|

By Tedster - 6 Years Ago

|

Do any of you guys fall prey to what I call "mission creep"? It goes something like this. Say you've decided that new valve stem umbrella seals are needed. You get in there, and wanting to do a good job, start measuring stuff. And other stuff too. Naturally it's all out of spec. And .... before you know it, a $20 set of umbrella seals turns out to be new valves, retainers, guides, springs, shims, machine work to install hardened stellite seats yadda yadda. And, those Aluminum Mummert heads are looking kind of tempting...Hm.

So I've seen this movie before. I've got to stay focused. I've convinced myself the need to replace the timing set in my otherwise stock 292. I can trust that a stock cam in a stock engine with a stock replacement timing chain and gears, should offer a noticeable improvement. "But as long as you're in there ..."

I can see where this is going. I don't have a degree wheel or a dial indicator with fixtures. But, "I gots to know!!" right? So I said to my self, "Self, you just know there's got to be a good ole' boy way to do this." In other words, a compromise or middle way between doing nothing and hoping for the best, and, spending a week waiting for more tools, immersing myself in a crash course on the finer points of valve overlap and lobe separation. Like here:

http://www.eatonbalancing.com/2015/09/24/degreeing-in-the-camshaft-part-i-finding-tdc/#more-907

These are GREAT articles, I love reading stuff like this.

This is of course the way to do it. Though I'm not building a high performance engine, OCD means I'd like to ensure at least that any tolerance stackup is towards the "advanced" side of things. This begs the question, why isn't the cam already advanced? Or is it? Why don't they grind them that way in the first place, and compensate for inevitable chain stretch in the first place? As always those of us not spinning 6000 RPM kind of have to read between the lines on some of this stuff.

It DOES look like one way to achieve a rough measurement on valve overlap would be to measure this way taken from the Iskenderian website, without using any special tools or equipment. It might be interesting to see what it is right now, before timing set replacement with what I estimate is significant chain stretch or wear, and then afterwards.

CHECKING VALVE OVERLAP WITHOUT DEGREE WHEEL OR DIAL INDICATOR

When installing a camshaft, or when an occasion arises where it is necessary to make a check on valve timing and no appropriate instruments are available, the recommended Isky procedure is as follows:

Insert the camshaft and mesh the timing gears on the stock marks. Do not as yet install the timing gear cover.

Adjust the valve lash of the intake and exhaust valves of the No. 1 cylinder.

Using a long wrench or lever, turn the engine over in the normal running direction. Use enough leverage to get an even, steady movement instead of a jerky motion. Rotate until the intake and exhaust valves of No. 1 cylinder are in the overlap position (both valves opened slightly). Stop exactly on T.D.C., which is marked on the harmonic damper.

Now loosen and back off the rocker arm adjusting screws until the intake and exhaust valves are just barely closed. Lock the adjustment screws so that the intake and exhaust valves are at exactly zero clearance.

Now turn the engine over exactly one revolution of the crankshaft to T.D.C. on the harmonic damper. You are now at T.D.C. on the compression or firing stroke.

Take Notice! Now there is a large space between the rockers and valve stem tips. The space indicates the actual amount the valves were open at T.D.C. of the overlap period (less valve lash, of course).

We will measure this gap space by probing with common feeler gauges of various thicknesses combined until we determine the gap space. After computing the gap, record the figures for both intake and exhaust in your notebook. If the amount of gap on intake and exhaust is exactly the same, you have a perfect split overlap.

AN EXAMPLE USING AN RPM 300 CAM

Advanced Cam Position: If your intake happens to come out with .100 gap, and the exhaust with say .080 gap, your cam is in an advanced position. In this position, the came will produce more low-speed power or torque. However, there might be a slight loss of power at high RPM.

Retarded Cam Position: If, on the other hand, the intake came out with .080 gap, and the exhaust at .100, your cam is in a retarded position. In this position, there will be some loss in low-speed torque and power, and probably some subsequent gain in high-speed power.

Split Overlap: If the intake and exhaust gap read out exactly even, or within .005 of each other, you have a split overlap. Generally speaking, all racing cams run best in the split overlap position. While there are exceptions to this rule, it is usually best for overall performance.

_______________________________

Ted, fellow Y-blockers, etc any thoughts on this method or other factors to consider? Would a few degrees of camshaft advance generally be adviseable for a stock 8-1 compression 64 292. I see that offset woodruff keys are available.

|

|

By 57RancheroJim - 6 Years Ago

|

I recently thought the same thing about chain stretch. I helped a friend who had a small leak at the timing cover to repair it, this engine only had about 5000 miles on it and I was amazed at how much stretch there was. He had used a Cloyes OEM type chain on the build. This was a stock 292 daily driver and the difference was never really felt that he could tell. A few years back another friend with a Tbird tried both advancing 2 degrees and retarting 2 degrees and as far as just driving it never could tell a real difference. I'm my street engines I just install straight up as is and drive them..

