|

By cjs1958 - 7 Years Ago

|

|

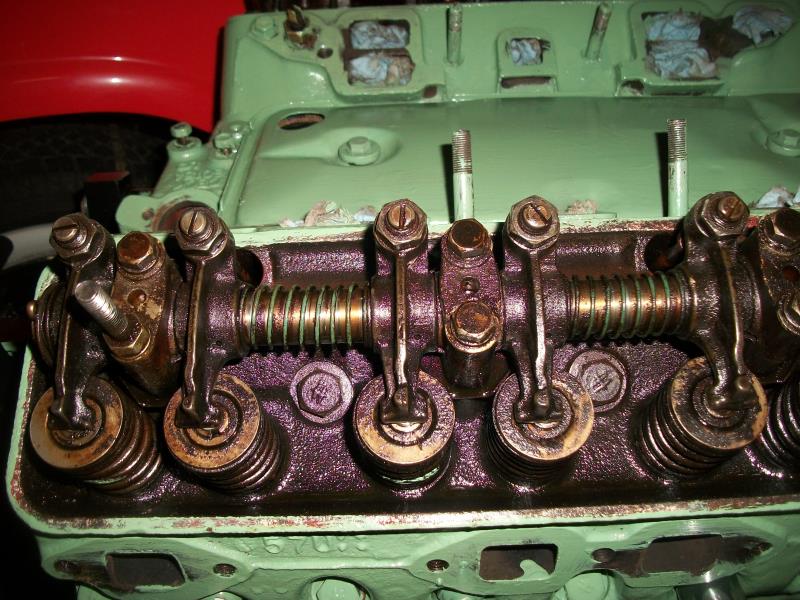

I've got a 292 in a 55 t-bird. Engine has less than 50k miles. I pulled the valve covers to set lash and found some of the rocker arms are not centered on the valve stems. They are off as much as 1/8" to 3/16". The ones that are off are too close to the mounting pedalstal. Is this normal? The engine is clean inside. There doesnt apear to be any excessive wear. It runs good. Are their left and right angled rockers and mine were put in wrong? Should I replace rocker arms? Should I install spacer washers between rocker arms and pedalstals? Should I set the lash and close it up? Any help would be appreciated.

|

|

By darrell - 7 Years Ago

|

|

nothing wrong its the way they are

|

|

By oldcarmark - 7 Years Ago

|

cjs1958 (1/8/2019)

I've got a 292 in a 55 t-bird. Engine has less than 50k miles. I pulled the valve covers to set lash and found some of the rocker arms are not centered on the valve stems. They are off as much as 1/8" to 3/16". The ones that are off are too close to the mounting pedalstal. Is this normal? The engine is clean inside. There doesnt apear to be any excessive wear. It runs good. Are their left and right angled rockers and mine were put in wrong? Should I replace rocker arms? Should I install spacer washers between rocker arms and pedalstals? Should I set the lash and close it up? Any help would be appreciated.

Because the Tips of the Rockers are not worn uniformly it becomes inaccurate using Feeler Gauges to set Valves. You may be better to use the 1/4 turn Method. You tighten adjuster down enough that Lash between Arm and Push Rod is taken up. Push Rod should still be able to turn with your Fingers with a little bit of Effort. Then You turn the Adjuster out 1/4 of a Turn and lock the Adjuster. Should give you the specified Valve Lash. . .

|

|

By cjs1958 - 7 Years Ago

|

|

Thanks for the replies. I was worried about the rocker alingment. I used the "Walt Knuckels" quarter turn meathod before. I bought a P&G Valve Gapper on ebay last week, that is why I wanted to adjust the valves. They are a pretty cool tool. My valves were 0 lash to .033 before adjusting, so they did need it. Some of my adjuster nuts were a lot easier to turn than others. is that normal or a problem? Also I had somebut not a lot of oil flow out of the right rocker overflow tube, should I worry about it? Thanks. I just found this site and have been doing a lot of reading. Is there a search function on this forum?

|

|

By Tedster - 7 Years Ago

|

If the adjuster screw turns too easily they should be replaced. There is a published minimum torque they need to meet in the manual as I recall, but I couldn't find it. Otherwise though they will tend to loosen.

