|

By ac289ace - 5 Years Ago

|

I was the one that bought the engine Buzz posted about in the Racing Section a couple of days ago. As Buzz said in his thread, all markings have been ground from it and I would like to make sure I know what I have. My plan for the engine is to put it in a '57 T-bird and while I don't mind performance enhancements, I would like to make sure it is reliable and streetable.

Now for the questions-

For the crank, it doesn't have the aspirin mark, has a EC marking, a 15/16" hole on the front counterweight, and the rods are EBU so from what I have read, all of this checks out as a 292. Is this correct?

It looks very clean and has what looks like aluminum pop up pistons. I think they are aluminum because they are non-magnetic. Does anyone recognize the pistons? I am trying to understand if I am going to end up with a high compression ratio if I put this back together as is.

The heads are ECZ-G heads and it looks they have stainless exhaust valves and some mild porting, but the rockers needs a little clean up.

Based on what can be seen from the limited pics and info so far, could this be a good match for my needs or should I consider a piston swap?

Here are a couple of pics and I can get more if it helps pin things down a bit.

|

|

By charliemccraney - 5 Years Ago

|

The crank is 272 or 292. Measure the cylinder bores. You will need to know the combustion chamber and dome volume, as well as the thickness of the head gaskets that will be used and the relation of the top of the piston to the surface of the block (in or out of the hole and by how much) for a static compression calculation. The heads can be cc'd. I don't know what the procedure is for piston domes but I'm sure there is a way to determine that as well. Some head gasket volumes can be found here: https://www.eatonbalancing.com/2012/06/30/head-gasket-volume-calculation/

Once you have all of that, you will also need to know which cam you will use and the specs, which is used to determine the dynamic compression in order to determine if it will run on pump gas.

These are things that a machine shop can help with if you don't have the tools or know-how.

|

|

By Cliff - 5 Years Ago

|

|

The chambers have been cut to match the piston domes, you must measure the chambers to know what you have, the pistons will hit a standard head.

|

|

By paul2748 - 5 Years Ago

|

The rocker arms (they start with 575) are the 1.43 ratio, not the 1.54. Unusual for a "G" head

|

|

By DryLakesRacer - 5 Years Ago

|

|

By today’s standards typical 292’s were low compression. 8 - 8.5 to 1 with shim style original gaskets. I’m the type who would make a plaster mold of the piston top and cc the head myself because I have the tools. I use the compression calculator on the KB piston website: you need to know a lot to be accurate. I would love to have a 9.5 to 1 292+” Yblock. Good luck..

|

|

By ac289ace - 5 Years Ago

|

Thanks all for the input and once again I find myself in over my head on Y-blocks. My original plan was to take it in to the local machine shop (they seem to speak Y-Block) so I should be able to get things sorted out with them. However, I do want to educate myself as best possible going in to them so I can ask the right questions and try to understand what they are saying.

Charliemcraney, thanks for the 272/292 bore info. Buzz measured it at 3.77" and the machine shop will confirm. Thanks also for the chamber compression ratio info. I have done static calcs before but will need to look into dynamic CR.

Cliff, Thanks for that and I'll talk it over with the machine shop to make sure we understand possible interferences.

Paul2748, Nice catch on the rocker arms. Maybe they were changed to accommodate the pistons?

DryLakesRacer, I had not thought about the 292 being a lower compression. Was that due to the heads, pistons, or stroke? Just wondering if the ECZ-G heads would have raised the compression or were they also used on the 292 when stock?

Sorry if my questions seem trivial, but I'm still on a steep learning curve.

|

|

By miker - 5 Years Ago

|

You really want to establish the static and dynamic ratios. Not to mention valve to piston clearances. My first y block, back in 1967 was a 40 over 312, with “11.25” Jahns pistons. Pro built engine by a guy in AA fuel for his roommate in a 55 bird. That’s a whole story in itself. That car would only run on scrubron “Custom Supreme” advertised as 105 octane minimum.

When I put the aluminum heads on my 9:1 static 40 over 292 stoker the static went to 10.7x to 1. We spent a long time picking the cam specs (thanks to Ted Eaton and John Mummert) to ge the dynamic down to 8.7 IIRC. It’s still very marginal on today’s pump gas.

