|

By yblock57 - 6 Years Ago

|

Update 12/17/20 — issue in this case turned out to be the throttle valve installed wrong in the valve body. Mine ended up being installed incorrectly by the rebuilder. Once this was corrected, the transmission shifted correctly.

**********************

Howdy everyone. Apologies in advance for the long post. Any help you have to offer is greatly appreciated!

Looking for some advice/direction on how to solve late shifting and very harsh downshifting issues on my medium-case Fordomatic in my '57 bird.

Background:

Transmission was rebuilt by a local trans shop that specialized in older stuff. We pulled engine out to keep costs down and took trans in for a bench job. Everything went back together fine. Transmission shift points are very late (30+mph regardless of throttle pressure) from 2nd to 3rd. It also downshifts back to 2nd at around the same speed (harsh). All linkage adjustments were checked and reset several times per the shop manual to try and remedy. No change in shift points — it doesn't matter how far the rod is shortened or lengthened. Car went back twice to the shop and they basically threw in the towel and said that's how it works. Car went to two other shops where the valve body was dropped and they discovered a sticky throttle valve. This also made no difference to the shift points. Reset linkage again and no matter where the adjustment, car shifts same (late). In fact, it shifts the same with the kick-down rod completely disconnected. Something else is going on here.

The transmission goes into gear very quick and crisp from park to reverse, drive & low and shifts nice and firm — just late. From reading the Fordomatic manual, I'm leaning toward the governor being a possible issue. What would you do in this situation? I'd like to pull the tail shaft off and take a look at the governor and see if it's clogged or sticky. I know this won't be ideal in the confined space of a thunderbird, but would beat pulling everything back out again. I have an extra governor that I could try but am interested in fixing this right and not throwing parts at it. Local shops around here are worthless.

We have a couple of other cars with this same transmission and have no problems adjusting the shift points with the kick-down rod. In fact, they're fairly sensitive to small adjustments. They all can be made to shift around 22 mph per the shop manual as well.

Would a line pressure test indicate a faulty governor? Or should I be looking at something else? Fluid is still very nice and red and fresh smelling. Only a 150ish miles put on since the overhaul.

Thanks in advance!

Kent

|

|

By blocky - 6 Years Ago

|

|

hi kent i have had similar troubles with autos here in oz and you are on the right path with the governer . always worth a look and cheap too.good luck

|

|

By paul2748 - 6 Years Ago

|

I'm no expert on Fordo's, but could it be the fluid your using? Different fluids can determine how it shifts depending on what is inside. I assume you are using the fluid recommended by the rebuilder?

|

|

By yblock57 - 6 Years Ago

|

paul2748 (10/7/2020)

I'm no expert on Fordo's, but could it be the fluid your using? Different fluids can determine how it shifts depending on what is inside. I assume you are using the fluid recommended by the rebuilder?

Hey Paul2748 -

Using Type F fluid. Per rebuilder and many other's recommendation. Should have mentioned in my original post. Thanks for pointing that out.

|

|

By yblock57 - 6 Years Ago

|

blocky (10/7/2020)

hi kent i have had similar troubles with autos here in oz and you are on the right path with the governer . always worth a look and cheap too.good luck

Thanks, Blocky

Have any tips on what to look for in the governor? I was under the impression that if there's any contamination, to clean it up and make sure the valve inside is working. Anything else I should look for?