I don't know whether something like blue loctite would work in this situation. Seems like it would. The P&G tool works excellent and will result in a very smooth running motor.

|

|

By darrell - 7 Years Ago

|

|

the right side never oiled as much as the left.if your getting some oil its ok.

|

|

By oldcarmark - 7 Years Ago

|

cjs1958 (1/8/2019)

Thanks for the replies. I was worried about the rocker alingment. I used the "Walt Knuckels" quarter turn meathod before. I bought a P&G Valve Gapper on ebay last week, that is why I wanted to adjust the valves. They are a pretty cool tool. My valves were 0 lash to .033 before adjusting, so they did need it. Some of my adjuster nuts were a lot easier to turn than others. is that normal or a problem? Also I had somebut not a lot of oil flow out of the right rocker overflow tube, should I worry about it? Thanks. I just found this site and have been doing a lot of reading. Is there a search function on this forum?

I picked up a Valve Gapper also couple of Weeks ago Looks interesting. Haven't tried it Yet..You might find the Rocker Shaft(s) are partially plugged. They can be disassembled and cleaned out. If You are getting Oil on both Sides You should be good. They don't need a lot of Oil to work. There's little squirter Holes on the Rocker Arms. They can be cleaned out with a Paper Clip.

|

|

By cjs1958 - 7 Years Ago

|

|

It's good to know the right doesn't oil as much as left. I have a couple adjuster nuts to watch. Do you have to replace the rocker or just the nut, which usually wears? I'll clean oil holes out before i close it up. Thanks guys.

|

|

By darrell - 7 Years Ago

|

|

if they dont hold you can replace them with the old screw and nut.i dont think you can buy the self locking screws anymore.i havent been able to find any.

|

|

By Tedster - 7 Years Ago

|

They do seem to be scarce, see them online sometimes at parts houses or eBay.

Anybody see any reason why Blue Loctite wouldn't work OK if they aren't too badly worn?

|

|

By DANIEL TINDER - 7 Years Ago

|

|

Unless running a high rpm motor and concerned with ‘valve float’, adding locknuts is likely the best long term solution to worn hex screws. Be advised though, that tightening the nut always alters the gap, so you must allow for that when adjusting the screw.

|

|

By 2721955meteor - 7 Years Ago

|

the engine in question has the lock nut style adjustors,so some of the previous posts did not give correct advise.

I noticed a engine that has not had regular oil changes and the top end is in trouble,a short turn cure would be remove rocker asembleys you will find scoring on the shafts especially the 1s farther from oil entry.new rocker shafts and refaced rockers would help. even with some scoring of rockers new shafts and removal of spill tubes,and blocking the out flow.sadley the rockers do not get enough lube due to flow spilling reduces flow and sludge builds up mostly at far end.when rockers off check valve seals,they can be changed with out removing heads. there are several cheap tools that make it easier. good luck

|

|

By DANIEL TINDER - 7 Years Ago

|

The O.P. wrote “some ‘nuts’ were easier to turn than others”, thus initiating confusion. Also, it likely isn’t uncommon to find that some mechanic may have swapped out the original adjusters over the years for the interference type, since setting the lash is so much faster without locknuts.

Though he claimed the engine looked clean, I assume 65 yrs. of sludge/corrosion may eventually cause some of the screws to bind a bit, or maybe overtightening the locknuts could have damaged the threads (?).

|

|

By KULTULZ - 7 Years Ago

|

|

I pulled the valve covers to set lash and found some of the rocker arms are not centered on the valve stems. They are off as much as 1/8" to 3/16". The ones that are off are too close to the mounting pedestal. Is this normal? ]

I was hoping TED would comment on this.. If the rocker arms are allowed to walk, it may be a reason that they throw push-rods.

|

|

By Tedster - 7 Years Ago

|

It does look a little strange at first glance, it is normal, this way Ford didn't need to make left and right hand rockers.

All the Best

The other Ted.

|

|

By Ted - 7 Years Ago

|

The rocker arms not being centered on some of the valve stems is normal for the Ford Y. With the Ford Y rockers having an extra wide stem contacting pad, one rocker fits all. This was part of the original design and was likely the most expedient way of putting the engine into production. If Ford would have gone to the trouble of centering the rockers over the valve stems without modifying the valve layout accordingly, three different rockers would have been required and that would have created a nightmare scenario both in production and for the later rebuilds. When I do the roller rocker arm setups using Harland Sharp or Dove Manufacturing rockers, I end up using centered, left, and right adjusters to make everything work out while centering the roller tips on the stems. I’ve seen the Rocker Arm Specialists rockers having five different rockers in which to make that all work. It can get overly complicated very quickly. Ford simplified the rocker situation by just having a wide pad to fit all the various valve stem locations.

|

|

By KULTULZ - 7 Years Ago

|

|

The rocker arms not being centered on some of the valve stems is normal for the Ford Y. With the Ford Y rockers having an extra wide stem contacting pad, one rocker fits all.