Doing it over, I’d have cut or changed the pistons. So take your time to figure it all out and do it right. Just go price racing fuel, that will get you motivated.

|

|

By ac289ace - 5 Years Ago

|

miker (7/5/2021)

You really want to establish the static and dynamic ratios. Not to mention valve to piston clearances. My first y block, back in 1967 was a 40 over 312, with “11.25” Jahns pistons. Pro built engine by a guy in AA fuel for his roommate in a 55 bird. That’s a whole story in itself. That car would only run on scrubron “Custom Supreme” advertised as 105 octane minimum. When I put the aluminum heads on my 9:1 static 40 over 292 stoker the static went to 10.7x to 1. We spent a long time picking the cam specs (thanks to Ted Eaton and John Mummert) to ge the dynamic down to 8.7 IIRC. It’s still very marginal on today’s pump gas. Doing it over, I’d have cut or changed the pistons. So take your time to figure it all out and do it right. Just go price racing fuel, that will get you motivated.

Thanks for this and I am really trying to get to a good street motor that will not need a lot of care and feeding. To that end, replacing the pistons is certainly an option on the table, and I realize there would probably need to be other changes as a result of a piston change. A different cam and rockers may be in the final recipe. Characterizing what I have now is the first step. I have the time to get it right, but need to understand what right is.

Thanks again to everyone sharing their knowledge. It is very much appreciated

|

|

By Ted - 5 Years Ago

|

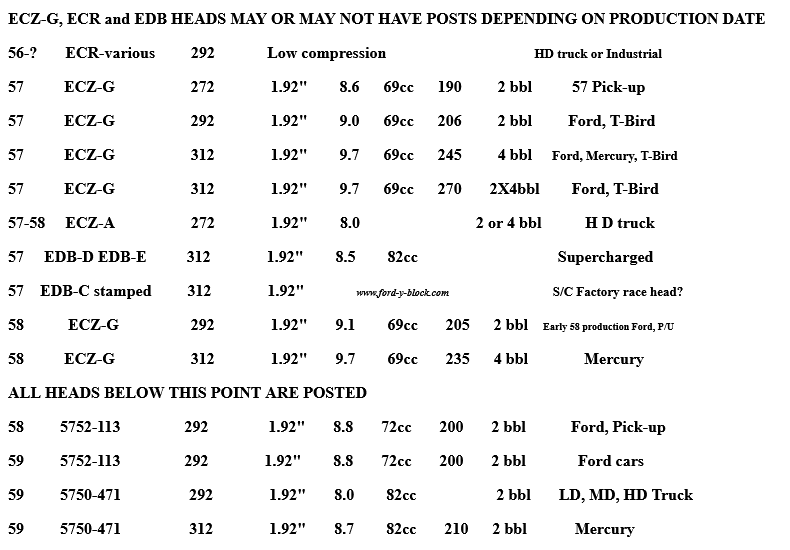

While the G head is often referred to as the 312 head, it was the standard cylinder head on the 1957 Ford 272, 292, and both the D and E code 312 engines. It was also available on the 1957 Mercury 312 engines. That helps to explain why there are so many G heads floating around.

The nominal advertised combustion chamber volume for the G head was 69cc meaning that in a best case scenario, the combustion chambers would be as low as 69cc. On stock and unmodified heads, it’s not unusual for them to be larger than that as 69cc was the minimum size for those heads. Until the heads are measured, it’s questionable as to what the actual combustion chamber volumes are. For the G heads, the amount to mill them for a 1 cc reduction is 0.0064”.

There are both small letter and big letter G heads. All the small letter G heads are unposted. The big letter G heads cast at the Cleveland foundry after May 1957 are posted while those being cast at the Dearborn facility remained as unposted until the end of G head production at Dearborn. The service manual was adamant in not milling the unposted heads any more than 0.010”. The posted heads have been known to be milled as much as 0.065” and not have head gasket sealing issues even with increases in compression ratio. Here’s the link on how to identify posted G heads.

http://forums.y-blocksforever.com/FindPost6764.aspx

|

|

By Ted - 5 Years Ago

|

I see grade six head bolts in one of your pictures. It would be a good idea to change those out to grade eight head bolts when the time comes.