|

|

By Hoosier Hurricane - 6 Years Ago

|

|

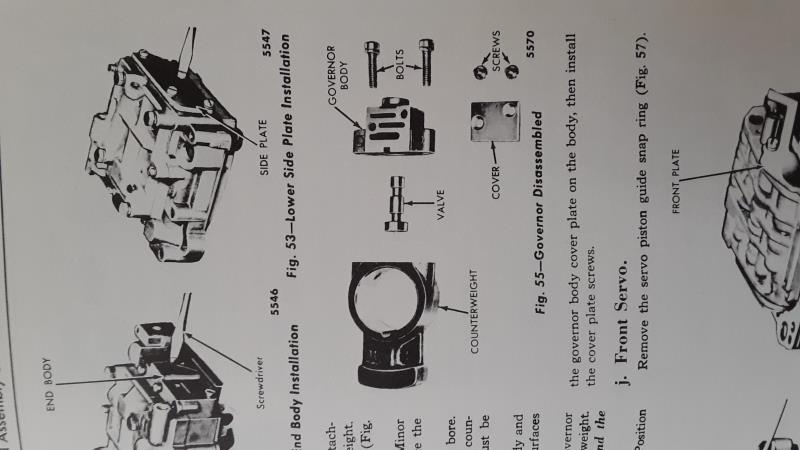

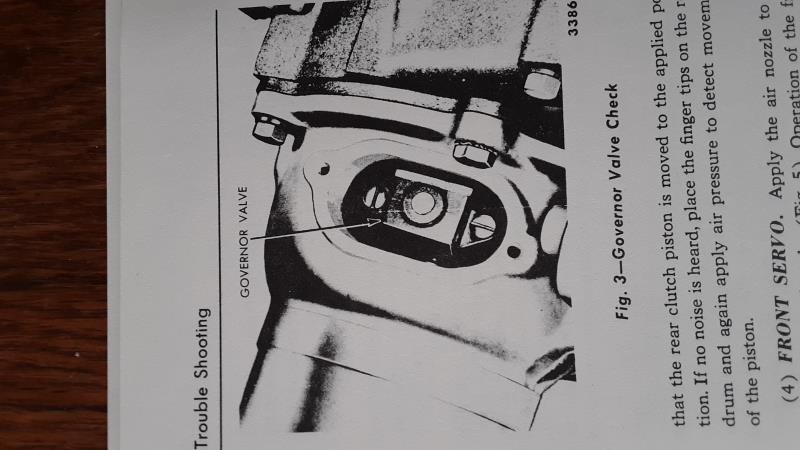

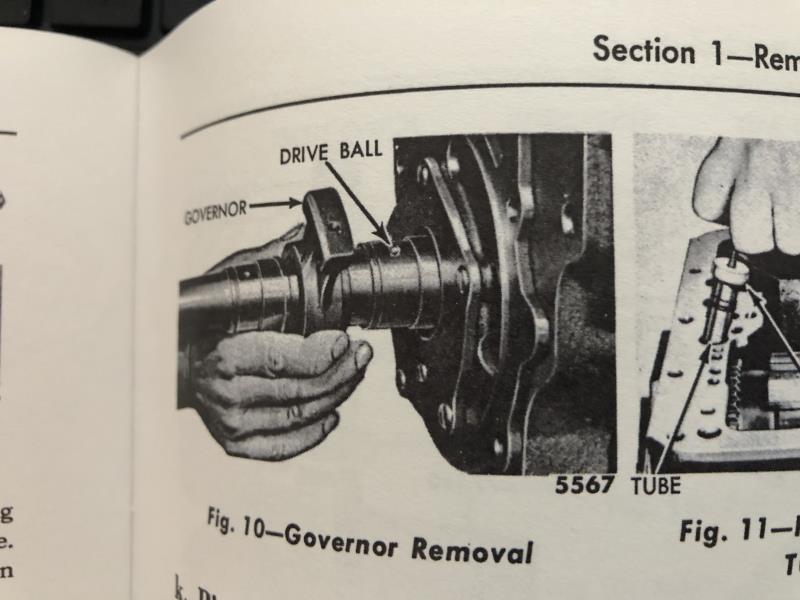

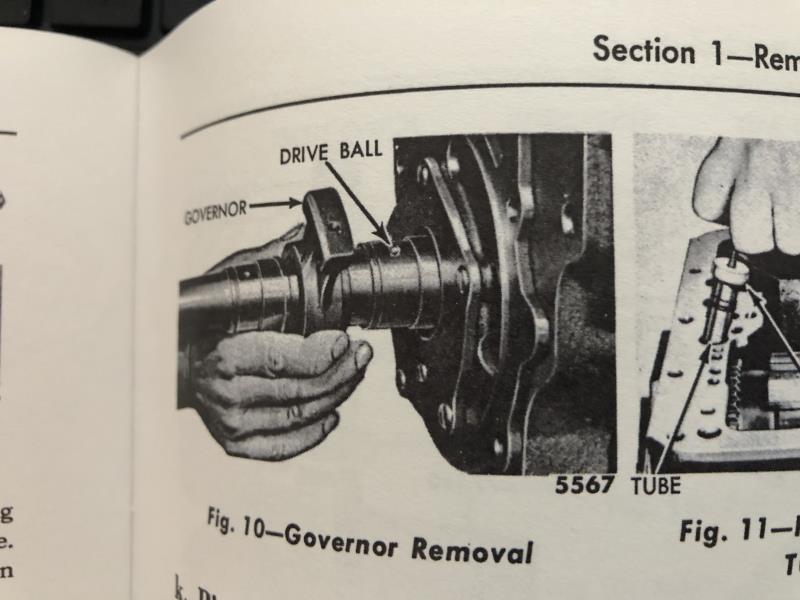

Kent, you do not have to remove the tail housing to access the governor. There is a metal plate on the passenger side of the tail housing with two screws, take that plate off, and turn the driveshaft until the governor appears in the opening. Take the two screws out of the governor and pull it from the opening. Be careful not to drop those screws into the housing or you may find yourself removing the tail housing, not a very easy task in a T-Bird. Make a note of which way the governor goes, it will fit both ways but will only work one way.

|

|

By DryLakesRacer - 6 Years Ago

|

If you do everything thru the access opening make sure to get a new or make a new gasket. I also used bolts instead of the screws. Make sure the cover is flat. If your torque converter leaks back, which is normal and ok, the rear will get a lot of the oil and the cover will leak.

With what you said about the sticky valve in the body, and the governor might be not functioning correctly your trans shop should owe you money. With what Hoosier says maybe it’s in wrong....

|

|

By PF Arcand - 6 Years Ago

|

This note isn't likely to fix your problem, but has come up before. Ford originally specified Type "A" fluid. It's in the manual, not type F. It has morphed into Dexron II etc.. Good luck with your problem.

|

|

By yblock57 - 6 Years Ago

|

Hoosier Hurricane (10/8/2020)

Kent, you do not have to remove the tail housing to access the governor. There is a metal plate on the passenger side of the tail housing with two screws, take that plate off, and turn the driveshaft until the governor appears in the opening. Take the two screws out of the governor and pull it from the opening. Be careful not to drop those screws into the housing or you may find yourself removing the tail housing, not a very easy task in a T-Bird. Make a note of which way the governor goes, it will fit both ways but will only work one way.

John —

I was looking at that plate and thinking there had to be a reason they put it there. Appreciate the information very much! This will really help me out in the cramped quarters of the infamous 'X' member.

If the shop put it on the wrong way (highly possible), would it be obvious in how the passages line up in the governor halves? Anything else you'd recommend looking at?

I was planning on getting a pressure gauge to see what the thing is doing when it shifts. I suspect it's getting pretty high but would like to know for sure. Any recommendations on decent gauges?

Thanks again!

Kent

|

|

By yblock57 - 6 Years Ago

|

DryLakesRacer (10/8/2020)

If you do everything thru the access opening make sure to get a new or make a new gasket. I also used bolts instead of the screws. Make sure the cover is flat. If your torque converter leaks back, which is normal and ok, the rear will get a lot of the oil and the cover will leak. With what you said about the sticky valve in the body, and the governor might be not functioning correctly your trans shop should owe you money. With what Hoosier says maybe it’s in wrong....

DryLakesRacer —

Thanks for the tip! I'm pretty green messing with these things but not afraid to get my hands dirty. Maybe watching some of the youtube videos of a few tear-downs might have made me a little overconfident. ha

They don't seem too complicated, so this has to be something that can be remedied without too much trouble — at least that's what I keep telling myself.

The shop that did this changed ownership during the 'rebuild' and all actions where taken short of legal to get them to make it right. At this point I'd just like to learn how to overhaul these things myself and take all swindlers and amateurs out of the equation in the future.

Thanks,

Kent

|

|

By yblock57 - 6 Years Ago

|

Removed the governor. Appears to have been installed correctly. Valve moves freely. Has a very light spring that doesn't require much effort to move the valve. Everything appears to be in good shape. There is a very slight amount of side-to-side play in the piston. Is that normal or should I be concerned?

Any recommendations on where to go from here? I'm at a loss as how to solve this late-shifting issue.

|

|

By FORD DEARBORN - 6 Years Ago

|

Yblock57, I don't remember a spring being part of the early FOM governor assembly. Checking the 56 - 57 FOM shop manual shows an exploded view with no spring and no spring is mentioned in the text. You might try installing it with out the spring and see what it does. Also, a line pressure test would be very helpful.  Hope this helps, JEFF.............edit: This also raises another question, like, where did this spring come from? Hope this helps, JEFF.............edit: This also raises another question, like, where did this spring come from?

|

|

By yblock57 - 6 Years Ago

|

FORD DEARBORN (10/16/2020)

Yblock57, I don't remember a spring being part of the early FOM governor assembly. Checking the 56 - 57 FOM shop manual shows an exploded view with no spring and no spring is mentioned in the text. You might try installing it with out the spring and see what it does. Also, a line pressure test would be very helpful.  Hope this helps, JEFF.............edit: This also raises another question, like, where did this spring come from?

Jeff --

Thanks for chiming in. This is my first time inside this thing. The shop that supposedly rebuilt it must've done that. I found an NOS governor and bought it. Was concerned about the small amount of side-to-side slack the piston had.

Will be interesting to see if the NOS one has the spring. All I'm using is the top piece so will be sure to post my findings.

Bought a gauge to pressure test and will also get some #'s posted as well.

Thanks again!

Kent

|

|

By FORD DEARBORN - 6 Years Ago

|

If you determined that spring does not belong in the governor, then more than likely it belongs somewhere in the valve body. Keep us posted.................

|

|

By yblock57 - 6 Years Ago

|

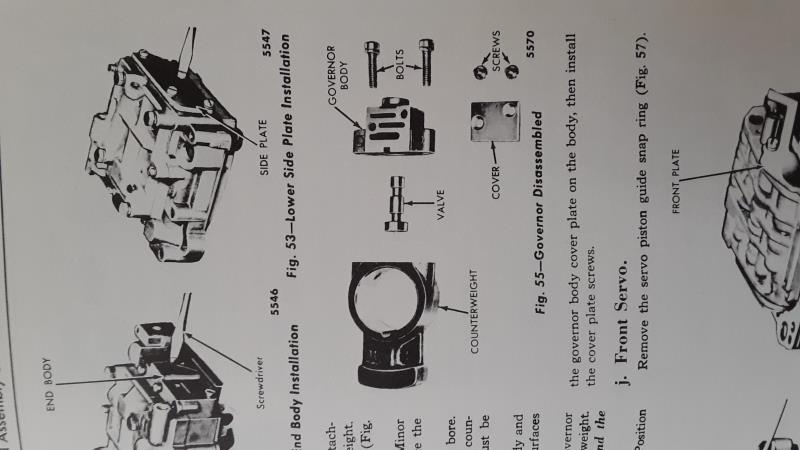

I think I might be onto something here. After watching a ton of tear-down/rebuild videos and looking at diagrams, I think the governor was installed backwards at the time of rebuild.

Here's a link to the video I made. Apologies on the quality. Working under a '57 bird without a lift is no picnic. I pulled the top part of the governor off previously to check the piston operation.

