|

Author

|

Message

|

|

darrell

|

|

|

Group: Forum Members

Last Active: 3 Months Ago

Posts: 455,

Visits: 22.2K

|

ive taken apart 2 y blocks with the spacer behind the cam gear pushing the gear out about 1/8 inch.both motors had miles on them and no harm was done.you can see wear on the edge of the gear do to the misalingment.

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.2K,

Visits: 1.8K

|

Cloyes, not Rollmaster?

|

|

|

|

|

Florida_Phil

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.2K,

Visits: 285.6K

|

I am not a professional engine builder, so take that into consideration. What I can offer is to share my personal experience on this issue. Over the years I have had numerous issues with Y-Block cam end play. Something is going on here that is not as you would expect. When I built the engine in my TBird, I could not get enough cam end play. At first, I blamed it on the Cloyes double roller timing chain. I later learned there are different thickness washers and spacers involved. If your engine is a mixture of parts from different engines, you could have similar problems. After about a week of messing around, I used the parts from another stock engine I had in storage and all went well. By this time, it is very common to assemble a Y-Block engine from a box of spare parts. Cam end play is critical. Beware, these parts are not all the same.

|

|

|

|

|

NY59F100

|

|

|

Group: Forum Members

Last Active: 6 Months Ago

Posts: 52,

Visits: 34.5K

|

Ted, I am certain I must have pried up on the chain links but did try to use the gear itself more often. I will have to re-examine the pins. Well, after a number of spacers and numerous measurements, I discovered that I never had the correct beveled spacer “6265” but instead had the thicker spacer “6291” installed. This explained why my “by eye” cam end play was about 1/8” and later measured to be about .070”! Digging through old parts yielded two more of the thicker spacer but no beveled spacer. Then I came across a useless old cam that, upon closer inspection, still had the cam key installed and the elusive beveled spacer. Upon cleaning it up and measuring it, it proves to be .005 thicker than the thrust plate. After re-installing everything again, cam endplay is just over .001, and everything seems to be in order. As a side note the beveled thrust spacer is also larger in outside diameter than the the thicker spacer. I did not measure that thickness, but it is obvious when holding the two together.  Soffian Adam

Soffian Adam

Jamestown, NY

59 F100, 55 Club sedan

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 5 days ago

Posts: 7.5K,

Visits: 205.8K

|

When removing the gear set, be sure to catch the plates on the back side of the chain and not the pins when prying the chain forward. Contacting and prying on the pins will push them forward and that will become a starting point for a chain failure down the road.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 5 days ago

Posts: 7.5K,

Visits: 205.8K

|

The ‘6265’ cam thrust spacer has a bevel only on one side of it. It’s important that the bevel faces to the rear or against the camshaft journal. Putting the bevel forward can minimize the woodruff key penetration into the fuel pump concentric and also make for too much camshaft end play. The ‘6265’ cam thrust spacer is approximately 0.004”-0.006” thicker than the ‘6269’ cam thrust plate. It’s that thickness that controls the camshaft end play. The ‘6265’ cam thrust spacer is not as thick as the ‘6291’ spacer that goes in front of the fuel pump concentric. They are different thicknesses with the ‘6291’ spacer being the thicker of the two. While it probably doesn’t make much difference if it’s grade five or grade eight for the lock washer, use the grade 8 if it’s available.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

NY59F100

|

|

|

Group: Forum Members

Last Active: 6 Months Ago

Posts: 52,

Visits: 34.5K

|

When I move the slotted spacer behind the fuel pump concentric, only a small part of the woodruff key gets into the concentric. It looks like the timing gear needs to go on a little more. I put the thicker spacer I found, and everything seems right, with the exception of the slight engagement onto the key by the fuel pump concentric.

Although I know I’m supposed to have a lock washer, I have yet to find one on any of the few engines I’ve torn apart. Should I just use a grade 8 lock washer? Or grade 5?

Soffian Adam

Jamestown, NY

59 F100, 55 Club sedan

|

|

|

|

|

NY59F100

|

|

|

Group: Forum Members

Last Active: 6 Months Ago

Posts: 52,

Visits: 34.5K

|

Ted,

I seem to be missing the thick, non-keyed spacer (6291) in your diagram. I found one from another motor, but it looks just like the beveled spacer that goes behind the gear. Are they the same thickness?

Soffian Adam

Jamestown, NY

59 F100, 55 Club sedan

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 5 days ago

Posts: 7.5K,

Visits: 205.8K

|

|

|

|

|

|

NY59F100

|

|

|

Group: Forum Members

Last Active: 6 Months Ago

Posts: 52,

Visits: 34.5K

|

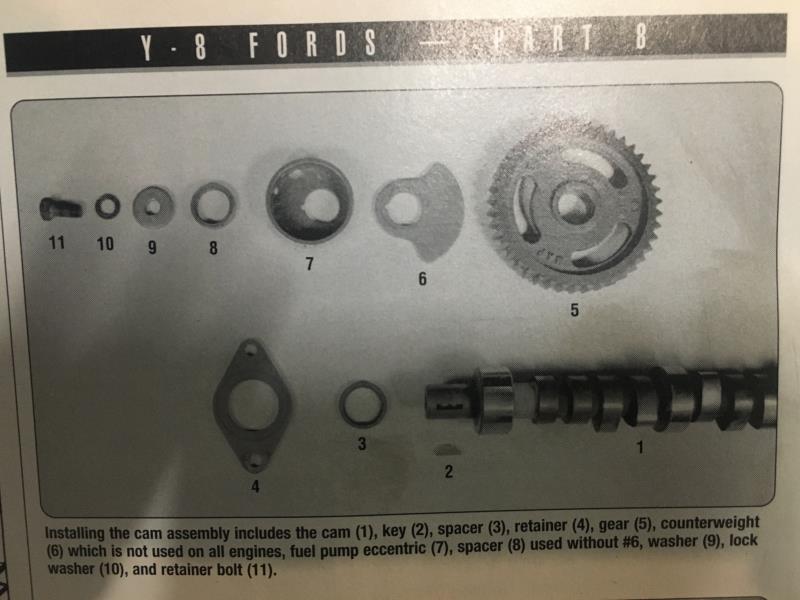

I do not have the counterweight (#6), shown in the photo.  Soffian Adam

Soffian Adam

Jamestown, NY

59 F100, 55 Club sedan

|

|

|

|