|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 53,

Visits: 1.7K

|

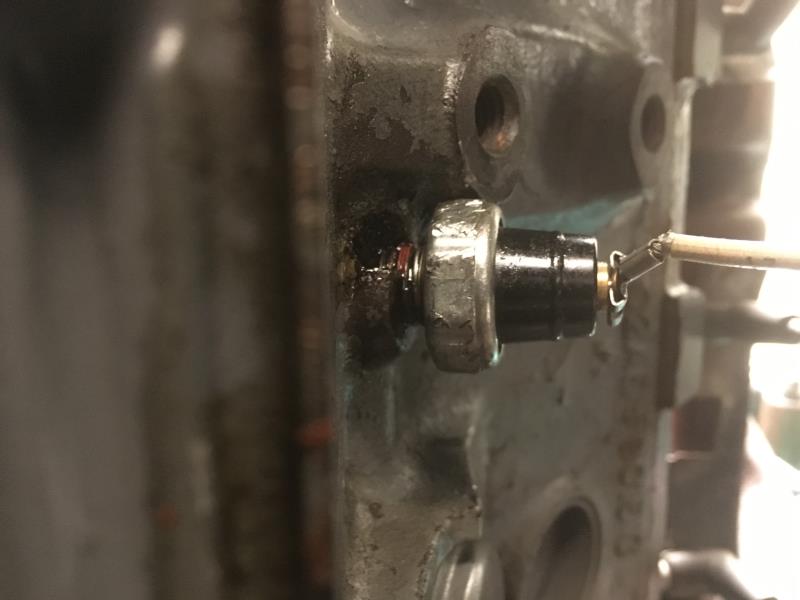

I have a rebuilt engine in my 61 f100 With about 2k miles my builder unfortunately passed. I installed both gauge and idiot light sending units but the gauge was reading low. I swapped out the idiot light sender with an oil pin gauge to check for proper readings and adjusted the electronic gauge. After re installing the idiot light sending unit It leaked a lot. Found this today  Any idea on a repair?

|

|

Group: Moderators

Last Active: Yesterday

Posts: 6.1K,

Visits: 442.8K

|

Did you use teflon tape on the threads? I don't notice any.

Lawrenceville, GA

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 878,

Visits: 13.5K

|

Yes, that can be fixed, next time don't tighten the sender so tight, that is a tapered thread (pipe thread), if your lucky you can remove the sender, grind the block flat and still have enough threads left to mount the sender, use pipe compound

|

|

Group: Forum Members

Last Active: Last Year

Posts: 3.3K,

Visits: 238.8K

|

Can't tell from the photo.. is the block flange cracked? If so you could clean it really well & try J.B. weld. Try to maintain the threads or run a pipe tap in very gently, then wait 24 hrs & install the sender with sealer & as already suggested, snug it up, do not overtighten!.

Paul

|

|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 53,

Visits: 1.7K

|

Thanks Guys, Yes it is cracked and missing a chunk as well, I did not catch it when removing the sending unit. Over tightening may have had a lot to do with it but going by the damage to my oil filter I may have picked up something on the road as well.

I will try the JB weld trick with a pipe plug, I will then tee off the other oil boss and put both sending units in tandem. I will also use pipe thread sealer.

John

|

|

Group: Forum Members

Last Active: 3 hours ago

Posts: 3.6K,

Visits: 497.7K

|

I don't use any type of sealer an any electrical sending unit if its a pipe thread

54 Victoria 312; 48 Ford Conv 302, 56 Bird 312

Forever Ford

Midland Park, NJ

|