|

By CK and his 55Tbird - 11 Years Ago

|

Ok so I am rebuilding my 292. Planning on decking the block, Pistons flush, accounting on a .040" gasket.

The heads are 5752-113 and I've read what I can find online "thanks Ted, John, Tim and everyone else posting info"

What I would like is some guidance to porting these heads. Is it true that they will flow 175cfm stock and may port out to 235cfm?

I won't need to go to far as I'm running a fairly mild cam 265-109 and eventually 1.6 rockers. I'm aiming at about 5200rpm if it goes further then that will be great.

So the porting to start with, match porting and cleaning any rough raised edges and what ever tips I can gain from you guys.

I understand induction works by volume and average diameter. Therefore if the average diameter was small and the port would then be long with an equal volume, the rev would be slow. yet alternatively a larger average dia. with eq. volume will rev quickly. Perhaps higher rev's too. So I don't want to flood the engine and expect it to rev to quick, yet some pazzaz to 5'500 will be great.

I am considering locking the orig. dizzy "load o matic" and running a Ez-EFI 2.0 carb. Love a mummets manifold yet difficult getting onto him, as I'm from Melbourne, Australia and E-mailing is my only option of contact, John.

So what its going in is a 55' Tbird 3speed stick build# 247 and gee it feels great to be cruising with the top down. I'll be glad to have it back on the road with in a month or two. I finally got my American classic convertible.

All the best, CK

Oh, Keep your wheels turning free!

|

|

By speedpro56 - 11 Years Ago

|

|

The 113 heads flow 155-160 cfms stock. Getting to 200 cfms will take some good porting and that's at around .500 lift. Getting up to 235 cfms is possible and that is a race port for an iron head and will take some pretty good skill but can be done, good luck on your project.

|

|

By PF Arcand - 11 Years Ago

|

|

On a fairly mild cammed 292, the #113s likely will flow plenty as is.. J. Mummurt issued flow figures years ago in stock form of around 170+ cfm, but at very high lifts. 235 cfm is likely possible, but only by an expert, again at high lifts. These figures were based on an over bored 312". He has pointed out more than once, that those heads are also held back by original intake manifolds.. One thing that #113s do need is more compression, but you're planning to deck the block, so that's a ? mark.

|

|

By Ted - 11 Years Ago

|

|

For backyard porting, concentrate on ‘line of sight’ flow which means smoothing up the bends around the head bolt bosses. Knocking off the casting flash or roughness and doing some bowl blending also goes a long way in getting those flow numbers up. Minimize what is done on the short turn radius and especially on the lower ports as the flow speed suffers in that area if the short turn radius is ‘straightened’ out. The final finish of the ports still needs to have some texture and not be mirror smooth so that some ‘friction’ or turbulence can be maintained between the port wall and the flow; this will assist in keeping the fuel from dropping out of suspension.

|

|

By CK and his 55Tbird - 11 Years Ago

|

Thanks guys

The cam is a high lift about or close to .500" with 1.6 rockers

What are your thoughts on re surfacing Lifters?

I was just reading some of Ted's recommendations on exhaust ports and not to take away the section over the plugs, which I'm glad because I probably would have rounded them out. Though I am a bit cautious obviously and why I'm asking.

And I now have a greater opinion of the Saunders type headers I was thinking of buying. I guy here in Aust. is making sets in Stainless, good money too. I found them on eBay. Maybe all thru 2 1/2" system from the graphs.

And the inlets is exactly the info I was hoping to receive. However aren't the claims of design regarding the change of direction in the ports to aid in a greater swirl pattern? Though I have read this to be controversial being the restrictive nature of design.

|

|

By slick56 - 11 Years Ago

|

|

CK and his 55Tbird (1/26/2014)

I was just reading some of Ted's recommendations on exhaust ports and not to take away the section over the plugs, which I'm glad because I probably would have rounded them out. Though I am a bit cautious obviously and why I'm asking.

And I now have a greater opinion of the Saunders type headers I was thinking of buying. I guy here in Aust. is making sets in Stainless, good money too. I found them on eBay. Maybe all thru 2 1/2" system from the graphs.

Hey CK, can you post a link to Teds info on exhaust ports?

Those headers on fleabay for $249 + shipping seem excellent value, but he does not say what they will fit or where they are made.

Cheers,

.

|

|

By CK and his 55Tbird - 11 Years Ago

|

He told me they were the same as Saunders after some persistance, as I had previously seen.He also has a selection of stainless pipes and mufflers, including various bends etc.

I will write it up.

|

|

By lyonroad - 11 Years Ago

|

|

Those headers on fleabay for $249 + shipping seem excellent value, but he does not say what they will fit or where they are made.

Got a link to those stainless headers?

Thanks

|

|

By slick56 - 11 Years Ago

|

lyonroad (1/26/2014)

Those headers on fleabay for $249 + shipping seem excellent value, but he does not say what they will fit or where they are made.

