|

Author

|

Message

|

|

Rono

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.3K,

Visits: 80.0K

|

Thanks Jim! I planned on that. In fact, the wife bought a new radiator knowing that I have to pull the old one anyway. Also, new ball joints and a few other goodies. I'll see how much of the work she can do. Rono

Ron Lane, Meridian, ID Ron Lane, Meridian, ID

|

|

|

|

|

Rusty_S85

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 310,

Visits: 2.7K

|

Not to hi-jack this topic, but how do you tell when one is too far gone to attempt to repair it?

Mine has some rust holes in it directly below the passenger side lower control arm mount but it so far is such a small area I planned on either filling in with weld or boxing the cross member in with new metal and blending in. I am just wondering if its one thing I should not attempt to do if theres a level that you reach and its too far gone to safely patch it and still put it on the road.

1956 Ford Fairlane Town Sedan - 292 Y8 - Ford-O-Matic - 155,000 mi

|

|

|

|

|

Rono

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.3K,

Visits: 80.0K

|

Rusty; My front cross member was rusted on both sides and when I jacked it up in the middle of the cross member, the metal caved in there too. If I were you, I would poke at the cross member with an ice pick and see if there are any other soft spots. Once dirt gets in there through the rust holes, it will trap the moisture and continue to rust. I personally would not try to patch over the cross member if the possibility exists that it can still rust out from the inside. Rono

Ron Lane, Meridian, ID Ron Lane, Meridian, ID

|

|

|

|

|

Daniel Jessup

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 2.0K,

Visits: 131.0K

|

If you look at my 55 Refresh and Resto Blog here in the this and that section you can see some good photos of the crossmember that a welder friend of mine and I repaired. Two things that he said about the crossmember... 1. It was very solid on the bottom end (no holes, strong metal, etc) so just the front face and rear face needed attention and 2. Since the whole front face was removed to install a new front plate up front, access was gained to the whole interior of the cross member. I removed over 2 lbs of debris and rust. I then purchased a product from Eastwood made for FRAME interiors so that you can coat it with some type of sealant that stops/inhibits/seals rust. I made a template for the new plates that needed to be welded to the faces front and rear, and then my buddy came over to give his two cents on whether or not it was strong enough. He poked around a lot and said, "Let's go" and welded it up nicely. No need for a new crossmember and to be frank, his work made the crossmember a whole lot stouter than new. Do you have anyone you know that welds for a living that can look at it for you?

Daniel JessupLancaster, California aka "The Hot Rod Reverend"

check out the 1955 Ford Fairlane build at www.hotrodreverend.com

|

|

|

|

|

Rusty_S85

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 310,

Visits: 2.7K

|

Well so far I haven't poked at mine with a ice pick but the only evidence of rust and the metal being soft is just a small portion just below the passenger side lower control arm mounting bolt.

I was thinking of just cutting that section out and fabricating up a new piece and boxing it in. When I ever get around to the frame being bare I planned on sand blasting and doing anti rust coatings on the inside of the frame where needed and then priming and painting the frame.

My only concern was I wasn't sure how far was too far gone. Ive bounced the car and even jacked the car up but I never used this front cross member as a lifting point. I don't think I ever would considering the crossmember under the engine is lower and provides a more stable jacking point.

1956 Ford Fairlane Town Sedan - 292 Y8 - Ford-O-Matic - 155,000 mi

|

|

|

|

|

Rono

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.3K,

Visits: 80.0K

|

Okay guys! I am deep into the Ranch Wagon project to replace the front cross member and have removed and rebuilt the upper and lower control arms, removed the radiator, grille and upper radiator valance. The short braces that run from the frame horn to the cross- member are welded there. So, to get access to them in order to cut the welds it looks like the lower splash pan needs to come out. Is that correct? . Since the front fenders are still on, I am leaving the radiator core support attached to the air deflectors to give the fenders more support. The motor is still in, but I have unbolted the steady rest from the cross member and jacked the motor up in the front just a bit I can't see how you can install one of these Goodall front cross members and not re-weld it to the braces that come off the frame horn and also weld the cross member to the bottom of the frame horn. Am I missing something here? I will post some pictures soon. Thanks, Rono

