions. Pad to bottom of the Gear and Pad to end of Shaft.

|

|

By oldcarmark - 8 Years Ago

|

|

I will be very surprised if any are correct. All are being assembled in Mexico now instead of USA where they used to be assembled (correctly). I wonder if they are somehow adding a small 1/4 inch Spacer or Bushing ( by Mistake) onto the Shaft before it is inserted into Housing causing the Shaft to sit 1/4 higher inside the Housing. The Measurements are 1/4 inch off below the Housing as a result. I told the Tech Guy at Cardone that they should stop selling these until they fix the Problem. These could destroy an Engine if they run long enough. Some People don't read the Insert in the Box. i sent mine back to the Internet Seller in Canada for a Refund.

|

|

By oldcarmark - 8 Years Ago

|

|

I just came back from working on my Friends 56. We had to pull the Distributor Carcone 30-2808 that I purchased for Him over a Year ago. Kinda held my Breath while We checked Dimensions. This is One built in USA before they shipped all Production to Mexico. This Distributor is correct as far as Dimensions. I still maintain the problems with these started when they changed to Mexico.They are not being assembled properly.

|

|

By oldcarmark - 8 Years Ago

|

|

That's a concern because some People don't read the warning and if its not correct why is Cardone selling them? I asked the Tech at Cardone the same Question. As far as I am concerned they should just stop selling them until they figure out the Problem. They are all wrong from what I am reading Online. The bigger Question is where do You get a replacement that is Correct because no One else seems to be supplying them? Contact Cardone at 888-280-8324 or Email tech@cardone.com. Maybe if enough People complain they might act on the Complaint.

|

|

By oldcarmark - 8 Years Ago

|

tbirddragracer (4/30/2018)

Oldcarmark, you are correct all 5 distributors from O'Reilly's were wrong. Wrong shaft length and wrong gear placement. O'Reilly's sent all of them back to Cardone marked incorrect. Cardone has a disclaimer pasted over the box flaps stating: WARNING " It is extremely important to match the replacement distributor to the original unit. Dimensions and gear description must be checked before installation. If the original shear pin or gear is worn or broken then the oil pump and or gear must be replaced. Using the wrong distributor, worn drive gear , or defective oil pump drive will result in extensive engine damage and VOID THE WARRANTY." In other words it is your responsibility, not Cardone's to make sure the distributor is correct. I found the distributor I need on E-Bay. Ernie Phillips

Where did U find a good One on Ebay because most of the rebuilt Ones I found are from Cardone. There are a couple listed as Autoline D404 which are Y block 1959 Application and should work also. They come with a new Cap and Rotor. I contacted Autoline also and they have no more available due to no Cores. Running out of Suppliers who still supply these Distributors.

|

|

By oldcarmark - 8 Years Ago

|

|

Very impressive. I just wonder if at some Point You will run into the same problem the other Suppliers have run into-no Cores. The different lower Shaft is what makes the Y block unique. Is there no other lower Shaft that can be used to build these because You are actually constructing a Shaft out of 2. anyway? There must be a lot of the original 55-56 Loadomatics out there that could be used thinking about it now.

|

|

By oldcarmark - 8 Years Ago

|

|

I don't think Business Adverts are allowed on the Site. These Distributors are an interesting Option I guess. I have only seen the "Offshore" Aftermarket ones on Ebay. Pretty Pricey especially if all You want is a basic Distributor to Swap for the Loadomatic.

|

|

By Kahuna - 8 Years Ago

|

Charlie

That is a GREAT idea. Something that Pertronix might just go for as there isn't too much R & D needed.

Excellent thought

Jim

|

|

By Kahuna - 8 Years Ago

|

Further on this issue:

Is the problem that cores aren't available, or, is it that no one else rebuilds these things?

I have a very good friend that does distributors for me & others on a part-time basis.

He did my 57 Dist on his machine that we then installed the Pertronix module.

If all that's needed is new bushings, etc., along with new parts he could do it readily.,

including the testing of Vacuum/Mechanical advance.

If, however, the task is more involved and new parts (shafts, etc.) are needed,that might

throw a wrench into the works. Otherwise, he's the man. Not sure he'd want too much more work,

but be assured his work is impeccable.