But if you feel you need to go through all the degee work on a stock street motor in a truck I would rather use a timing set with keyed sprockets rather then an of set key. But mine is only one of many opinions...

|

|

By Ted - 6 Years Ago

|

|

You degree in the camshafts due to machining variances in the various parts. Stack ups are your enemy as that's when all the variances align with all being positive or all being negative. In many instances those stack ups cancel each other out but like playing the lottery, sometimes you have a winner. In this case, you have a loser. I've found several engines now (all makes and brands) with the cam timing off as much as 18 degrees. They all crank and run. Some have detonation issues from being too far advanced while others are just sluggish due to being too far retarded. As a general rule, it takes about a four degree change to be noticeable in the seat of the pants. On the dyno, I can pick up differences with two degrees of change. If the camshaft has symmetrical lobes, then measuring the lifter rise off of the base circle of the camshaft at overlap can give a good idea of advance or retard at TDC, When being installed 'straight up', the exhaust and intake lifters will be the same distance off of the base circle of the camshaft. This is an easy check on an assembled engine as a straight edge can be put across both the intake and exhaust valve retainers or roller rocker arms and when they are both level with each other, then look at the damper and see how many degrees from TDC you are at. This is not as exact as doing the degree wheel method but it is close enough when looking for some serious discrepancies. If the camshaft is simply being installed with the link count or alignment of the timing marks, that is not necessarily being installed straight up. In those instances, the camshaft is simply installed and you do not know exactly where the lobes are in relation to TDC.

|

|

By Tedster - 6 Years Ago

|

57RancheroJim (8/11/2019)

But if you feel you need to go through all the degee work on a stock street motor in a truck I would rather use a timing set with keyed sprockets rather than a set key. But mine is only one of many opinions...

Yeah no like I said I didn't want to get tooinvolved. Too late for that, ha ha! It looks to me that there is 8° or 9° of stretch in this example, by carefull turning crank and observing rotor movement. Forgetting any potential stackup errors for the moment, that seems like a lot to retard to the cam? So I was looking to see that the centerline is at least on the "advanced" side of the crankshaft.

Does camshaft phasing affect cylinder compression testing? This engine measures 145-150 pounds cold across all cylinders, burns no oil, doesn't smoke etc. Heck it doesn't even leak, much. I see from reading forums some people advocate advancing or retarding a cam for best compression. This sounded promising to me, but I don't think it works that way. Is there a definite peak that is found as the cam phasing advances, and then it starts to fall off?

I assume, maybe wrongly, that engine manifold vacuum specifications listed in the manual are to be observed at factory idle ignition timing. In this instance say, 6° BTDC. TDC has been verified. I can get a nice steady 18" to 20" Hg. and smooth idle, but only by advancing the distributor timing by quite a lot. This has had me puzzled a bit, which isn't difficult. So that and other symptoms kind of led me to chain stretch. It kind of fits. I've played around with the mechanical advance and springs and such and it just seems to be a little anemic. When I replaced a fuel pump I noticed the chain looked old and was awfully loosey goosey on the slack side. I've heard the Cloyes sets are supplied with tighter tolerances, and the imported el-cheapos are to be avoided, but that's not news.

|

|

By Tedster - 6 Years Ago

|

Ted (8/11/2019)

When being installed 'straight up', the exhaust and intake lifters will be the same distance off of the base circle of the camshaft. This is an easy check on an assembled engine as a straight edge can be put across both the intake and exhaust valve retainers or roller rocker arms and when they are both level with each other, then look at the damper and see how many degrees from TDC you are at. This is not as exact as doing the degree wheel method but it is close enough when looking for some serious discrepancies. If the camshaft is simply being installed with the link count or alignment of the timing marks, that is not necessarily being installed straight up. In those instances, the camshaft is simply installed and you do not know exactly where the lobes are in relation to TDC.

In your article on camshaft degreeing I think you mentioned the relationship between #1 and #6 cylinders, I took it to mean that when #1 piston is at TDC compression, if the #6 valves are at overlap the camshaft and timing set is installed "straight up". It isn't that simple?

I'm a little unclear on this straightedge business, remember ya hafta dumb it down for us dummies. What do think of the Isky method using feeler gauges? If I can get this centerline business decidedly on the advanced side a little that would probably work for me and my OCD.

|

|

By bergmanj - 6 Years Ago

|

Tedster [and others],

" I can get a nice steady 18" to 20" Hg. and smooth idle..."