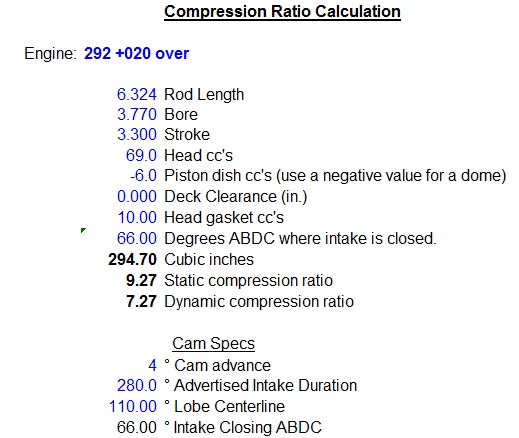

Without more specifics on your engine, here is a rough guess as to the compression ratio. Once you know the actual dome volume, deck heights, combustion chamber volume, and some of the camshaft specs, these numbers can be fine tuned to get the real compression ratio. As it stands right now, the domed pistons does have the SCR back in the neighborhood of where it needs to be for a healthy street engine.

|

|

By ac289ace - 5 Years Ago

|

Ted, Thank you very much for the running the numbers with what I had provided. It seems to point towards there not being a major problem with the configuration, but I realize its an estimate based on murky input from me.

The machine shop is starting the teardown so I should know fairly quickly if there are any major issues, and also have some actual info on chamber volume and cam configuration.

|

|

By Lord Gaga - 5 Years Ago

|

"I’m the type who would make a plaster mold of the piston top and cc the head myself because I have the tools."

Use paraffin wax instead. Bring the piston near the top of bore, level, pour melted wax in and let cool. Push wax mold out with piston and cc it. Works great. Get wax in canning supply section.

|

|

By ac289ace - 5 Years Ago

|

I've been on the road and not posting, but I am home now and thought I would provide an update. The machine went through the block and there are many issues with it so we will be boring .060" over and going completely through it. I plan to use my 312 crank in the 292 block and we will be getting new pistons so I do not need to worry about the pop up pistons and how they might affect the CR. I want to do a mild performance build so will probably go with stock pistons and a mild cam.

Is there a good off the shelf cam that might provide some mild performance benefits?

|

|

By KULTULZ - 5 Years Ago

|

Just a note -

ECZ-G CYL HEADS were also used into 1958 production (Date Codes Are Needed To Confirm). The 1.64 rocker arms were last used in 1957 production. 1958 went back to 1.43 and the 1958/59 SEVEN DIGIT CHARACTER PN SYSTEM shows on the rockers as CASTING ID. The 1.64 ratio rocker arms were later replaced with the 1.43 ratio rocker arm for service replacement.

SOURCE - http://www.ford-y-block.com/cylinderheadchart.htm

|

|

By PF Arcand - 5 Years Ago

|

About a Cam? link from this site to John Mummert's site. ( www.ford-y-block.com.) He lists several Cams with specs.. Also various parts, kits & up grade pieces etc..

|

|

By Ted - 5 Years Ago

|

|

ac289ace (7/22/2021)

I want to do a mild performance build so will probably go with stock pistons and a mild cam.

Is there a good off the shelf cam that might provide some mild performance benefits?

The Isky E4 is a proven upgrade over the factory 1957 camshaft without being overly rowdy. Just enough rumble to let you know you have a ‘better’ camshaft but not a heavy loper.

|

|

By YBLOCKMERC - 5 Years Ago

|

I'm going to give a largely seat of the pants description of what I did and how it works with a 292 +.40 and unposted G heads with 1.54 rockers. I wanted a cam to approximate the specs from the '57 245 hp, 4V factory item. I'm not sure the piston configuration, it was part of a Mummert rebuild kit with hypereutectic pistons. My build was done in 2004, but not actually run til 2012. My goal was to replicate the performance of a '57 4V Y-block.

The engine propels a '54 Merc convertible with a C-4 automatic and stock '54 rear end. Bottom line is I couldn't be happier with this engine. It sounds great with dual 30" glasspacks, especially on acceleration. It cruises effortlessly at all speeds and will push you back in the seat nicely when you're looking for a little speed satisfaction....freeway on ramps are a blast. It gets 13 - 15 mpg and runs on 87 octane without any pinging. All in all I got exactly what I was looking for and I definitely brag about it at car shows. Good luck with your choices.

P.S. - Lower compression is your friend for a street engine, somewhere under 9.0 I would guess. It lets you run regular gas and still provides enjoyable performance.

|

|

By one piece at a time - 5 Years Ago

|

|

Something to consider my experience anyway. “ Off the shelf “ cam e4 comes with a close lobe separation which produces a lower vacuum. If running power assist brakes may cause issues. It did for me anyway. I had to can my booster and go to hydro boost . Several hundred dollars more. My new build will be getting an E4 but with a custom order wider separation. You should also take into consideration what transmission and converter if it’s an automatic your running .