He's in Norcal.

|

|

By Kahuna - 8 Years Ago

|

Is it possible to purchase just the vacuum advance units for an original 57 & up distributor?

Thanks

Jim

|

|

By tbirddragracer - 8 Years Ago

|

I recently bought a Cardone # 30-2808 rebuilt distributor from my local O'Reilly's. The posts on this subject caused me to check the shaft length and gear placement. Guess what, they were the wrong dimensions. This Cardone box had a disclaimer pasted over the box flaps, that stated to

check the dimensions and gear placement for your application. It seems the posts on this site has caught Cardone's attention. My O'Reilly's

salesman ordered the remaining four distributors from their warehouse. I will post if at least one of these distributors is correct.

Ernie Phillips

|

|

By tbirddragracer - 8 Years Ago

|

Oldcarmark, you are correct all 5 distributors from O'Reilly's were wrong. Wrong shaft length and wrong gear placement.

O'Reilly's sent all of them back to Cardone marked incorrect. Cardone has a disclaimer pasted over the box flaps stating:

WARNING

" It is extremely important to match the replacement distributor to the original unit. Dimensions and gear description must be checked before installation. If the original shear pin or gear is worn or broken then the oil pump and or gear must be replaced. Using the wrong distributor,

worn drive gear , or defective oil pump drive will result in extensive engine damage and VOID THE WARRANTY."

In other words it is your responsibility, not Cardone's to make sure the distributor is correct. I found the distributor I need on E-Bay.

Ernie Phillips

|

|

By tbirddragracer - 8 Years Ago

|

Oldcarmark,

I bought a '58 Ford original distributor from one of the E-Bay Y-Block parts sellers.

Advertised to be in good used condition. Hope it is as advertised. Will post condition

upon arrival.

Ernie Phillips

|

|

By yblock57 - 8 Years Ago

|

I just bought a cardone (part #30-2808) from O'Reilly's to upgrade the load-a-matic that's in my '56 truck. Upon closer inspection, it looks like I have the same issues y'all have pointed out; incorrect shaft length and gear in wrong spot.

What are y'all using for distributors now? Should I order from one of the vendors like Mac's? I'd prefer to get one through a local auto supply that would allow me to swap in the future if there's ever a problem.

Thanks in advance!

|

|

By yblock57 - 8 Years Ago

|

|

Thanks for the info. I traded in a 57 core that was locked up, but am now regretting it. Parts guy at O’Reilly’s did his best to cross numbers up and even tried to get my old core back. Someone will eventually get the right distributor (if they rebuild my core). Sucks that parts vendors are so ignorant and unprofessional to not actually do the job right. Obviously no R&D.

|

|

By FORD DEARBORN - 8 Years Ago

|

Greetings to all: I think the word burnish is nothing more than a $.50 word for polishing. When ever I have replaced a distributor bushing, it was always used with the original, but good, distributor shaft. Therefore "burnishing" was never necessary. I still have a couple new bushings and found a new Y-block truck distributor shaft - one with the governor feature. The diameter is same as a car distributor. Slipping the new bushing over the new shaft revealed a perfect fit with no detectable slop/wobble but slid over the shaft perfectly. The part number is B8Q-12120-A and for what it's worth, Rear Counter Parts shows 143 in stock with a "common" rating. Dennis Carpenter, McDonald Obsolete Parts and Mustang, Etc. are also listed as having these bushings. I didn't contact them to verify this. Just Googled the Ford part number. FWIW, the bushing in the truck distributor with governor feature is of the oil-lite type. The NOS Ford bushings are steel, or some alloy of iron? If someone needs dimensions of a new bushing, let me know and I'll do my best to measure one. Hope this helps, JEFF.....................

|

|

By FORD DEARBORN - 8 Years Ago

|

Excellent find. A strib from a Lincoln Y 368 will work. Even the shaft is the correct length but you will need to precisely locate and pin a new Ford Y block gear on it. I needed a tack drive distributor for my truck and a 57 bird strib was out of the ball park on price. The 57 Mercury Turn Pike Cruiser with 368 was equipped with a tach.. This is one distributor that went under the radar but I had to remove the 15 tooth gear, (the Lincoln Y had a larger cam journal) and replace it with a 14 tooth gear for my 312 which has worked very well for several years now. Hope this helps, JEFF.............

