|

Author

|

Message

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

Well... I think we're getting off into the weeds just a bit. The P&G gapper tool is simply a very accurate method of setting valve lash particularly on well used rockers, I've measured the lash both at a slow idle and when static and the lash indicated on the dial is identical.

I think the main benefit of this tool is not just an increased precision but also that the lash has a consistency across all cylinders, that contributes to a very smooth idle. Most people though, aren't going to bother or care.

|

|

|

|

|

DANIEL TINDER

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.7K,

Visits: 154.3K

|

[quote][b]Tedster (1/14/2019)Is it a given that a compressed spring loses tension over time? I'm not persuaded this is necessarily the case, and even less that it would matter with a P&G valve gapper...

Spring ‘creep’ (the relaxation of tension from being compressed over time) is a measurable scientific fact. The degree of relaxation and it’s relevance to function is dependent on many factors (material, force, temperature, use, etc.). The only way to be sure of the simplest issue (time only), would be to find a NOS (new-in-the-box/unopened) original/unassembled unit (or replacement part), and measure it’s tension for comparison to another NOS unit/spring that was merely assembled, but never used. It IS possible that MY P&G tool was consistently used daily in a busy shop for many years to set valve lash while an engine was running, and then left attached to a hot motor until the next job. THAT would certainly wear out the spring much faster. I can only assume (from the P&G instruction manual and 50s era car magazine articles) that the original device must have worked better when new than mine does now (?).