This is from someone else's youtube account on reassembling a cruise-o-matic with a similar style governor — in the opposite orientation.

If anyone can confirm that the governor is indeed on backwards, that would really help! Also if anyone has ever pulled a fordomatic tail shaft on a 55-57 thunderbird in the car — that would be good to know if it's even possible.

Thanks for all the help!

Kent

|

|

By FORD DEARBORN - 6 Years Ago

|

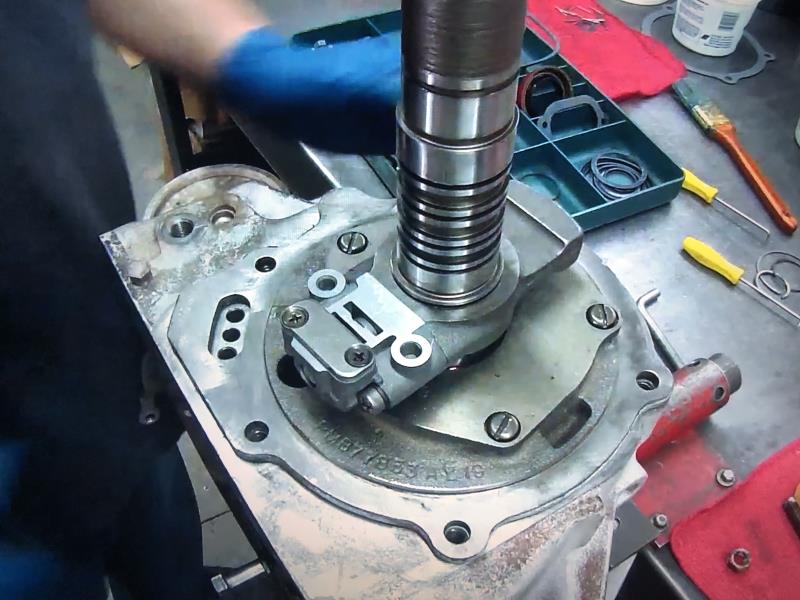

I'm assuming you have a 57 FOM. The trans governor pictured in your last post is a 2 stage gov. as used on a cruise o matic. FOM is different and is installed with cover plate facing forward as shown in the pictures I'll try posting. Also, it's difficult for me to see for sure but the phantom spring shown with your 57 governor appears to be broken. All springs in these transmissions have the ends finished by winding the end coils together to form a square so uniform/equal force is applied around the entire circumference. I don't know where that spring came from but it may be part of another spring. Therefore, the rebuilder may of had an "extra" spring and it looked logical to install it in the governor???? The pics I'll try sending are true 56/57 Ford illustrations. I'm never very good using descriptive text so hope this makes sense. Otherwise, send me a PM with contact number and we can discuss this in real time. It's been eons since I last rebuilt one of these but the information here is in    referenced to 57 published material. Hope this helps, JEFF......... referenced to 57 published material. Hope this helps, JEFF.........

|

|

By yblock57 - 6 Years Ago

|

Jeff —

What you said makes sense. Good to know pulling the tail shaft is not necessary. Didn’t think I’d be able to do it in this car anyway.

You are correct that this is a water-cooled ‘57 Fordomatic I believe to be original to the car. Can’t find much online info regarding these so that’s why I referenced the cruise-o-matic. Much different animal obviously.

I have a NOS governor on order and am planning to use just the top valve assembly and reinstall on my existing gov body.

The knowledge being gained here is invaluable. Will post my findings.

PM sent.