|

|

By FORD DEARBORN - 8 Years Ago

|

Greetings to all: I think you all are on the right track. My way of doing something isn't always the best way for someone else. But yes, the collar stops the shaft fly weights from being pushed up against the bottom of the breaker plate, As 57RancheroJim stated, .024" sounds in the ball park. So, in this case, with the distributor fully seated in the block. there should be something LESS than the .024" thrust as when uninstalled. This ensures the bottom of the driven gear is indeed seated against the machined thrust surface in the block, the fly weight mechanism will not be contacting the bottom of the distributor bowl and the remaining thrust will ensure nothing will bind when up to temperature. Make sure your dial in on the distributor shaft tip and not the breaker point cam as the cam in the 57 & up distributors has some thrust also and will produce a false reading. With all things working properly, I too have never seen the stop collar contact the bottom of the distributor housing. Fellas, I'm not too good at explaining things but hope this may clear up the theory of this thrust business. JEFF.................

|

|

By FORD DEARBORN - 8 Years Ago

|

Greetings to all: I installed a cam from a 64 distributor into my 57 tach drive distributor for reasons 57Ranchero stated.. It fit and works as advertised. I'm also running Pertronix 2. Hope this helps, JEFF.................

|

|

By FORD DEARBORN - 8 Years Ago

|

Greetings folks: It's been a few years since I last assembled a Y-bolck distributor but the dimension from the bottom of the gear to the bottom of the mounting flange is measured with the shaft all the way down, seated against the bushing. The '64 shop manual refers to a "special tool" and to set the new gear requires all end play taken out. Here is how the book describes that procedure: With the backing screw on the support tool tightened enough to remove all end play, press the gear on the shaft to the specified distance from the bottom face of the gear to the bottom face of the distributor mounting flange. Then pin the gear. FWIW, I made a note in the book that the bushing was originally set .009 above the bottom of the bowl. Hope this helps, JEFF.......................

|

|

By FORD DEARBORN - 8 Years Ago

|

Sounds to me like you have it all down very well. Tightening the screw on the "special tool" would push the shaft down against the bushing/bowl. You are also correct in that there is a typo in the '64 book. It should be as you state, .022, not .002. This procedure establishes the correct positioning of the collar only. Then, feeler gauge removed and the shaft pushed against the screw, the shaft now moved upward .022, the collar is to be placed against the bottom of the housing and pined there which will therefore establish the .022 end play. There were different cam slots. The one that was in my '57 tach strib was 14 or 15* and I replaced it with the cam from my stock '64 strib which was something less, like around 12 or 13* I'm not at home and this is from my old memory. With out a distributor machine, a degree wheel placed on the cam would probably be the only way to check movement. As to the shaft and bushing fit, your mention of .0012 - should work. I personally have never had to "burnish" a bushing as I always was able to reuse the old, but good shaft. In your case, some tweaking of the bushing will be necessary. During the course of this thread, I did indeed check the fit of a new shaft and a NOS bushing which fit properly. That is, moved freely with no detectable slop. If I was home, I would measure these parts. Hopes this helps, JEFF............

|

|

By DryLakesRacer - 8 Years Ago

|

|

Florida Phil...when it dies again I'll bet it's the Chinese condenser. Replaced twice on my 56 before I installed a Pertronics ll. Never a problem in 5 yrs now. I bought their correct coil also and used my existing ballast resistor. Good luck.

|

|

By john2747 - 9 Years Ago

|

Gear placement: 302 ford dimension from bottom of distributor housing mounting flange to bottom of gear for all 289/302 distributors: 4.031"-4.038"

Gear placement:y-block,from bottom of distributor housing mounting flange to bottom of gear for all y-block distributors:

4.991"-4.996"

This measurement can only be taken accurately with the distributor shaft pushed to the bottom and some type of straight edge clamped to the bottom of the distributor gear.Use a high quality digital caliper.

A 302 distributor housing fits the y-block without problems,but the shaft is .958" too short. If an attempt is made, the gear will not fit tight.A Y-block shaft can be used to replace the 302 shaft if it is in good shape.The gear must run on the pad in the block with .008"to .012" end play or it will not live very long.