We should all remember that gauge-measured vacuum will also generally vary depending on altitude (will show less with higher altitude); and, specifically can vary from time-to-time (hours, days, weeks, season) due to changing atmospheric pressure/weather/temperature/season: Our Atm. Press. ["Hg] here at my home, 1,200' Above Mean Sea Level, has varied from lows of 27" to highs of 31"; and, summer temps can be +100*F or more (rare) with winter down to -45*F or more (also rare) - this will affect "vacuum" readings similarly; so, if you keep records, also note the atmospheric pressure and other conditions at the time you take your reading - for comparison. Just another little "tidbit" to keep in mind.

Regards, JLB

|

|

By Tedster - 6 Years Ago

|

That's a good point, altitude particularly plays a big role. Someone who lives in Denver won't see 20", and it would be interesting to know the best an engine in Leadville could pull.

Can't recall what ignition timing setting I found achieves good manifold vacuum but I'm pretty sure it exceeds 12°, it shouldn't be required to advance the timing much beyond this to get in the zone? See where I'm goin' with that?

Engine starts reasonably well cold though I think not as snappy as it should. Could be way off base on this chain stretch, it shouldn't hurt anything.

The manual shows the 12 pins and dits oriented on the fuel pump side. I takenit this is with #1 at overlap and #6 at TDC?

|

|

By Joe-JDC - 6 Years Ago

|

Camshaft phasing as you call it can create problems with aftermarket camshafts. Ted and I recently found out that there is a problem with the industry standard for grinding camshafts for the Y Block Ford engine in that they are using the wrong lifter angle from bank to bank when custom grinding a camshaft. If you use a camshaft from any company other than Isky, then they are using the industry manuals that list the degree for the Y Block, and it is wrong. If you install the camshafts straight up, then the engine will run fine, but if you advance or retard the camshaft, then you run into problems (think phasing) with the bank angle causing one bank to be several degrees wrong, and will not perform as expected. Last year I had a custom Comp Cam given to me for the EMC engine as a sponsorship, but we could not use the cam due to trying to advance it as suggested. The lobes were all over the place in the 2* and 4* advanced position, causing us to go back to the Isky. I recently had this confirmed when another brand of camshaft was custom ground for our EMC entry for this year, and straight up, it was Ok, but when we went to advance it, one bank was retarded, and the other was advanced, making it unusable. I sent the camshaft back, and it was put on the Cam Doctor machine and confirmed that it had been ground wrong according to the industry standard information. After obtaining the correct specifications for lifter bore angles, the camshaft has been reground and parkerized, and in on its way back to us for dyno testing. Anything other than stock Ford or Iskendarian camshafts should be degreed if you are serious about performance gains without valve to piston, valve to cylinder wall, interference issues or degraded performance. I am sure Ted will have enough material for a magazine article after we get through with this EMC dyno session dealing with double checking your performance camshaft installation. Joe-JDC

|

|

By charliemccraney - 6 Years Ago

|

|

Interesting. I know it will probably fall on def ears, but did you tell those companies that they are doing it wrong? If they don't know, they can't fix it.

|

|

By Joe-JDC - 6 Years Ago

|

charliemccraney (8/11/2019)

Interesting. I know it will probably fall on def ears, but did you tell those companies that they are doing it wrong? If they don't know, they can't fix it.

I was told that I was the first to bring up the issue, and yes, the owner of this company is now aware, and is also reworking two more camshafts that they custom ground for me earlier this year. That makes three custom camshafts that he will personally make sure gets done correctly. Can't ask for better customer service than that. The listings in Howards Cams, Comp Cams, and several others is wrong, and unless someone goes to the trouble of degreeing all the lobes as Ted and I just did, they will never know that the camshafts are actually ground wrong. Straight up is ok, but anything else will be off bank to bank. Joe-JDC

|

|

By KULTULZ - 6 Years Ago

|

Now that was very interesting and informative ...

|

|

By FORD DEARBORN - 6 Years Ago

|

Extremely interesting to say the least. Shouldn't there be a fool proof way for those of us that are using custom ground cams to check this? I'm not an expert on the art and science of cam grinding but since #6 in in sync with #1, I would think the valve/push rod movement should duplicate, at the same degrees, as #1? My cam was ground by Oregon Cam, it's a clone of the stock cam used in 1957. I found the sweet spot is 4* advanced. It seems #1 is the cylinder we always use to dial in a cam. I never thought to back those readings up against a cylinder on the other bank - #6 in this instance. I have never seen anywhere any reference to where the lifter bore is at. Evidently all are not equal. Good discovery. Any feedback would be very welcome. Thanks in advance, JEFF...................

|

|

By Tedster - 6 Years Ago

|

The issue I have now is everything is removed, the Isky field method of determining which side of the fence the overlap falls on needs the balancer and pointer and TDC. I guess I could use a piston stop and mark the crank snout and block or something like that. Not a show stopper to determine TDC though awkward. The chain stretch did exceed limits of 0.5, the new timing set should arrive today.

|

|

By pintoplumber - 6 Years Ago

|

|

You can print a degree wheel off the internet and print it on your computer.

|

|

By Tedster - 6 Years Ago

|

pintoplumber (8/12/2019)

You can print a degree wheel off the internet and print it on your computer.

