|

Author

|

Message

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 8 hours ago

Posts: 1.8K,

Visits: 306.3K

|

DAMN!!!Ask and 'ye shall receive ...

I didn't mean for a right-a-way answer as I know you must be busy, but it is greatly appreciated.

So you machined your own intake adapter plates?

What CI did it finally arrive at? Was it dynoed?

You take in a lot of MEL work or did you do that as a favor?

Again, thank you very much.

____________________________

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.5K,

Visits: 205.9K

|

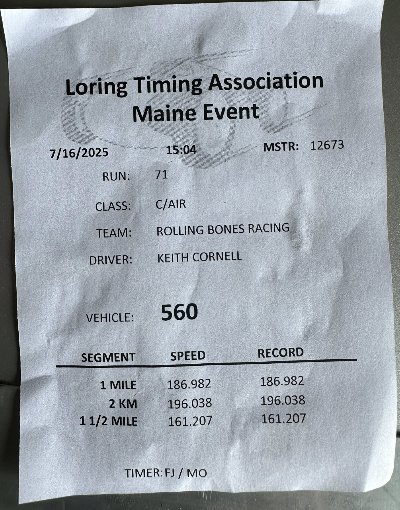

Kultulz. This should answer most of your questions. This is the same engine that I was needing a specific main bearing for. And I did find the bearings. The rod bearings are BBC as the Mercury 383 crankshaft must be destroked anyhow to fit the ‘C’ engine class for Bonneville. The car itself is configured for the AIR (American Iron Roadster) class. While destroking the crankshaft, the rod journals are reduced to the BBC 2.200” size. The factory MEL rod journal size is 2½” so there’s a lot to work with here. By luck of the draw, the journal width for the MEL is exactly the same size as the BBC which allows BBC connecting rods to be used without any accompanying rod or journal modifications other than just reducing the journal size. An aftermarket 7.100” long BBC H-Beam connecting rod is being used due the extreme shortness on the stroke and the need to get the wrist pin back in a position closer to the top of the piston. A single plane intake manifold for a 460 Ford with a 1050 cfm carburetor takes care of the induction chores. Fabricated spacers adapts the 460 Ford manifold to the M-E-L heads. The heads are from the 462 engines which have smaller intake ports than the 383, 410, and 430 heads. The 462 heads outflow the earlier heads significantly due to the improved short turn radius in the heads. That is a result of maintaining the same intake port dimension at the top of the port but making the intake ports shorter overall which helps the short turn radius. The camshaft is a 1961 Isky roller grind that was a new, never used, camshaft when the Bonneville MEL project was hatched. This particular camshaft uses the stepped cam bearings similar to what you find in the SBF engines. While the roller lifters for the M-E-L are the same diameter as the LYB, FE, SBF (289, 302, 351W), 335 series (351C), 385 series (429/460), and others, the tie bar that connects the lifter pairs had to be longer due to the lifter bore spacing being wider in the MEL engines than the others. But with some perseverance, longer tie bars were located that would work with the lifters that were being used. The block that was pictured is a ’61 430 block and it’s the one that is in the car right now. Keith Cornell fabricated his own steel bellhousing that allows the 5 speed manual transmission to be used behind those 1961 and later blocks. Hence the reason an earlier block with the standard FE bellhousing pattern was not used as the car was originally set up with the 462 block thinking that the larger bore size would help the cylinder head flow. I had previously drilled the oil galleys larger in the 462 blocks without issue but the two 430 blocks that I tried to do the same oil galley enlargement did not like that as the enlarged oil pump to filter hole would break through the casting on the inside of the block. I eventually just sleeved the holes back to the stock size and then decided to simply stop the sixteen oil leaks at the lifter holes to help supply enough oil to the bottom end of the engine for extended full throttle running. The idea behind using the 430 block instead of the prior 462 block was to capitalize on the smaller bore size which would allow a corresponding increase in stroke and still be within the rules. The horsepower with the previous combination (larger bore, shorter stroke) was at a plateau and was running just shy of 200 mph. At this point and because the previous engine had dropped a valve and destroyed the block, it was decided to just increase the torque by increasing the stroke. To keep the cubic inches within the rules, the smaller bore size after boring dictated what the new and longer stroke would be. Some algebra took care of that calculation and the 383 crankshaft was destroked accordingly. If an Edsel 410 block had been available, that would have been even better as the bore on those is 4.200” versus the 4.300” on the 430 blocks. As it was, there was a nice increase in both the horsepower and torque but it does come in at a much earlier rpm now. The car did some shake down runs at the Loring, Maine track just a couple of days ago and it looks promising for running 200 MPH plus at Bonneville. Bonneville does happen again starting in a couple of weeks. Here are pics of both the car and a timing slip at the Loring, Maine track.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 8 hours ago