Cardone has likely run out of y-block distributors cores and are trying to make y-block distributors out of 302 cores,that can't be done without using .958" longer shafts,they are just making junk,and they could kill your engine.'

john2747

|

|

By john2747 - 9 Years Ago

|

Gene

I have read about bad Cardone rebuilds in the past,it seems they only do "cosmetic" rebuilds.Y-Block specs for distributors are in the 1957 ford shop manual.With the distributor removed from the engine they give a measurement of .022"to .030" total main shaft end play,this can be measured with a feeler gauge at the gap between the bottom of the housing and the small collar that is pinned to the shaft.Your measurements indicate that your distributor has .032" shaft end play,that

should be close enough.Using your measurements for the shoulder to bottom of the gear it appears that the gear was pressed on the shaft about .076" to far,or the gear is from another distributor,or the original pin hole was drilled crooked and

the gear was turned 180* when it was reassembled.Taking that measurement is a bit tricky,the ford mechanics used gauge

to position the gear.Double checking the distributor in an empty block,with a feeler gauge is allot easier.With the distributor installed in the block and clamped down and the main shaft pulled up a gauge of .008"to .012" should be ok

between the gear and the machined pad in the block.With the main shaft pushed down the gear must make contact with

the pad.If it dose not contact the pad then it is not located properly.There is a weight plate pinned to the shaft near the top when the shaft is pushed down it contacts the top of the shaft bushing,but it is not meant to run like that,and will wear away the top of the bushing,not good.Perhaps finding a good used distributor that has never been rebuilt is a better way to go.I think the 59 to 64 distributors are better than the earlier ones.I hope things work out.

john2747

|

|

By john2747 - 8 Years Ago

|

Go back to page # 1.I am a retired machinist worked in a machine shop for 44 yrs.I have worked with some very talented welders,I doubt that any of them would claim they could weld two shafts together and maintain a .005" tolerance in length.If it has ever been done it was due to lots of talent.Both length and straightness would be a big challenge.The measurement is taken properly from bottom of distributor housing flange to the bottom of machined pad on the bottom of the gear,not to the bottom of the gear teeth.I have built tach drive distributors from scratch using some original parts.A SBF distributor shaft is about .958" too short to use in a y-block.Like they say there is no substitute for length.SBF distributors can not be reconfigured to ford spec's for y-blocks,it is simply impossible without making the shaft longer That picture from Cardone is simply ridiculous,the measurement to the top of the gear is meaningless,distributor gears differ in height from different producers only the bottom pad on the gear comes into play.

john2747

|

|

By Dobie - 8 Years Ago

|

|

You might give these guys a call: Performance Automotive, 239 671 3974 or email them, perfignition@nctc.com. They rebuild and modify distributors. They're located in southwest FL.

|

|

By Dobie - 8 Years Ago

|

|

They likely will stop making them,. I can't see them making new shafts where they were reusing the original shafts before. It probably wouldn't be cost effective. I think we Y-blockers may sowed the seeds of this situation by sending in Loadamatic units as cores when we bought the rebuilt '57+ units. Sooner or later they were going to run out of the later cores to rebuild. I don't know if the Loadamatic units use the same shaft as the later ones but maybe they could use those.

|

|

By 57RancheroJim - 9 Years Ago

|

I just checked two OEM distributors and the shaft is 6". I had a friend return two Cardones, one had the hole for the gear pin redrilled and the gear moved 1/4", I forget now what the other reason was.

|

|

By 57RancheroJim - 8 Years Ago

|

Looking back at your pictures from a few weeks ago the difference looks like a 1/4". I don't have a loose FE oil pump shaft to measure, just a thought.

|

|

By 57RancheroJim - 8 Years Ago

|

Thank you, thats good info to know, I had no idea they had a longer shaft after 60-61..

|

|

By 57RancheroJim - 8 Years Ago

|

A little off topic from the original post but I found something really strange when I was making one good dizzy from two old ones. These were both 1960 COAF models and after disassembly and cleaning I put some oil in the oil cup to see if it was going to the top bushing but it wasn't happening on either unit, WTF?? Talking to a friend about it we decided to dig deeper, to get the bushing out of the bad one we cut the dizzy in half to push it out. The bushing is solid steel and hard like tool steel and no way for the oil to get to the ID from the oil cup. We then split the dizzy in half length wise right through the oil passage. At the bottom of the oil passage there is a small chamber area for the oil that goes around the OD of the bushing, what good does that do?

