|

Author

|

Message

|

|

PF Arcand

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 3.3K,

Visits: 238.8K

|

About a Cam? link from this site to John Mummert's site. ( www.ford-y-block.com.) He lists several Cams with specs.. Also various parts, kits & up grade pieces etc..

Paul

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.8K,

Visits: 306.3K

|

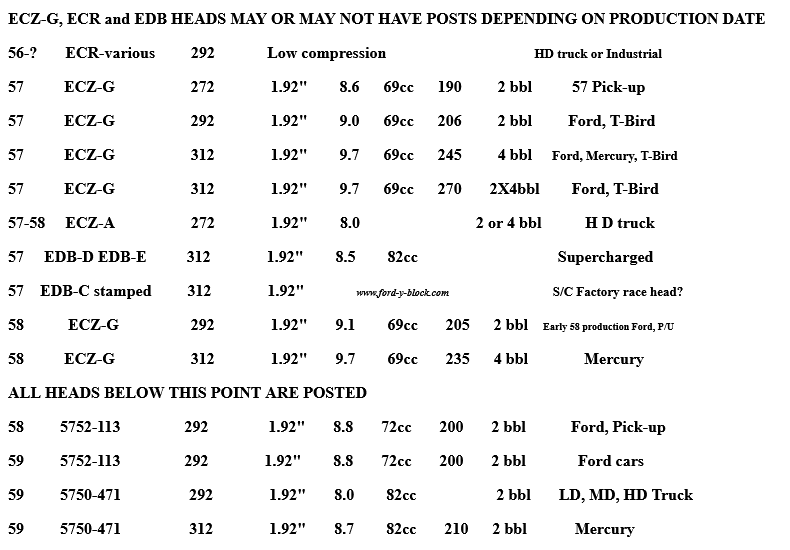

Just a note - ECZ-G CYL HEADS were also used into 1958 production (Date Codes Are Needed To Confirm). The 1.64 rocker arms were last used in 1957 production. 1958 went back to 1.43 and the 1958/59 SEVEN DIGIT CHARACTER PN SYSTEM shows on the rockers as CASTING ID. The 1.64 ratio rocker arms were later replaced with the 1.43 ratio rocker arm for service replacement.  SOURCE - http://www.ford-y-block.com/cylinderheadchart.htm

____________________________

|

|

|

|

|

ac289ace

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 34,

Visits: 371

|

I've been on the road and not posting, but I am home now and thought I would provide an update. The machine went through the block and there are many issues with it so we will be boring .060" over and going completely through it. I plan to use my 312 crank in the 292 block and we will be getting new pistons so I do not need to worry about the pop up pistons and how they might affect the CR. I want to do a mild performance build so will probably go with stock pistons and a mild cam.

Is there a good off the shelf cam that might provide some mild performance benefits?

|

|

|

|

|

Lord Gaga

|

|

|

Group: Forum Members

Last Active: 7 hours ago

Posts: 468,

Visits: 183.3K

|

"I’m the type who would make a plaster mold of the piston top and cc the head myself because I have the tools."

Use paraffin wax instead. Bring the piston near the top of bore, level, pour melted wax in and let cool. Push wax mold out with piston and cc it. Works great. Get wax in canning supply section.

"FREE SAMPLE"

|

|

|

|

|

ac289ace

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 34,

Visits: 371

|

Ted, Thank you very much for the running the numbers with what I had provided. It seems to point towards there not being a major problem with the configuration, but I realize its an estimate based on murky input from me.

The machine shop is starting the teardown so I should know fairly quickly if there are any major issues, and also have some actual info on chamber volume and cam configuration.

