|

Author

|

Message

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

You can usually index the plugs to get more clearance. You also want to be sure that the pistons have enough clearance, not simply that they don't touch in a static situation. It could still be tight enough that it will hit at high rpm. I don't know what that clearance should be, though. I haven't yet built a high compression racing engine.

Lawrenceville, GA

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

|

|

|

|

|

Joe-JDC

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 773,

Visits: 22.7K

|

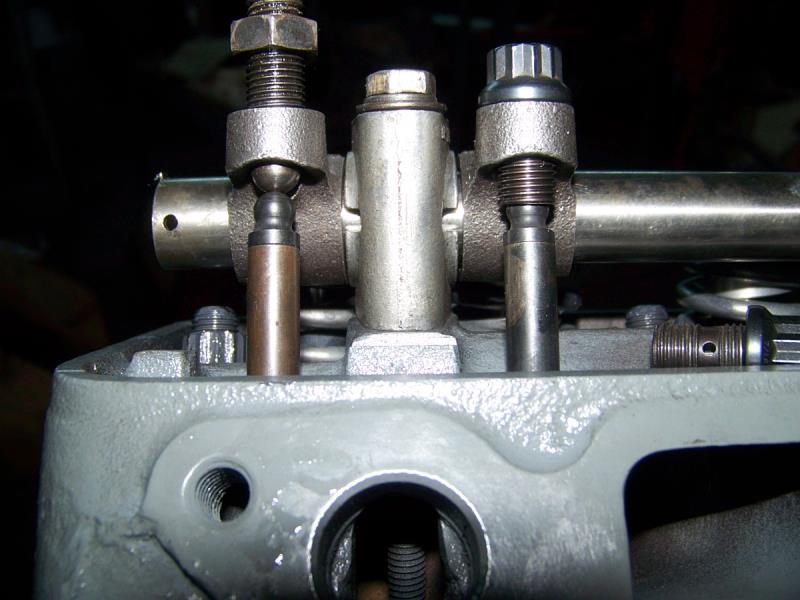

It looks like you will need longer push rods from those pictures. Most blue printing of rocker arms to pushrods have one thread showing below the rocker body so that you have a better angle and more stable valve train at high rpms. It usually moves the pushrod away from the head a bit better, also. Would need to check adjuster to valve cover clearance if you do go to longer pushrods. Joe-JDC

JDC

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

Longer pushrods also give you a higher rocker ratio because of the relation of the adjuster to the centerline of the rocker bore. The scrub pattern on the stems also looks like it would benefit from a geometry adjustment - shimming or milling the stands. An easy way to get an idea if geometry is near optimum is to have the engine in the appropriate spot that the valve is at half lift and observe the relation of the pushrod to the adjuster screw. In line is at or near optimum. Angled is not. Best way is to know is to shim, and see what happens. When I did this, I got a bunch of arbor shims for checking. Worked out well. If you want to tackle this, pick a rocker screw position and then use an adjustable pushrod to set your lash for checking. When you find the correct geometry, measure that adjustable pushrod to determine the length of pushrod required. It's a good thing to do because it transmits information more accurately from the camshaft to the valve, so you get more valve lift, and duration as well as less strain on valve train components.

Lawrenceville, GA

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

I had to cut into the rocker a channel to oil the top ball (5/16 ball, top and bottom), if I use a longer push rod and move the adjuster up it uncovers the oil channel, this is the longest push rod I can use, I will post pictures next time I'm at work, I took this into account when I specified the cam and rocker ratio, I have all the lift I can fit in the engine now, at full lift I have .050 clearance to the top of the block (counting the notches), and large fly cuts in the piston and only have about .070 piston to valve (intake) and .090 (exhaust), remember that adjuster is a female cup,, the push rod ball is inside the cup, if you take that into account there are only 2 full threads showing ( hard to tell in the pictures) the Erson push rods are 8.426 long, the Fords 8.11

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

Cliff. Thanks for sharing the pictures. Good find on those rockers and they do look like the later Gotha rockers that use to be available for the FE’s. Be sure to let us know what ratio those rocker arms are once it’s known.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

I'm jealous of the prize you got

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Hi, the contact on the push rod is ether the top of the ball or the bottom of the cup, if I were to use this length of push rod with a cup, and the ball on the rocker it would be to long, the side of the cup would hit the rocker at full lift, I chose to use the longest push rod I could (hence the ball and ball), I was going to keep quiet, however since I'm showing all I might as well explain why, I do not follow anyone but have always gone my own way, the contact patch on the valve is just about center through the whole cycle, the added support can be seen in the water port. Cliff Murray

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

Hey, did you guys notice that the retainers have the center milled out? these are titanium, but a little more weight was saved. Cliff

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

These Hi Lift rockers check out @1.48 (+), looks like these all check out from 1.47 to 1.485, I'm going to pick the best ones I can find (I have many sets to chose from) will check Ford rockers next, and maybe I will check out others, I have Thomas, and Fenton (new). I'm checking these on the engine so it takes time, I may have the cam broken in before it's done (lots of turning)

|

|

|

|