|

By Rono - 11 Years Ago

|

Our 56 Ranch Wagon needs a front cross member. It's pretty rotten. Has anyone tried Goodell Fabrications replacement front cross members? They are advertising on E-pay.

Rono

|

|

By PWH42 - 11 Years Ago

|

|

I've bought a couple of them and was well satisfied with them.They don't look like the original,but are probably made better.Well worth the price.

|

|

By Rono - 11 Years Ago

|

Paul;

Thanks...that's what I was hoping to hear.

Rono

|

|

By Rono - 11 Years Ago

|

Paul;

Just a couple of questions regarding the replacement of the front cross member; Did you tack weld in a brace at the end of the frame horns to maintain the correct dimension before you cut out the old cross member? Also, is it necessary to pull the motor or can you work around the front steady rest?

Thanks,

Rono

|

|

By PWH42 - 11 Years Ago

|

|

Rono...................Both of them that I did was with the engine out and front clip off the car,so I had nothing to work around.I didn't weld in a brace because both times I had all the suspension off and just had a bare frame.

|

|

By Rono - 11 Years Ago

|

Paul;

Thanks! I was just trying to figure out if this was going to be a short or long term project. We have a few modifications we were planning, but were thinking about doing one thing at a time and trying to keep the wagon on the road. It doesn't feel like "Winter" here, but it is so I may as well plan on putting the car up and doing all the heavy work at once (pull the motor, disk brakes, new radiator, & C4).

Rono

|

|

By stlroken - 11 Years Ago

|

Rono

I'm very happy with the cross member in my '56 Victoria. Goodell was easy to work with, price was right.

Engine in the car and no welding required. Good Luck.

Jim

|

|

By kansas - 11 Years Ago

|

did cross member with engine in and front clip on Was not hard to do

jim

|

|

By Rono - 11 Years Ago

|

Guys;

Thanks for your response. I feel a little more at ease knowing that you guys didn't have a hard time with this. The original front cross member is welded in and the information on the new cross member indicates that welding is required. So, I'm confused when you say no welding required. Did you drill and bolt the mounting flange to the inside bottom of the frame horn?

Rono

|

|

By kansas - 11 Years Ago

|

The one I used had to be welding in, I did remove the radiator first

jim

|

|

By Rono - 11 Years Ago

|

Thanks Jim! I planned on that. In fact, the wife bought a new radiator knowing that I have to pull the old one anyway. Also, new ball joints and a few other goodies. I'll see how much of the work she can do.

Rono

|

|

By Rusty_S85 - 11 Years Ago

|

Not to hi-jack this topic, but how do you tell when one is too far gone to attempt to repair it?

Mine has some rust holes in it directly below the passenger side lower control arm mount but it so far is such a small area I planned on either filling in with weld or boxing the cross member in with new metal and blending in. I am just wondering if its one thing I should not attempt to do if theres a level that you reach and its too far gone to safely patch it and still put it on the road.

|

|

By Rono - 11 Years Ago

|

Rusty;

My front cross member was rusted on both sides and when I jacked it up in the middle of the cross member, the metal caved in there too. If I were you, I would poke at the cross member with an ice pick and see if there are any other soft spots. Once dirt gets in there through the rust holes, it will trap the moisture and continue to rust. I personally would not try to patch over the cross member if the possibility exists that it can still rust out from the inside.

Rono

|

|

By Daniel Jessup - 11 Years Ago

|

If you look at my 55 Refresh and Resto Blog here in the this and that section you can see some good photos of the crossmember that a welder friend of mine and I repaired. Two things that he said about the crossmember... 1. It was very solid on the bottom end (no holes, strong metal, etc) so just the front face and rear face needed attention and 2. Since the whole front face was removed to install a new front plate up front, access was gained to the whole interior of the cross member. I removed over 2 lbs of debris and rust. I then purchased a product from Eastwood made for FRAME interiors so that you can coat it with some type of sealant that stops/inhibits/seals rust. I made a template for the new plates that needed to be welded to the faces front and rear, and then my buddy came over to give his two cents on whether or not it was strong enough. He poked around a lot and said, "Let's go" and welded it up nicely. No need for a new crossmember and to be frank, his work made the crossmember a whole lot stouter than new.