Thanks again,

Kent

|

|

By DryLakesRacer - 6 Years Ago

|

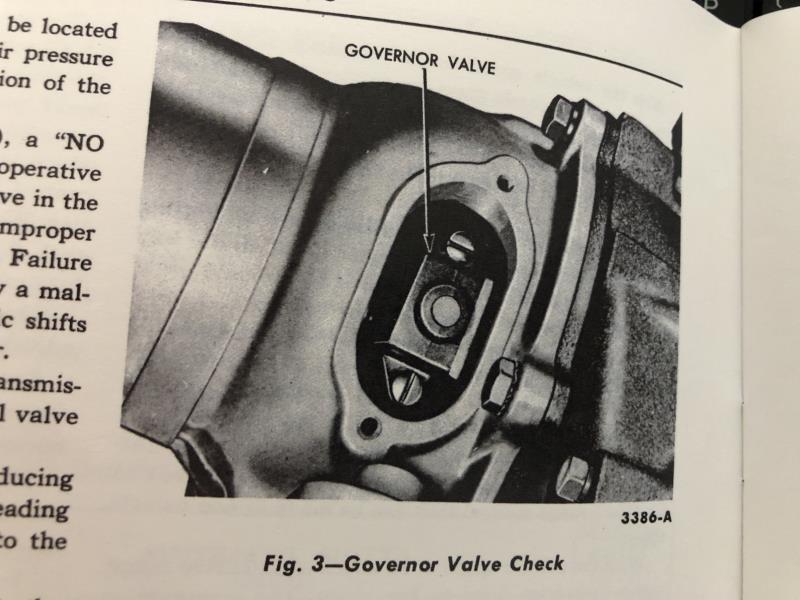

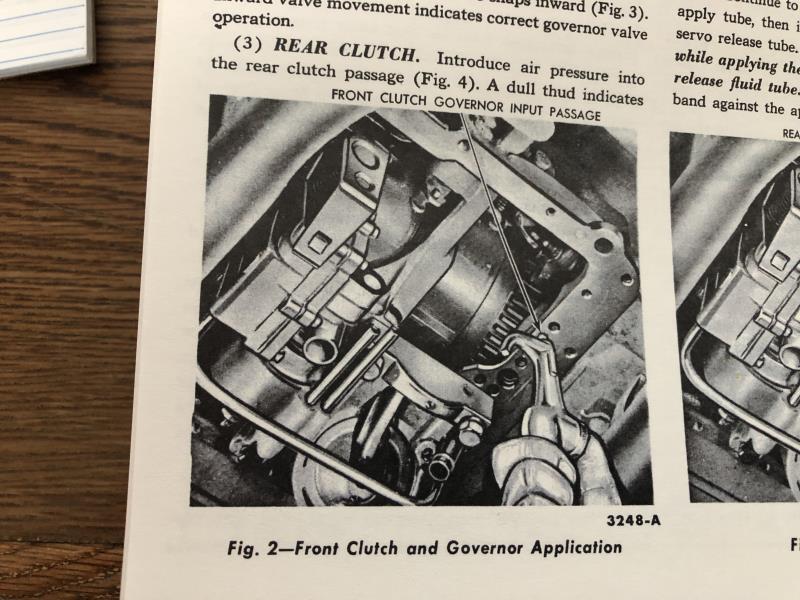

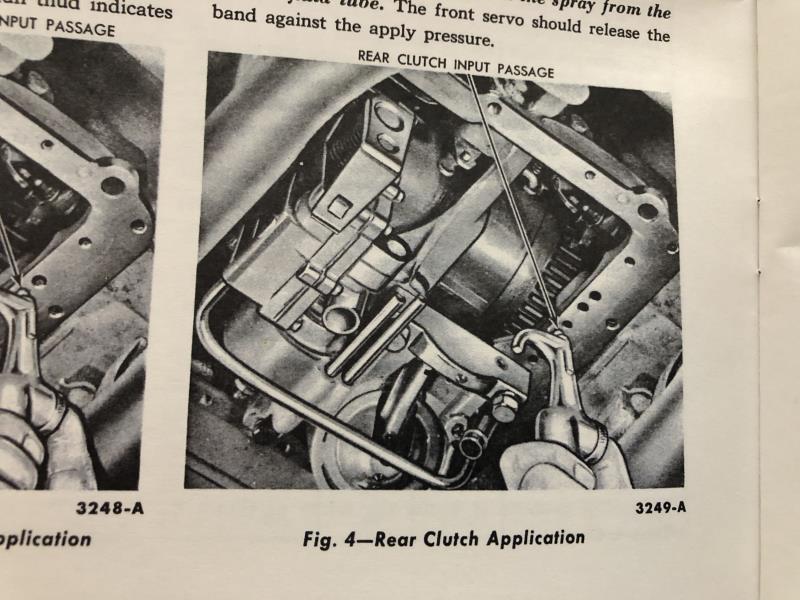

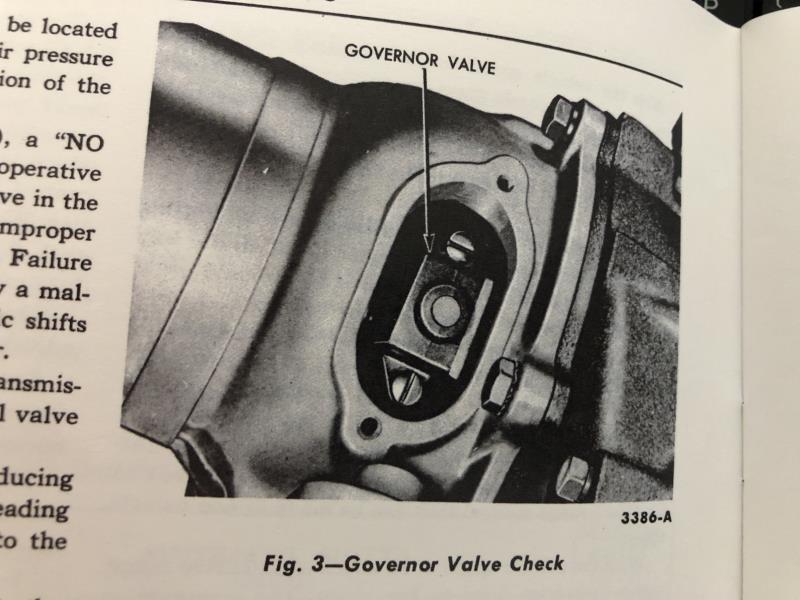

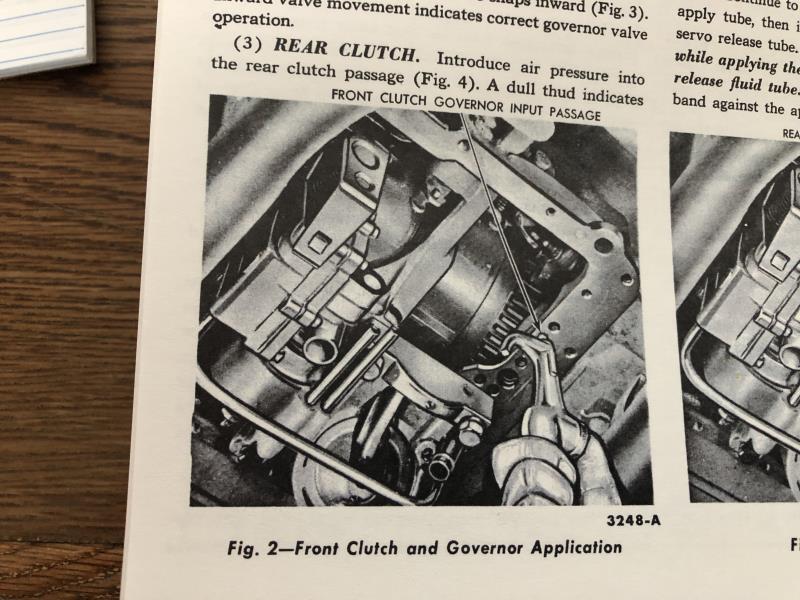

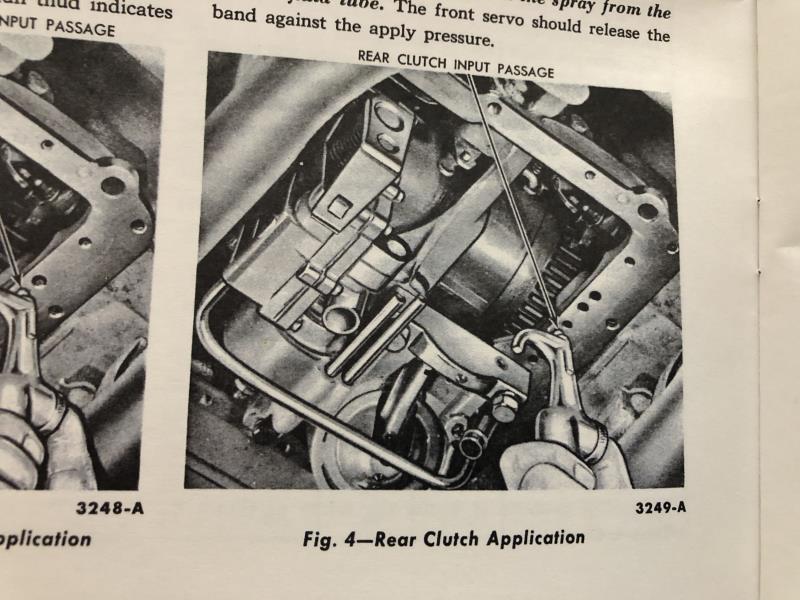

Kent, I am no auto trans expert or novice for that matter but I have a 56-57 Ford0matic manual and looking at photos ant trouble shooting for the governor on pg 26 the show it mounting with the plate forward, but does not show the part left in the trans with the actuator off. There places in the manual showing the removal of the governor from the shaft and there is a drive ball involved. I’m not sure on its function but I’m sure it’s your 90* of movement.

From your video it looks like the longer slant is towards the rear of the trans and this “ appears” to be correct in the figures I can see.

There is also a way to used air pressure thru a hole in the case with the pan off to listen for the governor working. I’ll take a photo of a figure in the book but it may not help. I bought this manual on the net.

I would get this correct manual first before taking any more apart.

I have new case of type A trans fluid. Hope this helps.

|

|

By yblock57 - 6 Years Ago

|

DryLakesRacer (10/17/2020)

Kent, I am no auto trans expert or novice for that matter but I have a 56-57 Ford0matic manual and looking at photos ant trouble shooting for the governor on pg 26 the show it mounting with the plate forward, but does not show the part left in the trans with the actuator off. There places in the manual showing the removal of the governor from the shaft and there is a drive ball involved. I’m not sure on its function but I’m sure it’s your 90* of movement. From your video it looks like the longer slant is towards the rear of the trans and this “ appears” to be correct in the figures I can see. There is also a way to used air pressure thru a hole in the case with the pan off to listen for the governor working. I’ll take a photo of a figure in the book but it may not help. I bought this manual on the net. I would get this correct manual first before taking any more apart. I have new case of type A trans fluid. Hope this helps.

Hey DryLakesRacer —

Appreciate the info. I did get my hands on the same fordomatic manual. Not as nice as yours, but should be a big help in the right direction. Thanks for posting the pics.

Found the right governor on eBay and should be here sometime this week. Will give it a try (without spring) and report my findings. Hopefully will get lucky.

Thanks again,

|

|

By DryLakesRacer - 6 Years Ago

|

|

Hope it all helps. My manual is a repop along with the car manual and blow apart manual.

|

|

By yblock57 - 6 Years Ago

|

DryLakesRacer (10/18/2020)

Hope it all helps. My manual is a repop along with the car manual and blow apart manual.

Where'd you get the blow apart manual?

|

|

By yblock57 - 6 Years Ago

|

I did get the NOS gov installed last night. Unfortunately it didn't make any difference in shifting. Still shifts at 33 mph regardless of kick-down rod adjustment. Removed it from the equation at least.