|

|

By PF Arcand - 5 Years Ago

|

Duane's point about the E-4 lobe seperation is well taken.. I believe that point has come up before... As to references to the 1957 Cam.. Oregon Cams in Vancouver Washington (across the river from the Oregon border) has copies of it available, taken off an unused original.. I don't recall the price but it wasn't unreasonable.

|

|

By Florida_Phil - 5 Years Ago

|

Here is some personal feedback you may find useful. My TBird engine is a .060 over 292 with G heads, flat top pistons, 57 intake, Holley 465 carb and 57 ignition. Except for the 312 crank, it's very similar to the engine you are working on. I have run both the E4 Isky cam 301444 cam (duration 260) and the 301333 cam (duration 270) in my street Y-Blocks. I have a 301333 cam in my car now. Both cams are good street cams. The 301333 is significantly more radical at idle. My car has a manual transmission and it idles at 800 rpm. The E4 rumbles like a healthy engine. The 301333 pops through the exhaust pipes with a definite lope. Both cams will operate at low RPM without bucking or hesitation. My 301333 cam pulls about 14 pounds of vacumn at idle. Mid range torque is excellent. Friends that have ridden with me say they are surprised that a Y-Block runs that well. I never rev my engine over 5,500 rpm, so I can't comment on high rpm performance. If you like a quieter milder mannered car, I would choose the E4. If you like a touch of race car attitude, you may like the 301333 better. Keep in mind that my car is a light TBird with a manual transmission and a lower rear gear ratio.

|

|

By ac289ace - 5 Years Ago

|

Thanks everyone for the cam insight. Based on the input I think the E4 will be a good fit for the '57 Tbird with a Ford-O-Matic , but will talk to the machine shop about the possible vacuum issues. FWIW, I am using the fuel pump that incorporates a vacuum boost chamber ( at least I think that is what it does) so the vacuum may not be an issue. That being said, I keep getting surprised on this car so will definitely perform some due diligence there.

Thanks again to everyone for their ongoing help.

|

|

By Florida_Phil - 5 Years Ago

|

Getting adequate oil to the rockers is an issue with these engines. The oil holes in the head are small and they tend to clog up though the years. In addition, the oil runs through a dog leg that you can see with the heads off. Milling the heads can make this worse. Mummert cuts the center cam oil grove deeper to .030" in his cams to increase oil flow. Before I installed my Isky cam, I measured the cam grove depth and found it was .018" deep. We put it in a lathe and cut it to .030". I tested the flow manually on the engine stand and it made a big difference. So much so that I was afraid I would flood the heads with oil. When I ran the engine, I found it to be perfect. I left the value train stock and it's been working for over 3,000 miles. There are threads on this subject if you want to learn more. This forum is a great resource of information. It's wonderful that so many people care about these old motors.

|

|

By KULTULZ - 5 Years Ago

|

|

I am using the fuel pump that incorporates a vacuum boost chamber ( at least I think that is what it does) so the vacuum may not be an issue.

The vacuum boost section of the pump is intended to compensate for varying manifold vacuum while driving. It is considered operational only when pulling 10HG with manifold vacuum source removed (test procedure).

Also, if using a vacuum brake booster, it needs to see at a minimum 18HG to be fully operational.

|

|

By ian57tbird - 5 Years Ago

|

|

Many moons ago I added a vacuum tank to the brakes on a car I had because of the cam. The tank was from a 1970 Galaxie that operated the headlight covers. I had a vacuum gauge attached to it to see how much was there. I did have to make sure the vacuum was up before I drove off, but I could get an incredible amount of stops out of it once vacuum was up.

|

|

By ac289ace - 5 Years Ago

|

KULTULZ (7/27/2021)

I am using the fuel pump that incorporates a vacuum boost chamber ( at least I think that is what it does) so the vacuum may not be an issue. The vacuum boost section of the pump is intended to compensate for varying manifold vacuum while driving. It is considered operational only when pulling 10HG with manifold vacuum source removed (test procedure). Also, if using a vacuum brake booster, it needs to see at a minimum 18HG to be fully operational.

Thank you for this. It's great to have some actual numbers to check against. Right now the brake booster is non functional so I shouldn't have a problem, but will be rebuilding it as the project moves along so will need to figure it out. I have seen many vacuum canisters that could be used and seem to remember some active 12V vacuum pumps that can be used so I think there are many solutions for the brakes if I need it. Today's project is replacing all the vacuum lines and cleaning up all of the exterior engine parts to get them ready for painting.

The machine shop is starting to gather the parts so I hope to have the engine back in a few weeks and want to be ready.

.

|