Was there ever a time maybe in earlier years the that oiling through the cup actually oiled the bushing?

|

|

By 57RancheroJim - 8 Years Ago

|

Hoosier Hurricane (8/8/2018)

The wick under the rotor was to oil the cam/advance plate assembly, not the top bushing. The distributors that I have worked on had oilite bushings which could absorb oil from the cup, though few people ever put oil in the cup. Correct, the oil wick under the rotor is only for the advance. I was also expecting to see an oilite type bushing, maybe those were used in earlier models. This one is hardened steel, I touched it to a grinder and the sparks were the same as tool steel. I know this is a 100% original '60 dizzy..

I guess the oil goes up the spiral in the shaft some how but thats baffling to me..

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/8/2018)

That's different. Maybe it was a Monday morning distributor at the factory? I figured it was one of those oilite bushings. Oil cup seems to work on this one I'm rebuilding. Checked end play. OK. Spec is .022" to .032", the lower the better.  Both of the dizzy's have the same bushing so I don't think it was a fluke.

Just a wild guess but I wonder if too many bushings wore out from people not oiling them and they changed the design?

I wonder if Cardone even replaces the bushing and what do they use?

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/21/2018)

57RancheroJim (8/21/2018)

This just gets more confusing. I pulled out an old one and it's very hard to get a really accurate measurement with the tools I have but the best I could do was 4.940 with the shaft pushed up and 4.965 pulled down. So those numbers aren't even close to what they call for in the manual,???? Don't know what to say at this point.. OK, thanks very much for that info. So it's roughly (at least) 0.026" too high? Same amount roughly as the endplay. Did they install it wrong?? I better go lay down for a while. LOL I have a digital vernier caliper on the way. Highest quality - $6.99 delivered to my door. Maybe a machinist can explain this to me (hafta talk to me like I'm 5) but the plan is on installing the gear within the 4.991" to 4.996" range with the shaft pulled out. What does the gear wear pattern look like on that one? On the cardone it was clearly engaging only about the bottom 1/3! The shaft itself looks to be the right length oddly enough. The rotor end of the shaft is a bit longer though. Makes ya wonder who signed off on that operation. Sorry for the late reply but my mouse went dead and I had to wait until this morning to go get batteries LOL.

To add to the confusion is the measurement taken to the bottom of the gear where the teeth are or to the bottom of the stepped area that meets the block surface?? That adds about another .030..

The distributor I'm measuring is a completely original 59 model. The wear pattern is as close to center as I can tell.

Is the new bushing steel or bronze?

A 57 shaft would have 26 degrees of advance.

Are you rebuilding the Cardone or another one?

|

|

By 57RancheroJim - 8 Years Ago

|

OK, I was only able to measure the gear surface, if I add the machined surface then it comes into spec. and that was with the shaft pushed up with the collar against the body. It must be correct as that engine ran for countless miles since 59 and everything is still tight.. I just saved it for a back up or some future use..

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/22/2018)

57RancheroJim (8/22/2018)

...if I add the machined surface then it comes into spec. and that was with the shaft pushed up with the collar against the body. Huh. Well there you have it. Thanks Jim! I owe ya beer. Ted, forget what I said, I confused myself again. The measurement from flange to gear was 4.965 + .030 to the machined surface on the bottom of the gear = 4.995 with the shaft PULLED DOWN.. Sorry

|

|

By 57RancheroJim - 8 Years Ago

|

I hope it is a sign of them taking responsibility, it would help their credibility as a supplier. If they just stop making due to a lack of proper shafts it could hurt people in the future needing them

|

|

By 57RancheroJim - 8 Years Ago

|

Ted, is that for the steel bushing or the older oilite with the hole?

|

|

By 57RancheroJim - 8 Years Ago

|

I like the idea of the oilite type bushing and if I ever did it again I would use it. I doubt I'll ever wear out the steel bushing in my lifetime LOL. Does the oilite bushing actually absorb oil? If it does as a I guess there is a large chamber in the casting that would allow a good amount of oil to be in there..