The NOS gov did NOT have a spring as several have mentioned on here. Installed without a spring and was hoping that would get me in the ballpark, but no dice.

Any suggestions on where to look next appreciated.

I know I need to get some pressure readings and have bought a gauge. Will run the tests and post back.

Thanks

|

|

By DryLakesRacer - 6 Years Ago

|

On line I think.... it’s a repop. Check the old Ford supplier’s like Carpenter, Concours. Etc: 7 pages of the auto trans... includes part #’s

|

|

By yblock57 - 6 Years Ago

|

DryLakesRacer (10/20/2020)

On line I think.... it’s a repop. Check the old Ford supplier’s like Carpenter, Concours. Etc: 7 pages of the auto trans... includes part #’s

Thank you sir.

|

|

By yblock57 - 6 Years Ago

|

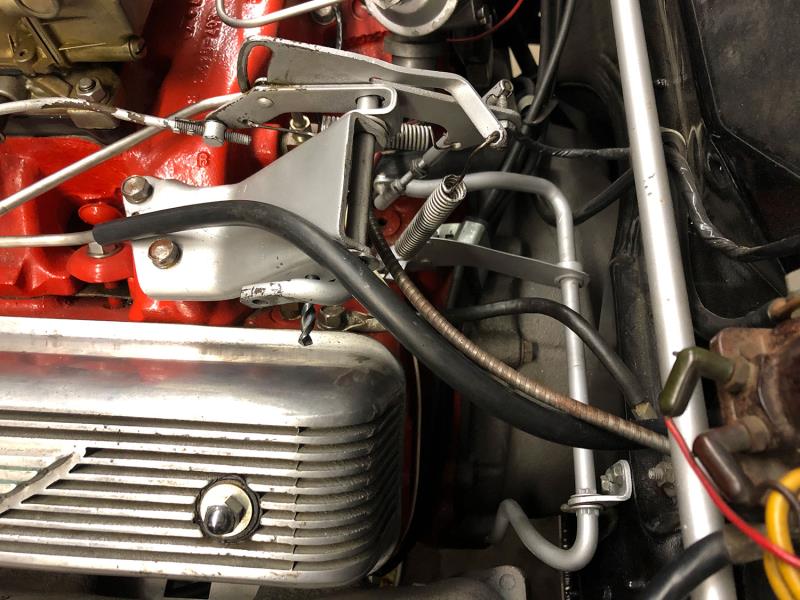

I did a little checking on the throttle linkage. Dad said he set the linkage and accelerator pedal height per the shop manual with the 1/4" drill bit to lock the pieces in place and get everything set. I have not double-checked his work, but it looks correct. What seems to be an issue here is the throttle stops at about 1/2 travel. If you remove the kick-down rod it moves completely open with no resistance. I can't believe this was not noticed until now. I've included a link below to a video I made to help explain what I'm looking at.

This was an issue when we put the transmission back in and was explored then. I thought this had been resolved but obviously not. For the sake of comparison, I made a video of a friend's '57 thunderbird with the same functioning setup and his kick-down rod appears to have the same amount of travel (approx. 1")

I'm going to go back through the steps listed in the manual on setting up the bell-crank linkage and see if that possibly changes things. I feel a positive stop when depressing the rod and it springs back up to the top again. Looking at page 20 in the fordomatic manual it mentions the throttle lever internal stop can be bent towards or away from the valve body to change idle pressure. I see this as a strong possibility given the limited movement I'm getting.

The fact that the 2-3 shift point stays the same when I removed the kick-down rod indicates that there's an internal issue possibly in the valve body causing high line pressure.

I'm going to get pressure readings and then drop the pan and have a look.

Any other suggestions?

|

|

By oldcarmark - 6 Years Ago

|

|

The Rod should move much further than that allowing full wide open Carburetor. I think you are onto the right Track by checking the Lever assembly on the Transmission. That Rod controls Pressure right throughout the Throttle Position. Should not be driven with Rod disconnected.

|

|

By yblock57 - 6 Years Ago

|

I drug my butt off the couch last night and got the pressure readings on the thunderbird. As suspected, they're higher than the ranges specified in the book. The stall tests were low due to things binding at half-throttle due to the kick-down rod not moving enough. I made sure everything was up to temp before getting readings.

I rechecked the linkage adjustments before I started the test. The only thing I couldn't get in spec was the accelerator pedal height. Book says '57 thunderbird should be 4 7/8". I couldn't get any more than 3" with the adjustment set as far as it would travel. Not sure that matters much in the scheme of things but wanted to make a note of it.

Line pressure readings (psi):

Idle in drive — 80 — Book says 55-70

1k rpm in drive — 140 — Book says 80-85

Stall in drive — 150 — Book says 147-180 (not really full throttle as my linkage limits me around 1/2 throttle so this is probably a lot higher)

Stall in reverse —190 — Book says 194-216 (same as above)

Thought about dropping the pan but was too tired. Now that I have the numbers, that confirms what we talked about. I removed the kick-down rod from the transmission and measured 3/4" movement. I think it needs to move more. It would explain the linkage binding. I'll be looking closely at the 'L' bracket on the throttle body when I drop the pan.

This is starting to make sense. Trans is seeing too much pressure and shifting late because of it. Hopefully the 150ish miles put on it haven't damaged anything.

|

|

By DryLakesRacer - 6 Years Ago

|

|

I drove my Ford0 once with the throttle pressure rod off by mistake. The car went thru the gears 2-3 fine but shifted quick, 15 mph. Not knowing it was off I stepped on the gas harder at the next light and it still shifted at 15 again when I knew it should have been higher. That’s when I found it off. Sounds like pressure at low speed has a lot to do with what’s happening. Good luck.

|

|

By yblock57 - 6 Years Ago

|

Ok, got the pan off and took at look at things. Made another video showing the TV linkage against the ‘L’ bracket. It’s obviously putting pressure on the valve at the ‘Rest’ position and limiting travel of the linkage. I think this is the key to the entire problem.

I went ahead and pulled the valve body and disassembled. Everything looks good and all springs are present and accounted for. All pistons move freely.

Would y’all go ahead and bend the ‘L’ bracket back and check for free movement and reassemble? For grins I hooked up the TV rod to the trans with valve body removed and I get full articulation with no binding.

Here’s a closer look at the TV & L stop

I'm concerned that even bending this L won't give me the amount of travel I need without seriously distorting things. Thoughts?

Thanks,

|

|

By yblock57 - 6 Years Ago

|

I did not bend the L bracket. Didn't feel right. Didn't look like that was the actual issue.

After several of y'all pointed out and I initially missed, the back side of the throttle valve was NOT moving freely. It was being stopped by the back cover plate that had a small protrusion just barely covering the edge of the TV bore, thus creating a hard stop on the valve. Pics I viewed in the FOM manual clearly show the TV protruding out the backside of the bore. Mine was not. Apologies on the videos. I accidentally stopped in between showing the issue.

I don't have an explanation on why that back cover plate was interfering with the valve, but I went ahead and filed it down to get the clearance I needed. It only goes on one-way so no way it could've been flipped or put on backwards. Now it operates with MUCH more movement than before. I suspect this will translate into the additional articulation I need to get the linkage set correctly and have full throttle without binding.

I'll be sure and check movement of everything when I reinstall the valve body and before the pan goes back on. If anyone has any additional thoughts or ideas on what I should look at while the pan's off, I'm all ears!

I'll be setting the TV rod using my pressure gauge when it gets to that point. I want to verify this gets me back into the ranges shown in the FOM shop manual.

