|

Author

|

Message

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

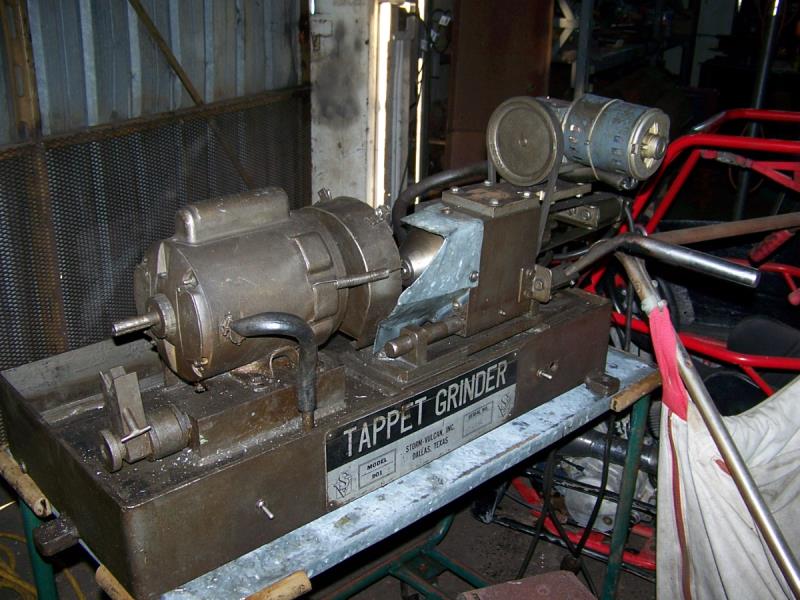

While I do have a Storm Vulcan milling machine, I was not aware of Storm Vulcan making a tappet grinder. Should prove interesting when you get it up and running. I’m curious as to how the adjustment is made to vary the radius on the lifter face. For many lifters, you are looking for a 50-54 inch radius.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

Better picture, there is a scale on the side, I also found a manual, the Y Block tappet radius is to be set at the 5 mark.

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

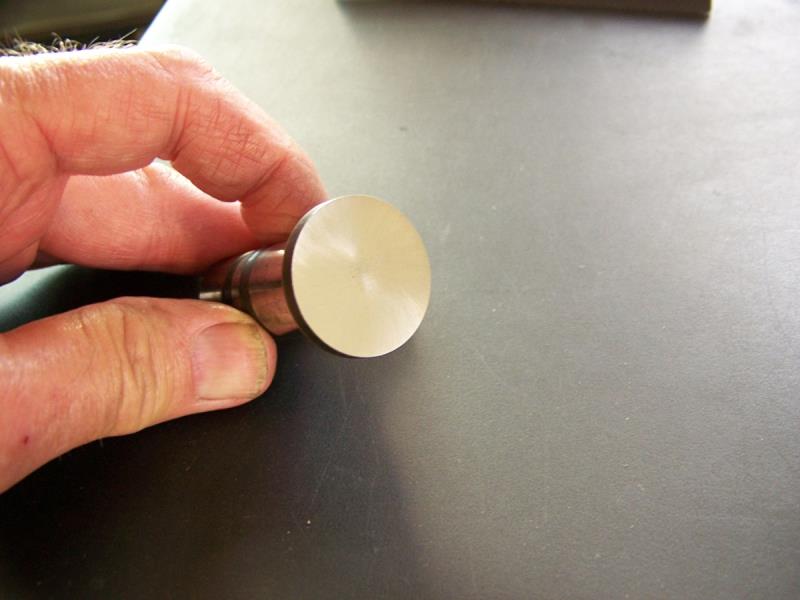

So I found a pitted wore out VW lifter, I put it in the machine to see what it will do, this lifter was concave to start now it has a convex curve, it is still is pitted, I didn't dress the wheel or do any setup, the finish it almost a mirror, I think this thing is a winner.

|

|

|

|

|

yblock57

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 99,

Visits: 6.7K

|

Very nice. Can't imagine how much shipping cost for that thing. Probably pay for itself after grinding a few sets.

Kent — Round Rock, TX

'56 F-100 | '56 Crown Vic | '57 Fairlaine 500 | '57 Thunderbird

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

My son went for a 200 mile drive (round trip)

|

|

|

|

|

FORD DEARBORN

|

|

|

Group: Forum Members

Last Active: 9 days ago

Posts: 798,

Visits: 113.5K

|

Cliff, that machine is awesome, nice find. What is your thoughts on nitriding or?

64F100 57FAIRLANE500

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

Thinking about some kind of heat treatment, not sure yet.

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 927,

Visits: 190.0K

|

cool machine. I have a home made grinders chuck the lifter in my lath have a stone on a grinder that turns same speed ,but opposite direction. after set up I grind 1 and compare to some new ons, after the grind do a polish on the lathe only. hav ground several sets so far. used a set of reground with a new cam in my 292 in 49 mercy. would be interested in how to accurate get the angle. took some to a local cam grinder he sead they are great. but still looking how to get the same as the new ones in a factual way. takes me 15 min to do1 including final polish. the original hardness is fine after the grind. my truck has5600 miles,never had to adjust the valves all the same as original. the 2nd grinder is attached to the garage so when I came setup need to do several sets. have 1 set ready to go. 5,00 cn each with a core.

looking for ideas

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

Hi, the radius is hard to replicate, I was lucky to find this machine, a taper is not what you want, how did you measure the hardness? I worry about grinding to far and finding soft metal.

|

|

|

|