Do you have anyone you know that welds for a living that can look at it for you?

|

|

By Rusty_S85 - 11 Years Ago

|

Well so far I haven't poked at mine with a ice pick but the only evidence of rust and the metal being soft is just a small portion just below the passenger side lower control arm mounting bolt.

I was thinking of just cutting that section out and fabricating up a new piece and boxing it in. When I ever get around to the frame being bare I planned on sand blasting and doing anti rust coatings on the inside of the frame where needed and then priming and painting the frame.

My only concern was I wasn't sure how far was too far gone. Ive bounced the car and even jacked the car up but I never used this front cross member as a lifting point. I don't think I ever would considering the crossmember under the engine is lower and provides a more stable jacking point.

|

|

By Rono - 10 Years Ago

|

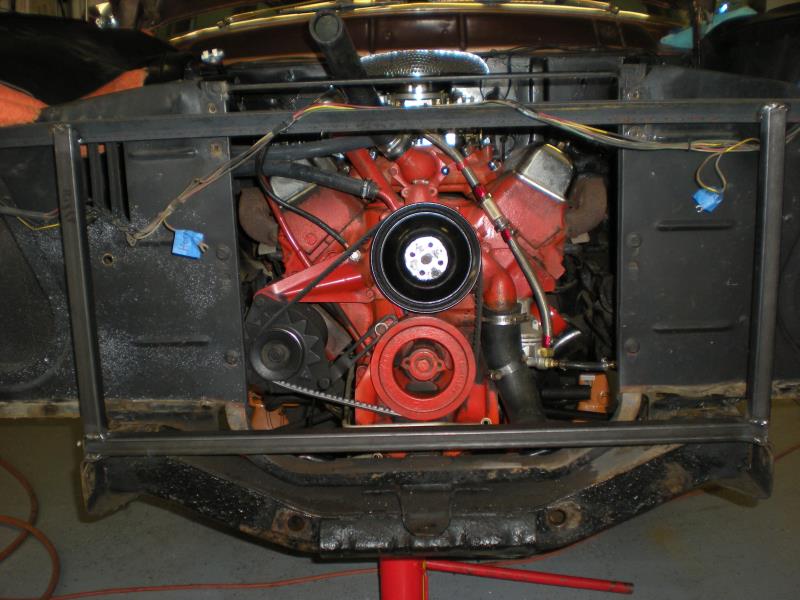

Okay guys! I am deep into the Ranch Wagon project to replace the front cross member and have removed and rebuilt the upper and lower control arms, removed the radiator, grille and upper radiator valance. The short braces that run from the frame horn to the cross- member are welded there. So, to get access to them in order to cut the welds it looks like the lower splash pan needs to come out. Is that correct? . Since the front fenders are still on, I am leaving the radiator core support attached to the air deflectors to give the fenders more support. The motor is still in, but I have unbolted the steady rest from the cross member and jacked the motor up in the front just a bit

I can't see how you can install one of these Goodall front cross members and not re-weld it to the braces that come off the frame horn and also weld the cross member to the bottom of the frame horn. Am I missing something here? I will post some pictures soon.

Thanks,

Rono

|

|

By Talkwrench - 10 Years Ago

|

Wish I could remember exactly how we did it on mine . We removed the front guards and radiator frame all still bolted together, couple of guys and walked it off. Rick is the best one to get info from [Rick55]. I just remember it was not an easy task and still so very thankful to the guys in our club. Rick , John and Gary still cant thank you enough!

Post the pics Ron I'm sure you will get help.