This has been a great learning experience. I can't thank everyone enough who's chimed in with all the help and suggestions. Very much appreciated! I'll be sure and post my findings.

|

|

By Lord Gaga - 6 Years Ago

|

|

Thanks for the great description and videos Kent!

|

|

By 2721955meteor - 6 Years Ago

|

years ago put my govoner in backwerds, woud not shift into high atall,turned around worked ok. if you do eventualy int high ,it was in corectly

stickey or gasket incorect

|

|

By 2721955meteor - 6 Years Ago

|

|

my screwup was a 57merc and removed tailshaft and turned the whole asemblyaround,was my1st crack at a auto trans,that worked,found out later could axcess threw the cover,tho in my case just turning govener may not have worked

|

|

By FORD DEARBORN - 6 Years Ago

|

Great work, you nailed it.............

|

|

By yblock57 - 6 Years Ago

|

While I'm waiting on my valve body part, I wanted to try to get the linkage set the best possible by the book. I can't get the accelerator pedal height up past 3" and the book calls for 4 7/8" on a '57 thunderbird.

As a consequence of this, when you floor the pedal, you do not get full throttle engagement. When you work the 'grasshopper' under the hood by hand to full throttle, the rod pops out of the back of the accelerator pedal. Obviously there's something wrong here.

I've locked the 'grasshopper' in place with the 1/4" drill bit and the threaded rod that sets the pedal height is extended as long as it will go. 3" is all I can get out of the adjustment.

I went ahead and removed the piece of linkage from the accelerator pedal that goes through the firewall and measured and took a few pics. If anyone has one I can compare mine to, that would be great. Not sure if the curve in it is correct or not — it doesn't appear bent to the naked eye. I don't want to flatten that curve in a vise if it is indeed correct and the problem is elsewhere. Tip to tip is 5 7/8"

Nothing else in the setup looks bent or twisted.

Thanks!

|

|

By oldcarmark - 6 Years Ago

|

|

What did You need for the Valve Body?

|

|

By yblock57 - 6 Years Ago

|

oldcarmark (10/30/2020)

What did You need for the Valve Body?

Forgot to update. I made an error in filing off that 'tab' on the end plate that was blocking the throttle valve. According to the book, (which I missed) you're supposed to push the valve out past the first land then install the plate. It acts as a stop to keep the valve from over travel and prevents it from fulling returning inside the valve body. Amateur mistake.

Luckily, Dad has a couple extra in his parts stash that we can scavenge. I'll be sure to update the thread once corrected and installed for future reference.

In the meantime, Getting the accelerator pedal height correct and having everything in the linkage work as it should is my next hurdle.

If anyone has another threaded rod they could check total length when fully extended, that would help me a ton. Mine measures 5 1/4"

If this is too short and incorrect for a '57 thunderbird, that would explain the issue. If not, looks like I'll end up having to 'tweak' my firewall rod.

Thanks!

|

|

By DryLakesRacer - 6 Years Ago

|

|

1/4x20 rod and coupling from a hardware store like ACE can help. It’s how I made the carb linkage when I change to 2 carbs. Good luck

|

|

By yblock57 - 6 Years Ago

|

After looking at pics on here and my friend's '57 and comparing setups, the conclusion was my double-L rod on the firewall was bent... slightly. I removed it from the car and mounted it on my workbench. Was expecting a battle to get any bending action, but it moved surprisingly easy.

Got lucky as I bent it it just the right amount the first time. Verified 4 7/8" pedal height with the 1/4 drill bit in the bell crank. Adjusted the rod going to the carburetor and presto — everything works as advertised. No more binding, and I get full throttle with the pedal — at least everything up top is moving the way it should... we'll see how it goes with the throttle rod once the valve body goes back in.

Now it's just a matter of getting the valve body back in the transmission and verifying throttle rod travel and getting pressures set correctly.

Thanks to all who've chimed in and helped. I'll keep y'all posted on how this turns out.

|

|

By oldcarmark - 6 Years Ago

|

Any new Updates?

|

|

By Rusty_S85 - 6 Years Ago

|

PF Arcand (10/9/2020)

This note isn't likely to fix your problem, but has come up before. Ford originally specified Type "A" fluid. It's in the manual, not type F. It has morphed into Dexron II etc.. Good luck with your problem.

Yep I am going to be adjusting my intermediate band to see if the overdue adjustment will help my falling out of gear, Ive been using Type A that I was able to get in the Accell brand via amazon but its out of stock and Accell states its discontinuned so I am going to switch to Valvoline Dexron to replace it with. I dont know how many times Ive seen people recommend Type F as the replacement for Type A when all my research has pointed to Type A being a GM fluid and being replaced by Dexron.

|

|

By KULTULZ - 6 Years Ago

|

|

Ive been using Type A that I was able to get in the Accell brand via amazon but its out of stock and Accell states its discontinuned so I am going to switch to Valvoline Dexron to replace it with. I dont know how many times Ive seen people recommend Type F as the replacement for Type A when all my research has pointed to Type A being a GM fluid and being replaced by Dexron.

TYPE A was discontinued in the late fifties. The only use I know now is for dirt bike gear boxes,

DEXRON is a GM marketing name. MERCON is a FOMOCO marketing name.

I believe the latest is GM DEXRON IV (non-synthetic). FORD dropped MERCON several years ago and offers only MERCON V partial synthetic as a back-fill (not for TYPE F call outs).

TYPE F can be used in a DEXRON application giving firmer shifting. DEXRON cannot be used in a TYPE F call out

For any application past say 1970, make sure you check the OWNERS MANUAL or appropriate LUBE CHART..

|

|

By DryLakesRacer - 6 Years Ago

|

|

I have a case of A. I use Mercon II in my 62 cruise-o because I was told to by the shop that built it.

|

|

By Rusty_S85 - 6 Years Ago

|

KULTULZ (11/14/2020)

Ive been using Type A that I was able to get in the Accell brand via amazon but its out of stock and Accell states its discontinuned so I am going to switch to Valvoline Dexron to replace it with. I dont know how many times Ive seen people recommend Type F as the replacement for Type A when all my research has pointed to Type A being a GM fluid and being replaced by Dexron.

TYPE A was discontinued in the late fifties. The only use I know now is for dirt bike gear boxes,

DEXRON is a GM marketing name. MERCON is a FOMOCO marketing name.

I believe the latest is GM DEXRON IV (non-synthetic). FORD dropped MERCON several years ago and offers only MERCON V partial synthetic as a back-fill (not for TYPE F call outs).

TYPE F can be used in a DEXRON application giving firmer shifting. DEXRON cannot be used in a TYPE F call out

For any application past say 1970, make sure you check the OWNERS MANUAL or appropriate LUBE CHART..

Correct you can use Type F in Dexron applications, many hotrodders I know did that as a shift kit in a bottle basically. I think thats what the transmission shop I will be having modify my C6 is recommending to run is the Type F for the firmer shifting which I am not too sure about since I am going with the RV/Tow shift kit to firm up the shifting already.

In my case I will be using the Dexron just cause it is a direct replacement for Type A and my transmission is original. Once I have it rebuilt I will be running what ever is recommended for the overhaul kit even if that is Type F. I just wont be draining my whole transmission currently of Type A when I do my band adjustment so I figure the dexron shouldnt give any issues with mixing with Type A since its supposed to be the replacement for Type A.

|

|

By paul2748 - 6 Years Ago

|

The fly in the ointment is that over the years, unless you do a chemical anaylsis, there could be anything in the transmission. We all assume that the proper fluid was used each and every time a trans was serviced or the original type friction plates were installed in a rebuild

|

|

By Rusty_S85 - 6 Years Ago

|

paul2748 (11/14/2020)

The fly in the ointment is that over the years, unless you do a chemical anaylsis, there could be anything in the transmission. We all assume that the proper fluid was used each and every time a trans was serviced or the original type friction plates were installed in a rebuild

Yep but type A was quite easy to find up till the 1990`s. When I talked to the local napa stores with old timers still working there when I was first looking for Type A some 10 years ago they all told me that they havent seen Type A on the store shelves since the 1990`s. With this taken into consideration my '56 has been parked since my grandfather passed away in 1986 so the odds in my eyes are very high that Type A was used in servicing the transmission as it would have still been obtainable in the 1980`s as Type A was still being used in many cars still. In my search I found many cars in the 80`s were using Type A as a hydraulic fluid for convertible tops.