Ron Lane, Meridian, ID Ron Lane, Meridian, ID

|

|

|

|

|

Talkwrench

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 898,

Visits: 23.2K

|

|

|

|

|

|

Rono

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.3K,

Visits: 80.0K

|

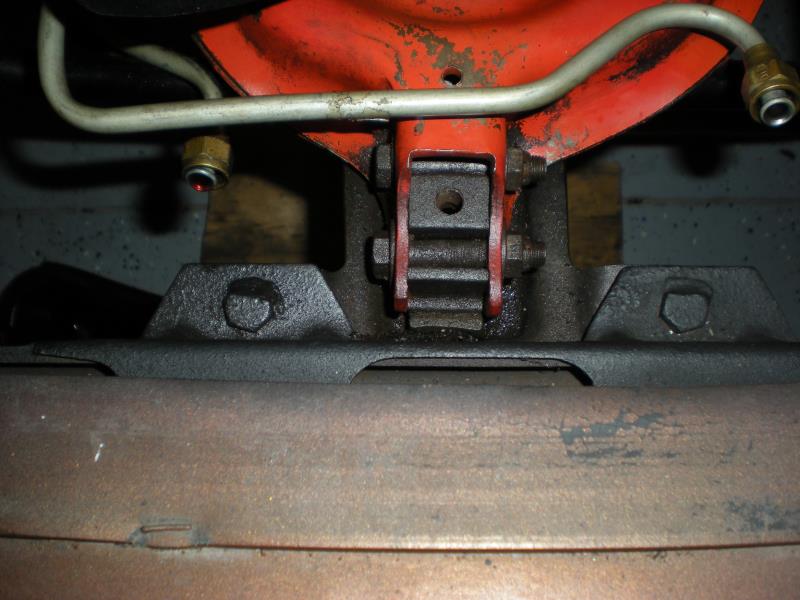

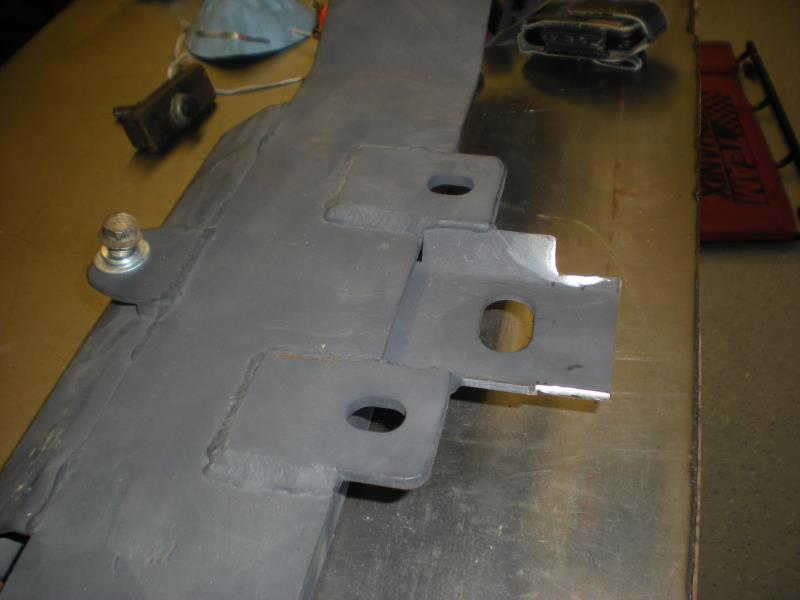

Okay, so below are some pictures to better describe where I am with this front cross member replacement project. Although this car came out of Nevada, it must have been sitting in some wet dirt or deep snow for a long time. The cross member was badly rusted from one side to the other. The photo below is of the passenger side;  The Ranch Wagon still has the original steady rest up front and according to Rick55 The new Goodall Fabrication cross member interfered with the steady rest sitting all the way down, so I modified that portion of the cross member so I wouldn't have that problem; Since the fenders are still on the car, I thought that by removing the grille, and lower splash pan I could leave the radiator core support in place (to support the fenders), cut the welds from cross member and the braces and slide the cross member out through the front of the frame horns. Now I realize that won't work because the core support has welded studs that go down through the cross member. So, I guess my question is, can I remove the radiator core support and the lower splash pan while leaving the fenders and air deflectors in place? Will they stay put without having the core support tying everything together? Thanks, Rono   Here is the modified version;

Ron Lane, Meridian, ID Ron Lane, Meridian, ID

|

|

|

|

|

Daniel Jessup

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 2.0K,

Visits: 131.0K

|

For all practical purposes, the entire front end sheet metal is resting on those two studs and the pesky rubber block underneath that is sandwiched between the core support and the cross member. Also, that horizontal bar up top on the support is helping to keep the fenders "tied" together so to speak. If you remove the core support, and I certainly understand why, you will have to find a way to ... 1. Keep the front end sheet metal "up" and not fall towards frame 2. Keep the fenders tied together laterally. My suggestion is to use angle iron.

Daniel JessupLancaster, California aka "The Hot Rod Reverend"

check out the 1955 Ford Fairlane build at www.hotrodreverend.com

|

|

|

|

|

Rono

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.3K,

Visits: 80.0K

|

Good thought about the angle iron Daniel. Let me chew on that for a bit. Rono.

Ron Lane, Meridian, ID Ron Lane, Meridian, ID

|

|

|

|