|

|

By Rono - 10 Years Ago

|

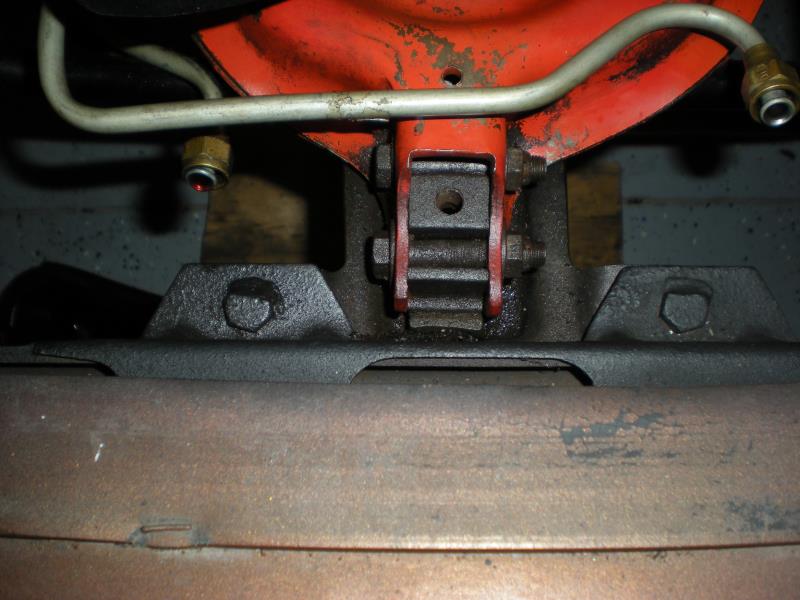

Okay, so below are some pictures to better describe where I am with this front cross member replacement project. Although this car came out of Nevada, it must have been sitting in some wet dirt or deep snow for a long time. The cross member was badly rusted from one side to the other. The photo below is of the passenger side;

The Ranch Wagon still has the original steady rest up front and according to Rick55 The new Goodall Fabrication cross member interfered with the steady rest sitting all the way down, so I modified that portion of the cross member so I wouldn't have that problem;

Since the fenders are still on the car, I thought that by removing the grille, and lower splash pan I could leave the radiator core support in place (to support the fenders), cut the welds from cross member and the braces and slide the cross member out through the front of the frame horns. Now I realize that won't work because the core support has welded studs that go down through the cross member.

So, I guess my question is, can I remove the radiator core support and the lower splash pan while leaving the fenders and air deflectors in place? Will they stay put without having the core support tying everything together?

Thanks, Rono

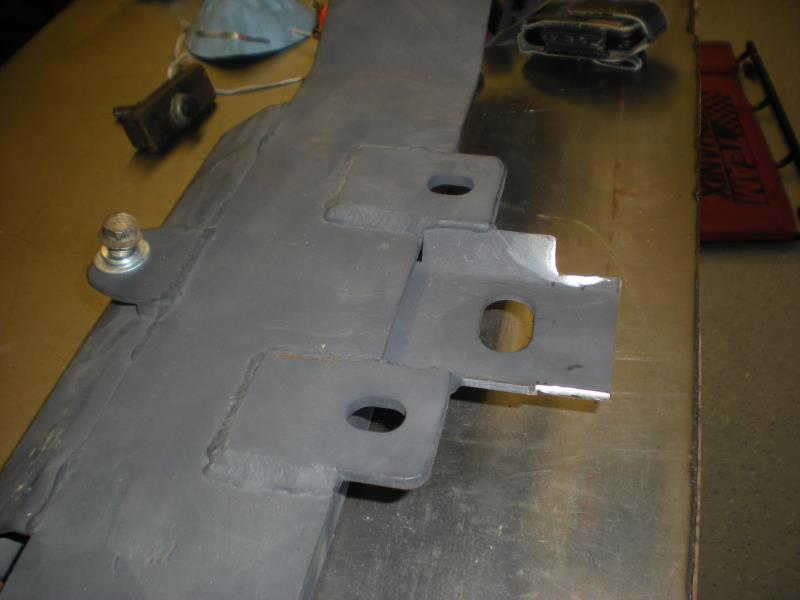

Here is the modified version;

|

|

By Daniel Jessup - 10 Years Ago

|

For all practical purposes, the entire front end sheet metal is resting on those two studs and the pesky rubber block underneath that is sandwiched between the core support and the cross member. Also, that horizontal bar up top on the support is helping to keep the fenders "tied" together so to speak. If you remove the core support, and I certainly understand why, you will have to find a way to ...

1. Keep the front end sheet metal "up" and not fall towards frame

2. Keep the fenders tied together laterally.

My suggestion is to use angle iron.

|

|

By Rono - 10 Years Ago

|

Good thought about the angle iron Daniel. Let me chew on that for a bit.

Rono.

|

|

By Talkwrench - 10 Years Ago

|

Pretty sure your going to have to remove the guards , otherwise we would have left them in place when we did mine. There is quite a bit of grinding etc to do so maybe best all out of the way.

