After driving it a couple days this week, it does seem like it might be a little more zippy at lower revs, but nothing like the improvement at high revs. It sounds different, too. Good different.

For those who are curious, I made the shims out of a strip of 3/4" wide 6061 aluminum. I marked the center of the strip and allowed 1/8" between to cut them apart. A spare rocker stand and transfer punches were used to mark the holes.

I then drilled them.

Cut them out and shaped them. Some came out a bit wonky but it's not really a problem - I just make sure a good one is in the oil hole position.

New Smith Brothers pushrods next to an old one for comparison. Because the rocker rotates toward the valve as the stands are raised, pushrods longer than the change in shim height are required. These are 8.362", so a 1/4" change in stand height required about a 3/8" change in pushrod length in this case.

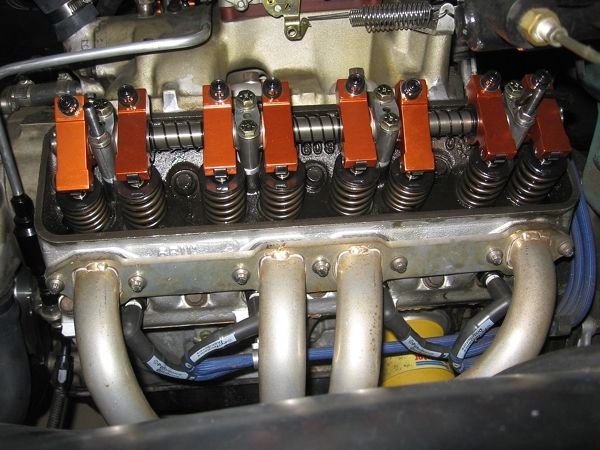

Everything in position.

and installed

I went with valve covers from spotlitekustomaccessories on eBay. The taller covers required that I move the coil which required that I change the fuel line routing - both things that I had been wanting to do but it wasn't really that important. With the old coil position, I could not remove the valve cover with the coil in place. I can remove the valve cover in the new position and a raised base 14" air cleaner should fit, if needed. The fuel lines just look less cluttered and more aesthetically pleasing now, I think.

Before

After. Breathers will be used until I've had a chance to do some spacer testing. Once I choose a spacer, PCV will be refitted. The rubber fuel hose will be replaced with a hard line once I choose a spacer.

A bracket to ensure that the regulator stays in place, even though it is mounted right on top of hard fuel fittings. Left plenty of room for a wrench to get at the fittings.

Lawrenceville, GA