THANX TED.

It makes perfect sense now that you have explained it.

|

|

By Tedster - 7 Years Ago

|

You're Welcome

Ted

|

|

By cjs1958 - 7 Years Ago

|

|

|

By cjs1958 - 7 Years Ago

|

|

Sorry I haven't looked in for a few days. This is the type of adjusters I have. I would call them an interference fit adjuster nut. Is this a later style adjuster? I think this engine was a replacement because it was painted green, not red when I got it. All the nuts except 2 take about 25 ft-lb to turn,the other 2 take about 5 ft-lb. I was going to squeeze those two in the vise or use blue locktite as suggested earlier. If I can get replacement nuts for those two, would that fix it, or do the threads on rockers wear?. Thanks for all the replies, i've learned a lot.

|

|

By Tedster - 7 Years Ago

|

Yes those are a later design, without the jamnut.

Something I found odd, replaced 16 rockers with NOS, after several hundred miles one or two had seemed to lose their interference fit more than I'd like to see. They have a pretty stout torque when new, better eat yer Wheaties, and while the lash doesn't vary it's unclear to me how this happens.

|

|

By oldcarmark - 7 Years Ago

|

cjs1958 (1/13/2019)

Sorry I haven't looked in for a few days. This is the type of adjusters I have. I would call them an interference fit adjuster nut. Is this a later style adjuster? I think this engine was a replacement because it was painted green, not red when I got it. All the nuts except 2 take about 25 ft-lb to turn,the other 2 take about 5 ft-lb. I was going to squeeze those two in the vise or use blue locktite as suggested earlier. If I can get replacement nuts for those two, would that fix it, or do the threads on rockers wear?. Thanks for all the replies, i've learned a lot.

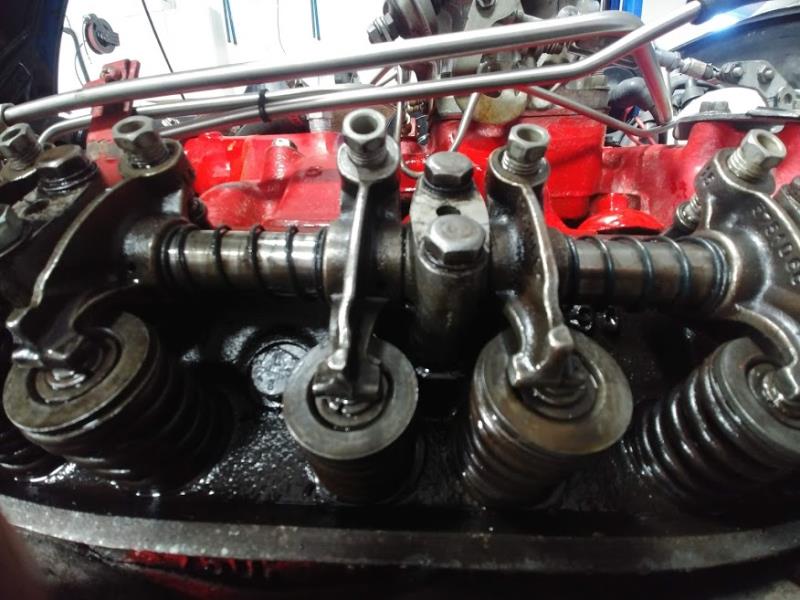

Are You in the US or Canada? Reason I ask is the Canadian Engines in 55-56 were painted Green. I just finished repainting mine back to the Proper Green Color after last owner repainted it Red over the Original Green. You can see that Color in the Picture I posted earlier in this Post..

|

|

By 2721955meteor - 7 Years Ago

|

these rockers are different than the Green engine,these are self locking, Green has jam nuts ,jam nut rockers use a different thread .