Got a link to those stainless headers? Thanks

|

|

By speedpro56 - 11 Years Ago

|

|

I'd go with new lifters for insurance. Cams and lifters are too hard to change and expensive when it comes to the difference in cost of new lifters vs. resurface which has a cost as well and thinning the hardness in the process can be a gamble. Isky, Comp cams and I believe Ted sell new USA lifters which should work and are high grade. I would NOT use anything made in China.

|

|

By lyonroad - 11 Years Ago

|

Too bad, they look good. The Canadian/Australian exchange rate is favorable but the shipping would be a killer. Just out of curiosity do they fit sedans? They kind of resemble Tbird headers. My brother in law will be in Wollongong in a month or so.

|

|

By CK and his 55Tbird - 11 Years Ago

|

|

I'm told the lifters are re-hardened once shaped.

|

|

By CK and his 55Tbird - 11 Years Ago

|

|

Maybe you could get a few guys together on this site to order in bulk and reduce costs further.parts and shipping?

|

|

By speedpro56 - 11 Years Ago

|

|

Heard of too many going south unless for a stocker.

|

|

By slick56 - 11 Years Ago

|

lyonroad (1/26/2014)

Too bad, they look good. The Canadian/Australian exchange rate is favorable but the shipping would be a killer. Just out of curiosity do they fit sedans? They kind of resemble Tbird headers. My brother in law will be in Wollongong in a month or so.

I will email him tonight to see if he knows if they will fit a full size Ford, if so i will order a set and keep you informed.

.

|

|

By CK and his 55Tbird - 11 Years Ago

|

"What colour is she" "Its green"

"Green, Greens nice"

|

|

By CK and his 55Tbird - 11 Years Ago

|

So back to porting.I've seen Ted's 375 with the block having notches in the tops of the bores.

This head had 2.02" valves I'm pretty sure.

Will this help my 292 ????

|

|

By Ted - 11 Years Ago

|

|

CK and his 55Tbird (1/26/2014)

....What are your thoughts on re surfacing Lifters? I have two separate thoughts on this. The first is as long as new quality lifters are available, then it’s more cost effective to use the new lifters versus the risk that’s involved with the reground lifters. The second thought is as more lifters are resurfaced, then the chance of regrinding a set of lifters that has already been previously reground gets higher which in turn increases the risk of reduced surface hardening attributes.. There have been many past discussions on this site regarding the use of reground lifters and the following link brings up several of those. . http://forums.y-blocksforever.com/FindPost66378.aspx

|

|

By Ted - 11 Years Ago

|

|

CK and his 55Tbird (1/27/2014)

So back to porting.I've seen Ted's 375 with the block having notches in the tops of the bores.

This head had 2.02" valves I'm pretty sure.

Will this help my 292 ???? With the iron heads, the notches are required to keep the intake valves from hitting the cylinders wall edges with any substantial lift at the valve. While the aluminum head valves have been relocated so that the intake valves will now free drop into the cylinders, the notches do still help the air flow in that area and especially when the valve lifts are increased beyond the mild performance stuff. When doing the notches, be sure that they are kept above where the top ring resides within the cylinder bore.

|

|

By CK and his 55Tbird - 11 Years Ago

|

Interesting Ted, thanks.

Another question regarding the chambers of the 113 heads. They seem to curl back at the head surface?

|

|

By snowcone - 11 Years Ago

|

I'm gonna hijack the thread again and say those headers look great for the money.

Will have me thinking about my now completed single system if they fit sedans

|

|

By CK and his 55Tbird - 11 Years Ago

|

I checked my manifold and found that it is an ECB 9425 B There is a witness mark showing how restricted the 113's are.

|

|

By CK and his 55Tbird - 11 Years Ago

|

So I ported the heads, as I'd like to flow test them I'm not going to. So I ported the heads, as I'd like to flow test them I'm not going to.

|

|

By CK and his 55Tbird - 11 Years Ago

|

I got about a 1/4 of an inch open through the head bolt and push rod posts. I got about a 1/4 of an inch open through the head bolt and push rod posts.

|

|

By CK and his 55Tbird - 11 Years Ago

|

|

|

By CK and his 55Tbird - 11 Years Ago

|

And the exhausts. And the exhausts.

|

|

By CK and his 55Tbird - 11 Years Ago

|

|

|

By yblock - 11 Years Ago

|

regrind.just had a visit to shadbolt cams in vancouver bc canada. they did a cam for me (used a 57merc profile)barry the owner tels me the older cams are far better material than the new ones.he also refaces lifters,he claims hardness is not a isue and is selective on how far and what style he refaces. frt should be reasonable for cam and lifters.flights ar dailey van to aust.

