I Think you can do a bit more in the exhaust side of the head. Here is a pic of a G head sectioned to show the exhaust port. Notice that the black sharpie line on the long radius side of the head runs from the edge of the guide to the center of the ex port flange. You can remove all this. You can also widen the port a bit to get it more round in appearance. The drilled hole shows a lot of material. I found that the biggest improvement was from putting in larger ex valves, I used 1.6" scrub valves that were 0.200" longer but now you can get exact fit valves from John M. The marks on the ex valve and bowl show where to grind a little undercut but removing too much causes loss of compression.

This pic shows the kind of shape I wanted at the exhaust flange. The top manifold in the pic has already been done the bottom one is marked for grinding. I matched gaskets but these days for manifolds like this I would just use HT silicone.

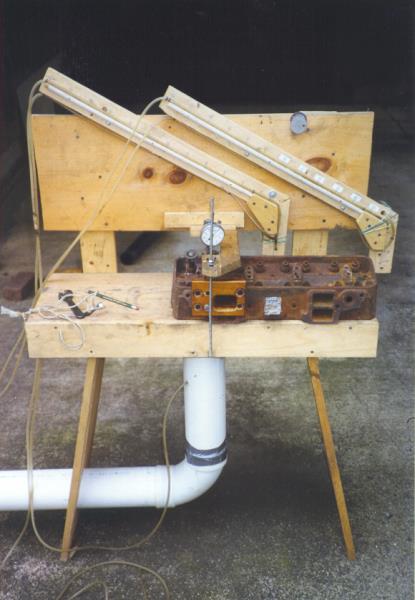

I developed these ideas and some others using a home made flow bench in the early 1990's

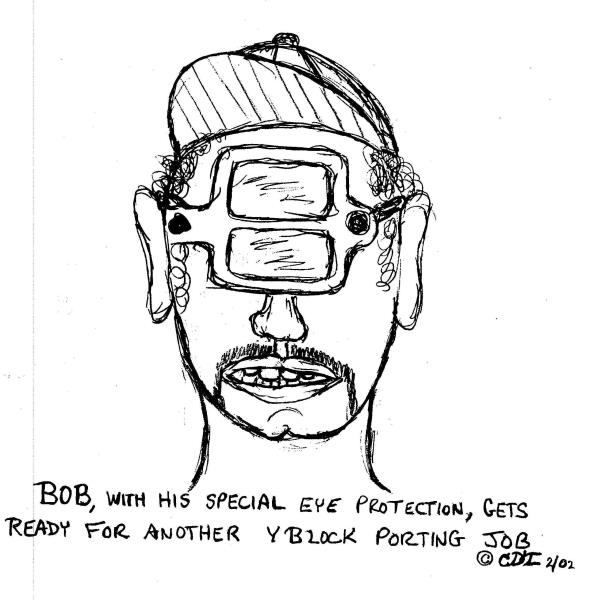

Finally if you are going to have fun porting don't forget your special Y Block Goggles

Doug T

Doug TThe Highlands, Louisville, Ky.