Green engine has jam nuts

|

|

By oldcarmark - 7 Years Ago

|

|

Thats my '56 Engine. The 55's were all Locknut Type. I know some 56 Engines came with Locknuts and some with the Adjusters that don't use Locknuts. Was it a mid Year Change or just random until the old Style were used up? The self locking Ones are certainly much easier to adjust.

|

|

By cjs1958 - 7 Years Ago

|

|

I am in USA. I think the car came out of New Mexico.

|

|

By cjs1958 - 7 Years Ago

|

|

I set the valves today with my P&G Gapper at a slow Idle. It would not be possible to do it running if it had screws and locknuts. I did locktite the two loose ones. We'll see if they stay. I've driven this car for 9 years and the never gave any real trouble. Thanks to all you guys.

|

|

By oldcarmark - 7 Years Ago

|

cjs1958 (1/13/2019)

I set the valves today with my P&G Gapper at a slow Idle. It would not be possible to do it running if it had screws and locknuts. I did locktite the two loose ones. We'll see if they stay. I've driven this car for 9 years and the never gave any real trouble. Thanks to all you guys.

How did You find it using the Valve Gapper? Figure out how it works?

|

|

By KULTULZ - 7 Years Ago

|

|

I know some 56 Engines came with Locknuts and some with the Adjusters that don't use Locknuts. Was it a mid Year Change or just random until the old Style were used up?

