|

By Cliff - 5 Years Ago

|

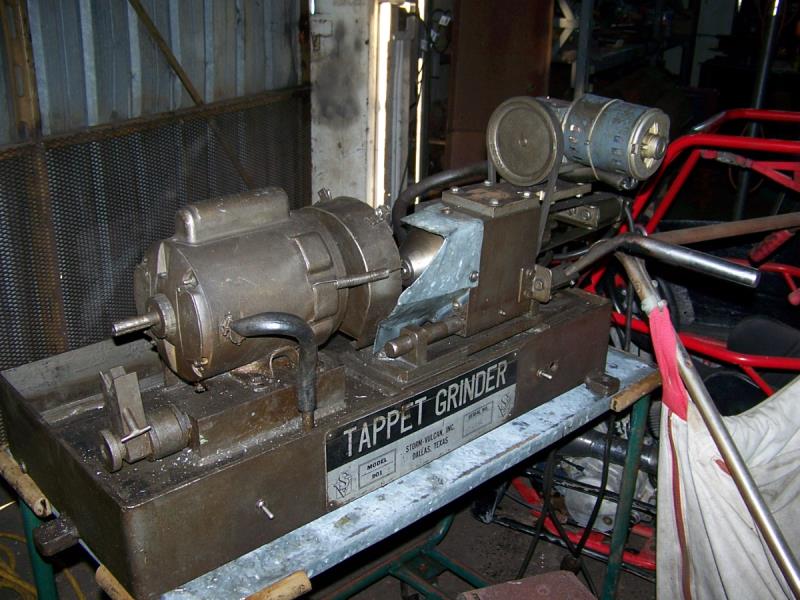

I just bought at auction a Storm Vulcan 901 Tappet grinder, I know nothing about it, anybody ever used one?

|

|

By Ted - 5 Years Ago

|

While I do have a Storm Vulcan milling machine, I was not aware of Storm Vulcan making a tappet grinder. Should prove interesting when you get it up and running. I’m curious as to how the adjustment is made to vary the radius on the lifter face. For many lifters, you are looking for a 50-54 inch radius.

|

|

By Cliff - 5 Years Ago

|

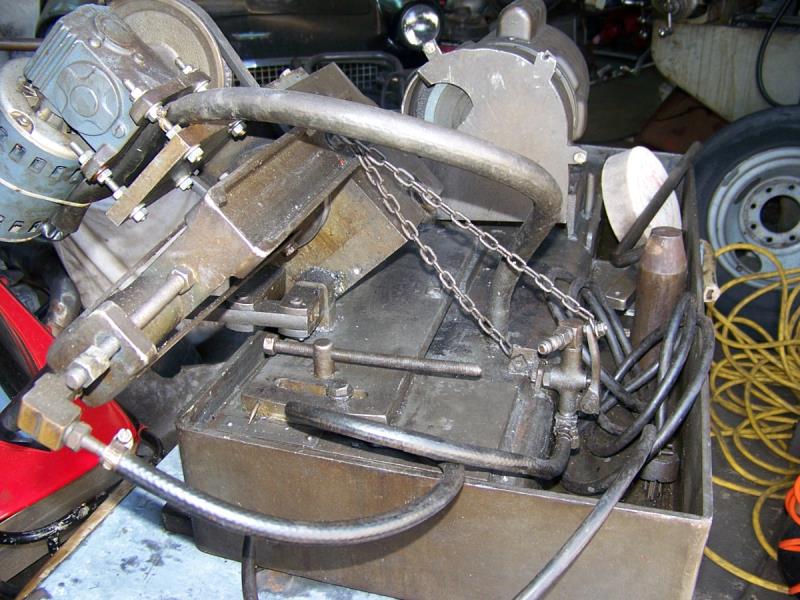

Better picture, there is a scale on the side, I also found a manual, the Y Block tappet radius is to be set at the 5 mark.