I'm just as confused if you measure with the shaft pushed up or pulled down. I reused the gear and collar so they just went back in the original location and it measured .024 end play when I was done and I called it good.. I'm thinking the max of .032 it about the limit or the rotor may start hitting the cap?

|

|

By 57RancheroJim - 8 Years Ago

|

Regardless of what type bushing, the Pertronix will put no side force on the shaft like points do. I've been using the Pertronix II for about four years now..

|

|

By 57RancheroJim - 8 Years Ago

|

No LOL, I only used the shaft, gear, collar from the one I sacrificed. I put it in my housing and it had a tight bushing so I didn't replace it. My shaft had a issue with the advance. While doing this I was curious why I didn't see any hole in the bushing or a way for the oil to get to the shaft so I cut up that one I wasn't going to use, I have a few others..

I measured the clearance between the collar and housing with the shaft pulled down. Also after I cut down the rotor I checked this morning and there is no sign of hitting the top inside of the cap as before. I've only put 160 miles on it since I reinstalled it. Hasn't missed a beat yet..

|

|

By 57RancheroJim - 8 Years Ago

|

I understand what you are saying and I don't have an answer, I'm not sure if it's measured with the shaft up or down. Do you have an old one to measure? I used the same gear and collar on the shaft so I didn't have to locate it or drill holes..

I broke out the shop manual and the way I read it is the measurement is taken from the body to gear with the shaft pushed up...

|

|

By 57RancheroJim - 8 Years Ago

|

This just gets more confusing. I pulled out an old one and it's very hard to get a really accurate measurement with the tools I have but the best I could do was 4.940 with the shaft pushed up and 4.965 pulled down. So those numbers aren't even close to what they call for in the manual,???? Don't know what to say at this point..

|

|

By 57RancheroJim - 8 Years Ago

|

FORD DEARBORN (8/15/2018)

Greetings to all: I installed a cam from a 64 distributor into my 57 tach drive distributor for reasons 57Ranchero stated.. It fit and works as advertised. I'm also running Pertronix 2. Hope this helps, JEFF................. Thank you for confirming that.

Ted, I would grab that 59 piece, I own three Ford V8's, Y, FE, 302 and in all my travels to different sites and suppliers I have never seen that part for sale..

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/15/2018)

57RancheroJim (8/15/2018)

FORD DEARBORN (8/15/2018)

Greetings to all: I installed a cam from a 64 distributor into my 57 tach drive distributor for reasons 57Ranchero stated.. It fit and works as advertised. I'm also running Pertronix 2. Hope this helps, JEFF................. Thank you for confirming that. Ted, I would grab that 59 piece, I own three Ford V8's, Y, FE, 302 and in all my travels to different sites and suppliers I have never seen that part for sale.. Yeah, first question right outta the box, they asked me what year T-Bird I had. (I have an F100) for a second I wondered if maybe, they might not sell it to me. Better tell 'em I have a '57! They should have 4 left. http://www.tbirdhq.com type in 12210 and it should pop. $50 bucks, they have some other Y related stuff too. If anybody needs the flyweights, DC supposedly has 250 on hand. Nobody else does, except for a single lonely weight on the 'bay. Good find, never thought to look at the Bird sites. It looks like the right one. Good luck and let us know when you receive it..

They list it as 57-59, Whats funny is I don't think Tbirds had Y blocks after 57, they all had FE or 430 Lincoln engines and it maybe the same part used in an FE???

|

|

By 57RancheroJim - 8 Years Ago

|

That must be an error in the shop manual, see those all the time. When revisions and corrections are made the dealers get a service bulletin, we don't..

Yes the bushing goes down to a lip, if my old camera will cooperate today I'll try to take a picture of the housing my friend and I cut in half.

Were did you find the new bushing?

MACs listing for many parts are screwy at best...

I'm only guessing but I would think the 60-64 would be the same, and I only say that because I have a 59 that is different. The plate that the springs attach to is three pieces riveted together, of course I can't guarantee that is 100% original. Also it doesn't use the 3 little nylon buttons for the breaker plate to slide on, it has brass screws..

|

|

By 57RancheroJim - 8 Years Ago

|

A lot of the time REAR COUNTER tells me some one has XXXX but when you contract them they tell me they don't..

