|

Author

|

Message

|

|

NoShortcuts

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.4K,

Visits: 179.6K

|

Regarding using a wrap on your headers, if you check the Sanderson exhaust header webpage (I looked at the page for early 'Bird headers) Sanderson states in their disclaimers: Wrapping your Sanderson Headers with ANY thermal tape voids your header warranty. The best thermal protection for your headers is our Aluminized Ceramic Coating that is available for every Sanderson Header.The Ford Powertrain headers are more expensive than the Sanderson units. Unfortunately, when Ted Eaton did the extensive dyno testing of exhaust header, the FPA units seemed to be the only ones he did not have a set of to test.  From an exhaust header design standpoint, I believe that the FPA units will outperform the Sanderson headers particularly above 3,000 rpm. My thinking is based on the detailed info provided in David Vizard's SA book How to Build Horsepower. Without the dyno tests, my opinion is merely speculation.

NoShortcuts

a.k.a. Charlie Brown

near Syracuse, New York

|

|

|

|

|

skygazer

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 112,

Visits: 1.5K

|

Greenbird, that's a clean looking engine compartment! Tell me about the CAI/air cleaner... is that your own design?

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

Hi Pete - I did "sort of" dust them off a bit with a sanding disc to take away the worst of the casting divots (actually suggested by Ted years ago). I'd say that if you did a careful (and complete) job, it would really make them spectacular.

I mostly just was looking to get the top surfaces a bit more reflective and let it go at that...... Between the coating and the truck style heat shields, the rocker covers are staying pretty cool now. Next polishing project is the set of groady T-bird aluminum covers i accumulated a couple of years back.

Steve Metzger Tucson, Arizona

|

|

|

|

|

Pete 55Tbird

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 721,

Visits: 93.2K

|

Steve Your JetHot coated exhaust manifolds look great. I have a question for you, did you ever consider using a grinder and doing a mild "clean up" before having the manifolds coated? Or would that have effected the value and was that part of the decision making process? Just idle curiosity. Thanks Pete

|

|

|

|

|

Noob

|

|

|

Group: Forum Members

Last Active: 10 Years Ago

Posts: 158,

Visits: 1.8K

|

Thanks Steve, Vic, Alan... I'll proceed... I like the idea of re-orienting the heim joint as suggested. Cheers... Brian

Cylinder Index = 84 Current Experiment = `57 Tbird, Grand Rapids, Michigan

|

|

|

|

|

Vic Correnti

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 347,

Visits: 12.3K

|

Noob, I questioned the steady rest design from FPA but after trying to find a good way to come up with something better I gave up and thought I would fix it if there is a problem. As Allen said I like to leave hard and if something brakes I try to fix it better so it won't break there again. With both wheels off the ground and more nitrous then a 312 cu in Y-Block was ment to have the steady rest design from FPA has never failed me. I have broke everything else though. I have come to the conclusion that nitrous and a clutch should not be in the same car but don't worry about the steady rests.

Vic Correnti Vic Correnti

|

|

|

|

|

bird55

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.1K,

Visits: 58.8K

|

Noob, My bird has about 310-hp with an AOD trans with an open rear gear standard. Vic's bird probly makes more with a traction loc and for certain he has the guts to launch his much harder than i do. Seen him, wheels up numerous times. In fact I saw him last year break at Columbus on launch. But it was the trans tailshaft or driveshaft related as I recall So…with all that happening the engine was apparently anchored down pretty well or else those steady rest/engine mounts could have gone somewhere instead. Just my thoughts. the issue is you would never want to ever let them run loose, just like you wouldn't want a loose motor mount or steady rest.

A L A N F R A K E S ~ Tulsa, OK

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

try out this link......... http://birddropnz.blogspot.com/

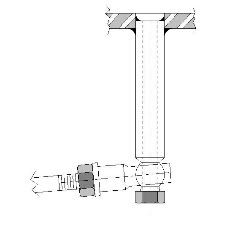

These Heim joints were never intended to be side loaded............easy to fix though.

Steve Metzger Tucson, Arizona

|

|

|

|

|

Noob

|

|

|

Group: Forum Members

Last Active: 10 Years Ago

Posts: 158,

Visits: 1.8K

|

Vic/Alan... to you specifically since I suspect you've both got a few ponies under the hood... a non-forum owner of a cammed E-bird with FPA's says he had to do some additional reinforcement work to "keep the motor from twisting outta the car on launches"... referencing he had posi-trac and manual tranny. Did either of you find the alternate steady rest design from FPA to be insufficient or have to add reinforcements anywhere? I'm working with a 3.52 posi, a T-5 tranny, and a warmed 312, so his input is giving me second thoughts... Brian

Cylinder Index = 84 Current Experiment = `57 Tbird, Grand Rapids, Michigan

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 12 hours ago

Posts: 7.5K,

Visits: 205.8K

|

GREENBIRD56 (3/2/2011)

......the inside and outside coating of the iron manifolds dropped their surface temperature by 225°F as the car sat at idle. After a quick check of the temp of the raw castings (to be sure they were the same side for side), I put a newly coated manifold on the RH side and ran my test again - 550° on the raw side - 225° on the coated. I'm absolutely sure it has a beneficial effect on the underhood temperature.Steve. I suspect that the lower temperatures being generated with the coatings would also extend the life of the manifolds and at the very least, slow down the propensity for breaking or cracking. Good info and thanks for sharing.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|