|

|

By Cliff - 5 Years Ago

|

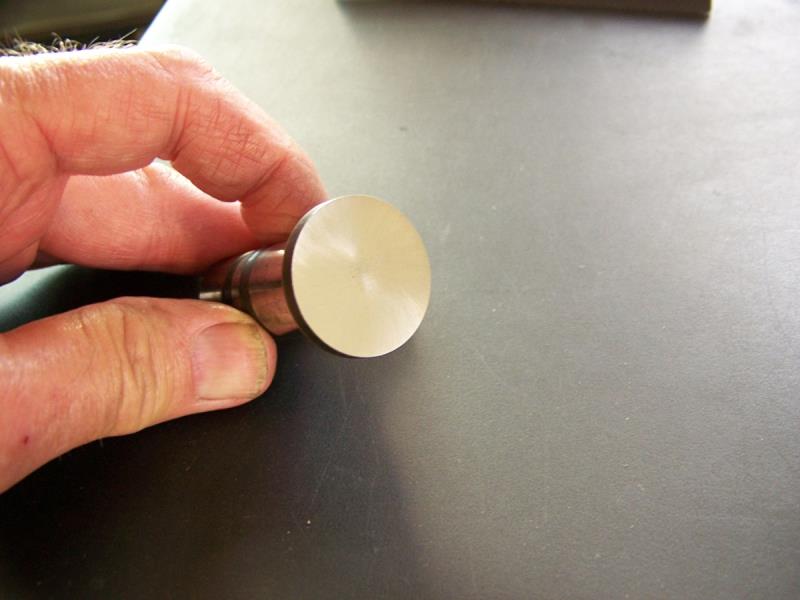

So I found a pitted wore out VW lifter, I put it in the machine to see what it will do, this lifter was concave to start now it has a convex curve, it is still is pitted, I didn't dress the wheel or do any setup, the finish it almost a mirror, I think this thing is a winner. So I found a pitted wore out VW lifter, I put it in the machine to see what it will do, this lifter was concave to start now it has a convex curve, it is still is pitted, I didn't dress the wheel or do any setup, the finish it almost a mirror, I think this thing is a winner.

|

|

By yblock57 - 5 Years Ago

|

|

Very nice. Can't imagine how much shipping cost for that thing. Probably pay for itself after grinding a few sets.

|

|

By Cliff - 5 Years Ago

|

|

My son went for a 200 mile drive (round trip)

|

|

By FORD DEARBORN - 5 Years Ago

|

Cliff, that machine is awesome, nice find. What is your thoughts on nitriding or?

|

|

By Cliff - 5 Years Ago

|

|

Thinking about some kind of heat treatment, not sure yet.

|

|

By 2721955meteor - 5 Years Ago

|

cool machine. I have a home made grinders chuck the lifter in my lath have a stone on a grinder that turns same speed ,but opposite direction. after set up I grind 1 and compare to some new ons, after the grind do a polish on the lathe only. hav ground several sets so far. used a set of reground with a new cam in my 292 in 49 mercy. would be interested in how to accurate get the angle. took some to a local cam grinder he sead they are great. but still looking how to get the same as the new ones in a factual way. takes me 15 min to do1 including final polish. the original hardness is fine after the grind. my truck has5600 miles,never had to adjust the valves all the same as original. the 2nd grinder is attached to the garage so when I came setup need to do several sets. have 1 set ready to go. 5,00 cn each with a core.

looking for ideas

|

|

By Cliff - 5 Years Ago

|

|

Hi, the radius is hard to replicate, I was lucky to find this machine, a taper is not what you want, how did you measure the hardness? I worry about grinding to far and finding soft metal.

|

|

By Ted - 5 Years Ago

|

Cliff. Total agreement on the hardness. For lifters that have never been resurfaced before, the hardness is much more likely to be okay versus resurfacing lifters that have been previously resurfaced. There are some Y-Block tappet horror stories floating around in regards to resurfacing lifters that had been previously resurfaced. My thought process on resurfacing lifters is to only resurface lifters when new lifters of a suitable quality cannot be purchased. I’ve run both non-nitrided and nitrided new lifters with no issues either way. The cam lobes are always nitrided and that may be the saving grace for lifters that are not nitrided.