Good time to have the radiator serviced and do the front seal and timing chain ; ) and so it goes on ...............

|

|

By Rono - 10 Years Ago

|

Not sure what you mean by removing the "guards"? Do you mean the fenders? The radiator is new and the motor was rebuilt not too long ago so I am not worried about them. I think I can support the fenders with angle iron across the top (as Daniel suggested) where the upper radiator valance was bolted. I can then use my shop crane to keep the front of the fenders up while I disconnect the core support and lower splash pan. I think I can keep the front bumper attached but remove the outer bumper bracket bolts so the cross member can come out the front of the frame horns.

While doing some pre-measurements, I did find that the inside width between the frame horns is 35&3/4", but the width of the new cross member is only 35". So there will be about 5/8" space on either end of the new cross member inside the frame horns. I don't think this will matter much because the top and bottom of the cross member is where the weld points are.

Rono

|

|

By Talkwrench - 10 Years Ago

|

..HAhahaha.. Yes "fenders" Bonnet = Hood , Boot = trunk, doors = doors ... seems a door is a door..

You had better put up some pics if you find a way to do it.

|

|

By Rono - 10 Years Ago

|

I thought I would try to follow my original plan and leave the fenders ("guards") on while I try to remove the front crossmember. To do this, I used a 1&1/2" piece of angle iron (46" long) bolted across the front fender mounting flange where the upper radiator valance bolts. After removing the two small rubber splash aprons between the bottom of the air deflectors and top part of the crossmember, I could see that the entire width of the top part of the crossmember is welded to the upper part of the frame horn. Since the core support is still in place, I used an air chisel and was able to cut the entire weld under the air deflector without removing it. Tomorrow, I will cut the other side along the top of the crossmember and then weld a piece of 1" square tubing horizontally across the ends of the frame horns and then weld two vertical 1" tubing pieces up to the angle iron. This should stabilize the fenders both horizontally and vertically when I remove the core support.    There is one issue that I haven't quite figured out yet and that is the factory tabs that extend through slots in the frame horn and are then bent over and welded in place. The aftermarket "Goodall" crossmember doesn't have these tabs, so I need to decide whether to fabricate them once the crossmember is in place and bolted up to the lower control arms or just not bother with making any tabs. All the other welds should hold it in place. What do you guys think? There is one issue that I haven't quite figured out yet and that is the factory tabs that extend through slots in the frame horn and are then bent over and welded in place. The aftermarket "Goodall" crossmember doesn't have these tabs, so I need to decide whether to fabricate them once the crossmember is in place and bolted up to the lower control arms or just not bother with making any tabs. All the other welds should hold it in place. What do you guys think?

Rono

|

|

By Rowen - 10 Years Ago

|

Pure speculation, I'm thinking those tabs are alignment tabs for mass production. I doubt that they are "structural" in nature.

Rowen

|

|

By Rono - 10 Years Ago

|

Rowen;

I think you are probably correct. The tabs probably just generally located where the crossmember was supposed to go. In fact, it was probably placed in a jig and then the frame rails were brought in from either side. Since I had the lower control arms out, I replaced the bushings but may have pressed them in a little too far. I checked for fitment with the new bushings against the old crossmember and will need to press each one back out about 1/16". Also, when I took the arms off the original cross member, there were 2 washer "shims" on the driver's side, but only 1 on the passenger side. Below is a picture of those shims. I'm wondering if I should adjust the bushings so that I don't need the shims at all or adjust them so they will match how it was originally set up.

