While I'm waiting on my valve body part, I wanted to try to get the linkage set the best possible by the book. I can't get the accelerator pedal height up past 3" and the book calls for 4 7/8" on a '57 thunderbird.

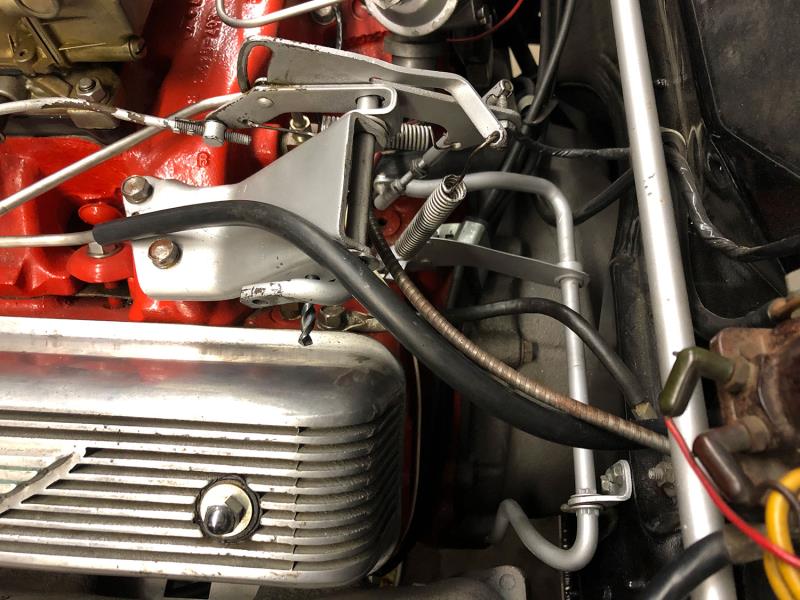

As a consequence of this, when you floor the pedal, you do not get full throttle engagement. When you work the 'grasshopper' under the hood by hand to full throttle, the rod pops out of the back of the accelerator pedal. Obviously there's something wrong here.

I've locked the 'grasshopper' in place with the 1/4" drill bit and the threaded rod that sets the pedal height is extended as long as it will go. 3" is all I can get out of the adjustment.

I went ahead and removed the piece of linkage from the accelerator pedal that goes through the firewall and measured and took a few pics. If anyone has one I can compare mine to, that would be great. Not sure if the curve in it is correct or not — it doesn't appear bent to the naked eye. I don't want to flatten that curve in a vise if it is indeed correct and the problem is elsewhere. Tip to tip is 5 7/8"

Nothing else in the setup looks bent or twisted.

Thanks!

Kent — Round Rock, TX

'56 F-100 | '56 Crown Vic | '57 Fairlaine 500 | '57 Thunderbird