|

|

By 2721955meteor - 5 Years Ago

|

|

I purchased a new hayd lifter for a fe used the new lifter to set my angle, also the new lifter was not nitrated.,I compared the sparks for a hardness test. had a good idea re hardness from my ancent valve refacer,grinding a exhaust valve has different sparks and sound than a intake valve. not a very fool proof procedure . I purchased 4 lifters for a ford tractor engine, they are nitrited as well a grove for a snap ring so 1 would have a way to hold the lifter from falling out. they are identical to the y blocks, but very expensive.the face is the thin type for high lit cams.i used there thickness to determine how much to take off

|

|

By Cliff - 5 Years Ago

|

|

I'm going to buy a hardness tester soon, then I should know what I'm doing, as of now I think it's just to much of a gamble, I want to use FOMOCO Steel lifters (tappets) in some of my race engines, I've seen to many broken cast lifters for my taste.

|

|

By 1946international - 5 Years Ago

|

|

Cliff, great find on that grinder, I just paid $200 for a set of tappets so if you can get the details worked out it may earn it's keep.

|

|

By 2721955meteor - 5 Years Ago

|

set my grinder with a new lift so the radius is as close as possible. have ground som damaged lifters and the finish shows a change, this is after.020, so I do not try to salvage 15 to 20%.

I am very envious of the machine you found ,majer cam grinder hear does not have a tool like you do

|

|

By Cliff - 5 Years Ago

|

|

There easy to find, just look for 10-15 years, ask everybody you think may have or know of one, read every book you can find, I found this in an auction of a VW engine rebuilding Co.in San Diego, CA, it was an internet auction, I bid it without seeing it (gamble).

|

|

By Cliff - 5 Years Ago

|

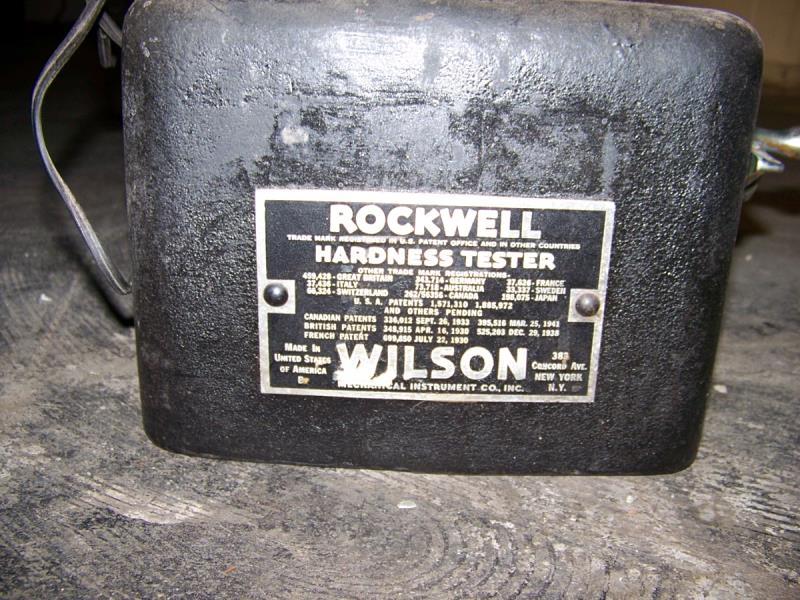

Well I bought a Rockwell Hardness Tester, now I have to learn how to use it, I should be able to reface and test lifters soon.

|

|

By Cliff - 5 Years Ago

|

Tested lifters today for hardness, VW (1600 air cooled) 49 C Rockwell, sealed power AT892 56 C Rockwell and Trend Tool Steel lifter 62 C Rockwell, I do not have a test block yet (to check calibration), however these are the numbers that I expedited.

|