I don't have the capability to print at this time.

I understand now a little bit better the routine Ted mentioned. Determine TDC, and install a pointer. (I guess I could use an old pie plate tin or something for my wheel)

Then rotate engine so #1 valves are perfectly at overlap using a straightedge.

Then check to see what side of the TDC mark on the wheel the pointer falls. If a few degrees BTDC, it would mean the camshaft is advanced. Though crude, it would indicate whether the camshaft is advanced, or "straight up", or retarded.

Checking the original timing set chain using the deflection method outlined in the shop manual seems to show it within spec, though the slop in the chain with respect to rotor movement seems a little sketchy. Seems to allow for about 8° or maybe 9° before the slack is taken up.

|

|

By Tedster - 6 Years Ago

|

OK, rigged up a disposable pie plate and a coat hanger for a pointer and determined TDC. With #1 valves at overlap, it looks to me like the camshaft falls well on the slightly retarded side of the fence, maybe ~ 4 degrees crankshaft or something like that. This translates to 2 camshaft degrees?

Seems to me timing chain stretch plays into this as well.

Late valve timing, any amount of chain stretch just makes things worse. My precision-engineered pie plate & coat hanger assembly should show the new crankshaft/camshaft relationship when a new timing set is installed or whether an offset key might be warranted.

|

|

By Tedster - 6 Years Ago

|

Something I've read on different forums, for a street driver is to simply advance/retard the camshaft phasing as required to achieve the highest static or cranking compression. This an acceptable procedure? In this method would there be something like a definite peak observed that would be found at straight up, or +1 or +2 whatever, and then it would start to drop off?

The old worn timing set chain resulted in the cam timing roughly 2° to 4° retarded or near enough. Given a factory 1964 camshaft and 8-1 compression, what cam timing is optimum? +1, +2, +3 ? I'm not trying to make a hot rod, don't misunderstand, just a smooth running machine.

It seems a 2° advance would compensate for chain stretch. Ford detuned the Y block considerably by 1964 though, I don't believe camshafts and/or timing sets were ground for emissions (retarded phasing) until much later. Basically, I want to do this right, and do it once.

|

|

By KULTULZ - 6 Years Ago

|

|

It seems a 2° advance would compensate for chain stretch.

The only way to compensate for chain stretch is replacement with a QUALITY TIMING SET.

Also consider if the block main saddle was ever trued, it may have raised the CL of the crank and therefore needs a specialty shortened chain.

|

|

By Ted - 6 Years Ago

|

Tedster (8/18/2019)

Something I've read on different forums, for a street driver is to simply advance/retard the camshaft phasing as required to achieve the highest static or cranking compression. This an acceptable procedure? In this method would there be something like a definite peak observed that would be found at straight up, or +1 or +2 whatever, and then it would start to drop off? The old worn timing set chain resulted in the cam timing roughly 2° to 4° retarded or near enough. Given a factory 1964 camshaft and 8-1 compression, what cam timing is optimum? +1, +2, +3 ? I'm not trying to make a hot rod, don't misunderstand, just a smooth running machine. It seems a 2° advance would compensate for chain stretch. Ford detuned the Y block considerably by 1964 though, I don't believe camshafts and/or timing sets were ground for emissions (retarded phasing) until much later. Basically, I want to do this right, and do it once.

Besides the variables involved with manufacturing all the various components, timing chain elasticity and stretch is why you want to initially advance the camshaft. Over time the chain will stretch which will ultimately retard the camshaft. Worn gears also contribute to camshaft retard. Six to eight degrees of camshaft timing retard is not unusual with a worn chain and gears. New chains will exhibit elasticity and that’s where the chain ‘expands’ with rpm and also retards the camshaft. This can be seen with a timing light with the vacuum advance disconnected and bringing the rpms up until total timing is achieved. By going even higher on the rpms, the ignition timing can be seen to actually start retarding. This is nothing to do with the distributor but instead is the timing chain stretching due to elasticity and further retarding the camshaft which in turn is retarding the ignition timing. As the rpms come back down, the chain comes back to its original length and camshaft timing falls back to its original position.