Good luck I hope you get the bushing.

This is the one I salvaged the shaft from and then cut it up trying to figure out how that oil hole lubes a solid steel bushing, it doesn't. I'm guessing they just cast thousands of them before they changed the bushing design.

|

|

By 57RancheroJim - 8 Years Ago

|

That may not be sludge, there is a wick in there. I like that bushing with the hole. My bushing seems like hardened steel ?

So many variations over the years..

|

|

By 57RancheroJim - 8 Years Ago

|

oldcarmark (8/19/2018)

57RancheroJim (8/19/2018)

That must be an error in the shop manual, see those all the time. When revisions and corrections are made the dealers get a service bulletin, we don't.. Yes the bushing goes down to a lip, if my old camera will cooperate today I'll try to take a picture of the housing my friend and I cut in half. Were did you find the new bushing? MACs listing for many parts are screwy at best... I'm only guessing but I would think the 60-64 would be the same, and I only say that because I have a 59 that is different. The plate that the springs attach to is three pieces riveted together, of course I can't guarantee that is 100% original. Also it doesn't use the 3 little nylon buttons for the breaker plate to slide on, it has brass screws.. You might also check out Green Auto Parts or Sales. They have a huge Inventory of Obsolete Parts. If it doesn't show on their inquiry site U might contact them direct and see what they have. good reminder, I had forgotten about Green.

|

|

By 57RancheroJim - 8 Years Ago

|

I agree, .006 sounds like too much. I do like their method of bushing removal.

|

|

By 57RancheroJim - 8 Years Ago

|

I finished up the distributor on Monday and started to install it yesterday using my old cap and rotor and noticed there was some wear marks on the top side of the rotor brass tip, also signs of it hitting the top of the inside of the cap, another WTF!

After measuring the height of the rotor with and without the Pertronix wheel over the point cam there was a .070 difference. I checked that measurement again with two different rotors, FOMOCO and a STANDARD, both measured the same. I ended up sanding the bottom of the rotor to bring it back to the same height as without the Pertronix wheel.

I finally got it fired up, set the timing and went for a ride and all is good...

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/15/2018)

That's weird. There sure is a lot going on inside these things that need to be looked at! Cheap distributor caps might be out of round in terms of the terminal ring, or made with old worn tooling and the dimensions aren't correct. I doubt that's your problem though. I bought a Standard FD125 cap a while back and was rewarded with sparkles of brass glitter sprayed all over the inside. Same deal, rotor tip getting a little too chummy with the terminals. I think it turned out just that the rotor wasn't fully seated. The cap itself, if it is installed cockeyed will interfere with the coil secondary voltages because the rotor gap varies across different cylinders. The cap is a NOS Standard with the brass terminals, wear was even so I doubt it's out of round. Just for fun measure the rotor height with and without the Pertronix ring on it.

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/15/2018)

57RancheroJim (8/15/2018)The cap is a NOS Standard with the brass terminals, wear was even so I doubt it's out of round. Just for fun measure the rotor height with and without the Pertronix ring on it. I did notice the clearance is real close on that, but the rotor and ring don't touch on the Ignitor I have installed. That is something to check. A little excess end play and that would do it too.. Hm. How much did you take off .020" or so? Good tip! I just sanded the bottom of the rotor a little at a time until it measured the same height as it would have been without the Pertronix wheel so that would have been close to .070. I had checked it with both my old Pertronix I wheel and the Pertronix II and they were the same, even same part # cast on the part.

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/15/2018)

KULTULZ (8/15/2018)

Basic PN 12210 is the points actual cam. Yes. This is a unicorn component these days I guess. What happens is the advance slots get banged up and worn excessively, and the centrifugal flyweight pins that ride in them also get grooved. Then the mechanical advance gets stuck, or erratic. The '57 and later "should" work judging by some online pics but I don't want to order the wrong part. Thanks for your help. I bet they used the same one for years, I wouldn't be surprised if the SB 289/302 motors use it also..

