|

Author

|

Message

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.8K,

Visits: 306.3K

|

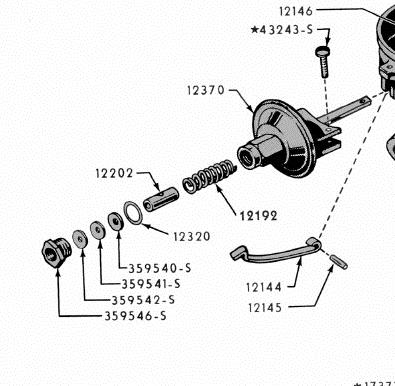

Yes, there are listings for the ADV DIAPH calibration hardware. If you have a 49/59 MPC, the stops, springs and washers will be given under BPN 12370. If no MPC, can you give a DIST ID STAMPING NO.? Is this the Single Plate or Pivot Plates design?

____________________________

|

|

|

|

|

Sandbird

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 131,

Visits: 542.7K

|

What is the correct bank angle?

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.5K,

Visits: 205.8K

|

Sandbird (8/26/2019)

What is the correct bank angle? The lifter bank angle for the Ford Y (239-312) as measured to the crank/cam centerline is 43° or 86° as measured from bank to bank. For a SBC it is 41° (82° bank to bank).

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 513,

Visits: 153.3K

|

Unfortunately my tired eyes can't read the dist # at its location. I'm not pulling that %##!!! thing again, tho I could probably install one blindfolded by now.

Looks to me from the manual, level cruising at ~ 2000 RPM the timing spec would be roughly 42 to 47 deg. I think that tube can be shortened easily enough. I wondered if there was simply a list of maybe 3 or 4 lengths. Bet that's all there were. I can shave it off till some rattle occurs and then add a washer back in.

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.8K,

Visits: 306.3K

|

12202 - STOP - DIST VACUUM ADVANCE.25" I.D. - .38" O.D. - .75"L .25" I.D. - .38" O.D. - .95"L .25" I.D. - .38" O.D. - .97'L .25" I.D. - .38" O.D. - 1.00"L There you go.

____________________________

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 513,

Visits: 153.3K

|

Perfect! I figured it was something like that. Many thanks.

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 513,

Visits: 153.3K

|

Ted, or anyone else, what is the received wisdom regarding cranking compression numbers on these Y-blocks? Charles Morris in his Y-block book says 160-165 psi is the norm for these engines.

But is there any rule of thumb on the psi difference between checking cold and hot?

Compression is supposed to be checked hot. The Morris book doesn't talk about engine temperature. The shop manual says to operate the engine for minimum of 30 minutes at a fast idle, etc, but specifications list 130-170 psi, that's quite a spread. My old MoToRs book says an 8-1 compression ratio should be 144 psi.

Would checking compression hot pick up maybe 8-10 points? I've never bothered checking cylinder compression hot, figuring if it's acceptable and even across cylinders when cold it should only improve at normal operating temperature. Who wants to work around a boiling hot motor? I might consider it if it was marginal or something like that, before condemning an engine for liw compression. It's more important that cylinders are even with each other, than an absolute number value.

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 513,

Visits: 153.3K

|

Yeah Baby!!

Took the last washer out of the vacuum advance and bumped the initial up to 16°, the total is close to 40°, and 54° with vacuum at no load spooled up in the garage. Definite improvement in the power band range with the cam dialed in better. It might need to come in earlier with a spring change or tweak of the spring arm, but it can wait. It really cruises sweet at 50 - 70 mph and sounds great with the ramshorns and porter steel-pacs. Big ole perma-grin cruisin' down the highway, thanks fellas!

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: Yesterday

Posts: 7.5K,

Visits: 205.8K

|

Tedster (8/26/2019)

Ted, or anyone else, what is the received wisdom regarding cranking compression numbers on these Y-blocks? Charles Morris in his Y-block book says 160-165 psi is the norm for these engines. But is there any rule of thumb on the psi difference between checking cold and hot? Compression is supposed to be checked hot. The Morris book doesn't talk about engine temperature. The shop manual says to operate the engine for minimum of 30 minutes at a fast idle, etc, but specifications list 130-170 psi, that's quite a spread. My old MoToRs book says an 8-1 compression ratio should be 150 psi. Would checking compression hot pick up maybe 8-10 points? I've never bothered checking cylinder compression hot, figuring if it's acceptable and even across cylinders when cold it should only improve at normal operating temperature. I might consider it if it was marginal or something like that. There is not a steadfast rule for what the cranking compression will be for engines in general. For a particular engine, there may be a range given in the service manuals for that engine. Those numbers are not necessarily the same for another engine even if it’s in the same family of engines (ie. passenger car engines versus truck engines, 272 versus 312, etc). There are lots of variables with the cam timing just being one of them. Warm engines will typically give a higher number simply due to ring end gaps being closed up some versus what they are cold. As the camshaft is advanced, the intake closing event happens sooner which in turn permits the cylinder to build up more compression. For this single reason, even engines that are similar can give significantly different values based on engine machining variances and/or timing chain stretch. When performing a cranking compression check, always block the throttle to the wide open position to insure that the cylinders injest a full complement of air. If the numbers for all the cylinders fall within 10% of each other, then it’s deemed that all the cylinders for that check are acceptable. While I haven't checked an engine cold lately, I suspect about a 10psi difference in readings between hot and cold with hot being higher.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 513,

Visits: 153.3K

|

I'll have to see what the cruising manifold vacuum is now. Prior, with the stretched chain it seems to me it was barely 15". Now maybe it is unrealistic to expect more in a heavy truck. I don't know if Ford ever ran their stock F100 with advanced camshaft, but it sure seems like they shoulda. The power band is much more usable with some advance. Don't get me wrong, it doesn't turn my Effie into a screamer, but is a welcome improvement.

The reason I wonder about the cruising manifold is it seems to me the carburetor is getting a lot crisper signal now. It is a little on the small side, the stock Autolite 2100 for 1964. It even has that "Rawwmmp" sound now, emanating from its impressive 1.02" venturis, LOL. I could never seem to get the standard specification ignition and carb calibration to jell before, now everything dropped right in, almost like I knew what I was doing.

|

|

|

|