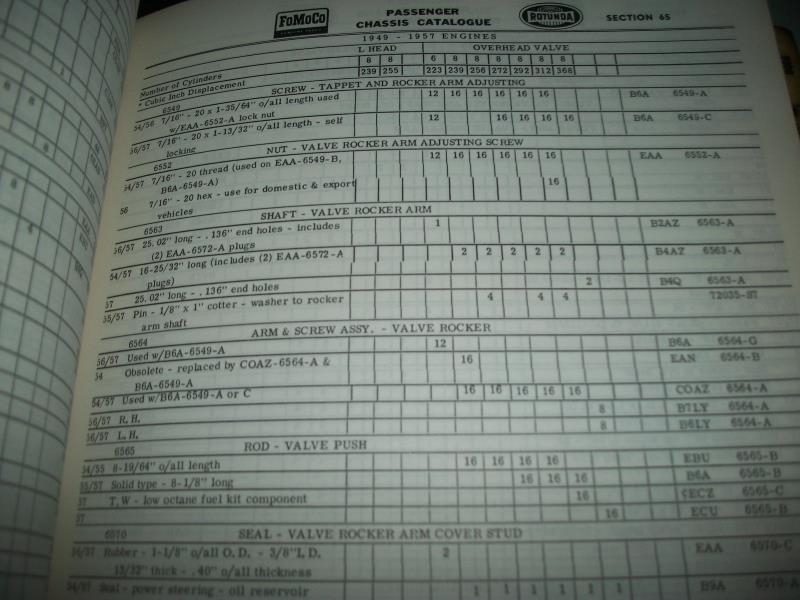

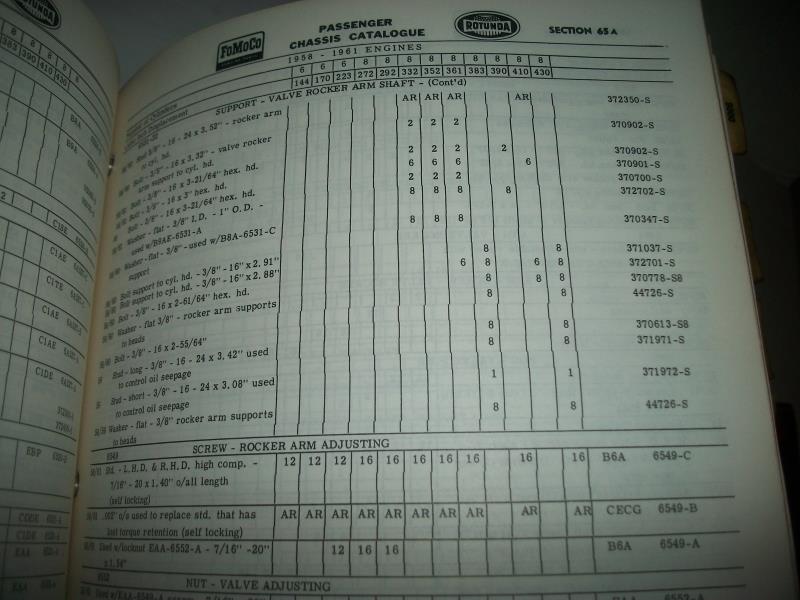

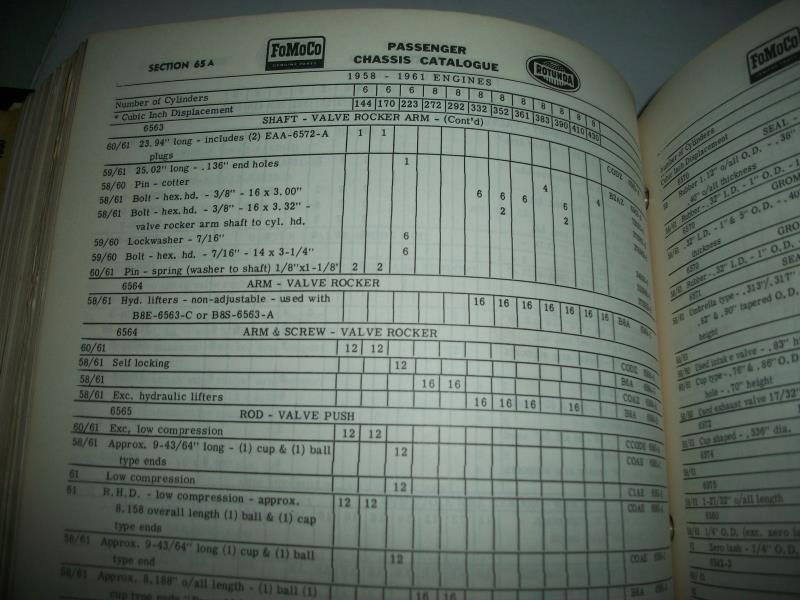

It was a mid-1956 model year changeover. It seems (without any official FORD documentation (Product Service Letters - original CHASSIS PARTS CAT to review), several changes were made when the 312 was released for PASS CAR assembly later in the 1956 model run.

EDIT -

Add SHOP MANUAL to reference materials as they were updated quarterly and the info most likely would have been available there.

|

|

By darrell - 7 Years Ago

|

|

canadianengines never stopped using the lock nut rockers.right through 57.if you find a different one it was changed.

|

|

By oldcarmark - 7 Years Ago

|

KULTULZ (1/14/2019)

I know some 56 Engines came with Locknuts and some with the Adjusters that don't use Locknuts. Was it a mid Year Change or just random until the old Style were used up? It was a mid-1956 model year changeover. It seems (without any official FORD documentation (Product Service Letters - original CHASSIS PARTS CAT to review), several changes were made when the 312 was released for PASS CAR assembly later in the 1956 model run. EDIT - Add SHOP MANUAL to reference materials as they were updated quarterly and the info most likely would have been available there.

Are You referring to the US Shop Manual or Canadian Master Repair Manual updated Quarterly?

|

|

By oldcarmark - 7 Years Ago

|

|

I can tell You the Chassis Shop Manual simply lists One with Locknut required and One with self Locking. No Date Code etc but both are B6A #'s.

|

|

By KULTULZ - 7 Years Ago

|

Well, here's the deal.

I have saved references from differing sources and come up with this w/o either a period SHOP MANUAL, SERVICE LETTER reference and/or PARTS CATALOG. The FINAL ISSUE 49/59 MPC - 1964) has deleted much of this info and only gives C0AZ 6564-A as the service replacement). But the differing length push-rods are still given needed for the rocker arm changes

CASTING I.D B6A 6564-A and B (I think) (SERVICE PN B6A 6564-A) require the two piece adj whereas SERVICE PN B6A 6564-C (and D has also been mentioned) takes the one piece. All of the above are 1:54 ratio, either style having a different thread pitch. Service Replacement C0AZ 6564-A are 1:43. The adjuster with the internal hex head came out in 1962 I believe as I do not have a period FORD TRUCK MPC any longer.

I appreciate your checking (what is the PUB DATE of your catalog?). If anyone else has any info, please share it.

|

|

By cjs1958 - 7 Years Ago

|

How did You find it using the Valve Gapper? Figure out how it works?