Advancing the camshaft timing causes all the opening/closing cam events to happen earlier. Of importance here is the intake closing event. When advancing the camshaft, the intake valve closes earlier which gives more time for the piston to compress the fuel/air mixture. This makes for a higher cranking compression number which in turn increases the low end torque of the engine. There are limits for the amount of camshaft advance so it’s always best to go with the camshaft manufacturers recommendations in lieu of experimenting.

Always remember that when changing the camshaft timing, the valve to piston relationship also changes. When advancing the camshaft, the intake valve gets closer to the piston while retarding the cam creates a scenario where the exhaust valve is closer to the pistons. For our flat tappet camshafts, changing the camshaft timing 4° typically results in about a 0.025” change in those valve to piston relationships. If valve to piston relationship is marginally on the close side, then changing the cam timing can force the need for additional depth on the appropriate valve pockets in which to compensate.

While four degrees of advance seems to be the industry standard for installing a street camshaft, altering this number can be beneficial in certain applications. I did a Mopar 360 that was a four wheel drive farm truck and was informed that it would be used on very rough terrain with lots of gulleys. That camshaft was installed with 8° of cam advance to make the engine more responsive in the very low rpm ranges where it would be driven the majority of the time. That truck does exactly what it was built to do.

|

|

By Tedster - 6 Years Ago

|

It sure seems that data for performance stuff is plentiful, though what about OEM stockers? Aftermarket cam grinders build advance into their products. Consequently they usually recommend installing their products "straight up". For us "as advertised" folks, it's a little harder to come by information. Some say a "small" cam doesn't benefit noticeably from advance, others with heavy cars and trucks sure seem to like it. Everyone agrees cam retardation has major problems in a street driven vehicle.

What did Ford do with the Y-block camshaft profile from the high point in '57 era all the way up till the '64 detuned version?

One advantage to stock or non-modified engine enthusiasts like me, it's much more difficult to assemble a selection of parts where stuff starts banging into each other. That is my hope anyway.

There would/should be "no danger" of valve/piston contact running a 4° cam advance, my thinking here is based simply on account of the fact there was no issue in that regard running 4° retarded? Or, maybe it's more complicated than that.

The Rollmaster set is about the only one with an adjustable crank gear for Y-blocks? No-one sells "just" the adjustable crank gear, natch. The Rollmaster timing set would allow for a maximum of 4° advance at the cam itself afaik. To add more camshaft advance would require a new offset key broach.

I'm surprised in a way the OEMs didn't maybe offer provision for an easier, more convenient adjustment method to cam timing, given how important it is.

One thing I noticed last year, was experimenting with valve lash. After tightening it up some below .018" to maybe .015" the manifold vacuum really dropped off. I assumed then a valve was hanging open. Now I'm not so sure, .015" shouldn't cause this - maybe it was more the result of an already excessively retarded camshaft timing? One thing I expect to see is improved engine manifold vacuum throughout its range at the initial (say, 6° BTC) factory settings. I'm not sure how jetting and carburetor calibration will be affected.

|

|

By Ted - 6 Years Ago

|

Tedster (8/18/2019)

...One thing I noticed last year, was experimenting with valve lash. After tightening it up some below .018" to maybe .015" the manifold vacuum really dropped off. I assumed then a valve was hanging open. Now I'm not so sure, .015" shouldn't cause this - maybe it was more the result of an already excessively retarded camshaft timing? One thing I expect to see is improved engine manifold vacuum at the initial (say, 6° BTC) factory settings. I'm not sure how jetting and carburetor calibration will be affected.

The Rollmaster timing sets for the Y with the multi-keyed crankshaft gears permit up to 8° of advance (measured in crankshaft degrees). Many of the oem camshafts have advance built into them from the git go so no problems there when simply installing them with the timing marks aligned or counting the links. The major issue with not degreeing in the cams is getting caught up with machining variances with the various parts. Hence the reason the cam timing needs to be checked during assembly.

The valve lash setting is an important tuning tool. Decreasing the valve lash increases the running duration of the camshaft. At the intake closing event, decreasing the lash makes it later which in effect is the same as retarding the camshaft. It also increases the degrees of intake/exhaust valve overlap which affects the manifold vacuum. As the amount of overlap increases, so does the amount of time both valves are open and subsequently the opportunity for a 'vacuum leak' leading to the exhaust which in turn equates to a reduced manifold vacuum.

|

|

By Tedster - 6 Years Ago

|

Thanks for the reply. With relatively low compression, it's still unlikely to run into engine knock or ping as a result of an advanced camshaft? (I realize this will shift the operating point and require resetting the base ignition timing) This is one of the few benefits to an OEM or stock engine, it has always burned just about any grade of gasoline without complaint.

