|

Author

|

Message

|

|

Florida_Phil

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.2K,

Visits: 285.6K

|

My 55 Thunderbird 292 has a Casco Alternator conversion. I have been chasing an intermittent fan belt squeak for some time. I installed a new water pump thinking I may have had a bad water pump bearing. The new water pump turns freely. The belt groves are aligned correctly. I installed a new single fan belt from my local auto parts store. The Alternator charges great and turns freely. I tightened the alternator as much as possible, but the squeak remains. I have an electric fan only. The squeak begins on startup when the engine is cold. If I hold the RPM around 1,500, the squeak is constant until it runs for a few minutes. When this happens, the alternator pulley get very hot. I assume the belt is slipping in the alternator pulley? The Casco alternator pulley grove is not as deep as the stock Ford water pump and crank pulleys. Is there a special Thunderbird fan belt? Anyone run into this before? Thanks!

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.8K,

Visits: 306.3K

|

If I hold the RPM around 1,500, the squeak is constant until it runs for a few minutes. When this happens, the alternator pulley get very hot. I assume the belt is slipping in the alternator pulley? The Casco alternator pulley grove is not as deep as the stock Ford water pump and crank pulleys. Is there a special Thunderbird fan belt?

When the belt squeals, spritz it with water. If it momentarily stops, the belt is either slipping and/or glazed (the pulley can become glazed also).

You will then need to find a pulley that matches the drive pulleys. The drive belt is most likely not seating into the pulley groove correctly and is slipping. If that is a GM DELCO ALT, it may be difficult to find a correct pulley. The ball is in CASCO court to supply a correct pulley (IMO).

____________________________

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 784,

Visits: 113.4K

|

You stated: "I tightened the alternator as much as possible." Does that mean you can't tighten the belt more even if you wanted to? Like, the adjustment is at the end of it's travel and maybe it needs just a little more tension to stop squeaking? Or, could possibly be a failing alternator bearing? Usually an alternator bearing will make a "hissing" sound when spinning the rotor by hand. Just something to try if the above water test doesn't change the squeaking sound.

64F100 57FAIRLANE500

|

|

|

|

|

Florida_Phil

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.2K,

Visits: 285.6K

|

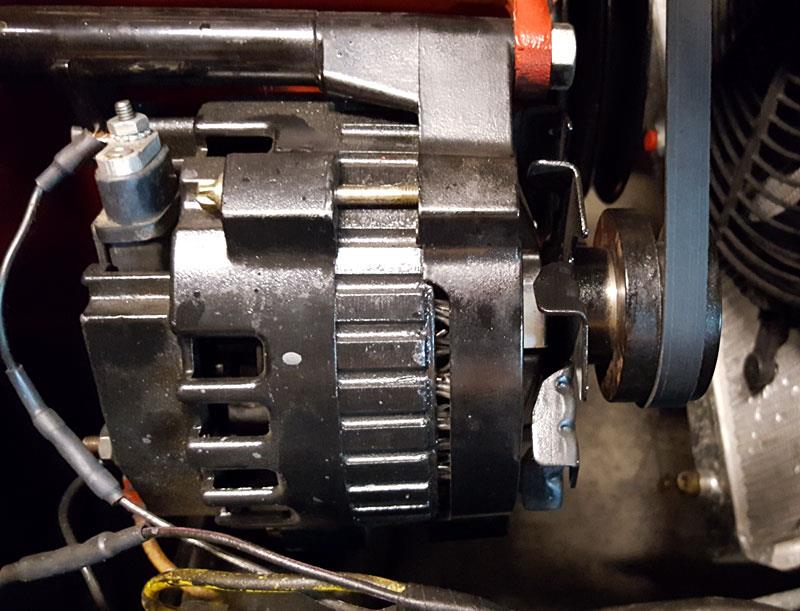

It makes sense that there would be more load on the belt at startup. It goes away after driving a few blocks. Here is a photo of the Casco alternator pulley. As you can see, the belt does not bottom out in the pulley grove. This is with the new belt I installed last week. It seems to be worse with the new belt. The tension adjustment is not bottomed out. I am going to call Casco this morning to discuss this issue. Changing the alternator pulley could be a hassle. I thought about roughing it up. More later.

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: 7 days ago

Posts: 784,

Visits: 113.4K

|

Another ides requiring no hassle or modifications would be a cogged belt which usually runs quieter than a standard belt. Hard to tell from your photo but it looks like a standard belt and possibly riding a "hair" high in the pulley grove.

64F100 57FAIRLANE500

|

|

|

|

|

Florida_Phil

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.2K,

Visits: 285.6K

|

The problem seems to be solved. I called Casco and they told me to use a shorter 41" belt as the alternator pulley is smaller than the stock generator pulley. The new belt I was using was also riding too high in the alternator pulley. I also believe I wasn't tightening the belt enough. Anyway, the belt is now about even with the top of the pulley and the belt is tight. No more belt noise for now.

|

|

|

|

|

Genuinerod

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 120,

Visits: 33.3K

|

Something for thought -- Ford changed the width of the belt from 1/2" to 3/8" in 1956 and 1957. From that time on most pulleys are for 3/8" belts. If you are running a 1/2" belt (normal for 55) on your engine, it may not be making good contact with the pully.

|

|

|

|

|

Florida_Phil

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.2K,

Visits: 285.6K

|

Genuinerod (6/21/2021)

Something for thought -- Ford changed the width of the belt from 1/2" to 3/8" in 1956 and 1957. From that time on most pulleys are for 3/8" belts. If you are running a 1/2" belt (normal for 55) on your engine, it may not be making good contact with the pully. Makes sense. After all these years, I was unaware of the differences in belt width. Went through three belts before I found the right one. Another lesson learned.

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.8K,

Visits: 306.3K

|

What I would wonder is the sheave sizing of the DELCO (or their aftermarket) drive pulley. CASCO does not seem to differentiate between the pulley sheave size(s) but just one fits all. And then you have those that use later WP pulleys (cooling - faster coolant flow) and if they consider sheave sizing on the replacement pulley from another application.  If the belt either runs high on the sheave or even bottoms, it will not charge properly at speed and will eat the belt and/or glaze the pulley over time. At least it is not a GM ONE WIRE (used for tractors).

____________________________

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Yesterday

Posts: 6.1K,

Visits: 442.8K

|

Pulley diameter for the two Delco alternators I've purchased was 2 5/8" diameter. 2 3/8" is best for most, maybe all street Ys because of the crank pulley diameter. According to Powermaster, 2 3/8" is the smallest that a V-belt pulley should be.

Lawrenceville, GA

|

|

|

|