But I am going to have my old aircooled Fordomatic rebuilt when I put the car down for a frame up restoration. I might even do it myself since I got the books just need the more specialized tools. But if the car is questionable as in you dont know its history then it does become very hard to tell what is or isnt in a transmission fluid wise. I sourced Texas Gold Type A transmission fluid as well as Accell Type A fluid which is the only transmission fluid I ever put in the transmission for top offs. When I drop the pan I got one bottle of Accell Type A left and after that I might just start topping off with Valvoline Dexron as I believe it will have less of a risk of a bad interaction with Type A than Type F that has a difference in friction modifiers from Type A and Dexron.

|

|

By 55blacktie - 6 Years Ago

|

|

Type A was originally used to provide smoother shifting. However, smoother shifting usually results in more slippage, which leads to overheating and premature failure. Ford that reason, Ford stopped using Type A and went to Type F.

|

|

By Rusty_S85 - 6 Years Ago

|

55blacktie (11/14/2020)

Type A was originally used to provide smoother shifting. However, smoother shifting usually results in more slippage, which leads to overheating and premature failure. Ford that reason, Ford stopped using Type A and went to Type F.

Ford also changed the clutch material as well. The use of Type F in a Type A system will from every source I have came across to date will prematurely wear out your clutches. Its why on original setups its best to use the proper fluid unless you have had it built and know the clutches can handle the fluid. Like my C6, it calls for Dex/mer fluid but after rebuild majority will cite to use Type F now.

|

|

By 55blacktie - 6 Years Ago

|

|

I would not use Type F unless you intend to go racing. Type F will firm up shifts but lacks the protection and longevity of Dexron.

|

|

By KULTULZ - 6 Years Ago

|

|

Ford also changed the clutch material as well.

The use of Type F in a Type A system will from every source I have came across to date will prematurely wear out your clutches.

Its why on original setups its best to use the proper fluid unless you have had it built and know the clutches can handle the fluid

TYPE F can be used in a TYPE A / DEXRON application. TYPE A / TYPE A SUFFIX A / DEXRON cannot be used in an original TYPE F application unless friction materials are updated.

TYPE A / TYPE A SUFFIX A (FORD different blending from GM 1959/ ) was used by FORD until the 1968 model year and beyond actually. TYPE F was designed to be a LIFETIME FLUID, that meaning once out of drive-train warranty.

GM DEXRON is a design progression from original GM TYPE A SUFFIX A as was 1959/ FORD fluid

|

|

By cokefirst - 6 Years Ago

|

PF Arcand (10/9/2020)

This note isn't likely to fix your problem, but has come up before. Ford originally specified Type "A" fluid. It's in the manual, not type F. It has morphed into Dexron II etc.. Good luck with your problem.

This question about fluid is not going to be solved. Several people think that Type F stands for Ford when it actually is just a letter designation. Years ago I was tech editor for a national car club and was asked the question about Dexron or Type F for the cars. I spoke to an oils engineer at scrubron (educated in these things far over my head) and he told me that the Dexron was the closest fluid to the Type A, Suffix A fluid that was used in the 1950's If you go by the logic, all US manufacturers of automatic transmissions specified Type A, Suffix A fluid. Since scrubrolet used the same fluid, it would then be logical to say that Type F should be used in the Powerglide or Hydromatics of the day. Of course, since Dexron is used on later GM cars, Dexron is what most people would put in an early GM automatic. I had a Ford mechanic tell me that type F is the correct fluid and anecdotally said he has used it for years with no problems. I suspect that either will work. The Engineer gave me a detailed explanation for the Type F having to do with friction modifiers and the later (late 1960's into the 1970'a Ford transmissions needing a harder lockup shift and that is what the Type F is supposed to accomplish. You are correct but the argument will never end.

|

|

By KULTULZ - 6 Years Ago

|

No, it is not going to be solved until everyone comes to a basic reading comprehension understanding. You could present pages of TECH but there will always be a few that will not believe what the facts are.

GM and FORD went their separate ways regarding fluids beginning in 1959. DEXRON and MERCON are marketing names only. You have to understand how to read and cipher API ratings and what a particular manufacturer calls out for a specific application (and subsequent changes/upgrades).

A statement such as Type A was originally used to provide smoother shifting. However, smoother shifting usually results in more slippage, which leads to overheating and premature failure. Ford that reason, Ford stopped using Type A and went to Type F is an example of not understanding the principle. How this argument keeps going on over and over when a simple search will give one the information needed is beyond me.

FORD as well as some EURO manufacturers still use TYPE-F in some applications. This is why FORD still offers TYPE-F.

|

|

By 2721955meteor - 6 Years Ago

|

|

mercon is now the trans guys at ford dealers sware by, had a old Mercedes with slippery shifts, on the advice of the ford trans guy drained the trans and filled with mercon. shifted way better, no slippage.

|

|

By DryLakesRacer - 6 Years Ago

|

Rusty, if you or anyone else is interested I have the Ford-O that was removed from 56 when I installed a 62 CruiseOmatic. The tail housing and torque converter are not with it. It’s air cooled and free to anyone wanting to pick it up. It has about 6000 miles on a rebuilt by the previous owner. Worked perfect but I wanted a 3 speed all the time without doing whatever you needed to do for that to happen. And I’m not interested in whatever it is.

I live in So Cal

|

|

By MontyRay56 - 6 Years Ago

|

Regarding the issue of transmission fluid Type A, Type F, Dexron, Mercon, etc., when the Fordomatic came out in 1951, it used Type A fluid. In 1961, they converted to Type F. The friction plates in the earlier transmissions were a metallic composition and by the time they changed to Type F, they changed to various forms of composition material. Around this time, General Motors changed their fluid to Dexron which evidently had more friction modifiers in it than Type F. The drawback to Type F is it does not lubricate as well as Dexron or Mercon. Thrustwashers, metal seal rings, bushings do not last as long with Type F. Ford in 1979 sent a Service Bulletin to their dealers to not use Type F in their transmissions any more. In 1976 they had changed with the C-6 to a different fluid and they called it Type CJ which was basically Dexron II. In 1979, the reason they stopped using Type F, was that in California, Granadas and Monarchs, because on those cars the catalytic converters were on each side of the transmission and in southern California, unless you live in the mountains, it normally doesn't get below 40 degrees. Because of the placement of the catalytic converters, there was so much heat generated by them that the fluid would turn brown instead of red and it lost its ability to engage the intermediate band. When you would drive the car, it would slip from first to second to third like a Buick Dynaflow. The only cure for this was to pull the transmission and replace the intermediate band and the direct clutches and to clean the transmission internally because the fluid would build up deposits that looked like mud, sometimes it would plug the filter and then the car wouldn't even move or it would make terrible noises of trying to pump the fluid through the filter. The reason I know this is that I worked at Ford dealers doing automatic transmissions from 1965 to 1995 and saw what happened to transmissions that used Type F. In addition, the governer with a spring in it was an aftermarket fix because if you set the engine idle speed too high, when you would come up to a stop, in the last little bit before you came to a full stop, it would clunk when it downshifted at a very low speed. So if your idle speed was set at 550 rpm in gear, you would get this issue when you came to a stop. I remember when I was younger, older people who had been used to driving cars with a standard shift, they wouldn't like for their car to creep at a stop light. So a lot of these cars had very slow idle speeds of 450 or 475 rpm and they didn't notice the clunk coming up to a stop. Just another opinion after working on these things for 30 years.