I'll experiment of course a little bit with my homebrew degree wheel and see where the different advance keys place the overlap. A fresh chain does place the cam "straight up", or near enough. I should be able to estimate the actual amount of previous cam retardation more accurately by observing the new cam position using the known advance key positions. I expect to use the 8° key (4° at cam).

|

|

By Tedster - 6 Years Ago

|

OK first thing I should thank Ted for supplying a keyway diagram for the Rollmaster crankshaft gear in the cam degreeing article at Eaton Balancing. It's definitely not intuitive to install and the supplied instructions are sparse at best. This saved a lot of time.

Using the 8° slot on the crank gear, TDC thankfully fell just about exactly where predicted. With #1 valves at overlap and my calibrated eyeball the cam is now phased roughly as many degrees advanced as it was retarded with the worn out timing set installed. Total camshaft degree change then is probably on the order of 8° or thereabouts. -4 to +4. Doesn't appear to be any valves kissing the pistons.

|

|

By Tedster - 6 Years Ago

|

Success!

Checked cranking compression on a few cylinders before firing it up. The cylinders that previously measured 150 cold ... still measure 150 cold. Hm. So, I checked the outliers, cylinders that previously measured 140 and 145 ... they now measure 150. I quit checking after a few. 150 psi it is I guess. It is a lot snappier on the compression gauge I suppose, it pumps up quickly.

I did remember to back off the distributor timing a skosh before firing it up, it started right up but timing was still well advanced. I bumped it down to 10° BTDC and was rewarded with a low smooth idle. It pulls 21 in. Hg of manifold vacuum at 550 RPM.

So the vacuum gauge was right all along, late valve timing, I just didn't know how to properly read it. And I think the deal with chain stretch, it might be tough to notice if it is slow and gradual, over time. Checked for leaks, runs, errors, everything looked good. Haven't driven it yet, but I can't imagine it will run any worse on the road. Thanks for everyone's help.

|

|

By Ted - 6 Years Ago

|

charliemccraney (8/11/2019)

Interesting. I know it will probably fall on deaf ears, but did you tell those companies that they are doing it wrong? If they don't know, they can't fix it.

I have brought this issue up with Comp Cams in the past and it does just fall on deaf ears. As a result, I just don’t use Comp Cams in any of my engine builds. While I use Isky camshafts for a majority of the Y builds, I’ve had no issues with lifter bank angles when using Clay Smith or Crower camshafts in the Y engines. The problem with the camshafts being ground on the wrong lifter bank angles is that the engines will still crank and run. In these cases, engine performance will not be optimal as the two banks will be running differently with one bank being more advanced than the other.

As a general rule, always double check the cam degree in process by degreeing in the #6 cylinder along with the #1 cylinder. This allows you to double check your methodology while also verifying that the camshaft is the same on both banks. Because the #1 and #6 cylinders share the same TDC on the degree wheel, it’s a simple matter to just move the dial indicator to the other cylinder for an additional check on the cam timing. Anything more than 1 degree of crankshaft difference between the banks on these two cylinders should be investigated further. In the case of Joe's EMC camshaft, we did go to the trouble of checking each lobe so that the manufacturer could properly address this. To my surprise, that manufacturer fessed up that it was a problem on their end and they have since corrected it.

|

|

By Tedster - 6 Years Ago

|

Took it out for a little shakedown cruise. It definitely starts easier, idles better, snappier acceleration, cruises nice and has a slight deceleration rumble that I kind of like.

The ignition timing is going to need a bit more sorting out before I can make a better determination, I think a few more degrees of initial might help. It's at 36° total right now and comes in quick, but it could use more, I think. I didn't hear any ping. The vacuum advance too is a little anemic, only adding maybe 5° or so at the crank.

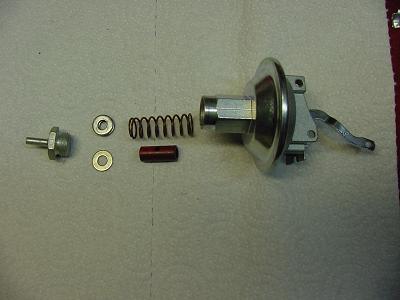

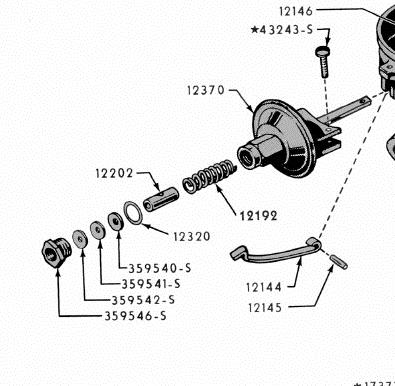

It's the older style vacuum canister that utilizes shims, a (red) spring, and a fiber tube. I'm a little unclear, do the shims affect the total degrees of advance or, just how fast? Not sure if simply removing shims will extend the the vacuum advance out far enough. Seems to me that the tube inside the spring, its length would act as a stop limiter iirc.

