|

Group: Forum Members

Last Active: Yesterday

Posts: 3.7K,

Visits: 497.9K

|

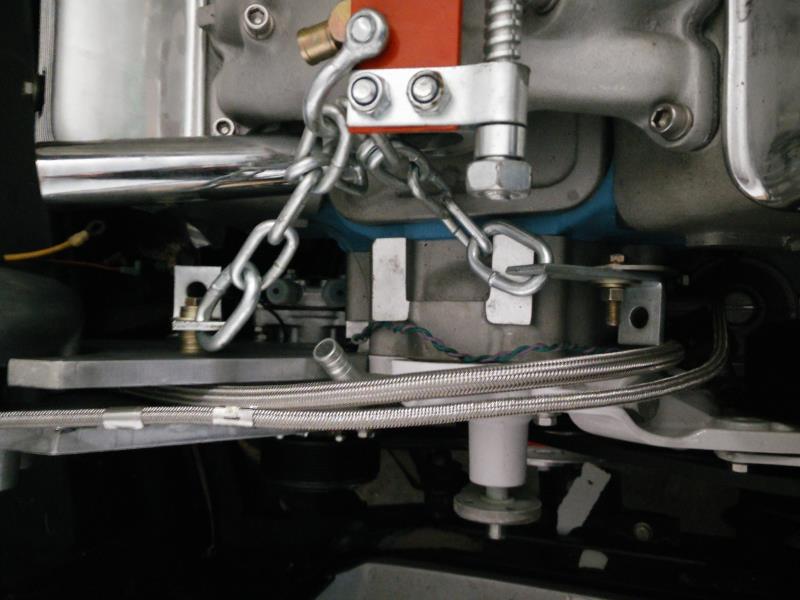

Thi is the ultimate in pivot for pulling engines in my opinion. 1,000 times better than the one with chains shown above. Mac's Pivot Plate http://www.macscustomtiedowns.com 54 Victoria 312; 48 Ford Conv 302, 56 Bird 312

54 Victoria 312; 48 Ford Conv 302, 56 Bird 312

Forever Ford

Midland Park, NJ

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 37,

Visits: 5.1K

|

As the originator of this post, maybe I should throw out an update as to how it worked for me. I did this in my garage using a cherry picker with a leveler and pulled the engine and tranny as one piece. With the help of my daughter and son in law, the whole assembly came out with no problems. I did jack up the rear end and had just enough room to clear radiator mount/frame. Pulling it just a little at a time and adjusting the leveler as we went along, we got it up and out, rolling it out the open garage door. When it came time to put it all back in, this time the engine was complete with the heads on, but not the intake manifold. My connection points for the lift were the intake manifold studs and they held the load without a hitch. By going a little at a time, adjusting the leveler as we went, the assembly dropped in and with a little jiggling and prying and a jack underneath, we got the mounts to all line up. I think the key here is don't hurry, have some help and make sure the beer is cold when you're finished.

|

|

Group: Forum Members

Last Active: Last Month

Posts: 470,

Visits: 183.3K

|

I've done that on a '57 passenger car, you shouldn't have any problem on your Bird.

"FREE SAMPLE"

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 48,

Visits: 2.9K

|

I've been reading some of the posts about removing a 292 with transmission from a '56 Tbird. I will have a cherry picker engine hoist, but I am worried about how much height is required above the cherry picker. Is there any chance I can pull the engine and transmission using a cherry picker in a typical home garage under the open garage door? If not, I guess I will have to push the car out into the driveway, pull the engine and transmission and push the car back into the garage. This is not the time of year I would want to do that.

|

|

Group: Forum Members

Last Active: 8 Years Ago

Posts: 178,

Visits: 5.0K

|

I think it was hot rod magazine that did a test years ago on the engine pulling hook devices that bolt in place of the carburetor. It took several thousand pounds of force to tear up the plates or tear the studs from the intake . Iron or aluminum. They scare the crap out of me but I have had several Y blocks with transmissions and FE's with transmissions swinging from them.

As was mentioned earlier be certain that you have healthy threads in the intake and good thread engagement . Other thing is to buy a good carb plate pulling tool. Mine came from Lakewood , is nice and thick and has good welds. Some of the offshore units that I have seen have thin steel and cold welds.

I have also found that by jacking the rear of the vehicle up , supporting the rear axle with stands and leaving the front end on the ground makes the removal / installation of the engine and trans unit easier since it decreases the angle when pulling the assembly out of the hole.

Just my 2 cents but this is stuff that has worked for me.

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.2K,

Visits: 137.8K

|

That all looks familiar. I dug out my engine leveler, the same one you have, today. Had not looked at if since I trial fitted the 4 speed about 2 years ago. I will use the back holes in the head like you did. may use intake bolts on the front. Have to look at the front cover bolts. Never thought about using those. Love that gadget. Like you, was able to slide the engine and trans in and out by my self with no issues. Wish I had invented it. Probably won't drop it in until after my Florida vacation next week. Got some painting and detail work to do on the underside of the floor and frame before I put it in. Great advice here as usual. Feel a lot better doing it that way than using bolting to the carb base, especially with the aluminum intake.

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 57,

Visits: 2.4K

|

I just pulled complete motor and factory automatic with exhaust manifolds and installed another motor with c4 in under an hour total by myself with most of the time spent moving the lift equipment. I used one of those chain straps with the crank attacked to the back holes on the heads and I made some lifting straps about three inches long with 3/8 holes to bolt to timing cover and the to chain. You will need a longer bolt next to distributor and be sure and put crank on saddle towards windshield.

|

|

Group: Administrators

Last Active: 5 hours ago

Posts: 7.5K,

Visits: 205.9K

|

While I don’t have any issues in using a carburetor lift plate to pick up just the engine, I’d be uncomfortable using that to pick up both an engine and transmission as a unit. And especially where the intake manifold is aluminum. If doing it this way, then be sure to use all four bolts and make sure the bolts are long enough to catch at least a 1/2" of thread in each hole.

If it’s a dual quad intake, then using a specialty lift plate and fastening with all eight carburetor bolts would make me more comfortable. An option here is to use two individual lift plates bolted to the intake interconnected with a single chain which would give some latitude on achieving the desired angle going into the chassis. My preference would be to use a lift chain that has four connecting points that would bolt to the corners of the engine. Even better would be one of those engine lifts that is adjustable in regards to the tilt so that the angle could be changed as the engine and transmission combo can be leveled out once it’s lowered in the chassis.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

You're being overly cautious. An aluminum intake and 3 or 4 bolts will support the weight just fine

Lawrenceville, GA

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.2K,

Visits: 137.8K

|

Anyone?

|