6 VOLTS/POS. GRD. NW INDIANA

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 3 days ago

Posts: 1.8K,

Visits: 306.4K

|

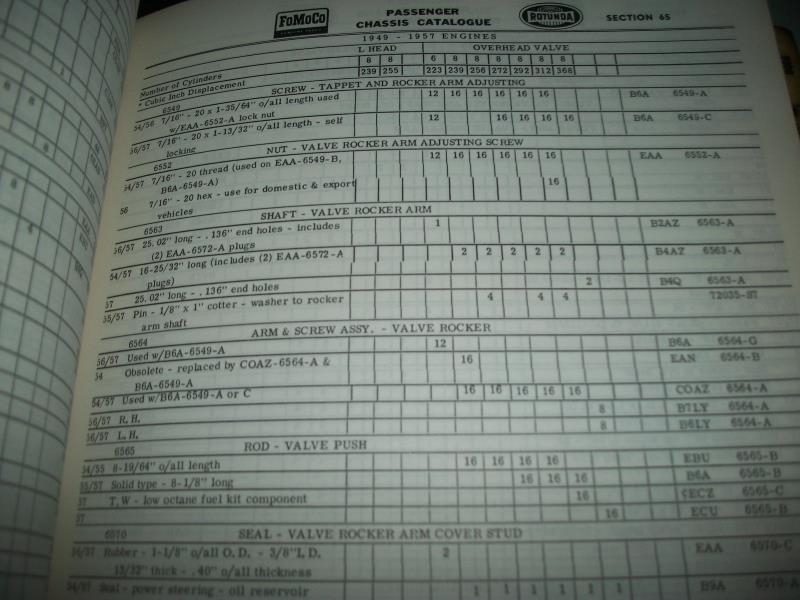

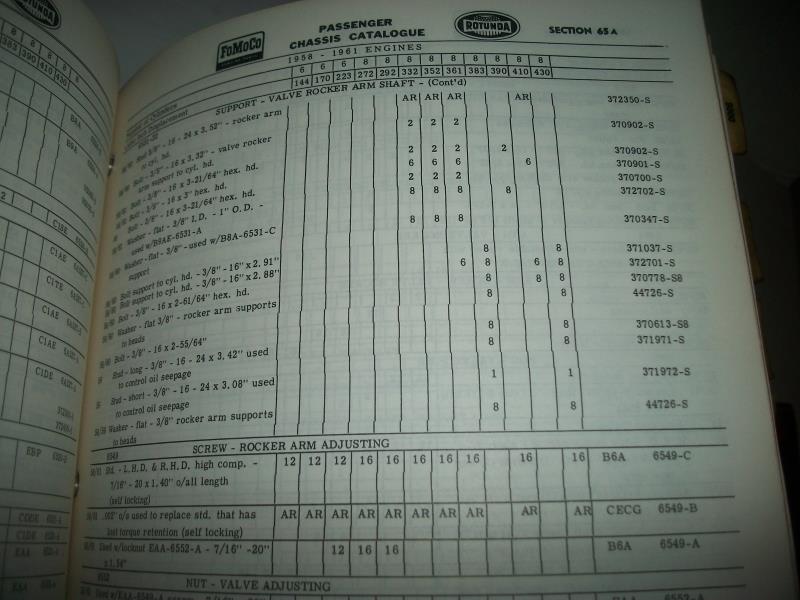

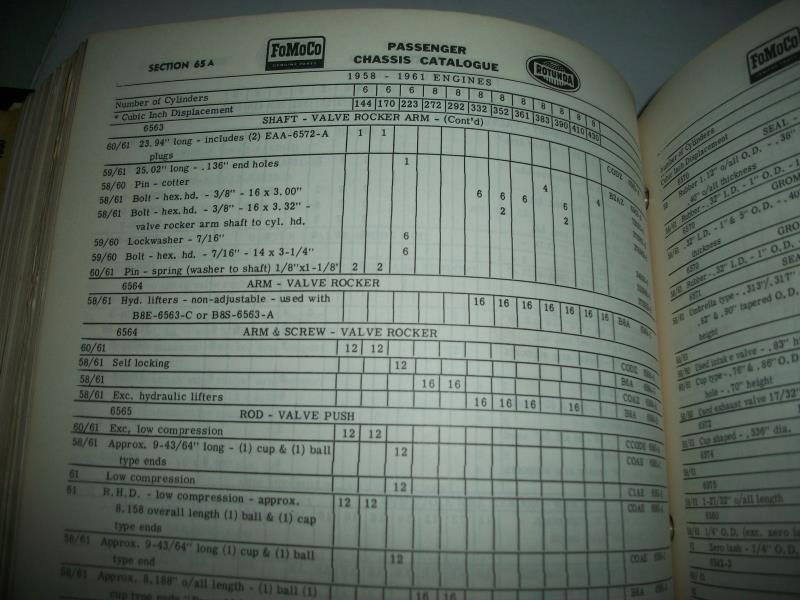

I don't see any Dates anywhere. I know they used to have Dates on the Pages when they inserted Updates. This is the 49-61 Big Master Parts Catalog and I think it may be the last Issue. I think your Parts List is correct. There were O/Size self locking Screws also available at One Time.

THANX for that Mark!

Being a 1961 FINAL ISSUE, the info (all needed) will have been removed also as most everything was R/B C0AZ 6564-A ASSY (1960)..

The O/S ADJ SCREW was C2AZ 6549-A - .0023" O/S - 7/16" - 20 x 1.40" - Optional w B6A 6549-C

____________________________

|

|

|

|

|

oldcarmark

|

|

|

Group: Forum Members

Last Active: 5 days ago

Posts: 3.7K,

Visits: 32.6K

|

KULTULZ (1/14/2019)

Well, here's the deal. I have saved references from differing sources and come up with this w/o either a period SHOP MANUAL, SERVICE LETTER reference and/or PARTS CATALOG. The FINAL ISSUE 49/59 MPC - 1964) has deleted much of this info and only gives C0AZ 6564-A as the service replacement). But the differing length push-rods are still given needed for the rocker arm changes CASTING I.D B6A 6564-A and B (I think) (SERVICE PN B6A 6564-A) require the two piece adj whereas SERVICE PN B6A 6564-C (and D has also been mentioned) takes the one piece. All of the above are 1:54 ratio, either style having a different thread pitch. Service Replacement C0AZ 6564-A are 1:43. The adjuster with the internal hex head came out in 1962 I believe as I do not have a period FORD TRUCK MPC any longer. I appreciate your checking (what is the PUB DATE of your catalog?). If anyone else has any info, please share it.  I don't see any Dates anywhere. I know they used to have Dates on the Pages when they inserted Updates. This is the 49-61 Big Master Parts Catalog and I think it may be the last Issue. I think your Parts List is correct. There were O/Size self locking Screws also available at One Time.

|

|

|

|

|

darrell

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 455,

Visits: 22.2K

|

im referring to 50 years of working on these engines.i have two 57 engines now in my garage with spots of green still showing.no canadian engines used anything but the lock nut.

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

Is it a given that a compressed spring loses tension over time? I'm not persuaded this is necessarily the case, and even less that it would matter with a P&G valve gapper.

Valve springs certainly wear out, due to millions of cycles and heat, but that's a different matter.

|

|

|

|

|

DANIEL TINDER

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.7K,

Visits: 154.3K

|

[b]cjs1958 (1/13/2019) I set the valves today with my P&G Gapper at a slow Idle. Was your P&G a NOS unit by any chance? Since most used models were left fully assembled, the spring thus lost so much tension from being compressed for many years, that setting lash accurately with the motor running is near impossible as the bouncing dial needle fluctuates too much, and you have to merely estimate the gap somewhere between the range extremes (likely the same reason new valve springs may allow a higher rpm before valve float occurs?).

6 VOLTS/POS. GRD. NW INDIANA

|

|

|

|

|

cjs1958

|

|

Hitting on all eight cylinders

Group: Forum Members

Last Active: 5 Years Ago

Posts: 10,

Visits: 286

|

How did You find it using the Valve Gapper? Figure out how it works? [/quote] I had to remove the inner barrel of the Gapper and do some cleaning and sanding to get it to move free. After that it was pretty self explanitory. It was a lot easier to read setting them cold, just rolling the engine over, but it was fun to recheck warm at a slow idle.

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 3 days ago

Posts: 1.8K,

Visits: 306.4K

|

Well, here's the deal. I have saved references from differing sources and come up with this w/o either a period SHOP MANUAL, SERVICE LETTER reference and/or PARTS CATALOG. The FINAL ISSUE 49/59 MPC - 1964) has deleted much of this info and only gives C0AZ 6564-A as the service replacement). But the differing length push-rods are still given needed for the rocker arm changes CASTING I.D B6A 6564-A and B (I think) (SERVICE PN B6A 6564-A) require the two piece adj whereas SERVICE PN B6A 6564-C (and D has also been mentioned) takes the one piece. All of the above are 1:54 ratio, either style having a different thread pitch. Service Replacement C0AZ 6564-A are 1:43. The adjuster with the internal hex head came out in 1962 I believe as I do not have a period FORD TRUCK MPC any longer. I appreciate your checking (what is the PUB DATE of your catalog?). If anyone else has any info, please share it.

____________________________

|

|

|

|

|

oldcarmark

|

|

|

Group: Forum Members

Last Active: 5 days ago

Posts: 3.7K,

Visits: 32.6K

|

I can tell You the Chassis Shop Manual simply lists One with Locknut required and One with self Locking. No Date Code etc but both are B6A #'s.

|

|

|

|