sorry i do not have his phone # as i am in az for 1 month. Ihave delt with barry for years,when i worked we used him alot.i have never had a failure with his products,just tell him what you want and take his advice.tell him cliff sent you.if you have time i have lifter cores no cams at present cliff

|

|

By LordMrFord - 11 Years Ago

|

Here are some pics from my ported heads to CK. Intakes are not so much ported but some bowl work and cleaning. Exhausts are quite big. Valve sizes are stock '59.

http://s188.photobucket.com/user/Reilukaista/library/Runners?sort=3&page=1

|

|

By Doug T - 11 Years Ago

|

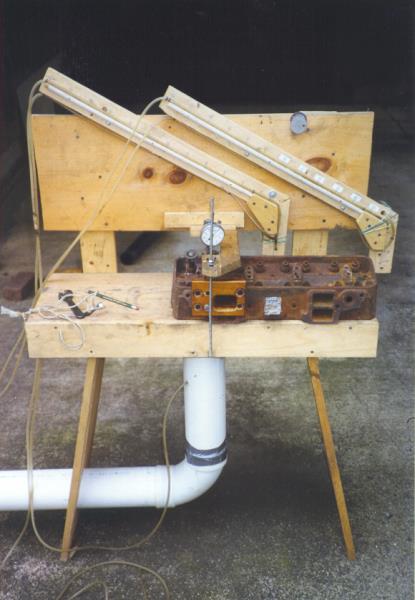

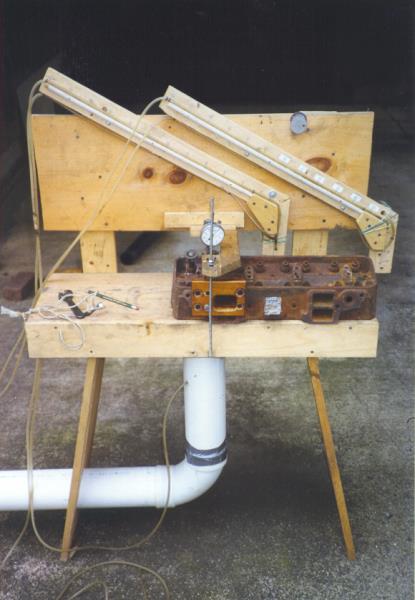

I Think you can do a bit more in the exhaust side of the head. Here is a pic of a G head sectioned to show the exhaust port. Notice that the black sharpie line on the long radius side of the head runs from the edge of the guide to the center of the ex port flange. You can remove all this. You can also widen the port a bit to get it more round in appearance. The drilled hole shows a lot of material. I found that the biggest improvement was from putting in larger ex valves, I used 1.6" scrub valves that were 0.200" longer but now you can get exact fit valves from John M. The marks on the ex valve and bowl show where to grind a little undercut but removing too much causes loss of compression. I Think you can do a bit more in the exhaust side of the head. Here is a pic of a G head sectioned to show the exhaust port. Notice that the black sharpie line on the long radius side of the head runs from the edge of the guide to the center of the ex port flange. You can remove all this. You can also widen the port a bit to get it more round in appearance. The drilled hole shows a lot of material. I found that the biggest improvement was from putting in larger ex valves, I used 1.6" scrub valves that were 0.200" longer but now you can get exact fit valves from John M. The marks on the ex valve and bowl show where to grind a little undercut but removing too much causes loss of compression.

This pic shows the kind of shape I wanted at the exhaust flange. The top manifold in the pic has already been done the bottom one is marked for grinding. I matched gaskets but these days for manifolds like this I would just use HT silicone.

I developed these ideas and some others using a home made flow bench in the early 1990's

