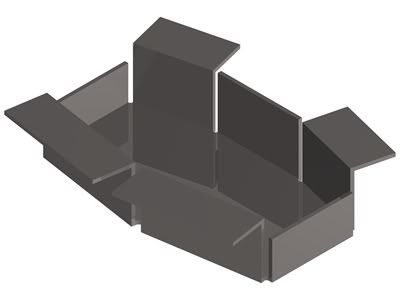

Well, with breathers, there was no need for a baffle. With the pcv valve, the vacuum is enough to draw the oil in to the breather looking housing and drip out onto the valve cover. This is what I've come up with for the baffle.

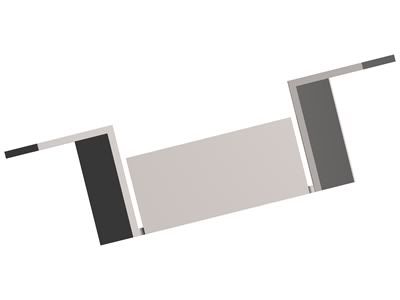

It will be oriented something like this, viewed from the front of the engine:

With it in this orientation, the notch at the V on the lower edge (visible in the first image) should allow any oil that manages to get into the baffle to drain.

I'm allowing 5/8" of clearance between the bottom of the PCV housing and the floor of the baffle. The two shorter sides are 1/4" shorter. So I think airflow will be sufficient for that little valve. The overall height is about .800", leaving about .450" clearance for the rocker arms throughout their travel.

I'd like to make sure I get this right the first go round. Is there any baffle science I should be aware of? Anything I should change?

Lawrenceville, GA