|

Author

|

Message

|

|

Ted

|

|

|

Group: Administrators

Last Active: Last Month

Posts: 7.5K,

Visits: 205.8K

|

If ordering the pistons with offset wrist pins, then make sure that the pistons are marked accordingly when you receive them. I recently received a set of pistons with offset wrist pins that were not marked indicating top, front, etc. Because I did catch this, it was a simple matter of looking at the wrist pin offset and marking the pistons with a Sharpie so that the rods could be installed correctly on the pistons.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Last Month

Posts: 7.5K,

Visits: 205.8K

|

Having received a couple of phone calls regarding how to calculate the wrist pin location in a custom piston, I’ll revisit this in slightly more detail. Besides knowing the wrist pin diameter to be used, you will need to specify where the wrist pin centerline will be as measured from the top of the piston. In piston manufacturing terminology, this is referred to the compression height (CH). The factory wrist pin diameter for the Ford Y is the same as the later produced small block Ford engines (SBF) which is 0.912”. If using aftermarket rods or retrofitting connecting rods from another engine family, then the wrist pin needs to be compatible with those rods. While the factory sized 0.912” pins work well with the factory connecting rods, both the 0.927” and 0.866” pins are popular choices when aftermarket rods are being used. Regardless of the pin diameter that is chosen, it must match the wrist pin size of the connecting rod being used. While the CH value calculation does not take into account the actual wrist pin diameter, the wrist pin diameter is a consideration in that it is a player in determining the amount of room that is available between the top of the wrist pin and the piston top in regards to piston ring placement. If going with a larger diameter wrist pin, then that area is going to decrease and in some cases, may be a tight fit for the ring package. The calculation for the CH is as follows. Deck height minus connecting rod length minus half of the crankshaft stroke. This is for a zero deck combination. If wanting to have the pistons down in the hole a given amount, then also subtract the amount that the pistons are going to be below the decks. Here’s an example of the numbers for a zero deck Y-Block combination assuming the decks are being machined for a 9.750” deck height. 9.750” – 6.125” – (3.600” / 2) = 1.825” CH If wanting the pistons 0.005” in the hole with a 9.750” deck, then the numbers look like this. 9.750” – 6.125” – (3.600” / 2) – 0.005” = 1.820” CH

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 788,

Visits: 113.4K

|

Very good information, much appreciated - thanks.

64F100 57FAIRLANE500

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Last Month

Posts: 7.5K,

Visits: 205.8K

|

Wrist pin offset is yet another consideration when making custom pistons. For the majority of custom pistons, the wrist pins are merely centered which makes the pistons suitable for use in either the left or right banks of the engine. Many OEM pistons are designed with an offset wrist pin. A factory ‘ECZ’ 312 piston I have sitting here has an offset of ~0.060”. The original pistons get around the need for specific left and right bank pistons by marking a front on them thus allowing the pistons to have the offset in the right position in relation to the major and minor thrust sides of the pistons. When you see the four valve reliefs in a piston, it is so that piston can be flipped either direction to ensure that the wrist pin offset can be in the right place in relation to crankshaft rotation. Most oem and replacement pistons simply have a notch at their tops designating front but some of the aftermarket replacement pistons will be stamped ‘F’ or ‘Front’. Why consider offsetting the pistons? By offsetting the wrist pin and when the piston is at either TDC or BDC, the rod is a slight angle to the piston bore and is positioned such that the piston will move or reverse directions with less resistance. In the centered wrist pin option, the rod is perpendicular to the stroke at both TDC and BDC and creates an additional amount of resistance for the connecting rod / piston combination to reverse direction. Having the offset wrist pins also makes for less piston slap (related to noise) when the piston is changing directions and thus a quieter engine. If doing offset wrist pins in a custom piston, care must be taken to ensure that the pistons are installed in the left and right banks based upon the direction of the offset. If the piston is a plain flattop, then the piston is simply marked to indicate the front of the piston. On the other hand, if the piston only has two valve reliefs, has a combustion chamber specific dish, or has a dome, then the pistons will be marked accordingly so that the pistons are installed specifically in the left and right banks. And this brings up another nuance as seen on the Flathead Ford V8 engines. Rather than offset the wrist pins in the pistons on those engines, Henry moved the crankshaft laterally to one side of the block thus allowing the crankshaft to be offset in relation to the centerline of the engine. This accomplished the same effect as using offset wrist pins. Just another way to have the connecting rods at a slight angle when the engine is at TDC and BDC.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

NoShortcuts

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.4K,

Visits: 179.6K

|

Ted and all. What a read this has been! OH! and GOSH! as a hobbyist, what I didn't know! Thank You!