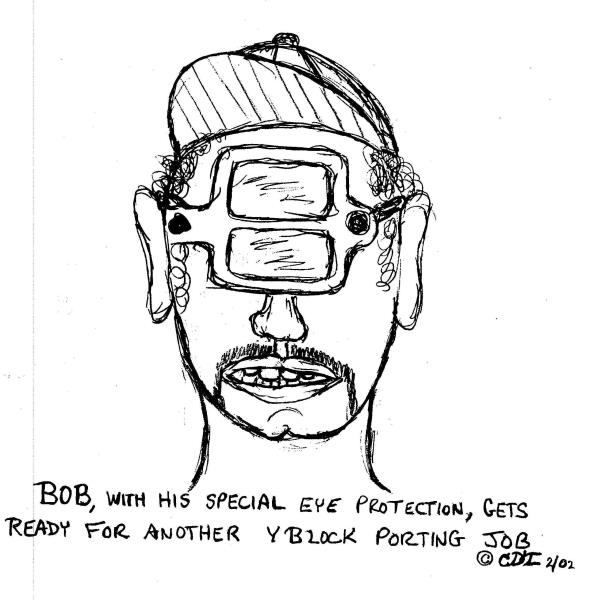

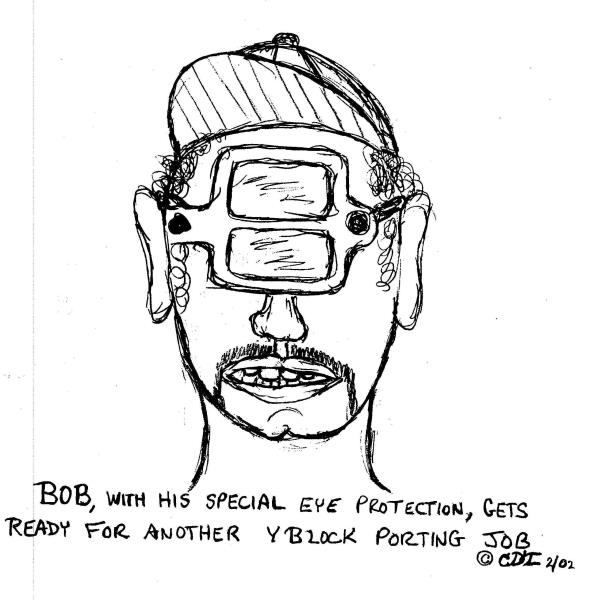

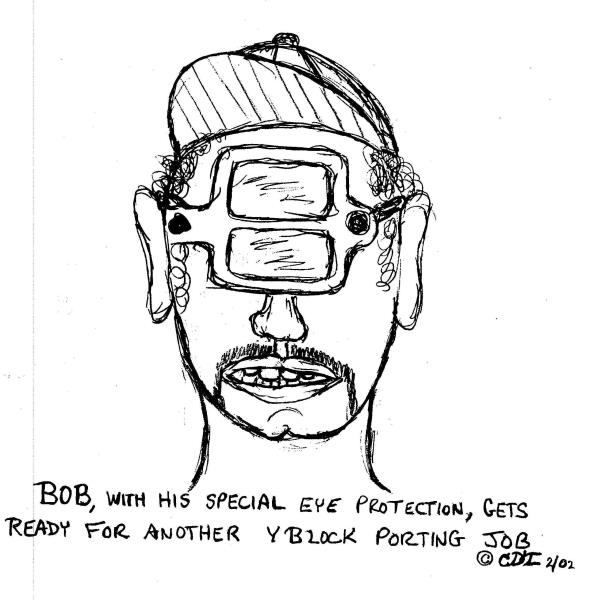

Finally if you are going to have fun porting don't forget your special Y Block Goggles

|

|

By Woody - 11 Years Ago

|

slick56 (1/27/2014)

lyonroad (1/26/2014)

Too bad, they look good. The Canadian/Australian exchange rate is favorable but the shipping would be a killer. Just out of curiosity do they fit sedans? They kind of resemble Tbird headers. My brother in law will be in Wollongong in a month or so. I will email him tonight to see if he knows if they will fit a full size Ford, if so i will order a set and keep you informed..

Those short headers look great! I am in Sydney area so happy to take my car around to check fitment if the guy is not sure. Just looking at them I suspect they would not fit a Customline/ Mainline engine bay but you never know....

Good luck with the mods CK.

Cheers, Woody.

|

|

By CK and his 55Tbird - 11 Years Ago

|

Doug T (2/3/2014)

I Think you can do a bit more in the exhaust side of the head. Here is a pic of a G head sectioned to show the exhaust port. Notice that the black sharpie line on the long radius side of the head runs from the edge of the guide to the center of the ex port flange. You can remove all this. You can also widen the port a bit to get it more round in appearance. The drilled hole shows a lot of material. I found that the biggest improvement was from putting in larger ex valves, I used 1.6" scrub valves that were 0.200" longer but now you can get exact fit valves from John M. The marks on the ex valve and bowl show where to grind a little undercut but removing too much causes loss of compression. This pic shows the kind of shape I wanted at the exhaust flange. The top manifold in the pic has already been done the bottom one is marked for grinding. I matched gaskets but these days for manifolds like this I would just use HT silicone.  I developed these ideas and some others using a home made flow bench in the early 1990's This looks amazing. well done.  Finally if you are going to have fun porting don't forget your special Y Block Goggles

|

|

By CK and his 55Tbird - 11 Years Ago

|

Consider potential energy and Kinetic. My theory is that if a good engine may convert 15-20% potential energy into kinetic then this should be the difference in port sizing.

ie. 2.02" In. and 1.6" Ex. the difference would be about 20%. So the volume of fluid induced is then aimed at and 20% less volume exiting the cylinder after heat conversion. obviously if you altered this formula you would be estimating a more efficent cycle.

So I have left std. valve 1.92" and 1.54" and gave a mild port to match a mild cam.

|

|

By CK and his 55Tbird - 11 Years Ago

|

Glad I have myself a pair Glad I have myself a pair

|