|

|

By FORD DEARBORN - 6 Years Ago

|

It's been awhile since I set one of these up but will try to explain it as I remember. The washers will affect the spring tension somewhat The fiber tube, which were available in various lengths, limit diaphragm travel. The tube and the washers determine the total stack. Looking at some old notes, the distributor in this instance had 3 washers and a .971 fiber tube. By removing 2 .040 washers the distributor vac. advance went from 6* max. to 11* max.. That's 5* distributor increase = an additional 10* at the crank.. Hope this helps, JEFF.................

|

|

By Tedster - 6 Years Ago

|

Yes, that definitely helps, thanks. I figured that's how it had to work. Removed the last shim/washer, and bumped the initial up. I'll see what that does to the curve with a timing light and seat of the pants dyno. It seems to me I can shorten the tube by a small amounts, maybe thickness of a shim at a time, and sneak up on it if necessary.

Noticed the spark plugs sure look a lot better, very consistent. Don't know what or whether cam phasing has anything to do with that. Typically I pull #5 as a reference. Turns out, when I pulled the plugs last week, #5 wasn't very representative of the rest. Some were looking fairly fouled, even. I wondered maybe PV going bad?

I did rebuild the carburetor while timing set &c was apart, but in any case they are burning great, reasonably clean base ring considering all the idle time and a light tan smudge on ceramic.

Is it possible for a power valve to fail without pooling fuel below it? It was dry in the chamber below it when I took it apart, but it seemed to lose pressure slowly, with the high tech method of sucking on it. So I replaced it.

|

|

By KULTULZ - 6 Years Ago

|

Briefly, add shims to the advance spring if you want to slow down the advance rate. Eliminate or reduce the number of shims if you want a quicker advance rate.

|

|

By Tedster - 6 Years Ago

|

KULTULZ (8/26/2019)

Briefly, add shims to the advance spring if you want to slow down the advance rate. Eliminate or reduce the number of shims if you want a quicker advance rate.

Right, but I suspect this advance can is for a dump truck. When I ran the engine up with a timing light, the initial at 10° the mechanical came in quick straight to 36°, I'd previously swapped in a lighter spring and tweaked the arm for less tension, but checking the vacuum advance was like hitting a wall, it is limited it appears by the length of the tube? Advance stopped at about 40° or so. Do you have access to a list of those different fiber tubes maybe? They might be marked by color.

This is a service replacement distributor, it has the old style vacuum advance but the latter year mechanical innards, versus the older style with the heavy comma or kidney shaped weights.

|

|

By KULTULZ - 6 Years Ago

|

Yes, there are listings for the ADV DIAPH calibration hardware. If you have a 49/59 MPC, the stops, springs and washers will be given under BPN 12370.

If no MPC, can you give a DIST ID STAMPING NO.? Is this the Single Plate or Pivot Plates design?

|

|

By Sandbird - 6 Years Ago

|

|

What is the correct bank angle?

|

|

By Ted - 6 Years Ago

|

Sandbird (8/26/2019)

What is the correct bank angle?

The lifter bank angle for the Ford Y (239-312) as measured to the crank/cam centerline is 43° or 86° as measured from bank to bank. For a SBC it is 41° (82° bank to bank).

|

|

By Tedster - 6 Years Ago

|

Unfortunately my tired eyes can't read the dist # at its location. I'm not pulling that %##!!! thing again, tho I could probably install one blindfolded by now.

Looks to me from the manual, level cruising at ~ 2000 RPM the timing spec would be roughly 42 to 47 deg. I think that tube can be shortened easily enough. I wondered if there was simply a list of maybe 3 or 4 lengths. Bet that's all there were. I can shave it off till some rattle occurs and then add a washer back in.

|

|

By KULTULZ - 6 Years Ago

|

12202 - STOP - DIST VACUUM ADVANCE

.25" I.D. - .38" O.D. - .75"L

.25" I.D. - .38" O.D. - .95"L

.25" I.D. - .38" O.D. - .97'L

.25" I.D. - .38" O.D. - 1.00"L

There you go.

|

|

By Tedster - 6 Years Ago

|

|

Perfect! I figured it was something like that. Many thanks.

|

|

By Tedster - 6 Years Ago

|

Ted, or anyone else, what is the received wisdom regarding cranking compression numbers on these Y-blocks? Charles Morris in his Y-block book says 160-165 psi is the norm for these engines.