Rono Rono

|

|

By Rono - 10 Years Ago

|

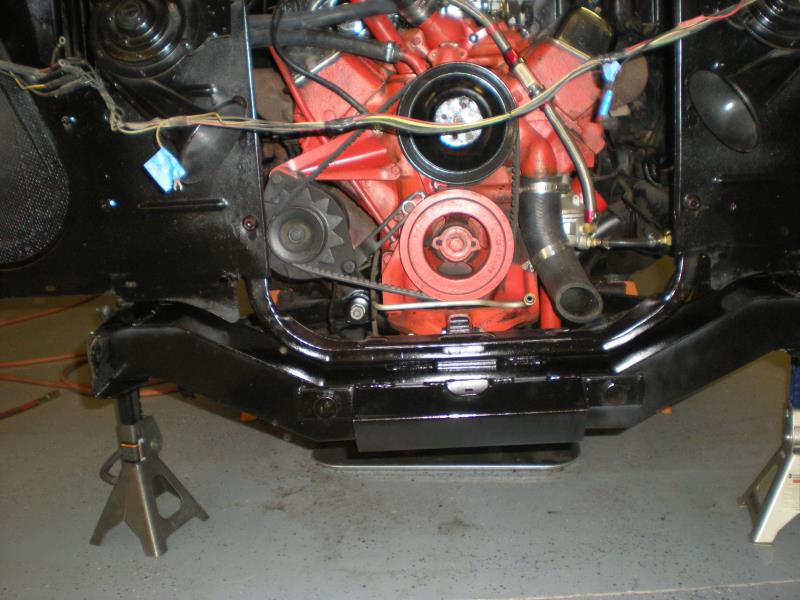

Okay, here's the latest. Looking back through this thread Kansas also did this replacement with the engine in and the front clip on. So, after I cut all the welds using mostly an air chisel, but also a cut off wheel and my plasma cutter, before I pulled the core support out I used angle iron between the fenders and then welded 1"square tubing across the ends of the frame horns and vertical 1" tubing up to the angle iron. When I disconnected the core support from the air deflectors the fenders didn't budge. With the motor jacked-up slightly in the front the steady rest came off the cross member and I was able to bang the cross member out through the front of the frame horns. As you can see from the photos, this old crossmember was rotted out from one side to the other. Hopefully the installation of the new cross member will go smoothly. I'll keep you posted.    Rono Rono

|

|

By rick55 - 10 Years Ago

|

The crossmember does not need the tabs but you use their position to locate the new crossmember. It is much easier to do the job with the front clip and bumper removed but if you choose to leave it on it just makes access difficult though not impossible to do some of the welding necessary. I don't know what the poster sometime previous meant when he managed to fit a new crossmember without welding it. Definitely not possible. Reno you have saved yourself some grief by grinding that rear lip off the crossmember. I ended up by not using the front engine steady rest because it was fouling that tab. It was too hard to cut it once I had the engine in place. The shimson the front bolt may or not be necessary to refit. They are merely to align both lower control arms. The rear of the control arms bolt directly to the crossmember and the shims at the front are to adjust play out of the control arm at the front. From memory mine didn't need any shims on my my 55.

You've got lots of bolts to undo if you're taking the front apron (stone tray) off the car. It is much easier just to take the whole font clip off in one piece. I'm all for the easy life.

Good luck however you do it. A job well worth doing. My 55 had the drivers side a arm chained to the crossmember. It was just swinging in the breeze.

|

|

By Rono - 10 Years Ago

|

Rick;

I did remove the front bumper for this job and I wanted to powder coat the lower stone guard and the upper radiator valance anyway. The main reason for not taking the front clip entirely off was that I didn't want to have to cut the wiring harness. Not ready for re-wiring yet. We plan on changing to an alternator and adding AC maybe next year so when we do that, it will be time for a new wiring harness.

I would like to know if you tack welded the new cross member in the correct position before trying to fit the control arms or if you tried to locate the correct position of the crossmember using the control arms? I tried the latter and that didn't seem to work so I now have the new crossmember tack welded in place and will try again tomorrow to fit the control arms. I pressed new bushings into all the control arms (upper and lower) and test fitted the lower arms with the new bushings against the old crossmember before I took it out and the front to rear distance seemed correct so they should be okay.

I also wanted to know if that new crossmember has a weld-through primer on it or if you ground off all that heavy paint where the welds need to go. I thought it might be a weld through primer, but it seems pretty thick to me.

Thanks,

Rono

|

|

By Rono - 9 Years Ago

|

The crossmember replacement is done. One final confusing detail was that I could not use the stock rubber pad on the bottom of the radiator core support because the mounting holes in the air deflectors would not line up. This pad is about 1/2" thick, but I replaced it with a leftover 56 gas tank pad that I cut down to fit. I'll move on now to the disk brake conversion and will be posting some pictures on how that job goes.  Rono Rono

|

|

By Talkwrench - 9 Years Ago

|

|

Coming along fine.. Yep she's rotted out like so many of them . Rick was an electrician [ among many other interesting occupations] so taking some of the wiring off to pull the front clip was no problem, cant remember if there was much anyway ? Welder her straight up !

|