Posts: 1.8K,

Visits: 306.3K

|

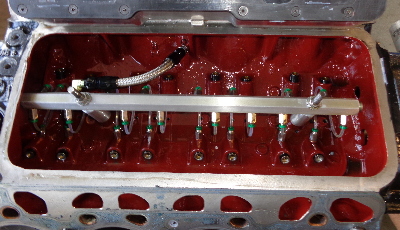

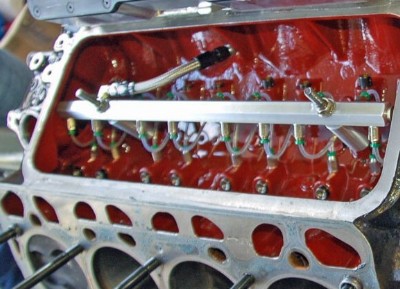

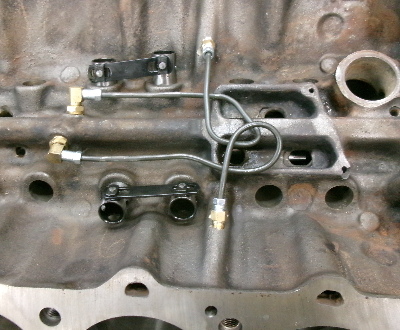

" With all that being said, here’s are pictures of what I had to do recently for a M-E-L engine. This plumbing was necessary to provide oil to the top end of the engine as a result of eliminating the oil going to the lifters.

Eliminating the oil to the lifters did away with 16 oil leaks in the system. What is not seen in the pictures are the four plugs in various passages to keep the oil flow from reaching the lifters. The 1961 M-E-L block in this case did not cooperate in making the oil galleys larger in diameter so the alternate fix is an effort to provide more oil to the main and rod bearings. This engine is using a solid roller camshaft so oil to the lifters is not a necessary requirement."

TED -

This is the same MEL you were searching for inserts?

When you have some extra time ( ), can you go into more detail the modifications you performed (similar to an FE center oiler - solids?), why and what did the customer use the engine for (driver - hot street - competition). ), can you go into more detail the modifications you performed (similar to an FE center oiler - solids?), why and what did the customer use the engine for (driver - hot street - competition).

SOLID ROLLER on a MEL? Man must have been serious.

This was a 1961 block?

As always, THANX for sharing your knowledge and expertise.

____________________________

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 8 hours ago

Posts: 1.8K,

Visits: 306.3K

|

I can understand pressurized rocker shafts (along with slots) to prevent rocker arm and shaft wear (hopefully). What I don't understand is completely blocking off the oilers at the end of the shafts meant for timing chain and distributor drive lubrication.

____________________________

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 8 hours ago

Posts: 1.8K,

Visits: 306.3K

|

Detergent engine oils were being introduced in the fifties. Prior to that, non detergent was used usually without a filter. It had no detergents/dispersants and when returned to the pan, most trash/carbon would fall out of suspension and remain in the pan. The service interval on non-detergent was also more frequent. Inadequate crankcase ventilation (ROAD DRAFT) only compounded the situation. If you notice on FORD NEW CAR OPTIONS (1950's FORD) a 'FULL-FLOW FILTER' was offered but there was an additional charge. So rule of thumb was to use non-detergent w/o filtering (no use as there was no dispersant package) and detergent with an oil filter. I remember (as a young and aspiring 're-fueling technician') that most customers had no concern for quality and just said throw the cheapest thing in (oil change on the front). There were premium oils available.