|

|

By KULTULZ - 6 Years Ago

|

|

In 1961, they converted to Type F

TYPE-F was not released until the 1968 production year.

|

|

By Rusty_S85 - 6 Years Ago

|

DryLakesRacer (11/28/2020)

Rusty, if you or anyone else is interested I have the Ford-O that was removed from 56 when I installed a 62 CruiseOmatic. The tail housing and torque converter are not with it. It’s air cooled and free to anyone wanting to pick it up. It has about 6000 miles on a rebuilt by the previous owner. Worked perfect but I wanted a 3 speed all the time without doing whatever you needed to do for that to happen. And I’m not interested in whatever it is. I live in So Cal

If I was closer I would go for it, I wouldnt mind having a spare to rob parts off of. But me being here in Texas, that would be a long way to travel to pick up a transmission. Mine is aircooled as well so it would be basically identical to mine. Seems like for the '56 model year most were water cooled and the aircool was a bit of a oddball for '56 but was common for '55.

|

|

By Rusty_S85 - 6 Years Ago

|

KULTULZ (11/27/2020)

No, it is not going to be solved until everyone comes to a basic reading comprehension understanding. You could present pages of TECH but there will always be a few that will not believe what the facts are. GM and FORD went their separate ways regarding fluids beginning in 1959. DEXRON and MERCON are marketing names only. You have to understand how to read and cipher API ratings and what a particular manufacturer calls out for a specific application (and subsequent changes/upgrades). A statement such as Type A was originally used to provide smoother shifting. However, smoother shifting usually results in more slippage, which leads to overheating and premature failure. Ford that reason, Ford stopped using Type A and went to Type F is an example of not understanding the principle. How this argument keeps going on over and over when a simple search will give one the information needed is beyond me. FORD as well as some EURO manufacturers still use TYPE-F in some applications. This is why FORD still offers TYPE-F.

Thats if you can track down the API rating through changes to find a modern equal to what you are needing. I never really looked into the API rating as there is no API rating listed in my '56 owners manual. I think the dipstick only states "use type A transmission fluid" with no API rating on it either. I would have to go outside and check that.

Correction, my original dipstick doesnt even say what fluid type to use, just says to check fluid level when hot.

|

|

By MontyRay56 - 6 Years Ago

|

I made my earlier comment about the Type F fluid came out in 1961 from memory. So I got out my 1960-1964 Ford parts book and in the front of the book, they list all the dealer appearance and maintenance materials (e.g. things that the dealer used and sold, paint, thinners, undercoating, parts cleaner, etc.). I found the part number for a quart can of Type F fluid C1AZ-19582-A. It also came in one gallon cans and 55 gallon drums. Having worked at Ford dealerships for all those years, most of the time when you looked at a part number, the first digit "C" indicated the decade 1960-1969 and the next digit was the year that it first came out "1" being 1961, "A" was generally a full sized Ford and "Z" had to do with stocking warehouses and depots. So this is why I said the type F came out in 1961.

|

|

By KULTULZ - 6 Years Ago

|

You're OK. FORD made it very confusing. The ATF PN during that period was C1AZ 19582-A and was retained om all ATF progressons including the intro of TYPE - F for the 1968 model year. You had to turn the can around to see what fluid was actually in the can - Type-F Fluid (M2C33-F)

FULL INFO SOURCE - https://en.wikipedia.org/wiki/MERCON#1967_-_Type_%22F%22_Fluid

But you were a line tech in a dealership I assume. You went to draw oils from a pump out of 50 gal barrels. Most likely not FORD oil but was supplied (and equipment serviced) by a local whole-seller. Hard to say what it is you were drawing or if it had the FORD classification. Been there and done that.

|

|

By yblock57 - 6 Years Ago

|

Apologies on not chiming in earlier. The transmission is closed up and ready to fill. I went ahead and pulled the pinion carrier out to address a very bad leak while the car is on stands. Have all the parts, just need to get preload fine tuned and back together.

Didn't want to fill the trans and test and then have to drop the driveshaft when doing pinion seal later and loose some ATF. Car needs quite a few other things, but trying to not go overboard with doing too much at once... famous last words.

Will be sure to update y'all when I get it back on the ground. Thanks again for everyone's help and advice!

|

|

By yblock57 - 6 Years Ago

|

Update — Success!

Just got back from test driving the 'bird. It's like driving a different car now. Everything behaves like it should. Talk about a relief!

Did the pressure test before taking it off the stands (as several of you mentioned) and had to lengthen the rod several turns to get the pressure up to specs. If you baby it down the street, it'll shift about 19 mph. If you drive lightly down a residential street, about 22-23 mph. All relative on throttle pressure — just like the book says. Feels like it's about where it needs to be.

The accelerator is so much lighter feeling and easier to hold. Before it was fatiguing after a while cruising down the highway (due to binding).

Wanted to thank everyone who answered on this thread and shared their knowledge. It is GREATLY appreciated. Special shoutout to FORD DEARBORN who spent a lot of time walking me through the troubleshooting process and nailing the issue. Everything I've learned during this fiasco is going in the vault and should hopefully help me or someone else in the future. This is a great site and the level of knowledge and helpfulness is very humbling. Thanks again for helping get this old 'bird back on the road!

|

|

By oldcarmark - 6 Years Ago

|

|

Good the hear you got it sorted out. So now You know it was the Transmission Shop that caused the Problem. The Manual is very useful if You take the Time to read it. I had to replace the shifter Arm Seal on mine which involves dropping the Valve Body. Used the Book instead of paying a Shop to do it. It is important that the Accelerator Linkage and the Throttle Pressure Rod be properly adjusted as You have shown with Yours.

|

|

By BamaBob - 6 Years Ago

|

|

Kent, I must have overlooked it, but what transmission fluid did you end up using?

|

|

By yblock57 - 6 Years Ago

|

BamaBob (12/18/2020)

Kent, I must have overlooked it, but what transmission fluid did you end up using?

Type F. I know this is a highly debated subject. We've always run Type F in all our fordomatics and never had any issues. Shifts firm but not harsh. Very positive feeling. Downshifts are no longer noticeable unless you specifically feel for them.

|

|

By yblock57 - 6 Years Ago

|

oldcarmark (12/17/2020)

Good the hear you got it sorted out. So now You know it was the Transmission Shop that caused the Problem. The Manual is very useful if You take the Time to read it. I had to replace the shifter Arm Seal on mine which involves dropping the Valve Body. Used the Book instead of paying a Shop to do it. It is important that the Accelerator Linkage and the Throttle Pressure Rod be properly adjusted as You have shown with Yours.

I agree! Had to read it several times as it gets very technical, but explains everything very well. Much better source material than what is printed now days.

Glad you were able to get yours sealed up and avoid the shop. Anything to keep it out of the shop is a good thing!

|

|

By Rusty_S85 - 6 Years Ago

|

oldcarmark (12/17/2020)

Good the hear you got it sorted out. So now You know it was the Transmission Shop that caused the Problem. The Manual is very useful if You take the Time to read it. I had to replace the shifter Arm Seal on mine which involves dropping the Valve Body. Used the Book instead of paying a Shop to do it. It is important that the Accelerator Linkage and the Throttle Pressure Rod be properly adjusted as You have shown with Yours.

I found most shops cause problems on these year model fords. My '56 was taken to a shop and the last time it went before sitting was the late 70s early 80s. Im not kidding they didnt even block up the bell crank with the 1/4" drillbit like the shop manual says to keep the bell crank in specified position before making the carburetor rod adjustment. Mine was so out of adjustment I had to adjust not just the bell crank, but replace the carb linkage as well as they cut it off to make it work and I also had to adjust the rod to the transmission as it was out of adjustment as well.

|