The 57 were 26 degrees of advance and the later ones are 24, thats why I don't use the 57.. That was for the cars, don't know about the trucks, I have a 57 truck manual I can check if needed.

|

|

By 57RancheroJim - 8 Years Ago

|

Ted,

It's just my personal choice, I like more initial timing, I use 12 + the 24 mechanical for a total of 36.

B9AF-12210-A That appears to be a 59 part number and would only have 24 degrees. Don't be surprised if later ones have a different number and still could be the same part, Ford was notorious for changing numbers..

I have never got this technical on a dist in the past, I miss the good old days when you just put in a new set of points, condenser, cap and rotor and drove it...

|

|

By 57RancheroJim - 8 Years Ago

|

Ted,

Both '60 models I have use the spiral cut shaft. The point spring pressure is adjustable if you have a scale to measure it. No parts book so I don't know what the part # is for the bushing. Good luck getting it out, it must take a special type tool, that why I cut mine in half at the bottom of the bushing so I could press it out..

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/9/2018)

[quote] 57RancheroJim (8/9/2018)

. Yes, but the Ford spec 17 to 22 ounces point spring pressure, that's a pound of force rapping on the side of the shaft, and most all of the cores available today are going to be loosey goosey. Any appreciable wear in the bushings will affect smoothness of tune. I'm certain this is a big reason the solid state modules are so popular, the distributors in collector cars are all wallered out. The electronic modules are not affected by this as badly. The other '64 truck core I have, unfortunately on closer inspection is bent at the gear end. Can see it wobble noticeably. How does a distributor shaft get bent like that? Bad stuff I'm sure, but. Explains why I could never set the dwell consistently years ago. Yes thats true. Luckily the housing I'm using has a pretty good bushing but I'll still be using the Pertronix.

|

|

By 57RancheroJim - 8 Years Ago

|

Tedster (8/9/2018)

Yes, the shop manual calls it "burnishing" to the proper size (whatever that is, they don't say, it's a secret I guess) suppose it just means held to a very close tolerance of the shaft diameter. Figured on getting the bushing on hand and then send it off to have a machine shop do it. Good luck finding bushings, if you find a supplier let us know. They were available from Ford but they haven't had them for years now..

|

|

By 57RancheroJim - 8 Years Ago

|

Ted,

Thats a good question. I've only worked on about a dozen over all the years and none have shown any wear on the bottom of the housing or had signs of excessive end play wear. The end play has always been between .020 and .025 and that's close enough for me.. The one I just assembled measured .024.

|

|

By 57RancheroJim - 8 Years Ago

|

Jeff,

I understand what you are saying and I agree.

|

|

By 57RancheroJim - 8 Years Ago

|

Ted,

I may be wrong but if the shafts moves up and down a few thousands it wouldn't change the dwell, the point gap would remain the same but it would change the timing a small amount. Dwell would only change from side to side movement like with a worn shaft or bushing??

|

|

By 30 coupe - 9 Years Ago

|

|

I bought a cardone rebuilt dist. a couple of years ago. The first time I told them I wanted a dist for a '64 ford truck with a 292. They went with the listing for the eng. size in Liters, and I ended up with a 289 dist. we finally ordered one for a '62 truck with a 292. got a dist that looked correct, but by the ford # on the dist, it was a 302, modified for a y-block. It had a shaft that was to short just as you guys describe, but unfortunately I had already converted it to a ford dura-spark internally , and could not return it. I did not use the dist. as I was concerned about not having enough of the oil pump drive shaft engaging in the dist. I was afraid of a pump shaft failure or some thing related going wrong and destroying a new eng. ended up buying a MSD electronic dist. still not sure I will use it. may have firewall clearance problems when I put the eng. in my '30 coupe. anyway , I think the cardone dist. are not very good.

|

|

By willys392 - 8 Years Ago

|

I have a Cardone 2808 distributor. The gear measures 5" from the mounting base surface to the bottom of the gear but the hex shaft measures only 5 13/16". Am I to believe that this distributor is of no use in a Y block?

Bill

|

|

By Gene Purser - 9 Years Ago

|

"Monarch, thank you for bringing this issue up.

John2747, thank you for providing these specs. I've been running a Cardone distributor in my '55 272" for about three months. I'm going to pull it out and measure it tomorrow.