But is there any rule of thumb on the psi difference between checking cold and hot?

Compression is supposed to be checked hot. The Morris book doesn't talk about engine temperature. The shop manual says to operate the engine for minimum of 30 minutes at a fast idle, etc, but specifications list 130-170 psi, that's quite a spread. My old MoToRs book says an 8-1 compression ratio should be 144 psi.

Would checking compression hot pick up maybe 8-10 points? I've never bothered checking cylinder compression hot, figuring if it's acceptable and even across cylinders when cold it should only improve at normal operating temperature. Who wants to work around a boiling hot motor? I might consider it if it was marginal or something like that, before condemning an engine for liw compression. It's more important that cylinders are even with each other, than an absolute number value.

|

|

By Tedster - 6 Years Ago

|

Yeah Baby!!

Took the last washer out of the vacuum advance and bumped the initial up to 16°, the total is close to 40°, and 54° with vacuum at no load spooled up in the garage. Definite improvement in the power band range with the cam dialed in better. It might need to come in earlier with a spring change or tweak of the spring arm, but it can wait. It really cruises sweet at 50 - 70 mph and sounds great with the ramshorns and porter steel-pacs. Big ole perma-grin cruisin' down the highway, thanks fellas!

|

|

By Ted - 6 Years Ago

|

Tedster (8/26/2019)

Ted, or anyone else, what is the received wisdom regarding cranking compression numbers on these Y-blocks? Charles Morris in his Y-block book says 160-165 psi is the norm for these engines. But is there any rule of thumb on the psi difference between checking cold and hot? Compression is supposed to be checked hot. The Morris book doesn't talk about engine temperature. The shop manual says to operate the engine for minimum of 30 minutes at a fast idle, etc, but specifications list 130-170 psi, that's quite a spread. My old MoToRs book says an 8-1 compression ratio should be 150 psi. Would checking compression hot pick up maybe 8-10 points? I've never bothered checking cylinder compression hot, figuring if it's acceptable and even across cylinders when cold it should only improve at normal operating temperature. I might consider it if it was marginal or something like that.

There is not a steadfast rule for what the cranking compression will be for engines in general. For a particular engine, there may be a range given in the service manuals for that engine. Those numbers are not necessarily the same for another engine even if it’s in the same family of engines (ie. passenger car engines versus truck engines, 272 versus 312, etc). There are lots of variables with the cam timing just being one of them. Warm engines will typically give a higher number simply due to ring end gaps being closed up some versus what they are cold. As the camshaft is advanced, the intake closing event happens sooner which in turn permits the cylinder to build up more compression. For this single reason, even engines that are similar can give significantly different values based on engine machining variances and/or timing chain stretch.

When performing a cranking compression check, always block the throttle to the wide open position to insure that the cylinders injest a full complement of air. If the numbers for all the cylinders fall within 10% of each other, then it’s deemed that all the cylinders for that check are acceptable. While I haven't checked an engine cold lately, I suspect about a 10psi difference in readings between hot and cold with hot being higher.

|

|

By Tedster - 6 Years Ago

|

I'll have to see what the cruising manifold vacuum is now. Prior, with the stretched chain it seems to me it was barely 15". Now maybe it is unrealistic to expect more in a heavy truck. I don't know if Ford ever ran their stock F100 with advanced camshaft, but it sure seems like they shoulda. The power band is much more usable with some advance. Don't get me wrong, it doesn't turn my Effie into a screamer, but is a welcome improvement.

The reason I wonder about the cruising manifold is it seems to me the carburetor is getting a lot crisper signal now. It is a little on the small side, the stock Autolite 2100 for 1964. It even has that "Rawwmmp" sound now, emanating from its impressive 1.02" venturis, LOL. I could never seem to get the standard specification ignition and carb calibration to jell before, now everything dropped right in, almost like I knew what I was doing.

|

|

By charliemccraney - 6 Years Ago

|

|

The trucks are not that heavy. Mine's 3675lbs with me in it. By comparison, my '88 Firebird is 3590. Older vehicles in general are not as heavy as people like to think. Modern materials are generally lighter but there is a whole lot more of it crammed into a similarly sized space, which actually results in a vehicle that is heavier.

|

|

By Tedster - 6 Years Ago

|

|

Good point, but it did occur to me this engine would be a LOT of fun in a lighter weight car. The T-Bird for example was about 500 lbs lighter give or take than my Effie and handling on curves is probably better.

|

|