____________________________

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.3K,

Visits: 1.8K

|

According to Howard's Cams, their Y-block cam's center journal oil groove is .020 deep (I've not measured it). I also purchased Schumann's Durabond cam bearings/w the outside groove to which Ted Referred. I intend to use 10w-40 conventional oil. My oil pump is a rebuilt gerotor. I'm considering having the rocker assemblies pressurized. Based on what I've just read, it sounds like it isn't necessary. Any other suggestions/recommendations?

|

|

|

|

|

alanfreeman

|

|

|

Group: Forum Members

Last Active: 5 minutes ago

Posts: 373,

Visits: 5.5K

|

I agree with Ted. I have four cars, all with low mileage or rebuilt Y-Blocks. I have had these same cars for nearly 40 years and have always run them on modern multi-grade detergent oil. I have two early 60's 292's, a 239 and a 256. They are all "bone stock" with no modification to the lubrication system and none of them have ever had an oiling problem. Back in the 50's the oil available was non-detergent and I think that it was that type of oil which clogged the passages and resulted in poor oiling to the rockers. With a clean engine following a rebuild, and the use of multi-grade detergent oil, the original lubrication system should work just fine.

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 8 hours ago

Posts: 1.8K,

Visits: 306.3K

|

THANX! TED for the explanation. I agree with lack of proper service intervals and poor quality lubricants. You think you are saving money but you are actually not. Interesting on the MEL.

____________________________

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.5K,

Visits: 205.9K

|

In reference to the above pictures, there are those engine builders out there that do not perform the necessary research into a perceived problem before just applying a ‘shoot from the hip’ fix. The problem with the internet and social media is that all these fixes get posted by people who are not experts in their respective fields, but these fixes get accepted and approved by the masses. Having pulled apart several Ford Y engines with over 300K miles on them and still having the stock oiling systems doing their job, I question some of those fixes that involves adding extra oil lines. Even my own ’55 Ford with well over 300K miles on it still has the stock oiling system and is still doing as Ford originally intended. The key to that one is scheduled oil changes along with what I would call a quality 10W-40 oil. That engine has been on the same 10W-40 since it was first purchased in late 1954. The latest crop of soft cam bearings does bring to the forefront the issue of the center cam journal meshing into the bearing and shutting off the top end oil supply. There are several fixes for that without going to the trouble of rerouting the oil thru auxiliary oil lines. Some of those fixes include machining the camshaft center groove deeper, using a cam bearing with the oil groove on the O.D. of the bearing, or simply adding another groove in the block behind the center cam bearing that allows oil to flow to the top end without having to circumvent the existing groove in the camshaft. Here are some pictures where additional oil lines are routed to each lifter (tappet) and in this case, special lifters were made in which to pass that rerouted oil thru them. This one was not mine as I’ve only gone so far as to simply put a groove in the block behind the cam bearing which suffices for the majority of Y builds that I do regardless of if they are simply a stock, street performance, or a racing engine. This takes care of the problem with using the softer babbit cam bearings.

With all that being said, here’s are pictures of what I had to do recently for a M-E-L engine. This plumbing was necessary to provide oil to the top end of the engine as a result of eliminating the oil going to the lifters. Eliminating the oil to the lifters did away with 16 oil leaks in the system. What is not seen in the pictures are the four plugs in various passages to keep the oil flow from reaching the lifters. The 1961 M-E-L block in this case did not cooperate in making the oil galleys larger in diameter so the alternate fix is an effort to provide more oil to the main and rod bearings. This engine is using a solid roller camshaft so oil to the lifters is not a necessary requirement. With all that being said, here’s are pictures of what I had to do recently for a M-E-L engine. This plumbing was necessary to provide oil to the top end of the engine as a result of eliminating the oil going to the lifters. Eliminating the oil to the lifters did away with 16 oil leaks in the system. What is not seen in the pictures are the four plugs in various passages to keep the oil flow from reaching the lifters. The 1961 M-E-L block in this case did not cooperate in making the oil galleys larger in diameter so the alternate fix is an effort to provide more oil to the main and rod bearings. This engine is using a solid roller camshaft so oil to the lifters is not a necessary requirement.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 8 hours ago

Posts: 1.8K,

Visits: 306.3K

|

BTT

____________________________

|

|

|

|