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 1 hour ago

Posts: 7.5K,

Visits: 205.9K

|

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 1 hour ago

Posts: 7.5K,

Visits: 205.9K

|

While the G head is often referred to as the 312 head, it was the standard cylinder head on the 1957 Ford 272, 292, and both the D and E code 312 engines. It was also available on the 1957 Mercury 312 engines. That helps to explain why there are so many G heads floating around. The nominal advertised combustion chamber volume for the G head was 69cc meaning that in a best case scenario, the combustion chambers would be as low as 69cc. On stock and unmodified heads, it’s not unusual for them to be larger than that as 69cc was the minimum size for those heads. Until the heads are measured, it’s questionable as to what the actual combustion chamber volumes are. For the G heads, the amount to mill them for a 1 cc reduction is 0.0064”. There are both small letter and big letter G heads. All the small letter G heads are unposted. The big letter G heads cast at the Cleveland foundry after May 1957 are posted while those being cast at the Dearborn facility remained as unposted until the end of G head production at Dearborn. The service manual was adamant in not milling the unposted heads any more than 0.010”. The posted heads have been known to be milled as much as 0.065” and not have head gasket sealing issues even with increases in compression ratio. Here’s the link on how to identify posted G heads. http://forums.y-blocksforever.com/FindPost6764.aspx

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

ac289ace

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 34,

Visits: 371

|

miker (7/5/2021)

You really want to establish the static and dynamic ratios. Not to mention valve to piston clearances. My first y block, back in 1967 was a 40 over 312, with “11.25” Jahns pistons. Pro built engine by a guy in AA fuel for his roommate in a 55 bird. That’s a whole story in itself. That car would only run on scrubron “Custom Supreme” advertised as 105 octane minimum. When I put the aluminum heads on my 9:1 static 40 over 292 stoker the static went to 10.7x to 1. We spent a long time picking the cam specs (thanks to Ted Eaton and John Mummert) to ge the dynamic down to 8.7 IIRC. It’s still very marginal on today’s pump gas. Doing it over, I’d have cut or changed the pistons. So take your time to figure it all out and do it right. Just go price racing fuel, that will get you motivated. Thanks for this and I am really trying to get to a good street motor that will not need a lot of care and feeding. To that end, replacing the pistons is certainly an option on the table, and I realize there would probably need to be other changes as a result of a piston change. A different cam and rockers may be in the final recipe. Characterizing what I have now is the first step. I have the time to get it right, but need to understand what right is. Thanks again to everyone sharing their knowledge. It is very much appreciated

|

|

|

|

|

miker

|

|

|

Group: Forum Members

Last Active: 8 days ago

Posts: 1.9K,

Visits: 194.9K

|

You really want to establish the static and dynamic ratios. Not to mention valve to piston clearances. My first y block, back in 1967 was a 40 over 312, with “11.25” Jahns pistons. Pro built engine by a guy in AA fuel for his roommate in a 55 bird. That’s a whole story in itself. That car would only run on scrubron “Custom Supreme” advertised as 105 octane minimum.

When I put the aluminum heads on my 9:1 static 40 over 292 stoker the static went to 10.7x to 1. We spent a long time picking the cam specs (thanks to Ted Eaton and John Mummert) to ge the dynamic down to 8.7 IIRC. It’s still very marginal on today’s pump gas.

Doing it over, I’d have cut or changed the pistons. So take your time to figure it all out and do it right. Just go price racing fuel, that will get you motivated.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

ac289ace

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 34,

Visits: 371

|

Thanks all for the input and once again I find myself in over my head on Y-blocks. My original plan was to take it in to the local machine shop (they seem to speak Y-Block) so I should be able to get things sorted out with them. However, I do want to educate myself as best possible going in to them so I can ask the right questions and try to understand what they are saying.

Charliemcraney, thanks for the 272/292 bore info. Buzz measured it at 3.77" and the machine shop will confirm. Thanks also for the chamber compression ratio info. I have done static calcs before but will need to look into dynamic CR.

Cliff, Thanks for that and I'll talk it over with the machine shop to make sure we understand possible interferences.

Paul2748, Nice catch on the rocker arms. Maybe they were changed to accommodate the pistons?

DryLakesRacer, I had not thought about the 292 being a lower compression. Was that due to the heads, pistons, or stroke? Just wondering if the ECZ-G heads would have raised the compression or were they also used on the 292 when stock?

Sorry if my questions seem trivial, but I'm still on a steep learning curve.

|

|

|

|