I had to remove the inner barrel of the Gapper and do some cleaning and sanding to get it to move free. After that it was pretty self explanitory. It was a lot easier to read setting them cold, just rolling the engine over, but it was fun to recheck warm at a slow idle.

|

|

By DANIEL TINDER - 7 Years Ago

|

|

[b]cjs1958 (1/13/2019) I set the valves today with my P&G Gapper at a slow Idle.

Was your P&G a NOS unit by any chance? Since most used models were left fully assembled, the spring thus lost so much tension from being compressed for many years, that setting lash accurately with the motor running is near impossible as the bouncing dial needle fluctuates too much, and you have to merely estimate the gap somewhere between the range extremes (likely the same reason new valve springs may allow a higher rpm before valve float occurs?).

|

|

By Tedster - 7 Years Ago

|

Is it a given that a compressed spring loses tension over time? I'm not persuaded this is necessarily the case, and even less that it would matter with a P&G valve gapper.

Valve springs certainly wear out, due to millions of cycles and heat, but that's a different matter.

|

|

By darrell - 7 Years Ago

|

|

im referring to 50 years of working on these engines.i have two 57 engines now in my garage with spots of green still showing.no canadian engines used anything but the lock nut.

|

|

By oldcarmark - 7 Years Ago

|

KULTULZ (1/14/2019)

Well, here's the deal. I have saved references from differing sources and come up with this w/o either a period SHOP MANUAL, SERVICE LETTER reference and/or PARTS CATALOG. The FINAL ISSUE 49/59 MPC - 1964) has deleted much of this info and only gives C0AZ 6564-A as the service replacement). But the differing length push-rods are still given needed for the rocker arm changes CASTING I.D B6A 6564-A and B (I think) (SERVICE PN B6A 6564-A) require the two piece adj whereas SERVICE PN B6A 6564-C (and D has also been mentioned) takes the one piece. All of the above are 1:54 ratio, either style having a different thread pitch. Service Replacement C0AZ 6564-A are 1:43. The adjuster with the internal hex head came out in 1962 I believe as I do not have a period FORD TRUCK MPC any longer. I appreciate your checking (what is the PUB DATE of your catalog?). If anyone else has any info, please share it.

I don't see any Dates anywhere. I know they used to have Dates on the Pages when they inserted Updates. This is the 49-61 Big Master Parts Catalog and I think it may be the last Issue. I think your Parts List is correct. There were O/Size self locking Screws also available at One Time.

|

|

By KULTULZ - 7 Years Ago

|

|

I don't see any Dates anywhere. I know they used to have Dates on the Pages when they inserted Updates. This is the 49-61 Big Master Parts Catalog and I think it may be the last Issue. I think your Parts List is correct. There were O/Size self locking Screws also available at One Time.

THANX for that Mark!

Being a 1961 FINAL ISSUE, the info (all needed) will have been removed also as most everything was R/B C0AZ 6564-A ASSY (1960)..

The O/S ADJ SCREW was C2AZ 6549-A - .0023" O/S - 7/16" - 20 x 1.40" - Optional w B6A 6549-C

|

|

By DANIEL TINDER - 7 Years Ago

|

[quote][b]Tedster (1/14/2019)Is it a given that a compressed spring loses tension over time? I'm not persuaded this is necessarily the case, and even less that it would matter with a P&G valve gapper...

Spring ‘creep’ (the relaxation of tension from being compressed over time) is a measurable scientific fact. The degree of relaxation and it’s relevance to function is dependent on many factors (material, force, temperature, use, etc.). The only way to be sure of the simplest issue (time only), would be to find a NOS (new-in-the-box/unopened) original/unassembled unit (or replacement part), and measure it’s tension for comparison to another NOS unit/spring that was merely assembled, but never used. It IS possible that MY P&G tool was consistently used daily in a busy shop for many years to set valve lash while an engine was running, and then left attached to a hot motor until the next job. THAT would certainly wear out the spring much faster. I can only assume (from the P&G instruction manual and 50s era car magazine articles) that the original device must have worked better when new than mine does now (?).

|

|

By Tedster - 7 Years Ago

|

Well... I think we're getting off into the weeds just a bit. The P&G gapper tool is simply a very accurate method of setting valve lash particularly on well used rockers, I've measured the lash both at a slow idle and when static and the lash indicated on the dial is identical.

I think the main benefit of this tool is not just an increased precision but also that the lash has a consistency across all cylinders, that contributes to a very smooth idle. Most people though, aren't going to bother or care.

|