Regards,

Charlie Brown

NoShortcuts

a.k.a. Charlie Brown

near Syracuse, New York

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Last Month

Posts: 7.5K,

Visits: 205.8K

|

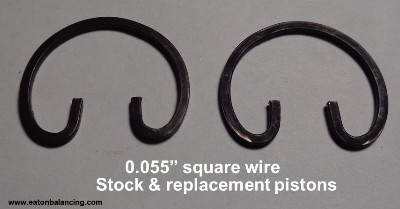

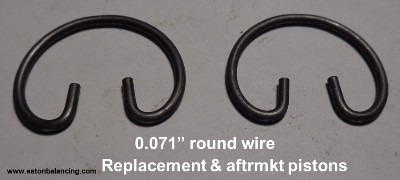

Another point to consider when custom ordering pistons are the wrist pin locks. The Ford Y had full floating wrist pins as delivered from the factory and as such, required wrist pin locks. The FE and MEL engines also used full floating wrist pins. The SBF (289/302/351W,C,M) and 385 series engines (429/460) used a press fit on the rods for the wrist pins and did not require locks on the OEM pistons. Full floating is recommended in performance applications as any friction in the wrist pin area is distributed to additional points thus reducing overall friction. Many of the factory wrist pin retaining clips for the Y were round wire. The replacement cast pistons would have either round wire or square wire clips. Keep in mind that whatever wrist pin locking clip the pistons are machined for is the clip or lock that must be used as they are not interchangeable. The grooves within the wrist pin holes are specific to the lock that’s being used. With any locks that have an opening such as most round, square wire, and Tru-Arc locks, then install those with the opening vertical to the piston movement. The aftermarket pistons use a variety of designs for the wrist pin retaining clips for the full floated pistons. They range from Tru-Arcs, single Spirolox (aka Spiro Locks), double Spirolox, and round wire clips. The Spirolox clips are typically easy to install but can at times be a challenge to remove. Tru-Arc locks do require a good pair of lock ring pliers in which to install/remove these locks. With the Tru-Arc locks, you’ll find a sharp outer edge and a rounded edge on the other side. Install these with the sharp edge facing to the outside of the piston. The 0.063” and larger round wire clips are much heavier in design than what Ford originally used in the Ford Y and while they can be hard on the thumbs when installing, they are relatively easy to remove as long as the piston has the notch in the wrist pin groove to allow a small pick or screwdriver to catch the underside of the round wire lock and simply pry it out. With these larger diameter round wire clips, it’s recommended that the wrist pin ends be chamfered on their outside edge to help keep the locks securely seated in their grooves. With all that being said, my own preference is the 0.073” round wire clips when I have a choice as I have the specific tools to aid with their installation. Those tools beat a lot of wear and tear on the thumbs when installing. When ordering custom pistons, just ask as to what the wrist pin lock options are as not all piston manufacturers offer the same options. Here are pics representing just a sample of the various wrist pin retaining clips that are available.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Last Month

Posts: 7.5K,

Visits: 205.8K

|

55blacktie (2/12/2022)

I'm assuming those 60cc heads are Mummert aluminum heads. If that's so, will the DCR be lower than with iron heads?In rereading your question again, I’m thinking maybe you are asking if the DCR requirements are different for the aluminum heads versus the iron heads? If that’s what you are asking, then for the Ford Y I use the 8.2:1 DCR as a maximum number for the aluminum heads and 91-93 octane gasoline. In theory, the aluminum heads can get away with a more compression ratio than the iron heads simply due to the aluminum not retaining the heat so if that’s what you are asking, then the maximum DCR number for iron heads and 91-93 octane gasoline would be slightly lower than what you would see for aluminum heads. For the time being, we’ll call that number 8.0:1 for the Ford Y using iron heads and pump premium without any definitive testing and/or results to back that up. I typically do not have an issue with the DCR number for iron heads mainly due to the compression ratio on most iron head combinations being less than optimum simply due to the heads being too large to begin with.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Last Month

Posts: 7.5K,

Visits: 205.8K

|

55blacktie (2/12/2022)

I'm assuming those 60cc heads are Mummert aluminum heads. If that's so, will the DCR be lower than with iron heads?Unless you change the camshaft and/or the connecting rod length, the DCR will ramp up and down at the same rate as the SCR ramps up and down when changing pistons or heads. If going with a larger chambered head on the above combination, then both the SCR and DCR will be lower.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.2K,

Visits: 1.8K

|

I'm assuming those 60cc heads are Mummert aluminum heads. If that's so, will the DCR be lower than with iron heads?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Last Month

Posts: 7.5K,

Visits: 205.8K

|

|

|

|

|